Author: Andy Carter

It’s well-understood that oxygen beer don’t belong together. While critical for yeast health during the initial stages of fermentation, post-fermentation oxygen exposure is known to lead to the development of trans-2-nonenal, a compound associated with unpleasant off-flavors, as well as beer darkening. Brewers employ a number of methods to reduce cold-side oxygen exposure, though for beers that require dry hopping, it poses some difficulty.

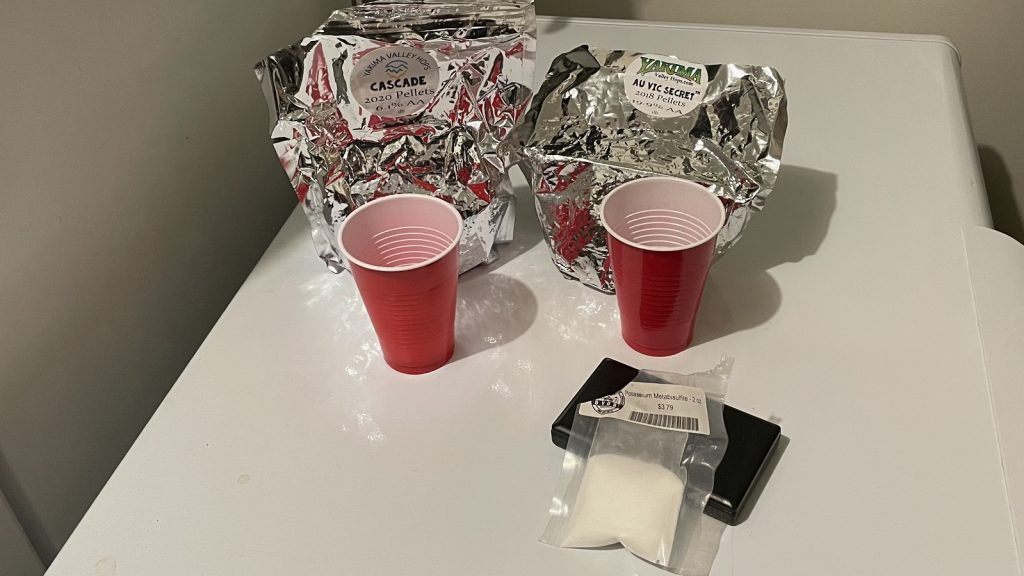

Recently, manufacturers of brewing equipment have come out with specialized tools for adding dry hops to beer in a closed environment, though they tend to require higher end fermenters, plus they can be cost prohibitive for the hobby brewer. Another option that has shown effectiveness at reducing the negative impact oxygen exposure has on beer involves adding sulfites, often in the form of potassium metabisulfite (PMB), though this usually occurs at packaging.

While it’s become quite common for brewers of IPA to dry hop during active fermentation as a way to avoid cold-side oxidation, I still prefer holding off until fermentation is nearly complete when making certain types of Pale Ale and IPA. I recently switched from carboys that have rather small openings to stainless bucket fermenters, which have much larger openings that provide a greater vector for oxygen ingress when dry hopping. Given the results of past xBmts on packaging with sulfites, I wondered if adding some at the time of dry hopping might have a positive impact and put it to the test!

| PURPOSE |

To evaluate the differences between an American Pale Ale dry hopped without PMB and one dry hopped with PMB.

| METHODS |

Not wanting to cover up any impact of the variable, I designed a moderate strength dry hopped American Pale Ale recipe for this xBmt.

Fix It In Post

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 61.1 | 5.4 SRM | 1.056 | 1.01 | 6.04 % |

| Actuals | 1.056 | 1.01 | 6.04 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt 2-Row | 9 lbs | 73.47 |

| Oats, Flaked | 3 lbs | 24.49 |

| Dextrose | 4 oz | 2.04 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Simcoe | 20 g | 60 min | Boil | Pellet | 13 |

| Cascade | 28 g | 15 min | Boil | Pellet | 5.5 |

| Vic Secret | 28 g | 15 min | Boil | Pellet | 15.5 |

| Citra | 43 g | 0 min | Aroma | Pellet | 13.5 |

| Vic Secret | 43 g | 0 min | Aroma | Pellet | 15.5 |

| Cascade | 28 g | 0 min | Aroma | Pellet | 5.5 |

| Cascade | 43 g | 0 min | Dry Hop | Pellet | 5.5 |

| Vic Secret | 43 g | 0 min | Dry Hop | Pellet | 15.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Independence (A15) | Imperial Yeast | 76% | 32°F - 32°F |

Notes

| Water Profile: Ca 78 | Mg 6 | Na 6 | SO4 116 | Cl 54 |

Download

| Download this recipe's BeerXML file |

I started my brew day by adding identical volumes of RO water to separate BrewZilla units then setting the controllers to heat them up.

After adjusting both to the same desired profile, I milled the grains into separate buckets.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure both were at the same target mash temperature.

While the mashes were resting, I prepared the kettle hop additions.

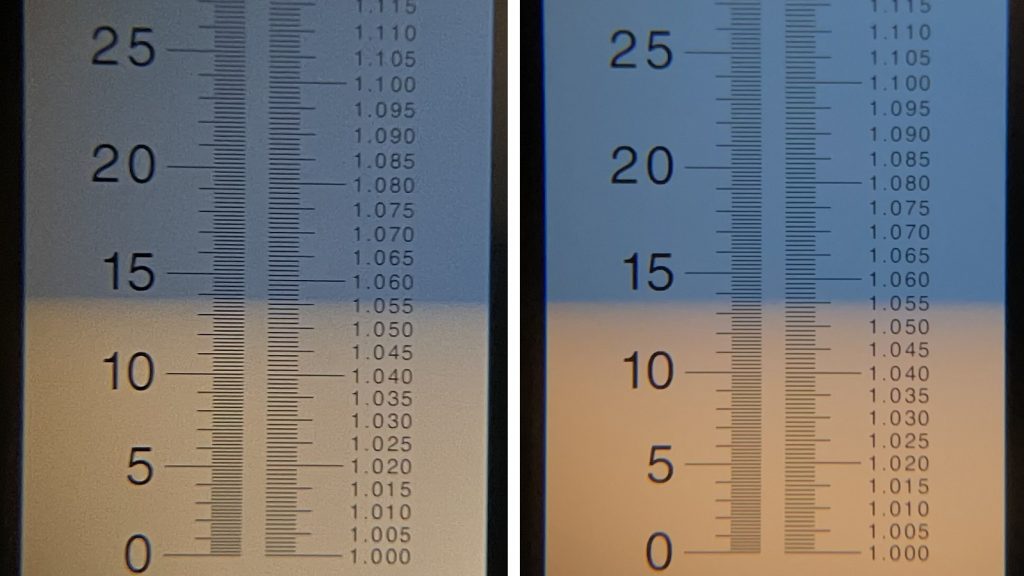

Once each 60 minute mash was complete, I batch sparged to collect the same pre-boil volume then boiled the worts for 60 minutes before chilling them during transfer to identical fermenters. Refractometer readings showed the worts were at the same target OG

The filled carboys were placed in my chamber and left to finish chilling to my desired fermentation temperature of 65°F/18°C for a few hours before I pitched a pouch of Imperial Yeast A15 Independence into each.

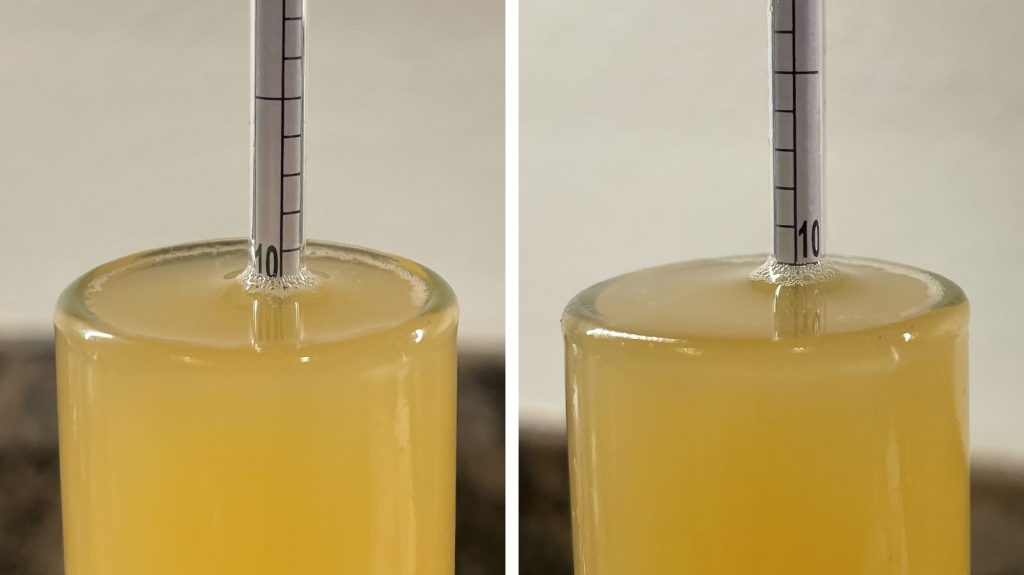

I left the beers alone for 2 weeks to ensure fermentation was complete before returning to add the dry hops, at which point one batch also received a 0.32 gram dose of PMB to achieve approximately 10 ppm of sulfite in the beer.

Hydrometer measurements taken 3 days later showed both beers finished at the same FG.

At this point, I pressure transferred the beers to CO2 purged kegs.

The filled kegs were placed in my keezer and left on gas for 3 weeks before they were ready to be evaluated.

| RESULTS |

A total of 15 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dry hopped without PMB and 2 samples of the beer dry hopped with PMB in different colored opaque cups then asked to identify the unique sample. While 9 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 6 did (p=0.38), indicating participants in this xBmt were unable to reliably distinguish an American Pale Ale dry hopped post-fermentation without PMB from one that was dry hopped with PMB.

My Impressions: Given the lower number of participants in this xBmt due to Covid restrictions, I completed a series of 10 semi-blind triangle tests, out of which I chose the unique sample just 4 times (p=0.44). Everything about these beers was identical to me, both possessing pleasant guava and passionfruit notes with a solid bitterness and clean fermentation.

| DISCUSSION |

Brewers have long been aware of the detrimental impact oxygen exposure has on beer, though it seems to have become a much bigger focus with the rise of IPA, particularly those of the hazy sort. For reasons still yet to be entirely understood, hoppy styles tend to be highly sensitive to oxygen exposure, which creates some concern when it comes to dry hopping. With evidence showing PMB can reduce cold-side oxidation when used at packaging, it’s been posited that adding a small amount when dry hopping may also be beneficial. However, tasters in this xBmt were unable to reliably distinguish an American Pale Ale dry hopped without PMB from one dry hopped with PMB.

These results seem to suggest that any oxygen introduced during dry hopping was too low to have a noticeable impact, though as some are wont to speculate, it’s possible both beers happened to be equally oxidized. While I’m open to this being the case, I have a fair amount of experience evaluating beer, and neither of the ones in this xBmt had any of the tell-tale signs of oxidation. I’m also rather neurotic about keeping oxygen away from my beer. Another oft expressed critique is that the beers weren’t allowed enough time for oxidation effects to set in, which may be true here, though 3 weeks of conditioning is arguably longer than most brewers wait to start drinking kegged beer.

Indeed, we’ve no ability to make any gross conclusions based off of this single xBmt other than the fact a group of tasters and myself were unable to reliably distinguish the beers from each other. However, seeing as we’re dealing with beer, I’m personally comfortable accepting that dry hopping, even when it occurs post-fermentation in a vessel with a large opening, likely doesn’t introduce enough oxygen to spoil beer, at least when done in a tactful manner. This mitigates some concern for me. While I certainly won’t use these results to justify tossing dry hops in all willy-nilly, I do feel more comfortable with the process I’ve been using and will continue to put more focus on reducing oxygen exposure at packaging.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

19 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Adding Potassium Metabisulfite (PMB) At Dry Hop Has On An American Pale Ale”

Process question: Was the PMB just added in dry form? Or was it dissolved in water before adding with the dry hop? This method seems like a viable method to also hinder the effects of hop creep in dry hopped beers as well. But that is an entirely different subject. Cheers!

“I recently switched from carboys that have rather small openings to stainless bucket fermenters, which have much larger openings that provide a greater vector for oxygen ingress when dry hopping.”

Since oxygen ingress via the large opening on bucket-style fermenters was part of the concern that led to this exbeeriment, why did you decide to use carboys for this test?

I think he went from carboys to bucket style, and used those. You can also see it in the pictures.

Great experiment. It might turn out that both beers were packaged in a way limiting oxygen exposure enough that there wasn’t much work for the PMB to have to do? It might be interesting once the kegs are getting near their end to pop the lids off for a while, allow some ambient air inside, and then re-pressurize them and wait another week for an additional tasting. Or something like that, but a way to see if some O2 exposure can be introduced, and find out how the PMB behaves then?

Boy, if you have to go to that much trouble to get the beer oxidized enough to taste then maybe oxidization is not that big a factor in homebrew. After all, much of the packaged beer sold is 6+ months old when you consume it. That is not the case with any standard beer I make, nor can I imagine it ever will be.

Ah yes, I see them in the kegging picture now. I had just seen this quote: “The filled carboys were placed in my chamber and left to finish chilling…” Must just be a typo.

He didn’t use carboys, Delta ferm tanks have full width openings when lid removed

Cool experiment, whenever I dryhop in my fermtanks I hook up co2 to the gas port on the lid & let it run in at 3 or 4 psi while i crack the lid open on the opposite side to add the hops. My hope being that the co2 I’m adding to the headspace will scare away any oxygen. Do you ever do anything like this?

Relieved how this one came out. I’ve got a sulphite allergy and it’s already hard enough finding decent beers to drink.

Worth keeping in mind that depending on your yeast strain and the bioavailable nutrients in fermentation, the yeast may produce some sulphites on its own. Lallemand released a paper on this recently with a breakdown of the impact of nutrients on yeast – worth a read.

I much prefer dry hopping my hops from within the tank using sous vide magnets, rather than opening the lid. It would be worth an experiment, but I get the sense the hop expression has been better since doing this as well.

Curious if you took the experiment further and packaged those beers in cans and then looked at them 2 weeks out again sort of thing?

Reassuring to see there didn’t seem to be a difference for sure. There are a lot of SMB / cold side O2 experiments now, I can’t remember, is there one where a hoppy beer is racked into unpurged kegs one with SMB and one without?

I’m interested in this as well. But only after 2 weeks of the beer being stored warm. My bigger question is on canning the beer and then doing this test 2 weeks later. We baseline test our DO in the brite tanks and really only pick up O2 on the packaging side. It is extremely easy to avoid O2 pickup before that point. Carboys, kegs, etc.

Kerry’s makes a product called BioHaze. It must contain potassium metabisulfite or something similar. It’s a great product but a PITA to use.

Nice xbmt! I’m curious if the PMB was added dry? Or was it dissolved in water first and then added? This approach may have added benefits to prevent hop creep for those who dry hop in primary with the beer still on the yeast cake.

You should wait 3 or 4 months to notice the diference betwen the beers.

I don’t think 3 weeks would give any noticeable difference in my experience. Seems to be a theme with a lot of these experiments which doesn’t give much time for the beer to change. 6-8 weeks would make more sense.

Good experiment but what I find missing in all of this oxidation talk is that can you measure dissolved oxygen in beer and if so what is an acceptable level.how much exposure/ surface area does it take to reach that level? This may not be possible but would certainly help decide what is necessary to prevent oxidation.

Ask and you shall receive! I was just perusing the old SMS Hazy IPA exbeeriment and was wondering exactly this. Maybe it would require double or triple dry hopping to get significant results.

I think another question this raises is whether the PMB also prevents hop creep? Given it’s often used in cider to kill the yeast and stop refermentation after back-sweetening, can we assume that it will also stop refermentation/hop creep from the dry hop charge?

I lived in the Philippines for a couple years, and my neighbors always burned their trash and tree branches on the street to kill insects that prevent the early flowering of mango trees; I asked if they just stopped doing it, and would it matter? Their response was like the old joke about growing radishes to keep out Wolverines. Ever seen a wolverine? No, them radishes sure work. Same with me and SMB in beer at packaging. Never seen oxidation in my beer, and I ain’t gonna look for trouble now. I always use SMB at kegging, and not gonna stop to find out if it helps. Works for me.