Author: Ray Found

When I first made the decision to go all grain, I discovered there were myriad ways to do so– traditional 3 vessel fly sparge, cheap-and-easy 2.5 vessel batch sparge, and Brew In A Bag (BIAB) were all considered. Most interested in taking the path of least resistance, and considering I had only an 8 gallon kettle for 5 gallon batches, I quickly ruled out BIAB. While the professional look and feel of a 3 vessel fly sparge setup was appealing, it seemed really cumbersome and had the highest startup costs. That left me with the batch sparge method where my boil kettle would perform double-duty as a hot liquor tank and the sweet wort would be collected in my bottling bucket. I had a 48 quart cooler lying around, which after a quick trip to the hardware store for some plumbing parts, became my first mash/lauter tun (MLT).

Despite modifications to accommodate larger batch sizes and brewing 2 batches simultaneously, my current brewing process remains largely identical. Truth is, I’d never considered trying anything different, dismissing other methods early-on undoubtedly due to my own biases. Having acknowledged this, I recently began thinking about the fly sparge method from a slightly more objective perspective. While I never fully bought the claim it necessarily yields higher efficiency than other methods, I wanted to see for myself, and more than that, I was curious if fly sparge might impact a beer’s character in ways batch sparge doesn’t.

| PURPOSE |

To evaluate the impact different mashing methods have on beer, the same recipe was brewed simultaneously using either fly/continuous sparge or batch sparge.

| METHOD |

Having agreed to provide beer for a relative’s wedding, something tasty-yet-approachable for both craft and macro drinkers in the crowd, I thought a light, crisp lager would fit the bill perfectly.

Make It Rain

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 90 min | 39.3 IBUs | 3.7 SRM | 1.060 | 1.014 | 6.1 % |

| Actuals | 1.06 | 1.01 | 6.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen (Dingemans) | 21 lbs | 93.33 |

| Vienna Malt (Gambrinus) | 1.5 lbs | 6.67 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 30 g | 60 min | Boil | Pellet | 12.1 |

| Saaz | 65 g | 30 min | Boil | Pellet | 3.2 |

| Saaz | 80 g | 10 min | Boil | Pellet | 3.2 |

| Saaz | 80 g | 0 min | Boil | Pellet | 3.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Notes

| 1.056 OG BATCH Sparge 1.060 OG Fly Sparge |

Download

| Download this recipe's BeerXML file |

When brew day rolled around, I started the batch sparge batch about 30 minutes before the fly sparge batch and was close enough to my target mash temp.

Since I was using my badass ThermoBarrel mash tuns, I put my old MLT to use as a HLT to assist in the fly sparge process, though never one to abandon my roots, I still collected the sweet wort in buckets and poured it into my kettles.

The batch sparge batch received the typical treatment, the second runnings so clear it almost looked like water.

While I waited for the batch sparge wort to reach a boil, I turned my attention to the fly sparge batch. After heating the initial volume of strike water, I mashed in and hit almost exactly the same target temp.

Following an hour long mash, I transferred the ~170˚F/77˚C sparge liquor by pitcher to a bucket, which I then hauled up a ladder to the HLT. For the first time ever, I thought maybe a pump would make life easier. The temperature settled in at 166.6°F, revealing that fly sparging is indeed of the devil.

After a brief vorlauf, I allowed the sweet wort to gently flow from my MLT at a rate similar to that which the sparge water was flowing into the MLT, aiming to keep about an inch of liquid atop the grains. I used a low-tech approach to make sure the sparge liquor didn’t cause any channeling.

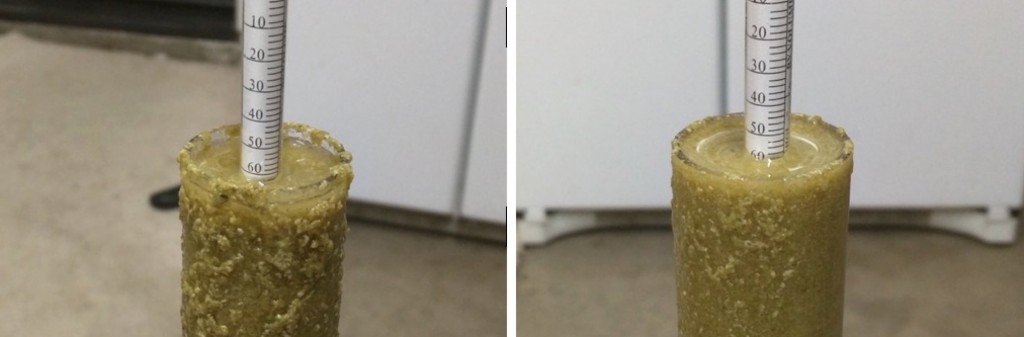

Once the sparge was finished, I noted the batch sparge grainbed had a thick pasty substance on it, which was familiar to me, while the fly sparge batch had none. Interesting.

I began the boil and set to the task of weighing out hops… I guess I’ll need to order more soon.

At the conclusion of their respective boils, each beer was chilled rapidly to just above my warm groundwater temp then placed in a regulated chamber where they would sit until dropping to my target 56°F/13°C fermentation temperature. A check of the original gravities revealed my original presumption was wrong, the fly sparge wort was .004 SG higher than the batch sparge wort, resulting in brewhouse efficiencies of 78.8% and 73.5%, respectively.

The next morning, wort temps had stabilized and I pitched a pack of rehydrated 34/70 into each fermentor. The beers were fermenting healthily a couple days later.

With active fermentation appearing complete, I took a hydrometer measurement that revealed both batches had reached an identical FG. Huh.

Two weeks after brew day, the beers were cold crashed, fined with gelatin, kegged, then placed in my keezer to condition and carbonate. After a mere 24 hours, I pulled a couple samples and found them not only delicious, but amazingly clear for a beer brewed just 20 days earlier!

| RESULTS |

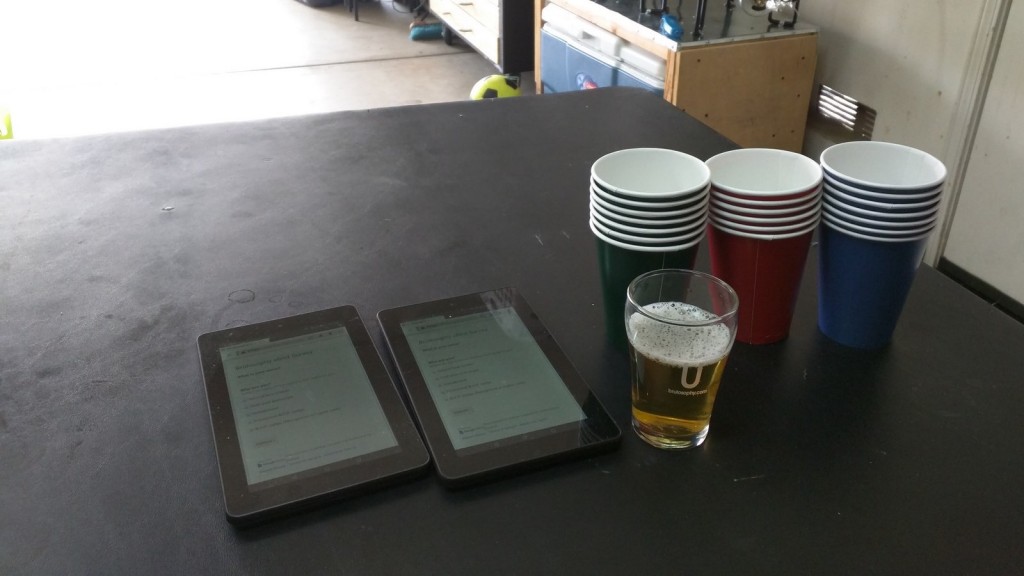

Thanks to all of the family, friends, local homebrewers, and club members who participated in this xBmt, there were 16 in all. Each blind participant was served 1 sample of the batch sparge beer and 2 samples of the fly sparge beer in different colored opaque cups then asked to identify the different one. Given this sample size, a minimum of 9 (p<0.05) would be required to correctly identify the odd-beer-out in order to, which is exactly how many did (p=0.026). These results suggests a pale lager made using the fly sparge process is reliably distinguishable from the same beer made using the batch sparge process, at least to this particular panel of tasters.

Responses regarding preference and ability to correctly identify the batch sparge beer yielded nothing of meaning, as responses were split pretty evenly on each question.

In conversations following completion of the survey, several panelists who were correct on the triangle test used adjectives such as crisper, drier, and hoppier to describe the batch sparge beer, which to me seems congruent with the fact it starting at a lower OG. But who knows?

My Impressions: Chock one up for the panel! In 3 “blind” triangle test attempts, I managed a correct response only 2 times. Armed with my bias, knowledge of the variable, and hubris, I believe I was able to identify some of what the panelists were saying, particularly that the fly sparge beer seemed a bit maltier, richer, and fuller, if only ever so slightly, and like the panelists, I had no preference for one over the other.

If served back to back, there is absolutely no way I’d be able to identify the beer had changed, I freely went back and forth between the two taps. I ended up taking a full keg of the batch sparge beer to the wedding where I’m pleased to say it was enjoyed thoroughly by the bride, groom, and their guests.

| DISCUSSION |

Given what I believe to be a fairly surprising difference in gravity, I guess I shouldn’t be shocked the panel was reliably able to discern a difference. With over 0.5% difference in ABV, it isn’t really a shock that the beers were perceived as being different, but still, this wasn’t the result I expected.

Personally, I’m inclined to view the difference in OG as the result, not only because it objectively seems to confirm the conventional wisdom that fly sparge can yield better efficiency, all else being equal, but it seems at least probable it’s what the panelists were reacting to. Maybe this is an overly simplistic perspective, or perhaps just my desire to maintain the position that identical beers can be produced using either method.

Ultimately, while I’ve no plans to abandon the method I’ve come to trust and know so well, this xBmt was a bit of an eye-opener for me and I look forward to learning more about the impact other mash methods have on beer.

What’s your mash method of choice? Are you a die hard fly sparger, a cheap and easy batch sparger, or do you BIAB? Perhaps you started with one method and switched to another? Whatever it is, please share your experiences in the comments section below!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

59 thoughts on “exBEERiment | Mash Methods: Fly Sparge vs. Batch Sparge In A Czech Premium Pale Lager”

Im not sure if its batch sparging. But since i RIMS my mash(step). I do the following.

for a 5 gal batch for example.

Mash in 24L (6.3gal) @ 55 oC ( 130F ) and after 30 mins i step up to 65-69oC (149-156)[depending]

Then test conversion after 30 mins. Step up to 75oC (167oF ) then transfert to keggle.

I then pour in from hlt 10 to 14L (2-3 gal) @ 75oC (167oF) in the mash and stir for a few mins while running the RIMS to keep the temp, then i transfert to keggle the “rinse”.

Ive been reaching in between 75-80% Efficency… thats my method.

Im not yet doing fly sparge..

Hi Ray,

Very nice exbeeriment. Before I was a fly sparger and mashing with continuous recirculation. Now I batch and non sparge with a cooler and I’m very happy. I can go out when I mashing, and my brew day is a little short. My efficiency has decreased.

For another similar exbeeriment, would be good try to get similar OG worts ( knowing your efficiency in both methods).

Cheers,

Interesting. Fly sparging has always seemed a bit cumbersome to me, and I’ve never given any serious consideration to adopting it. That’s what I love about this hobby…many different ways to make good beer.

I fly sparged twice because that’s what all the cool kids do. Threw my numbers off and since I’m lazy and didn’t want to go through with adjusting my recipes, I went back to batch sparging.

Ha!!! That’s exactly why after 3 years I still fly sparge. I’m too lazy to switch and recalculate my recipes based on efficiency difference. Plus during the fly sparge process…I just sit back and drink beer. Win/win.

Great read. It’s something I’ve been curious about recently. While not a huge difference in efficiency, it’s definitely notable. Perhaps fly-sparging would be more appropriate for certain styles of beer (stouts, bitters, etc.), whereas batch sparging would be more appropriate for drier, crisper beers (lagers, Schwarzbiers 😉 ).

Hard to say.

This may be anecdotal, but I actually think it’s the other way around. The Brits would batch sparge (gyle) their recipes, so it always made more sense to me to batch-sparge British styles. I have done several decoctions and always fly-sparge when I have done so, for no particular reason. With big grain bills (>13lbs of grain in a batch) for a 5.5 gallon batch I typically fly-sparge as well. I know this has no bearing on the article, sorry, just thought I’d pitch in on my experiences. To address the xbmt, I find it’s mostly a matter of efficiency which potentially effects the finished product.

I always fly sparge and have never batch sparged. I’m scared my numbers will be off since I’m so used to fly sparging. It would be nice to save some time though.

It isn’t as much of a time sink as I expected in the leadup to it. If I had a system designed for fly sparge from the get go, it would probably be only a little worse than batch in effort required, and likely almost no difference in total time.

I was a long time fly sparger and until a few year ago hadn’t heard of batch sparge. I started batch sparging recently and plan to stick with it. My efficiency has dropped down to around 65%. I don’t care about the extra grain needed I just want consistency. I hear most people get around ~70-75% with batch.

My methods for 5 gal.: strike water about 1.25 qt/# produces mash temp of 152 for 60 min. 1st runnings drain the mash tun (10 gal. round cooler) then I add about 5 gal 175 – 180 sparge water to get ~168 after stirring. Sit 5 min, verlouf and drain quickly to get final wort volume.

Do you have any suggestions to get typical efficiency?

Thanks and keep up the great work!

Most common suggestion is finer crush (I crush at .028) and stir a couple times during mash.

Ray – Could you possibly add a few comments regarding the time difference between the 2 methods on brew day? What was your fly sparge duration and what was your lautering device (false bottom, braid, bazooka, etc)?

Thanks for taking the time to do the experiment. Some good insights from this one.

Rob

Both were done in identical ThermoBarrel MLT with false bottoms. You can get the vessel details on the ThermoBarrel Review.

Regretfully, I did not keep a detailed account of timing, but I am guessing Lauter/sparge took about 30-40minutes total on the fly sparge, maybe 15-20 total on the batch?

While time wasn’t a huge difference, on my system, the effort/attention required for fly sparging was significantly higher.

Looking at getting a ThermoBarrel. Is the flow rate good when running off? I see you have a barb with tubing attached to the ball valve. Is that to enhance the siphon / flow rate into your buckets?

Also, how much deadspace does it have?

Yes, you NEED to have a piece of tubing on the outlet to get it to siphon, otherwise (like anything) it will not drain below the level of the valve.

Flow rate is nice, it is 3/8 fitting, so not quite as fast as 1/2″, which seems to make it harder to stick… runs off very smoothly, leaving very little deadspace, I’d estimate it leaves less than a quart of liquid after draining. It was something I was concerned about, but in retrospect it drains better than my cooler did.

Love it. Great xbeeriment. I started fly sparging and have a for several years (mostly cause I figure that’s what the pros do, it must be for a reason). However, I gotta say after reading this site for a while and a few others I have done some batch sparging now and think I am turning to that. I haven’t noticed a decrease in my efficiency at all though honestly. The first one I tried I had set for 75% in beersmith (I am usually 75 – 80 fly) and hit 81 %on the batch! The other that I tried I nailed it at 75. Both great beers and so much easier than fly sparging. Can’t say I am a total convert now but I will be doing mostly batch sparge I think now lol

I have at times gotten higher efficiency from batch sparging, but I am really consistent now.

Started out doing extract kits. Then jumped into BIAB for transitional ease IMO. Got myself a converted cooler started to batch sparge. After several batches. I needed to shave some time. Now I am back to BIAB. As it is better for me at this time. With this knowledge, any chance I get to share I do. Your results, the xBmt(s), The Brulosohy website. Awesome Work!

Sounds Good Jerry! You still planning on coming to corona tomorrow morning?

Batch for the pure simplicity and lack of additional equipment.

Thanks again for another great xBmt Marshall!

I have brewed with all 3 methods, Fly, batch, and no sparge. I fly sparged about 30 brews before switching to batch sparging, which I used for about a year and a half, before going to no -sparge BIAB, and have tried sparged BIAB and cold sparged BIAB as well.

This xBmt is interesting, I got slightly higher efficiency by batch sparging over fly. But I think a lot of it had to do with stirring at mash out. If I didn’t stir the mash extremely well, efficiency would suffer. And this would often cause issues with stuff getting through the false bottom and make it tough to vourlaf.

But what I find strangest is I get the highest efficiency with a cold sparged BIAB. I mash in 6-6.75 gallons depending on boil length , and after the mash I squeeze the bag, put it in a big SS bowl and pour about 1.5 gallons of water through the grain bag, add that to the kettle, and squeeze the bag again. It’s very low hassle and gives me great beer and 84% brewhouse efficiency. I’ve noticed zero difference between a hot or cold sparge using BIAB.

Try it sometime! 😉

You mean Ray? Hehe.

…well, both!

I get can get slightly higher efficiency with fly if all is well dialed in, and I am attentive. But with everything changing all the time, especially with the experiments, I’d rather cruise on easy mode and get a higher efficiency on average. The time, the ease, the consistency is tough for me to beat.

FWIW – I get a slight bump in efficiency with a hotter sparge.

“Regretfully, I did not keep a detailed account of timing, but I am guessing Lauter/sparge took about 30-40minutes total on the fly sparge, maybe 15-20 total on the batch?”

Do these different times mean the fly-sparged batch had longer conversion time as well as a different lautering method? If so, it’s not a straight comparison.

@Ben – I am really guessing on the times. I found the batch sparge drained faster, as I didn’t have to throttle at all and do the flow-matching. Since I didn’t record times (Probably should have) it is entirely possible that it just FELT faster because it didn’t require any attention vs the fly sparge that I had to keep an eye on.

That being said, I am not sure the conversion times were a factor, as we’ve seen very little difference with even VERY short mashes in previous xbmts.

@Ben – I am really guessing on the times. I found the batch sparge drained faster, as I didn’t have to throttle at all and do the flow-matching. Since I didn’t record times (Probably should have) it is entirely possible that it just FELT faster because it didn’t require any attention vs the fly sparge that I had to keep an eye on.

That being said, I am not sure the conversion times were a factor, as we’ve seen very little difference with even VERY short mashes in previous xbmts.

Cool idea mike. (No pun intended.) I hot sparge my biab but I’ll have to try your cold method sometime and see how it comes out.

I’ve soley done no & spatge BIAB, but I squeeze the ___ out of the bag. Last batch I mashed in with 8.2 gallons of water and a 12lb grain bill, I ended up with 7.75 gallons of sweat wort. My brewhouse efficiencies are also right around 84%.

Your xBmt could not have come at a better time! Based on your results, I’m sticking with my normal process…vorlauf, drain, sparge, stir, vorlauf, drain, sparge, stir, vorlauf drain.

If I ever were to fly sparge, I would be interested to know how much temperature the sparge water looses when doing a fly vs batch. I am in no way a mathematician but I would hazard that there has to be some formula that would calculate the water’s temperature loss based on exposure time to the ambient air plus other “mathy” things like πr*r (squared does not show). Where I live, at this time of year the ambient temperature in my garage has been as low as -2 F. I’m guessing that if I would attempt to fly sparge in sub-freezing weather, I would need to compensate a whole bunch for the loss of heat in some way. Higher water temps, insulation, etc.

Thanks for another very helpful xBmt that I can apply to my own brewing.

I’m also a batch sparger, learned how to do it on this site! No plans on switching to fly sparge, although I was always curious about what kind of differences it would produce. Thanks for doin this Xbmt!

I love batch sparging, for ease of use and simplistic design, also the minimalistic approach (and less vessels to clean). I currently use a paint stirring blade attached to a cordless drill to stir my mash tun and my efficiency has consistently been in the 78-82 range.

@ Ray

” I am not sure the conversion times were a factor, as we’ve seen very little difference with even VERY short mashes in previous xbmts.”

I’ve read the mash length xbmt and the results are based on a tasting panel. I prefer Kai Troester’s mash time experiment as the results are based on more objective measurements. He found conversion continued at least six hours into mash time. Hope one of these links works:

[IMG]http://i65.tinypic.com/23tpixy.jpg[/IMG]

http://i65.tinypic.com/23tpixy.jpg

“Since I didn’t record times (Probably should have) it is entirely possible that it just FELT faster because it didn’t require any attention vs the fly sparge that I had to keep an eye on.”

Yes the times could have been just the same by coincidence, I’ll grant you that..

I find myself curious now, what impact fly vs. batch sparging has on the final product when you adjust for efficiency. I think that is more typical of how we approach brewing past the first few uses of your system. You adjust any recipe you have to nail a specific O.G. based upon your normal efficiency.

If you adjusted would there be noticeable differences between the different methods with an otherwise identical recipe using the same grain percentages?

I used to do fly sparging, but when I made the transition to electric my space was limited in my basement and cost was a factor. I went with a single vessel E-BIAB with a RIMS system. LOVE IT.

Made a DIY Whirlpool arm and a DIY Hopspider. Brew day is quick, fast, and clean. Clean-up takes no time at all.

Also built a 5 pulley system to get the heavy ass 10 gallon batch grain bags out which was the only thing that initially concerned me.

Intersting article! I am a biab guy but I do it a little differently than most “traditional” biab-ers in that I don’t mash at full volume. I mash at the thickness I want for the style and then sparge thusly:

At end of the mash I pull the grain bag out of the wort and slow to moderately sparge/ rinse my grains over the wort with heated sparge water. Once complete, I’ll continue to vorlauf/rinse using a gallon pitcher for another 1-1.5 times the boil volume (7-10 rinses at 1 gal each) making sure rinse all sections of the bag and not just the center.

Using this method I’ve gotten mid to high 70s for efficiency where as I was in the low to mid 60s with whole batch traditional biab.

If anyone has a name for my technique/method let me know but for now I’m simply calling it “my way.” cheers!

Another surprising xBmt. As you said above: hart to tell if the testers could distinguish the beers because of the difference in process or because of the difference in OG.

So next up, a xBmt where you compensate for the expected difference in OG by using more grain?

Wonder how many people, like me, were intimidated by the equipment and process needed to do fly sparging and stayed on extract with partial mashies instead of going all grain? Cooler MLT has worked out great for me and I love the results compared to extract.

Did you take a mash efficiency reading after you were done sparging, right before you started to boil?

That seems like a HUGELY relevant piece of information in this experiment. It would give you a quantifiable difference between the two approaches before introducing more variables in the process.

After the boil, your fly sparge gravity was higher by 4 points. But was it even higher before the boil? It would be interesting to know right after the sparge what the readings were, before further slight deviation was introduced (two separate boils).

Fly sparing for me, largely because that was what I first read about in How to Brew. It does however afford me to brew larger batches in my 30 l kettle which acts as mashing tun, lautering vessel and boiling kettle. Both due to higher efficiency and as I do not need to leave much headspace to accommodate spare water.

I have brewed professionally for a while and taken a lot of classes via Siebel institute. The main reasons the big boys do fly sparging is for efficiency in fresh beer, but to minimize oxidation of the grain for beers made to age. This is why a level of water is kept on top of the grain bed for as long as possible. By doing it this way the grain is only exposed to air one time, and not two or three times as it is with batch sparging.

That being said, I batch sparge all my beers at home, except barleywines, saisons, biere de garde, and other strong beers made for aging. The 5 or 10% decrease in brewhouse efficiency can be overcome by a $2 increased cost in grain, which I can accept financially 🙂

To decrease the work involved in in maintaining a certain water level above the grain bed you can connect a float switch to a relay controlling the pump used for the fly sparge, or a toilet type float switch with a gravity based system. That way you can just walk away.

Thanks for chiming in and sharing your experience, Einar.

That’s the reason they give? To prevent/ minimize any potential effects of prepitch “hot side’ aeration. Do you feel that 170F (77C) sparge liquor is deaerated to make a difference?

And I wonder about an analogy I’ve used before in regard to HSA – chalking windows while the door is open. The centrifugal pump transfer from one tank to another etc is a violent O2 introducing pRochas unless a bfewer is imerging their tanks.

I understand taking measures to minimize if you can but I also challenge the degree of impact it has. With that stated, nor do I completely discredit the fact it may be a factor as it’s not my area of expertise.

That is correct. That is what Siebel Institute and the brewery I worked for said. I have never used a pump once the beer has been in a fermenter. From there it is all either CO2 pressure or gravity. This is to preserve hop oil aroma and to prevent oxygenation. John Kimmich from The Alchemist follows the same method.

My buddy and I have been brewing on And off for roughly 10yrs. As of the last year, we’ve taken it more seriously and have improved tremendously. Currently in the process of building a HERMS brewery. Fly sparge wasn’t our first choice in this iteration, but after trying it we wouldn’t go back. The key knowing someone whose GOOD at it. We didn’t and it was tricky to pick up. One issue we toiled over was crush size. We were crushing at .041 (shop max). Upon doing our research and reducing to .033, we had an immediate 10% efficiency increase. Point is, it’s not as easy as batch sparge (which I don’t knock), but the efficiency bonus plus the feel of being like a”real” brewery made it well worth it for us.

Which one tastes better? Which one is easier or faster?

I do ~3 gallon batches where I mash ~6 lbs grain in a stock pot/paint strainer bag on the stove. I then pull the grain bag and drop it in the BK that already contains 180* water. This is my “batch sparge”. I let it sit there for about 10 minutes before pulling the grain bag from that and I let it sit on a strainer over the original mash pot while the runnings are heated in the BK for the boil. I’m not getting the best extraction efficiency, currently at about 66% but with my next beer I’ll be double-crushing my grain, thinning out my mash, mashing and sparging for longer periods to get that efficiency up a bit.

It makes sense to me, as a chemical engineer. If you batch sparge, the wort that is held by the grain is going to contain more sugar than if you are continuously putting pure water in to the top and taking out wort from the bottom–it’s a more efficient extraction. That’s all assuming you use the same amount of water in both cases.

Actually this is not entirely correct… given an equal volume of water – the saturation of fermentable sugars should be equal, however since one method is based on a static volume which has a maximum quantity of sugar that can be absorbed for the given volume,and the other is of an unsaturated volume moving at a steady rate thru the medium, the potential for maximum absorption is never reached… so the fluid method actually has the ability to remove more sugars than the static method, even given the same volume.

There is a reason that commercial breweries use fly sparging over a no-sparge or even a batch sparge. it is to maximize the amount of fermentable sugars that can be removed from the grain bed.

One point I note is that it was asked “how long it took for each method?” and the response was that the Xbrmt did not take actually measure this. The result then is inconclusive for a proper comparison. It is well documented that fly sparging done correctly is not based on any given volume as batch sparging is usually calculated, but rather done at a very slow rate ( to allow for the absorption of sugars from the grain bed while passing thru it) and is normally concluded when the runoff reaches a SG of 1..010 (which is consider to be a completed sparge)

I have replied that it added a bit more time to the mash and that was added to the second batch. Here or one of the 8 other places…

I get it, you like to fly sparge. That is fine. You’ll notice we missed “conclusive” by one also. All is well.

Also, please note: This is home brewing. Commercial brewing methods are used in commercial brew equipment/setups, they don’t always directly translate.

I think that you need to determine why your batch sparge effi ciency was so low, to do a fair comparison. A beer in the 1.055-1.060 range should have an efficiency up around 85-87%, batch sparged (Kai has a nice spreadsheet that allows you to determine this, his Batch Sparge Simulator). The 74% that you saw is what would be expected from a no- sparged beer. These are both the numbers that can be mathematically determined and the ones that I measure from my brewing system.

85-87% with batch sparge? I’ve been batch sparging for nearly 5 years and the best I’ve gotten is 80% when using Pils malt in 1.050ish beers.

Yes, 85-87% mash efficiency is typical for me and my brewing buddies, once we got our systems, crush, and process dialed in. If you use Kai’s spreadsheet, you’ll probably find something near that range predicted for your’s. I’m talking mash efficiency, though, not brewhouse efficiency, which BeerSmith might still call mash efficiency, erroneously.

I completely thought you were referring to brewhouse efficiency. My mash efficiency is usually much higher as well, though I know of no who uses that as a gauge of their brewhouse efficiency.

BeerSmith refers to brewhouse efficiency as brewhouse efficiency.

Do you get near 100% conversion? That is often the crucial step, once you take care of the physical characteristics of your system that limit efficiency, like dead volume.

I’ve been brewing for quite awhile and have my system dialed in. Your using efficiency to refer to mash and not brewhouse efficiency is what caught me up 🙂

I just never found brewhouse efficiency to be a very good comparitor between breweries, since it varies with how much wort you choose to leave behind during a transfer. Mash efficiency will tell you what gravity to expect from a grain bill and more easily formulate recipes. Brewhouse efficiency’s usefulness seems limited to commercial breweries that need to worry about optimizing profit.

For reference, I just ran the brewhouse efficiency calculation for my last batch. That was 82.8% to packaging for a 5 gallon batch, but I have very small losses at transfer.

I am at a loss. I either fly sparge 10 gallon or no sparge 5 gallons. I net around 78% no sparge, or around 93% fly sparge. I assumed that was a common fly sparge efficiency number. I run constant recirc direct fired in a keggle with 2.5 gallons dead space below the grain bed (pico-style false bottom). This allows for any ridiculous numbers of rests with only a clock and a constant of 2.5degrees/minute on full throttle, instead of lengthy equations. Am I pulling quantum sugars from another dimension, or are multiple rest that much more effecient?

I thoroughly enjoyed reading your paper. Thank you for taking the time to write it up in such a professional manner. We also started with batch brewing and when the chance to purchase a 15 gallon Blichman system at a drastically reduced price, we jumped at the chance. The new system has a fly sparge, which we enjoy immensely. I don’t think that we have achieved the 90% efficiency yet but we are home brewers and realize that at some point we have to “relax and have a home brew”. We figure we enjoy drinking good beer, we enjoy each other’s company and we really enjoy drinking our beer more than the pubs and breweries in the area. Currently we brew on both systems in alternating months as we like to be able to brew three batches of different beers rather than 15 gallons of the same beer each month. As for the process, we engoy both systems and I don’t feel that we prefer one spargr method over the other.

The most interesting result IMO is that there were no adverse effects from the dreaded oxydation of the grains. It remains to be seen whether this would remain true after some seasoning. It might be that the grain oxydation fear is unwarrented. I am still looking for a source with clear evidence of different long-term consequences for different sparging methods. Any hint to sources appreciated.