Author: Will Lovell

There’s evidence to suggest that beer was initially stored in ceramic vessels, though as brewing knowledge progressed, wood became the material of choice, followed by glass, aluminum, and stainless steel. While polyethylene terephthalate (PET) was patented in 1973, it seems brewers have only recently begun to view this durable plastic as a viable option for beer storage.

One valid concern brewers have when it comes to storing beer has to do with oxygen ingress, which can lead to rapid staling, hence the overwhelming preference for stainless steel kegs. While standard PET isn’t as impermeable as steel, when treated is certain ways, it is a rather effective oxygen barrier that’s capable of holding enough pressure to maintain a beer’s carbonation. A relatively new product by Kegland, the Oxebar Mono Keg, offers brewers an affordable PET storage solution that’s said to have “high oxygen barrier properties with 3x better gas transmission than traditional PET.”

I’ve historically opted to package my beer in glass bottles or stainless steel kegs, both of which have proven effective at keeping oxygen and beer spoilage microbes out, and I tended to avoid any sort of plastic vessel. However, with the recent popularity of Oxebar Mono Kegs, I did some research and was curious enough about the claims of decreased impermeability to pick a few up. While my experience with these kegs has been quite positive, I was interested to see how they compare to standard stainless kegs and designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between a pale lager stored in a PET keg and one stored in a stainless steel keg.

| METHODS |

Simple enough to reveal any flaws, I went with a pale lager recipe for this xBmt.

Duplicitous

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 19.9 | 3.4 SRM | 1.047 | 1.006 | 5.38 % |

| Actuals | 1.047 | 1.006 | 5.38 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Llano Pilsner | 10.75 lbs | 100 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Amarillo | 11 g | 60 min | Boil | Pellet | 7.8 |

| Amarillo | 10 g | 30 min | Boil | Pellet | 7.8 |

| Amarillo | 10 g | 5 min | Boil | Pellet | 7.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

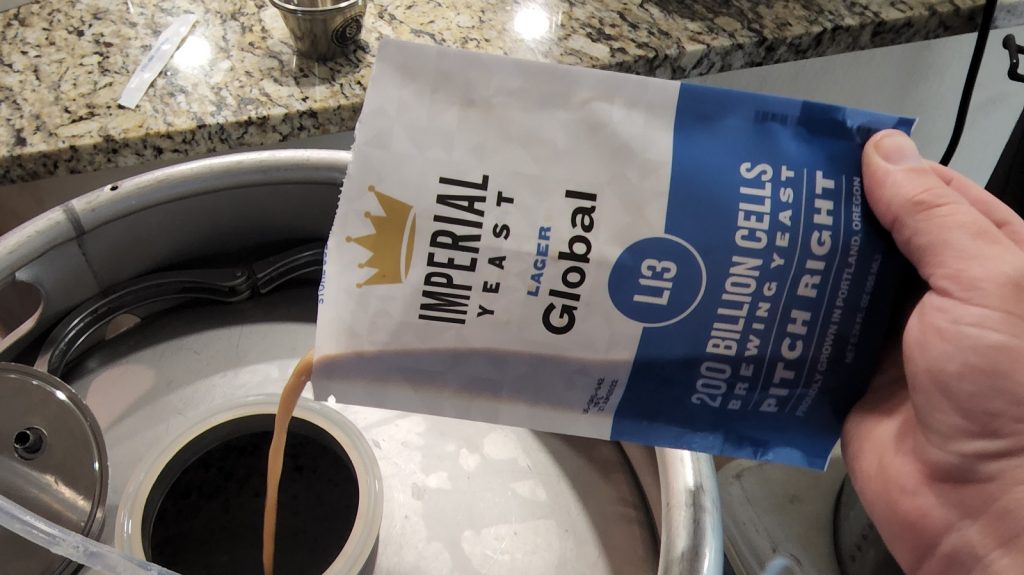

| Global (L13) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile Ca 53 | Mg 0| Na 0 | SO4 58 | Cl 50 |

Download

| Download this recipe's BeerXML file |

The night prior to brewing, I collected the full volume of RO water, adjusted it to my desired profile, then weighed out and milled TexMalt Llano Pilsner malt.

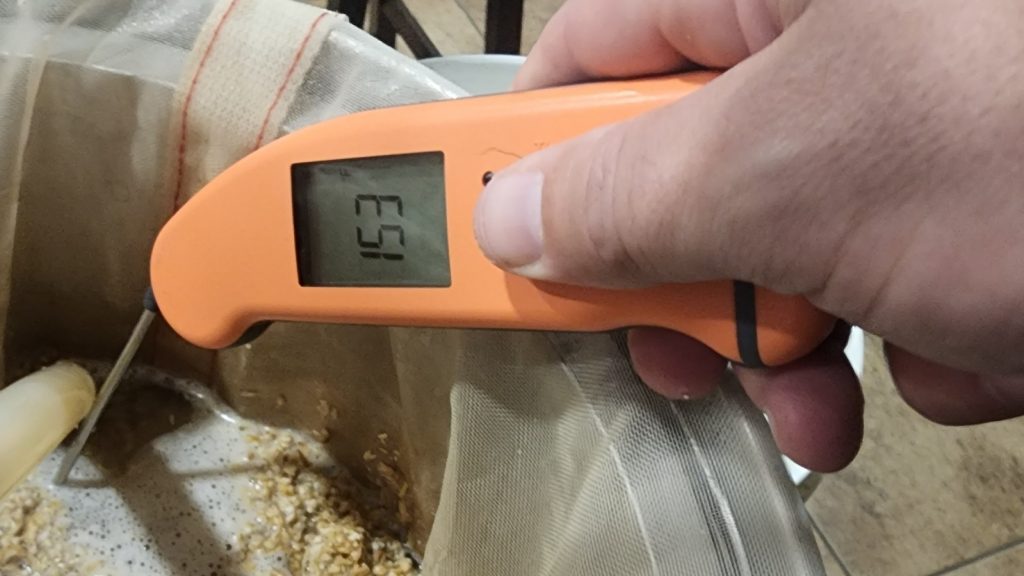

The following day, I heated the water before incorporating the grains and checking to ensure the mash was at my desired temperature.

During the mash rest, I prepared the kettle hop additions.

When the 60 minute mash was complete, I removed the grains, sparged to collect the proper pre-boil volume, then proceeded to boil for 60 minutes, adding hops at the times stated in the recipe.

When the boil was complete, I quickly chilled the wort then transferred it to a sanitized Kegmenter.

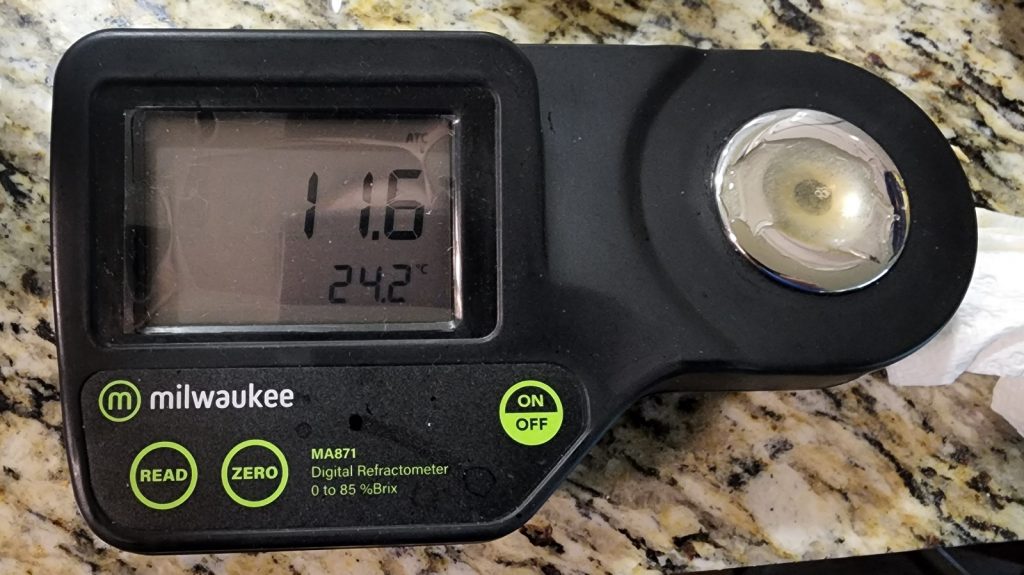

A refractometer reading showed the wort was at my target OG.

After transferring the wort to a sanitized fermented, I direct pitched a single pouch of Imperial Yeast L13 Global.

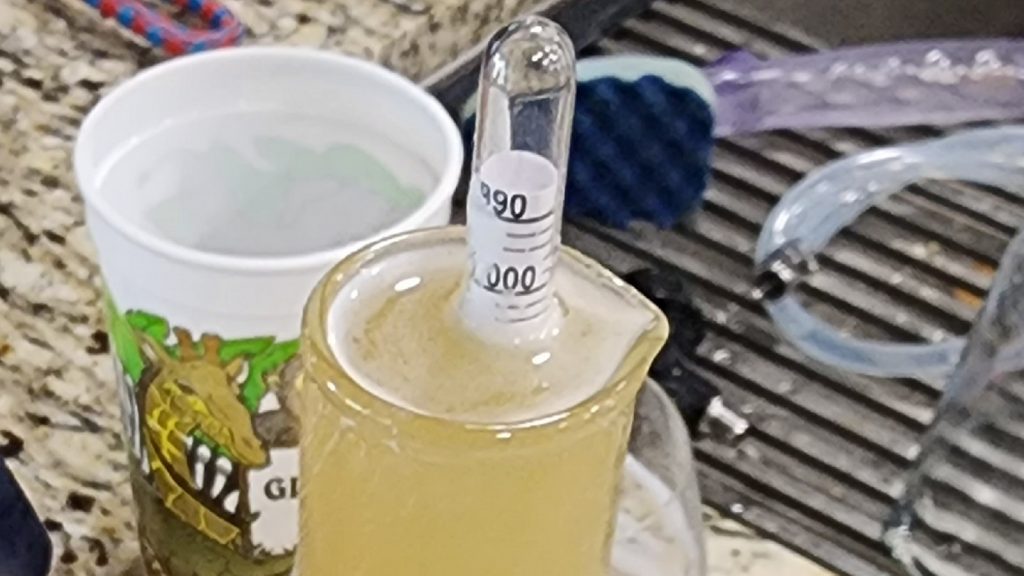

The beer was left to ferment at 64°F/17°C for a week before I took a hydrometer measurement confirming FG was reached.

With fermentation complete, I cold-crashed the beer then pressure-transferred it to a CO2 purged stainless steel keg that was placed in my kegerator and burst carbonated overnight before the gas was reduced to serving pressure. Once the beer was carbonated, I transferred approximately half of it to a CO2 purged Oxebar Mono Keg, which was stored on gas next to the stainless keg.

The beers were left alone for 10 days before they were ready to serve to tasters for evaluation.

| RESULTS |

A total of 28 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer stored in a PET keg and 1 sample of the beer stored in a stainless steel keg in different colored opaque cups then asked to identify the unique sample. While 15 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 11 did (p=0.31), indicating participants in this xBmt were unable to reliably distinguish a pale lager stored for 10 days in an Oxebar Mono Keg from one stored in a standard stainless steel keg.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just once. Despite the simplicity of these beers, they smelled and tasted identical to me, both featuring a subtle yet present Amarillo hop character supported by delicious crackery malt.

| DISCUSSION |

While plastic storage vessels have been very common for non-alcoholic beverages, they’ve largely been avoided in the beer industry due to concerns about issues like oxygen permeability, among other things. However, more durable PET options have been shown to be rather effective barriers to oxygen, which has led to increased use of this material. The fact tasters in this xBmt were unable to reliably distinguish a pale lager stored for 10 days in an Oxebar Mono Keg from one stored in a standard stainless steel keg suggests any qualitative differences were minimal enough as to be largely imperceptible.

The purpose of this initial xBmt on PET kegs was to see what impact storage over a fairly limited amount of time might have, and while the results suggest it was minimal, there’s a possibility extended lengths of time would lead to larger differences. Based on these findings, it would seem the Oxebar Mono Kegs are effective enough at blocking oxygen to allow for brief storage of beer.

I’ve used these PET kegs a handful of times prior to performing this xBmt and found them to be a very convenient way to take beer away from my home. These findings confirm for me that using them in such a manner likely has minimal if any impact on beer quality, making them an affordable option for beer storage and transport. While I definitely plan to repeat this xBmt with a longer storage duration, I’ll rest a little easier now when using these PET kegs for taking beer on the road.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

21 thoughts on “exBEERiment | Impact Storage In A PET Keg Has On A Pale Lager”

Hi!

You have a little typo in this section: “While 15 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 11 did (p=0.31), indicating participants in this xBmt were able to reliably distinguish a pale lager stored for 10 days in an Oxebar Mono Keg from one stored in a standard stainless steel keg."

Correct was "unable" 🙂

Cheers!

While 15 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, *only* 11 did (p=0.31), indicating participants in this xBmt were *un*able to reliably distinguish a pale lager stored for 10 days in an Oxebar Mono Keg from one stored in a standard stainless steel keg.

10 days of lagering… Add a couple of months at least and this test would actually be of interest.

As the only beer drinker in my house and friends circle, I definitely need to know the long term storage effects vs stainless steel.

Another promising exbeeriment ruined by poor experiment design. 10 days, seriously? That’s way too short to taste the impact of a container. Try 10 months, maybe. Also, for the record, macro beers are often sold in one-way PET kegs, so a lot of people have been drinking pale lagers in PET without noticing any difference.

I have used PET bottles for a portion of my beer production for many years. My Speidel fermenters are made of PET as well. Out of an 8-9 gallon finished beer batch size, normally fill one or two 44 ounce PET bottles (42.2 oz Coke bottles filled a tad higher). My son serves in the military and I will wait until I have 3-4 bottles of different varieties and send them to him in a box wherever around the works he is. Or send to son-in-law (Oregon to Florida), or brought some with me when visiting son-in-law.

This is not a blind test with this out of glass bottle or out of a keg, but I haven’t received any comments of strange taste, nor have I noticed any issues in times I drank beer from PET bottles. Variety of beer styles but German Pilsner is my #1 most brewed style.

NOTE: The Oxebar Mono keg with attachments for gas and a tap is an interesting product… This is the first I’ve seen it.

Speidel fermenters are usually HDPE, not PET.

I stand corrected on the fermenter. The pop bottle is a standard Coke bottle.

what I would be more interested in a longer term storage in the keg. And with the keg that you used. I didn’t see anywhere that it was non BPA. If our water bottles should be non BPA so should our kegs.

I think the storage time was too short

That is a fair criticism, but you have to start somewhere. I don’t have any further xBmts on the schedule, but pushing the storage time further out is definitely something I want to explore.

Right — this was a valid time to get a data point in a longer sequence.

It’s worth pointing out that as far as experimental design there often isn’t a single testing point that produces conclusive results. Even if the test showed a clear difference at, say, six months old, you’d still want to repeat the test at earlier intervals to find out how it performs at a younger age.

In other words, it doesn’t matter what order the tests are performed.

What’s more, a zero difference result at six months and a zero difference result at two weeks doesn’t mean there is no difference in between, because beer can vary far mor over time than something like NaCl, and not necessarily in a consistent way.

You basically have to figure out what a reasonable number of samples would be over time and then do the work.

I didn’t quite read the title text correctly. I was thinking what Pet are they storing in the keg? Second thought was they must’ve found a noticeable difference

I’m just curious how oxygen would ingress while the vet was under pressure, and had an available supply of co2 to refill any lack of pressure. I just don’t see why oxygen could ingress here.

Gases will diffuse regardless of overall pressure gradients, so you will end up with oxygen entering (with co2 diffusing out at a low rate too) but the pressure being the same.

This is the reason why beer left in lines (depending on material) for a few days will oxidise. I probably haven’t explained why super well but it’s true.

The effects of PET on a beer will be better demonstrated under a microscope. Millions of particles of microplastic get mixed with the beer which may not affect the taste but definitely affect your body internally.

Instead of just breaking it down, may I suggest something cool? If one of you has access to a fairly large brewing system, you could do one brew and have multiple experiments with it, by splitting the results.

So brew, have 2 normal kegs and 2 PET kegs as a result, verify the results after initial conditioning and leave the second set of kegs to verify after a longer period. 1 brew, 2 articles, without messing with multiple variables in either of the experiments.

I imagine this model could work in many experiments where time is a factor. It would be good for our knowledge, and for Brulosophy as well since more content also generates more views.

The average time it takes me to kick a corny keg is 1.5 months 2 months if the beer ain’t great.

Maybe a follow up in a months time on a side by side.

Actually gunna get some of these yo do side by sides so thanks for the exbeeriment.

I have an oxebar keg and the issues i’m seeing is that the keg doesn’t do a great job at holding pressure. even when all the fittings are securely tightened and checked with star san for leaks. Not sure if CO2 if diffusing out through the plastic or the disconnects. Curious if you’ve come across this issue and i’m not sure Id be happy serving from this keg if its slowly losing CO2, tank would be gone qucikly. at least would be good for bottling vessel

I did find a leak through the main tapping head and threads using starsan. The only way to fix the issue, and what I’ve done is to use Teflon tape on the threads. Also, morebeer sent me a new tapping head so they were pretty responsive. Marshal, your point on defusing is valid and the only reason I brought it up was because I was out of options on figuring out how to correct the leak without stripping threads. I just finished my bourbon vanilla Porter from the oxebar and everything was fine.

I love the potential this offers… I hate bottling, but I’ve avoided kegging so far because of:

1. the cost of entry

2. concerns about potential issues bottling off kegs for local competitions

As I typically do 2.5gal batches, these kegs could be perfect for remedying issue #1 a bit, as well as possible issue #2. I could see bottling 4-5 bottles for competition straight off my fermenter and priming them individually (which I often do anyway instead of a bottling bucket, since my batches are smaller), then kegging the rest in the 2.2Gal PET keg. Now I have a reason to start researching keezer construction!