Author: Cade Jobe

Cold-side oxidation occurs when fermented beer is exposed to oxygen, which leads to a number of deleterious effects, most notably rapid staling. In order to prevent such oxidation, brewers employ a number of techniques to ensure their beer is exposed to as little oxygen as possible, one of which is purging kegs with carbon dioxide (CO2) prior to filling them.

A common purging method involves using packaged CO2 to push liquid out of a keg into another vessel, thus displacing the liquid and oxygen-rich air with CO2. However, seeing as the fermentation process can produce anywhere from 20 to 40 times the amount of CO2 as the volume of beer, some brewers opt to repurpose the gas that would otherwise be lost to the environment. By simply connecting a line from the fermenter to the gas post of a keg full of sanitizer solution, then running a line from the liquid post of the keg to another vessel, the gas produced during fermentation will push the liquid out and thus purge the keg of oxygen.

As clever as this method is, I’ve been hesitant to try it out for myself. There’s no denying that fermentation is an odorous process, often emitting less than pleasant sulfur aromas that I’d prefer not be in my finished beer. However, people I trust have claimed that racking beer into a naturally purged keg has no negative impact on beer character, particularly when the keg is purged with the CO2 produced from that beer that will ultimately end up in said keg. Wanting a bit more evidence before I choose to change my process, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between Blonde Ales served from kegs purged with either CO2 produced during fermentation or packaged CO2.

| METHODS |

I opted to brew a simple Blonde Ale recipe for this xBmt in hopes any impact of the variable would be readily perceptible.

It’s A Gas

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 25.8 | 5.5 SRM | 1.049 | 1.006 | 5.64 % |

| Actuals | 1.049 | 1.006 | 5.64 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta: Pale American Barley Malt | 10 lbs | 90.91 |

| ESB Pale Malt | 1 lbs | 9.09 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

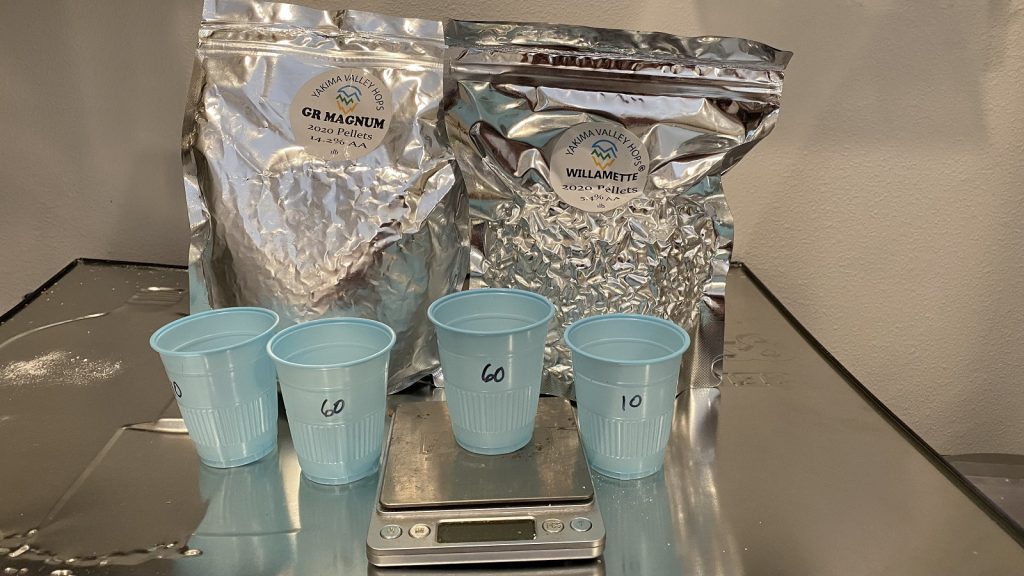

| Hallertau Magnum | 15 g | 60 min | Boil | Pellet | 12 |

| Willamette | 15 g | 10 min | Boil | Pellet | 5.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 140 | Mg 18 | Na 14 | Cl 55 | SO4 184 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for both batches and adjusting them to my desired mineral profile before setting the electric controller to heat it up.

With the water properly heated, I added the milled grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 152°F/67°C.

While the mashes was resting, I weighed out the kettle hop additions.

Following each 60 minute mash rests, I removed the grains then boiled the worts for 60 minutes, adding hops at the times listed in the recipe.

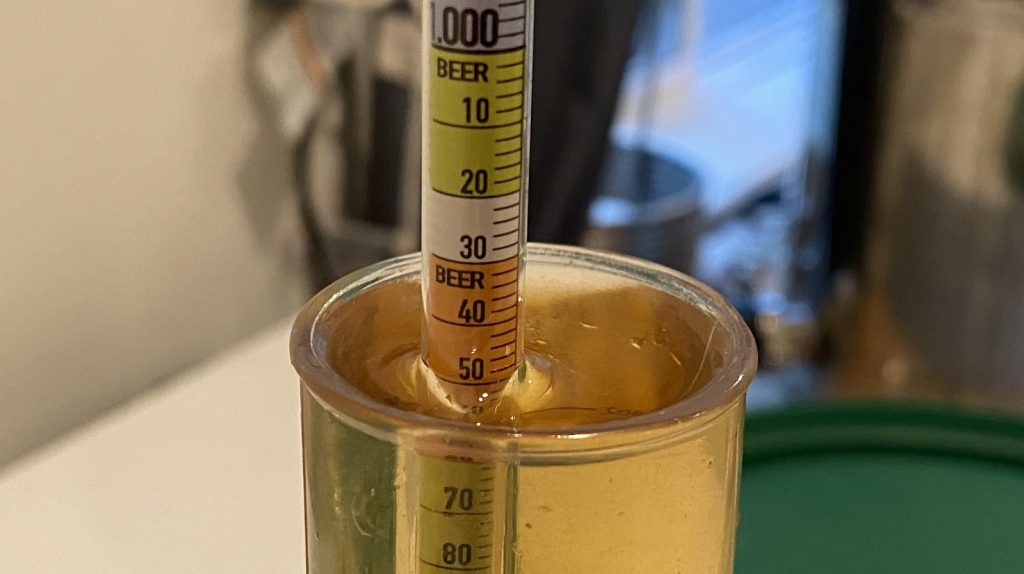

When the boils were complete, I quickly chilled the worts then combined them in single 14 gallon/53 liter Brew Bucket before taking a hydrometer measurement showing it was at my target OG.

The filled fermenter was placed in a fermentation chamber controlled to 66°F/19°C before I pitched 2 pouches of Imperial Yeast A07 Flagship.

I ran tubing from the fermenter to the gas post on a keg full of sanitizer solution, then ran tubing from the liquid post to the liquid post of an empty keg that had the PRV open to allow the sanitizer to flow in.

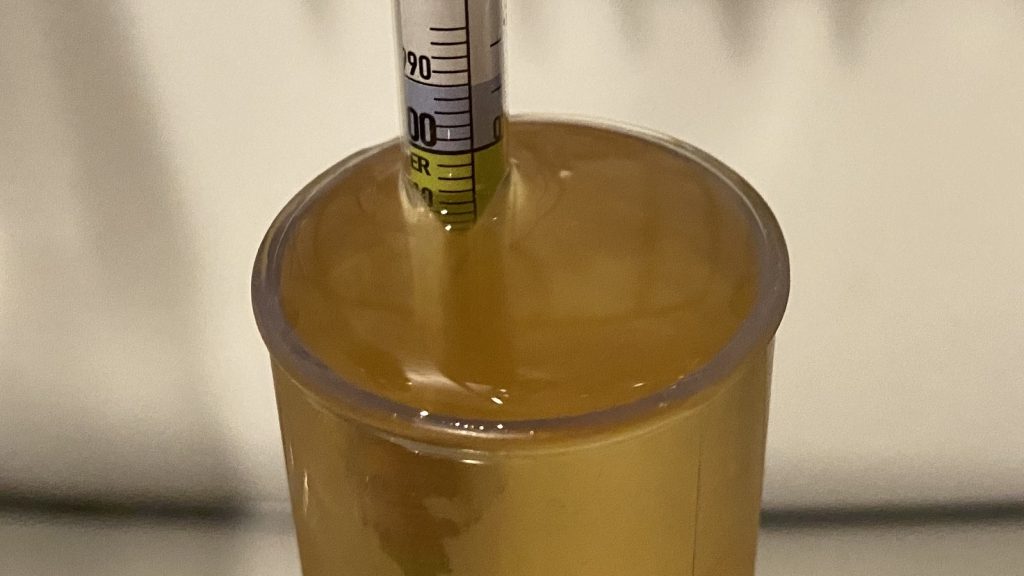

I noticed sanitizer solution flowing out of the primary keg 12 hours later, and it was completely empty less than 24 hours after pitching the yeast. I left the CO2 capture setup connected for the duration of fermentation to ensure as much naturally produced CO2 was in the primary keg as possible. With all signs of activity absent after 3 weeks, I took a hydrometer measurement indicating the beer had reached the expected FG.

At this point, I used CO2 from a tank to push sanitizer solution out of one keg before pressure transferring identical volumes of beer into it and the naturally purged keg. The filled kegs were placed on gas in my keezer and allowed to condition for 3 weeks before they were ready to serve to tasters.

| RESULTS |

A total of 17 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer from the keg purged with CO2 from a tank and 2 samples of the beer from the keg purged with CO2 produced during fermentation. While 10 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.33), indicating participants in this xBmt were unable to reliably distinguish a Blonde Ale packaged in a keg purged with packaged CO2 from one purged with CO2 naturally produced during fermentation.

My Impressions: To me, the beers looked, smelled, and tasted identical, which is great because this may have been the best Blonde Ale I’ve ever brewed. Subtly hoppy with light malt character and just enough body to hold everything together– I really enjoyed this beer!

| DISCUSSION |

While yeast require oxygen at the start of fermentation to synthesize sterols and unsaturated fatty acids to help regulate the flow of nutrients across their cell membranes, exposure to oxygen once fermentation is complete causes staling reactions to occur. A common method brewers use to ensure their beer remains free from cold-side oxygen exposure is purging kegs with CO2 before packaging, usually from a tank, though some choose to repurpose the CO2 produced during fermentation for this task. One point of concern when using the latter method is that it can carryover certain aromas and flavors produced during the fermentation process, though the fact tasters in this xBmt were unable to reliably distinguish a Blonde Ale from a keg purged with CO2 from a tank and one purged with CO2 produced during fermentation indicates any impact was minimal enough as to be imperceptible.

There are a number of volatile aromatic compounds that are pushed out of solution during fermentation via CO2 scrubbing, so it’s reasonable to expect that beer packaged in a keg purged with this CO2 would possess some of those compounds. However, the findings from this xBmt suggest minimal carryover of those characteristics. It’s possible the mechanics of filling a keg from the bottom without much agitation effectively pushed those compounds out of the keg.

Prior to this xBmt, I was admittedly slightly skeptical of purging kegs with CO2 produced during fermentation, but these results left me feeling like this method a viable way of reducing the risk of cold-side oxidation, plus it also happens to be cost effective. The one downside is that it requires the use of more vessels during fermentation, which creates a hurdle for those with limited space, but I’ll certainly be using this method more often in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “exBEERiment | Impact Purging A Keg With CO2 Produced During Fermentation Has On Blonde Ale”

I think it’s misleading to use the CO2 produced from a fermentation of 40L of wort to purge a single keg, as that’s not really representative of what people would usually do. Most people would use the CO2 from fermenting ~22L to purge a single 19L keg, and that means that you likely purged the keg with double the amount of CO2 a normal user would generate.

Waiting to split the batches until packaging also eliminates the variable of fermentation pressure. For the sake of illustration I’ll describe pressure in inches of water column (1″ = 5.2psf = 0.036psi). The batch with a standard bubbler will experience a consistent pressure of 1-2″ (distance between high and low water levels in the two chambers), depending on how full the airlock is. Pushing sanitizer out of a keg from one liquid dip tube to another would create widely varying pressures, likely starting at about 4″ for a keg filled to the brim and reaching up to 24+”, depending on the length of the dip tube and how high your tubing extends above the keg. Additionally, it is plausible that once the liquid tube on the receiving keg is primed with liquid it could start a siphon, creating a negative pressure on the fermentation vessel and lasting until the liquid levels are even, at which point the positive pressure again grows. This negative pressure could cause ingress of oxygen through the keg lid gasket or other seals that are not designed to hold a negative pressure. I agree with the scientific method of isolating variables, but the design of this experiment seems to have isolated a single effect of the variable.

When I clean my kegs, I give them a few PSI of CO2 to purge them and also to test the seal. Days or weeks later, I rack into my keg via the out post and open the blow-off valve to relieve the pressure. If opening the blow-off valve doesn’t release gas, I know the keg is not properly sealed.

Doesn’t happen often, but better to find out then rather than waste a bottle of CO2 trying to carbonate a leaking keg.

The first question I had before reading was, if you’re able to push all the sanitizer out of the keg during fermentation why even use a full keg of sanitizer? I would sanitize before hand and leave the keg empty and let the CO2 purge the keg on its own. This would allow for less equipment if you have limited space

Because if the keg is full of air, and you purge with co2 there’s no guarantee you’ve eliminated all of the air, because the gases mix.

If you fill with sanitiser first, you have displaced the liquid with 100% co2.

Saying this, I generally do this process without filling with sanitiser and the sheer amount of co2 that flushes through the keg during fermentation leaves me confident that the keg is properly purged.

There’s so much CO2 generated in fermentation that you don’t need to worry about that. Someone over at the Homebrewtalk forums did the math and pumping fermentation CO2 through a sanitized but otherwise completely empty keg would get it far below even commercial levels of O2ppm.

Math if you’re interested:

https://www.homebrewtalk.com/threads/keg-purging-with-active-fermentation.628658/

Thanks Simpsonia for the link – that confirms what I’ve always suspected. No need to push starsan – just push air out.

I exactly this! Except I allow a day or 2 to pass before booking up to avoid the O2 in the headspace being pushed through the keg.

On the space/vessels issue: are we sure it’s necessary to purge the keg by pushing starsan from one keg to another? Why can’t we just ‘push air’, i.e. attach the FV’s CO2 capture directly to a (pre-sanitized) empty keg’s liquid post, and then run a blow-off tube into a jar of starsan from the same keg’s gas post? This would just circulate all the naturally produced CO2 through that single keg on its way to the blow-off jar. Yes, the keg starts with air in it, but after five-or-so days of continuous fermentation and 40 volumes of CO2, won’t almost all of the original air have been pushed out (even with the gases mixing)?

I ask because I’ve always been wary of the ‘pushing starsan’ method because it’s complex and innevitably leaves a bunch of starsan at the bottom of the purged keg. (And yes the above experiment shows this is unlikely to be perceptable. But still!) The ‘pushing air’ method doesn’t, and is a simpler set-up. Perhaps ‘pushing starsan’ vs. ‘pushing air’ can be a future exBEERiment?

Without the sanitizer you can only assume the oxygen concentration is diminished, not eradicated. DONT FEAR THE FOAM

This is indeed the million dollar question. My instinct has always been that the residual oxygen after 5 days of continual CO2 flow would be pretty minimal. If you think doug293cz knows what he’s doing here, then the answer is less than minimal – it’s 0.005ppm!

https://www.homebrewtalk.com/threads/keg-purging-with-active-fermentation.628658/

But I’m an historian so the sums go well over my head. But it at least looks plausible. Bring on the exBEERiment!

Thats one reason for my comment above. I trimmed 3/4” from all my dip tubes when I used to ferment in kegs. Since then I used them for serving and there’d be a pool of star San left after pushing it out with CO2. I eventually stopped purging with star San because i had to open and dump it out anyways. Never had issues with O2 even with doing that

I’m sure you guys go through this beer relatively quickly. But, for the home brewer that maybe doesn’t drink 10 gallons of beer a month, I’m always concerned about if my brew is oxidizing. I’ve been using the same method for the last few batches and love it! My only concern when doing this is that when the fermenter starts producing enough pressure to purge sanitizer, is it pure co2? I prefer to use a blowoff tube for the first day then I make my connection to a keg on the second day to ensure no mixed air/co2 from the headspace is in the keg. We all know that people still use not telling buckets and may not even do closed transfers to purged kegs and the beers are fine for a few weeks at least. I like to take the extra step to minimize the oxygen in the fermenter headspace.

Great job! I don’t think this process is as hard as some think. I move the sanitizer from my keg into a bucket.

Like others above, I forego the starsan, as my kegs were already sanitized at the time if cleaning, and put away with a few pounds of pressure on them. However, I run the CO2 output from fermentation into the liquid post on the keg, pushing it to the bottom of the keg, with my spunding valve on the gas post. I’m my mind, much like filling a keg with beer from the bottom, the gases in the keg are displaced upward to the gas post. I then use the same transfer line, moved over to the floating dup tube on my All-Rounder, to transfer the beer to the keg.