I started kegging beer back in early 2011 because I hated bottling. I’ve never regretted this decision and still hate bottling. Since that point, I’ve gone through the process of kegging beer over 250 times. Here’s the method I’ve settled on that seems to work just fine.

Before I get into the actual kegging process, it might be prudent to first address keg cleaning. I don’t disassemble each keg between every single batch and I don’t run line cleaner or even water through the beer lines every time a keg kicks. If I’m reusing a keg that was recently emptied (and the beer in it wasn’t infected), I simply give it a hot rinse and sanitize it as usual prior to filling it with new beer. I do keep a keg of beer line cleaner next to my keezer, from full it usually lasts about a year since I only run the cleaner through my lines between every 3-4 kegs. There’s nothing wrong with being more anal about your cleaning routine, certainly better to be that than too lax, but my routine has been working fine for me. In the instances where I’m using a keg that has been sitting empty for a bit, I do typically disassemble the posts (pin lock requires a special socket) and at least hit everything with some hot water.

Cleaning the keg is the presumed first step– don’t put your beer in a dirty keg. On to the actual kegging method.

Step 1: Place full fermentor on a surface high enough for a siphon to work, wedging something like a towel or an old book under the front to allow more beer to be transferred to the keg.

Step 2: Sanitize your racking equipment, I very much prefer the sterile siphon starter for this for how incredibly simple it is to use, and not to mention sterile.

Step 3: Add some sanitizer solution to your keg, I usually use about a gallon, then shake it to ensure every bit of the innards have been touched before pouring it out. To sanitize the liquid-out diptube, I use a small CO2 injector with a pin lock disconnect to charge the keg a bit, then run some of the StarSan solution out using a cheap and simple picnic tap setup. If you don’t have (or want to buy) the CO2 injector, you can always hit the keg with some gas from your kegerator or keezer tank.

Step 4: Place sanitized racking cane into beer and tubing into your sanitized keg.

Step 5: Start your siphon… I blow mine.

Step 6: I like to place a paper towel drenched in StarSan solution over the opening of the keg to prevent flies and other bacteria carrying fuckers from getting in.

Step 7: I usually have slightly more than 5 gallons of finished beer, so I make sure to stop filling the keg before the beer touches the gas-in diptube in order to eliminate the chances of getting beer sucked in my regulator.

Step 8: Once the keg is full, I put the sanitized lid in place, move it near my keezer, hit it with a burst of CO2, then let it sit for a minute or 2 to let the gas settle below any O2 (I’ve heard this doesn’t really happen, but hey, it’s easy enough).

Step 9: Depress the gas poppet, releasing three 1-2 second bursts to presumably purge the keg of most residual oxygen.

Step 10: Move keg to keezer and attach a gas line set to 30 psi to the gas-in post– this is one of the main reasons I prefer secondary regulators to standard manifolds, the ability to have multiple kegs set to different pressures at the same time. You can also connect your beer line now, but I usually don’t because they’re often attached to other kegs.

Step 11: Come back 24-36 hours later, remove gas disconnect, purge keg, reduce pressure to 12-14 psi (or whatever’s appropriate for your setup and beer style), and replace the disconnect. If you use ball lock kegs, you won’t have to remove the disconnect at all, just reduce the pressure and pull the relief valve.

Step 12: While the beer will have noticeable carbonation after the last step, I’ve found that leaving it another 2-4 days not only ensures carbonation throughout the keg, but it gives the beer more time to clear up.

That’s it, pretty straightforward and simple. When a keg kicks, I remove it from the keezer, rinse it with hot water, disconnecting and spraying down the diptubes and posts, put it back together, then give it a 24+ hour soak in OxiClean solution if I don’t plan to re-use it immediately.

Perhaps you’re wondering…

Why don’t you purge your keg with CO2 before filling it with beer?

Truth is, when I started kegging I never considered this option, since my routine has worked fine for me for so long, I see no reason to do anything differently, especially if it adds a step. I’ve made some beer people don’t like, but I’ve never received a comment about oxidized flavors, even in beers that remained in the keg for 10+ weeks.

How do you store your kegs when they’re not in use?

I have a spot next to my keezer where I keep my kegs, stored upright with their lids sort of dangling in the hole.

Why did you choose pin lock over ball lock kegs?

Back when I was buying all of my kegging equipment, I read a few stories of people who fucked up their primary regulators due to accidentally connecting their gas disconnect to the beer-out post, which is impossible with pin lock kegs. Since I figured I’d be doing most of my kegging while sipping homemade beer, I figured better to be safe than sorry. Also, I was able to score pin lock kegs for about $30 apiece, while ball locks were going for closer to $50 per. I’ve never regretted this decision, though if you’re in the market, it may be important to keep in mind pin lock kegs are shorter and have a slightly larger diameter than ball lock kegs.

What’s your take on the carbonic bite argument?

I do seem to experience something different in a beer right after turning the CO2 from 30 psi to 12 psi compared to beer that’s been sitting at serving pressure for a few days, though I’m not certain it’s necessarily carbonic bite. I’m not really sure where I stand on this issue, but I can say with confidence that I prefer the beer that’s been sitting at serving pressure for a few days… which could just be due to the fact it’s had more time to clear-up and condition.

What do you think about the shaking method for forced carbonation?

I used this method when I first started kegging and it seemed to work fine, though the beer, while carbonated, was much hazier than I prefer. I get better results using my current method, which seems also to run a lower risk of oxidizing the beer or throwing out my back.

Cheers and thanks for reading! If you have any questions at all or want to share things you do differently, please don’t hesitate to comment or email me.

If you enjoy reading this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

36 thoughts on “Kegging Method”

Thanks for posting this, I changed my kegging regiment slightly because of this, makes it easy. Only thing I changed is rather than than filling by putting the siphon hose in the keg opening, I have a barbed swivel nut on the end of my siphon tube, a beer post quick disconnect for whatever keg I’m filling (I have a mixture of ball and pin kegs) goes on that.

This allows me to fill the keg by letting beer flow through the pick up tube, and also allows me to have the keg lid sealed while filling (I put a gas disconnect on the keg as well to allow the displaced air to flow out).

Benefits from this are:

1. No need for the soaked paper towel as lid is on and locked, no way for bugs to get in.

2. Don’t have to worry about sanitizing the outside of the tubing since beer only flows through it and it’s not immersed in beer.

Actually, I recently put a disconnect on the end of the siphon hose, which I connect to the liquid post for transferring, I just put a small plastic pin lock relief thingy on the gas out and keep the lid on the keg the whole time. Works well, though it does nearly 5 minutes longer. Cheers!

I just figured thus out too! No more worries about bugs and whatever else is floating in the air. One thing is that the liquid QD can get clogged really easy so I put a filter on the end of the racking cane. The first time I used this method to transfer a dry hopped IPA I spent a good 20 minutes fighting clogs before I found a filtering solution. It was a learning experience but now with the filter thing move along smoothly.

One other thing, if you were so inclined, you could fill your keg with statsan, push that out with co2, then hook up the keg’s gas line to the sterile filter and now you’d have a closed loop transfer using only co2. No risk of oxidation. Just remember to be careful of how much pressure gets applied to the carboy.

Can you elaborate on your siphon filter solution? I recently started transferring through the liquid out post as you mention (love it). What I don’t love is clogging due to dry hopping 🙂

I use 160 degree + water in the keg. Zero residual flavor, cheaper, and still no risk of oxidation. Just remember to release all the pressure in the keg before hooking up to the racking tube or it will disturb the beer in your carboy.

Thanks for posting – my begging regimen is very similar though I use a different syphon.

I like to store empty kegs charged with a little C02. Keeps the lids in place well and the keg stays clean. A little stars in the bottom keeps the environment moist and seals soft.

cheers

For sanitizing the beer line dip tube, I don’t bother to hook mine up to CO2. I fill the keg about 1/3 to 1/2 way with Star San, swirl the keg, then depress the beer line poppet. Some air stays trapped in the beer line dip tube, so when you depress the poppet, almost every time the sanitizer in the keg rushes up quickly enough that a little bit pours out over the top.

Another option is to use warm or hot water for your Star San solution. Pour it in, cover the keg, and shake it. Depress the beer line poppet, or connect a QD and beer line. The warm sanitizer will warm up the air in the headspace of the keg and slightly increase the pressure, forcing sanitizer through the beer line.

Just a quick Q: What temp do u have in your keezer when you carbonate like this? Like serving temp? 6 – 7 C? Thx!

I use a fairly old analog temp controller on the keezer that is set to ~43˚F, so 6.1˚C.

Mine sits at about 35-36F (~2C). It’s “too cold” for serving IMO but I sometimes store beer for looping periods so it helps. The super cold mean more CO2 vols for the given pressure. I just did 40 psig for 2 days (no shaking) for a Belgian inspired beers and it’s perfect. After two days I dropped it to serving pressure and vented it off. I’ll now store it at the desired pressure for 3.5 vols of CO2 at 36F.

I’ve taken the Micromatic Draft course. CO2 comes out of solution at 40˚F, so you’re looking for trouble at 43˚F. Proper serving temperature is 37˚F. Keep it at 37˚F and lock your regulator at 10-12psi (depending upon your line length, which in a keezer/kegerator is likely 4′-10′) and you should be golden.

hi

so the serving pressure is 12-14 psi? thanks

Yeah, that’s what I keep it at using 8′ of beer line in a 38F freezer.

12-14 psi isnt too high ?

Nope, it’s what I use every time.

Do you have any pictures anywhere of your keezer set up with all the regulators, fan, and dehumidifier?

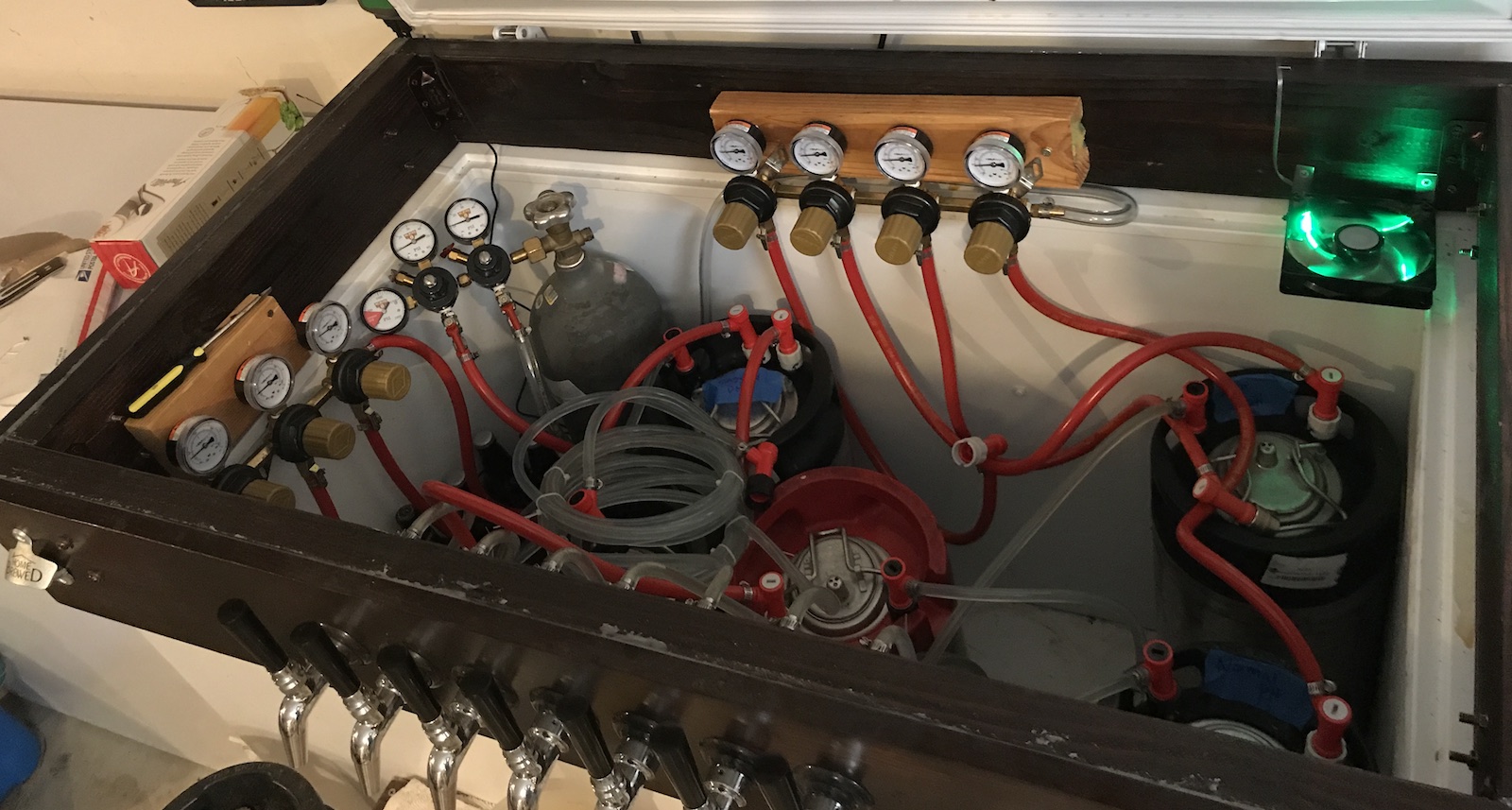

I don’t use a dehumidifier these days, I found it didn’t work very well and ditched it. I currently have 2 secondary regulators, a 3-body and a 4-body; if I were to redo things, I’d just get a 7-body and use a single body primary regulator, but meh. Here’s a pic:

Hi, how do you secure the larger size tubing for the racking cane over the smaller barb for the keg disconnect?

A small hose clamp.

What beer line cleaner do you use? Can you please elaborate on the method of cleaning your keg lines? Thanks!

Hi I have a noob question here!

So let’s say you did everything right and your keg is ready to serve. Can you disconnect the CO2 line and store your carbonated keg in the keezer ?

Same question : can you store carbonated keg OUT of the keezer ? I know that CO2 in a liquid depends on temperature, so is carbonating a keg right THEN bring it outsite in a warmer environment could be dangerous ?

Thanks

If the keg is airtight and the beer is carbonated to your desired point, then it doesn’t need to be connected to gas during storage, regardless of temperature – think of it the same way a can or bottle works. However, if you’re serving from that keg, you’ll need pressure to push the beer out and keep the headspace under pressure so the beer doesn’t go flat.

Thank you Marshall.

Another question (the last one I promise)

in step 11 you say :

<>

How do you know you reduce pressure to 12-14psi if you don’t have anything hooked up to the keg ?

Yeah, that’s a good question. You don’t really know until you hook the gas back up, but once you’ve released pressure a few times, you sort of get an idea based on the way it sounds. At least I do. I probably end up purging until there’s less than 10 psi, as when I hook up the gas, it takes a second for it to return to 12-14 psi.

Part of my comment was removed. I was copy/pasting this :

Step 11: Come back 24-36 hours later, remove gas disconnect, purge keg, reduce pressure to 12-14 psi (or whatever’s appropriate for your setup and beer style), and replace the disconnect.

Hey Marshall and the rest of the crew, just starting to keg after two years and interested in closed transferring to a purged keg.

My question is: how do you tell when to stop letting beer flow in to prevent overfilling it? Maybe I’m missing an obvious answer here from my inexperience but your help is appreciated!

I make to rack only 5.25 gal of wort to the fermentor. When kegging, I try to stop when it looks like there’s around 0.25 gal left in the fermentor… unless I’m using a Brew Bucket. Then it’s just a crazy guess.

Marshall, if you are now using the liquid out to rack the beer, how do you prevent overfilling the keg (filling up to and past the gas dip tube) when the keg lid is closed and you cannot see it?

Ha, maybe I should read the most recent comment! Sorry.

It can be a little tricky, but since I only ferment 5.5 gal of beer in the Brew Buckets, it’s pretty easy to avoid overfilling. In the warmer months, I can tell the level by the condensation on the outside of the keg.

A scale could be useful to avoid overfilling…

Marshall,

After the step 11 (Come back 24-36 hours later, remove gas disconnect, purge keg, reduce pressure to 12-14 psi (or whatever’s appropriate for your setup and beer style), and replace the disconnect)

Do you leave the keg on that pressure until the keg is empty??

This is assuming that the beer at this point is already in equilibrium with the CO2 pressure (according to the style) right??

Thanks

After reading this, every time I cover an opening with a star san soaked paper towel, I think about all the “bacteria carrying fuckers” that I am keeping out. Thank you for that.

I listened to the podcast on reducing oxidation. In the article discussed in the podcast you say you purge your kegs with CO2 and then keg as normal. Is the above method your are referring to?

For the most part, yeah.

This is goes under dumb question heading but how do you tell the actual pressure in your keg? Do you just close the tank valve & wait a while?