Author: Steve Thanos

Used to impart beer with increased levels of hop aroma and flavor, dry hopping is a technique that was originally used by British brewers for the primary purpose of preservation given the antimicrobial nature of hops. These days, it’s relied on as a matter of course when making any of the many modern hop-forward styles like IPA and American Pale Ale.

Traditionally, dry hopping consisted of adding a decent charge of hops to beer toward the end of fermentation and allowing them to mingle for a few days before moving onto packaging. However, brewers of late have started dry hopping sooner in the process, with some claiming the interaction of actively fermenting yeast and hops can lead to biotransformation, while others view it as a way to reduce the risk of oxidation.

The extreme version of early dry hopping involves tossing the hop charge in at the time of yeast pitch, which despite past xBmts suggesting works as well as dry hopping at the end of fermentation, has yet to gain much popularity. Curious of the impact this approach has when used in an American Pale Ale that’s more moderately hopped, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between an American Pale Ale dry hopped at yeast pitch and one dry hopped toward the end of fermentation.

| METHODS |

For this xBmt, I went with a simple American Pale Ale recipe in order for any differences to be more easily perceived.

That Aha Moment

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 36.4 | 5.3 SRM | 1.062 | 1.016 | 6.04 % |

| Actuals | 1.062 | 1.016 | 6.04 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale 2-Row Malt | 9 lbs | 90 |

| Vienna Malt | 1 lbs | 10 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Simcoe | 14 g | 60 min | Boil | Pellet | 13 |

| Mosaic | 28 g | 10 min | Boil | Pellet | 11.6 |

| Mosaic | 28 g | 5 min | Boil | Pellet | 11.6 |

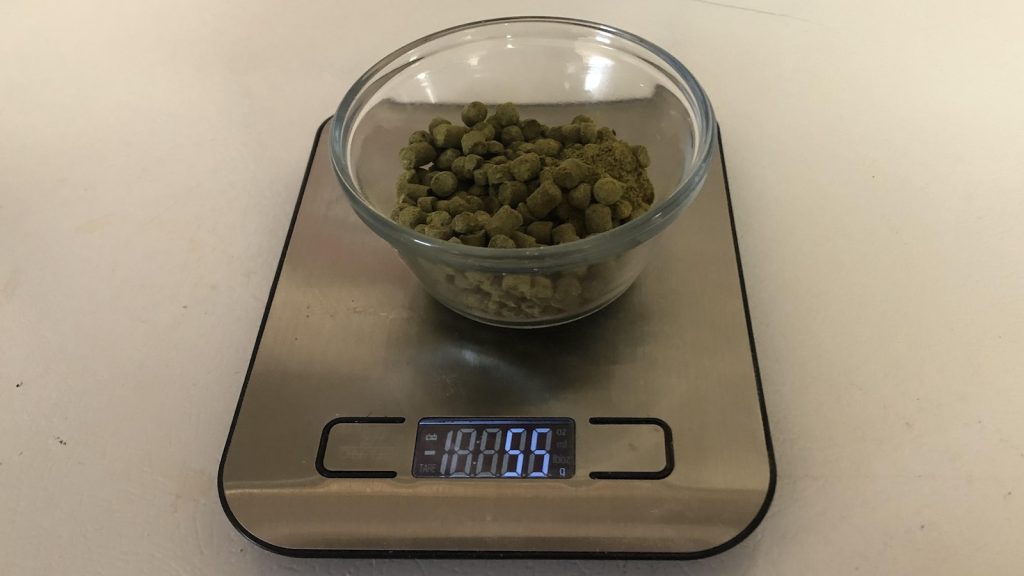

| Mosaic | 56 g | 5 days | Dry Hop | Pellet | 11.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 125 | Mg 20 | Na 8 | SO4 310 | Cl 56 |

Download

| Download this recipe's BeerXML file |

After collecting two identical volumes of water and lighting the flame to get them heating up, I weighed out and milled the grains.

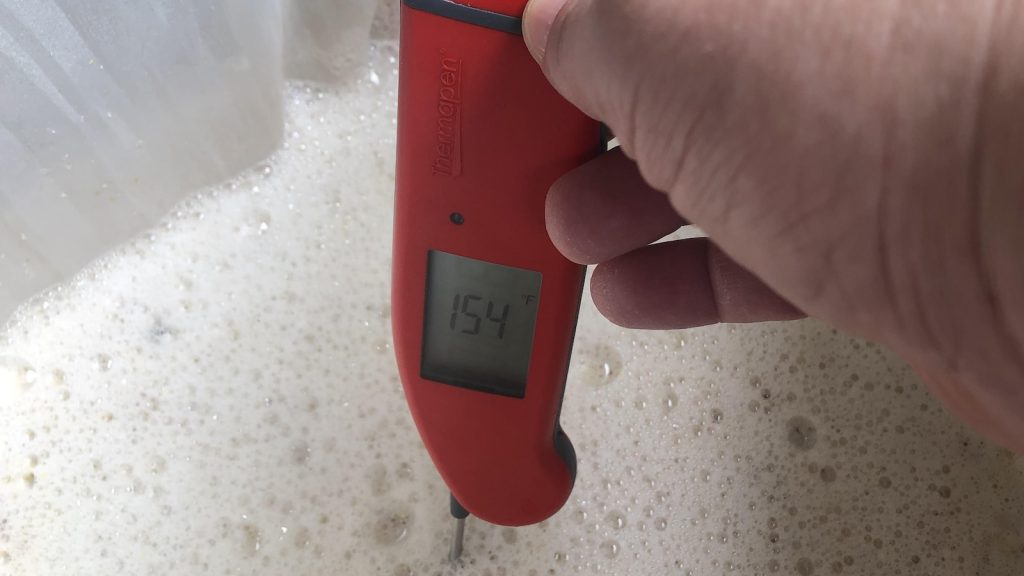

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure they were at my target mash temperature.

While the mashes were resting, I prepared the kettle hop additions.

Once each 60 minute mash was complete, I sparged to collect the same pre-boil volume then boiled the worts for 60 minutes before quickly chilling them with my JaDeD Brewing Hydra IC.

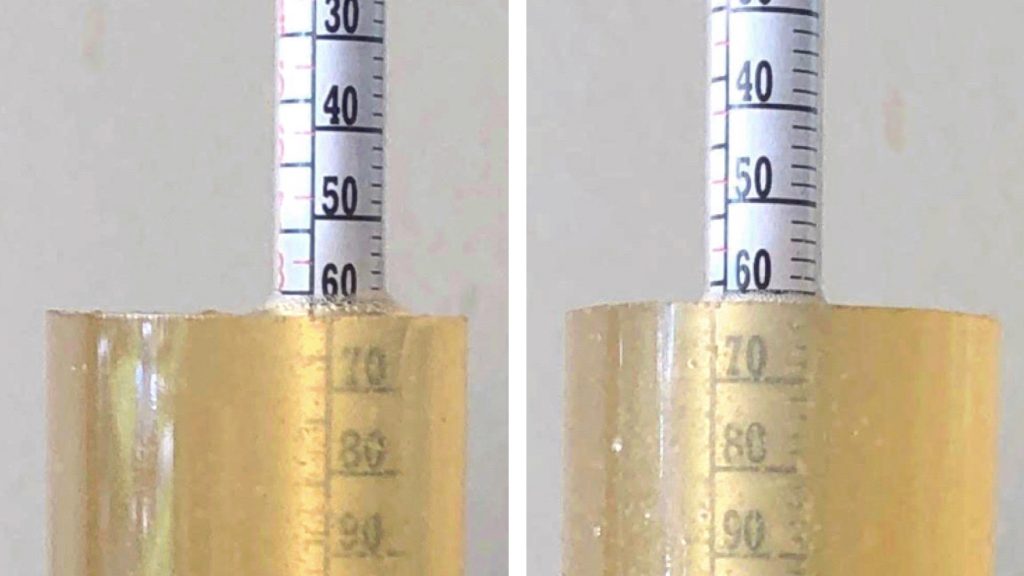

Refractometer readings showed both worts at the same target OG, as expected.

After transferring identical volumes of the chilled wort from each batch to separate fermenters, I pitched a pouch of Imperial Yeast A07 Flagship into each.

At this point, I added the dry hops to one of the batches while the other was left alone.

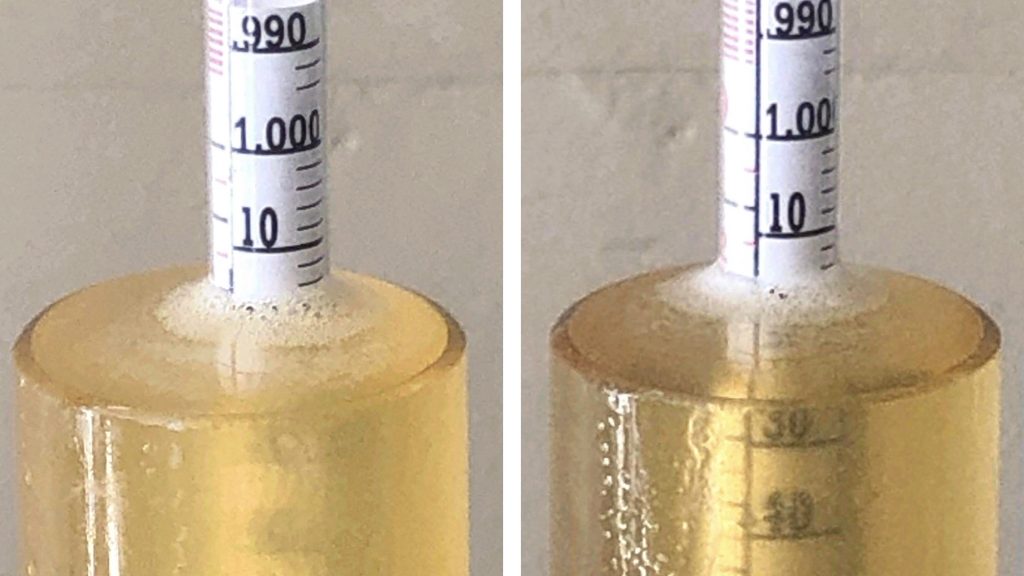

With signs of fermentation dwindling after 5 days, I added the same amount of dry hops to the other batch and left them in the beer for 7 days before taking hydrometer measurements indicating the beers were at the same target FG.

The beers were then transferred into CO2 purged kegs and placed on gas in my keezer where they were left to condition for 2 weeks before they were ready to serve.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dry hopped at yeast pitch and 2 samples of the beer dry hopped 5 days into fermentation in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.52), indicating participants in this xBmt were unable to reliably distinguish an American Pale Ale dry hopped at yeast pitch from one dry hopped 5 days into fermentation.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just once, and that was a lucky guess, as these beers were perceptibly identical to me. Both were crisp and clean with a pleasant hoppiness that I found to be quite refreshing.

| DISCUSSION |

Viewed as necessary for the production of modern hoppy beers, whether it be classic American IPA or West Coast Pilsner, dry hopping traditionally involves adding a dose of hops to beer toward the end of the fermentation process. However, in the early days of Hazy IPA, brewers began talking about certain benefits of dry hopping earlier, namely biotransformation and reduced risk of oxidation. Interestingly, tasters in this xBmt were unable to reliably distinguish an American Pale Ale dry hopped at yeast pitch from one dry hopped 5 days into fermentation.

These results indicate that dry hopping at yeast pitch produces a similar enough overall hop quality as dry hopping later in fermentation, which aligns with prior xBmt findings on the same topic. Equally as interesting is the fact the beer dry hopped at yeast pitch was in contact with the dry hops for 12 days as opposed to 7 days for the standard dry hop batch, suggesting a 5 day difference in dry hop duration had no perceptible impact as well. From a purely visual perspective, the beer dry hopped at yeast was notably more clear than the standard dry hop batch, which may be a factor worth considering for some brewers.

I’m fully of the belief that dry hopping is essential for creating the level of hop pungency expected in certain styles, and while I’ve historically opted for the more standard method of dry hopping toward the end of fermentation, these results have me reconsidering my approach. Considering the beers in this xBmt were indistinguishable by tasters and myself, it can be presumed there were no notable differences in oxidation. That said, there’s a level of insurance that comes with adding dry hops up front, and considering the evidence in support of this method, I definitely plan to continue using it in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

4 thoughts on “exBEERiment | Dry Hop At Yeast Pitch vs. Standard Dry Hop In An American Pale Ale”

The Morebeer website discusses this: Why not dry hop at pitching time? – https://www.morebeer.com/articles/primarydryhopping

They caution against it – “it’s safer to wait until fermentation is almost finished to minimize sanitation worries.” I haven’t done this, so I can’t offer any experience.

I’ve done this for dozens of batches without any sanitation issues. I’ve put the hops in before racking, and right after. I’ve also waited until high Kraüsen I simply use StarSan on the hop bag. (I’ve also carried hops over from flameout/whirlpool) I never have issues with my airlock or blow-off tube getting clogged. As for the loss of aroma claim, clearly here, not enough tasters noticed that either in this xBeeriment. I’d say the MoreBeer drive-by is just F.U.D. and speculation, which Brülosophy does a good job of testing and disproving over and over again.

As for the xBeeriment results, I understand 7 days to be a bit excessive for Post-Fermentation Dry Hop. There is some research being done that shows more than 48 hours provides extreme diminishing returns and can result in vegetal characteristics. (unfortunately, we don’t see any data showing what tasters perceived outside of not being able to distinguish them) There is also some research being done into the timing of the Dry Hop. The options I’ve seen are ‘after Kraüsen drop’, with a couple of points left in fermentation (pre-Diacetyl rest), after a Diacetyl rest but before cold crashing, and after cold crashing. This brew seems to have tested the first option which might have resulted in that charge being muted compared to say a later, shorter, post-chill addition. (effectively, not much different than a yeast-pitch addition, thus the results) A yeast pitch addition vs. a 1-2 day post-chill addition might yield a noticeable difference. The first will get ‘cleaned up’ by the yeast with the extended contact time, and the second will have the most ‘punch’. (at least in theory)

I’m not surprised at all by the clarity difference. I’ve experienced that myself in many batches. Science™ would have to weigh-in, but my guess would be any haze causing particles from the hops were pulled out of suspension by the yeast.

How are you getting a 1.062 wort from 10 pounds of grain in 5.5 gallons?

I’m not an expert with BeerSmith but from my figuring with it your mash efficiency is 101.5%