Author: Jake Huolihan

While brewers yeast can and will ferment anaerobically, a key component in promoting healthy fermentation and quality beer is oxygen. When pitched into wort, yeast rapidly absorbs oxygen for cell membrane synthesis, which encourages the production of sterols and unsaturated fatty acids necessary for cell growth, ultimately improving viability.

A common practice for many commercial breweries involves reusing the yeast from one batch to ferment another, a process that can be repeated over numerous generations. Pure oxygen is often used to dose the wort in such situations in order to ensure the healthiest yeast for future batches. For homebrewers who rely primarily on fresh pitches of yeast, oxygenation may not be as crucial, in fact a couple past xBmts seem to suggest it has little if any benefit. But what about in less favorable conditions?

I’ve bought into the benefit of oxygenation and dose every batch I made with pure oxygen with the belief it helps me produce the best beer possible. However, I’m aware of many who skip this step and have great results. With the growing popularity among homebrewers of harvesting and reusing yeast, I was curious how oxygenation might impact a high OG beer pitched with previously used yeast and put it to the test!

| PURPOSE |

To evaluated the differences between 2 high OG beers fermented with previously used yeast where one was dosed with pure oxygen and the other was not.

| METHODS |

Having harvested some Imperial Yeast B48 Triple Double from a recent batch, I designed a Belgian Quad for this xBmt.

Gasp

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 39.0 IBUs | 22.2 SRM | 1.089 | 1.015 | 10.0 % |

| Actuals | 1.089 | 1.014 | 10.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Odyssey Pilsner | 19 lbs | 88.37 |

| Candi Sugar, Amber | 2 lbs | 9.3 |

| Candi Sugar, Dark | 8 oz | 2.33 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 20 g | 60 min | Boil | Pellet | 10.3 |

| Loral | 30 g | 15 min | Boil | Pellet | 10.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Triple Double (B48) | Imperial Yeast | 76% | 65°F - 77°F |

Notes

| Water Profile: Ca 65 | Mg 0 | Na 8 | SO4 67 | Cl 68 |

Download

| Download this recipe's BeerXML file |

The night before brewing, I collected RO water and adjusted it to my desired profile.

I then weighed out and milled the grains.

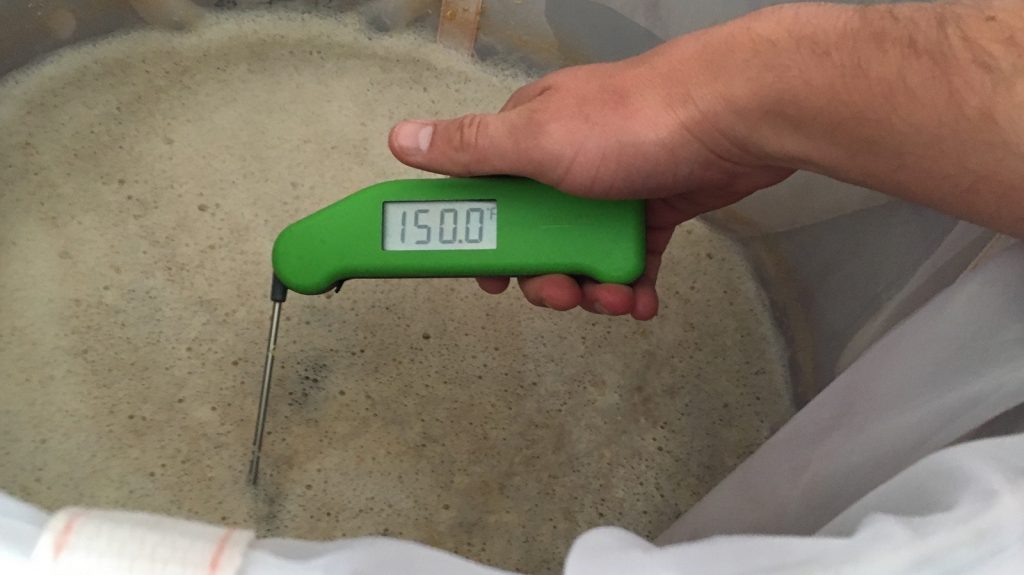

When I woke up the next morning, I turned on the elements to heat my strike water then proceeded to weigh out the kettle hop additions. When the water was slightly warmer than strike temperature, I transferred it to my mash tun, gave it a few minutes to preheat, then mashed in to hit my target temperature.

The mash was left to rest for 60 minutes with intermittent stirring.

Once the mash was complete, I collected the sweet wort in my kettle and brought it up to a boil.

Following a 60 minute boil, I turned the element off and quickly chilled the wort.

A refractometer reading showed the wort was at a respectable 1.073 OG.

I then gently racked equal volumes of wort to separate Brew Buckets, being careful not to aerate it during the transfer process.

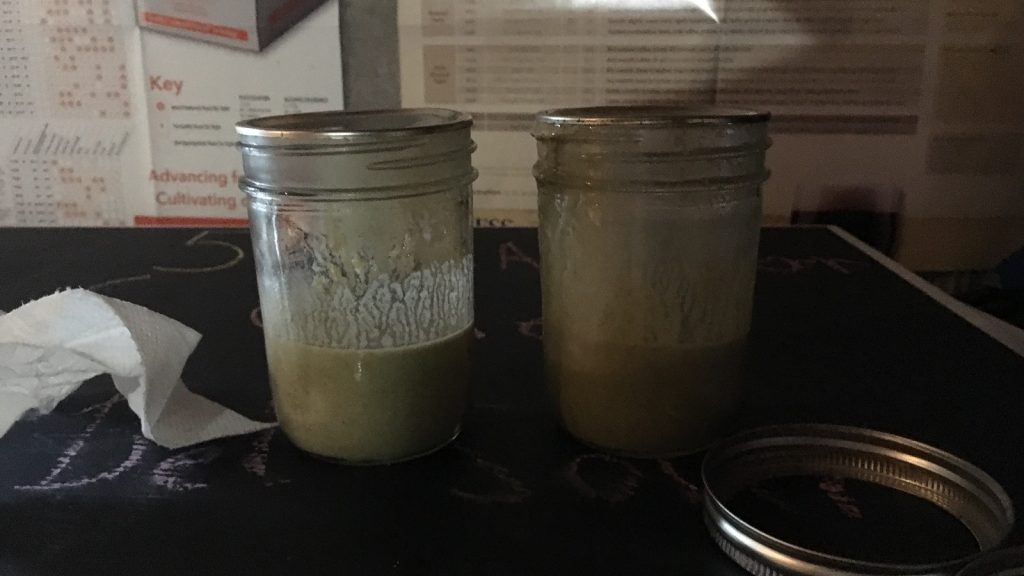

The fermentors were connected to my glycol chiller and rapidly cooled to my desired fermentation temperature of 66°F/19°C. At this point, I took a jar of Imperial Yeast B48 Triple Double I’d harvested from a batch 2 days prior, split it between a couple sanitized mason jars to ensure each wort received the same amount, then pitched one jar into either batch.

I proceeded to dose one of the beers with pure oxygen for 3 minutes while the other was left alone.

After 2 days of fermentation, I added equal amounts of Belgian Candi Syrup to each beer.

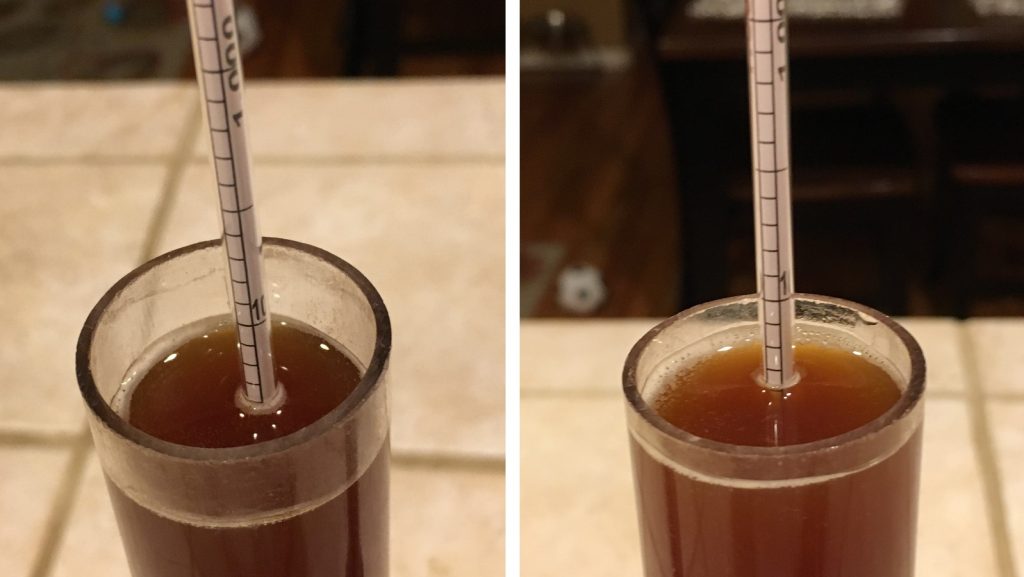

With signs of fermentation activity absent in both batches 13 days post-pitch, I took hydrometer measurments showing both had finished at a dangerously low 1.014 FG.

The beers were kegged.

The beers were left to cold condition and carbonate in my keezer. With its higher ABV, I left these ones alone a little longer than usual and noticed a slight difference in clarity after about a month in the keg.

When it came time to serve these beers to participants, the difference in clarity didn’t seem as stark, but was still present.

| RESULTS |

A total of 25 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the oxygenated beer and 2 samples of the beer that was not oxygenated in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 4 (p=0.99) did so, indicating participants in this xBmt were unable to reliably distinguish a beer whose wort was dosed with pure oxygen from one that wasn’t oxygenated when both were fermented with yeast harvested from a prior batch. For the curious, the two similar samples were selected by 10 and 11 participants.

My Impressions: Out of the 3 triangle tests I attempted, I identified the odd-beer-out 0 times, they smelled and tasted identical to me, which I did not expect. Both beers were fantastic, in fact they ended up doing quite well in a couple competitions I entered them in.

| DISCUSSION |

The role oxygen plays in the life cycle of yeast is well known and its impact on certain observable factors has been noted by many, making the slight difference in appearance between the beers in this xBmt not too surprising. Interestingly, though, whatever it was that led to the difference in appearance wasn’t enough to impact other characteristics, as blind participants were unable to tell apart the beer whose wort was dosed with oxygen from the one that wasn’t aerated, despite being fermented with second generation yeast.

Viewed in light of the results from past xBmts on the same variable, these findings add to the evidence suggesting wort oxygenation doesn’t have the impact on beer aroma, flavor, and mouthfeel as many believe. One possible explanation for these results could be that these xBmts have been completed on the homebrew scale and that results might differ in larger scale conditions, which may very well be true. However, many homebrewers fervently adhere to the practice of oxygenation under the belief it improves the quality of their beer, and these results yet again call this into question. Is it really worth it?

For me, it is. While these results have definitely left me feeling less compelled to advocate for oxygenation to others, I’ll continue to do it for most of my beers. Not only do I appreciate the impact it has on clarity, which I’ve observed in more than just this xBmt, but because I view it as a relatively cheap and easy way to insure against things potentially going awry. Also, I have the equipment, may as well use it…

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

29 thoughts on “exBEERiment | Wort Aeration: Impact Pure Oxygen When Repitching Yeast Has On A Belgian Dark Strong Ale”

I got all excited, last year, to get an oxygenation wand/stone only to read these xbeeriments afterwards. lol Thanks for all the work you do to help us make our brewing better!

Lol I mean, I still use mine on every batch

Interesting xbrmt. I sure there will be a lot of your wrong or I told you so on this one. I’m quite interested in the clarity results though. I have noticed the brilliant clarity in several of your more recent xbrmts. Do you have a hypothesis on the clarity affect?

I honestly think the biggest thing is the floating dip tubes I’m using. However it was quite interesting to see the clarity difference here and makes me think yeast health plays a larger role than I’d previously assumed

Those floating dip tubes are DEFINITELY on my Christmas list!

So I was reading that when yeast consumes oxygen it reproduces faster without producing a lot of byproducts, which would be good when pitching directly instead of doing a starter. With that said it would be interesting to test a beer with a direct pitch vs one that was oxygenated and also directly pitched. Might have some differences there, I’m guessing maybe in attenuation, flavor and time of fermentation. Btw great work! Love reading all the experiments you guys do.

recently brewed a 1.070 double IPA, i didnt had time to make a yeast starter and just had one pouch of 090. I aerated with oxygen for about a min or 2 then pitched. The difference I noticed was that it took longer to ferment, instead of being ready in 2-3 days, had to leave it like 6-7 days to completely attenuate. I’m guessing that if I hadn’t done that, it would’ve probably stressed out the yeast and not attenuate completely.

I wonder how much the agitation of the wort while chilling via the IC has on the O2 content and if the level is already boosted sufficiently for the yeast?

According to to the LoDO guys, you get an oxygen ingress in a homebrewing setting by approximately 1 ppm/h, so if you have a say 6 h lag you have a decent amount already there.

Was there a large difference in time between when each fermentation showed signs of active fermentation?

Very interesting and thanks for all the thought and effort you guys put into these experiments. I’m curious as to the timing of the candi sugar addition. In a recent Dubbel that I made I read to add it at the end of the boil but yours was two days into fermentation. Just wondering why.

With higher gravity beers that’s pretty much how I add sugar. Probably not necessary would be a fun xbmt

Is it still a high-gravity wort if you wait to add the sugar? 1.073 is high-ish–certainly not a session beer–but 1.089 is high.

I’ve read there is potential for a stuck fermentation when adding the sugar to the boil. The theory is that the yeast will consume the simple sugars (candi sugar) first and then stall out before eating the more complex sugars (barley). As Jake said “would be a fun xbmt”.

I swore by my oxygenation wand…… until my oxygen bottle ran out and I didn’t feel like buying another one. I definitely noticed faster, more vigorous fermentation after oxygenating, compared to just doing the old fermenter shake. But now I just use a $3 plastic wort aerator on the end of my tubing when I transfer to my fermenter, and the entire fermentation process goes just as well as aerating with pure oxygen.

If we believe that the oxygenation improves yeast vitality, knowing both how quickly fermentation was evident in the 2 brews and if there was a difference in how quickly each reached FG would be important. Essentially if the yeast was still healthy, having been recently harvested, oxygenation would make less of a difference than it might if the yeast had been stressed and stored for a lengthy period. We are told that a rapid start to fermentation reduces the likelihood of contamination or effects of wild strains. Many things affect the vitality of yeast: age, generation, storage, starters, vitality starters, yeast nutrient oxygen etc. If any one of these factors was suboptimal, the fact that the yeast was otherwise healthy might make that factor less important. To see a difference might be more obvious in “stressed” yeast. I don’t know anyone who would be interestested in doing the experiment where they take a chance on “stressed” yeast vs optimized yeast though. Hence, we tend to do all the things that optimize the health of the yeast.

i typically add oxygen then pitch my yeast. would there be any differences if you pitch yeast first then add oxygen. Or pitch yeast then wait a few hours, then add oxygen to wort before yeast starts to kick off?

Would be fun to test. I nearly always add yeast then oxygenate. My thought is it does a very good job of getting the yeast stirred up at the least

hello if someone want to do a boiling by firewoods not gas what will happen

Please accept this question as honest curiosity because I really don’t mean it to sound snarky. Given how many of your experiments (which are awesome) show that applying the rigor of commercial brewing to the homebrew scale (things like precise temperature control, aeration, mash time and temp, yeast pitching rates and lots of others) doesn’t seem to register with the average taster, do you ever wonder if high end equipment and professional-style procedures are adding anything to the end product?

I stopped wondering this a while ago after I concluded that the answer, at least for me and how I brew, is a resounding no. Denny Conn said it best: The brewer makes the beer, not the equipment. If a brewer reasonably knows what they’re doing, a simple brewing bucket, direct-pitching, and a reasonably cool place for fermentation is all that’s needed to make great beer.

That said, “professional-style procedures” would be crucial at the homebrew level if your goal was to minimize cost and/or turnaround time, or produce packaged beer that had a long shelf life in variable temperature conditions. So whether or not professional-style equipment and procedures would add anything to your end product depends on the extent to which your homebrew goals align with those of commercial breweries.

There are many misconceptions about the concept of statistical significance, and one of them is that lack of it indicates that there is no relevant effect. This is very wrong, especially for small sample (panel) sizes like in most exBEERiments. Among those 2/3 or whatever that show no statistical significance, there is often a 40-50 % correct selection, suggesting that there *is* a small effect, but more data is needed for getting a more conclusive answer. And many small differences may add upp to bigger ones. In this particular case though, I think it is safe to say that there was no relevant difference.

As someone always says – should have used a more neutral yeast strain 😉

Did you rack all the trub into the fermenter?

Some probably, but I’m pretty anal about keeping it largely out

Fix said fatty acids in trub will contribute in yeast viability. I was thinking if you have some in the fermenter, non aerated wort should be alright.

I’d love to see a follow up exBEERiment where the Candi sugar is added during the boil on one batch with it added two days after fermentation has commenced to see if it makes a lick of difference! Thanks another great read.

If you search “sugar” under Exbeeriments, it’s been done.

Interresting! It strikes me that every expiriment was pitched with a starter. So the yeast was already active and in fermentation mode and naturally aerated. Would love to see an expiriment where no starters were made eith and without aerating the wort. Keep up the good work!