Author: Matt Del Fiacco

There appears to be growing acceptance among brewers that making water adjustments is an important aspect of crafting delicious beer, with the general approach seemingly shifting from a focus on matching historical profiles to determining the particular profile best suited to the style being made. Historical water profiles being less a function of choice and due more to availability, plus the fact some breweries from centuries ago were actually adjusting their brewing water, add to the futility of attempting to match a particular profile.

A common method among modern brewers involves starting with a “blank slate” then adding minerals to achieve one’s desired profile, often relying on reverse osmosis (RO) water, which Wikipedia explains is…

…a water purification technology that uses a semipermeable membrane to remove ions, molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential differences of the solvent, a thermodynamic parameter.

Simply put– RO water is real clean, an ideal base from which to build on, though some believe it may not be the best option for use on its own. In addition to being nearly absent of flavor ions known to impact the character of beer, like sulfate and chloride, RO water is also lacking in minerals believed to be crucial for starch conversion, yeast health, and beer clarity.

With so many previous water chemistry xBmts returning significant results, I became interested in how a beer produced with super clean RO water not only would taste, but if it would effect other aspects of the brewing process. Having heard from others who reported success using unadulterated RO water for their beer, I decided to put it to the test!

| PURPOSE |

The evaluate the differences between a beers of the same recipe brewed with RO water that was either pure or adjusted to a particular mineral profile.

| METHODS |

Czech Pilsner is a style known for being brewed with a generally soft water profile, which contributes to a clean and balanced character I felt would be ideal for this particular xBmt.

Tabula Rasa

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5 gal | 90 min | 34.3 IBUs | 4.8 SRM | 1.057 | 1.021 | 4.8 % |

| Actuals | 1.057 | 1.015 | 5.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 9.25 lbs | 88.1 |

| Carafoam (Weyermann) | 9 oz | 5.36 |

| Carahell (Weyermann) | 8 oz | 4.76 |

| Melanoidin (Weyermann) | 3 oz | 1.79 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Czech Saaz | 7 g | 60 min | First Wort | Pellet | 3.5 |

| Czech Saaz | 15 g | 60 min | Boil | Pellet | 3.5 |

| Czech Saaz | 33 g | 30 min | Boil | Pellet | 3.5 |

| Czech Saaz | 69 g | 10 min | Boil | Pellet | 3.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile (adjusted batch only): Ca: 50 | Mg: 5 | Na: 0 | SO4: 60 | Cl: 60 |

Download

| Download this recipe's BeerXML file |

I built a single large starter of Imperial Organics L17 Harvest a few days beforehand.

I woke up early a couple days later and turned on my elements to heat the water I’d prepared the night prior, both using the store-bought RO with one being adjusted to the profile indicated in the recipe.

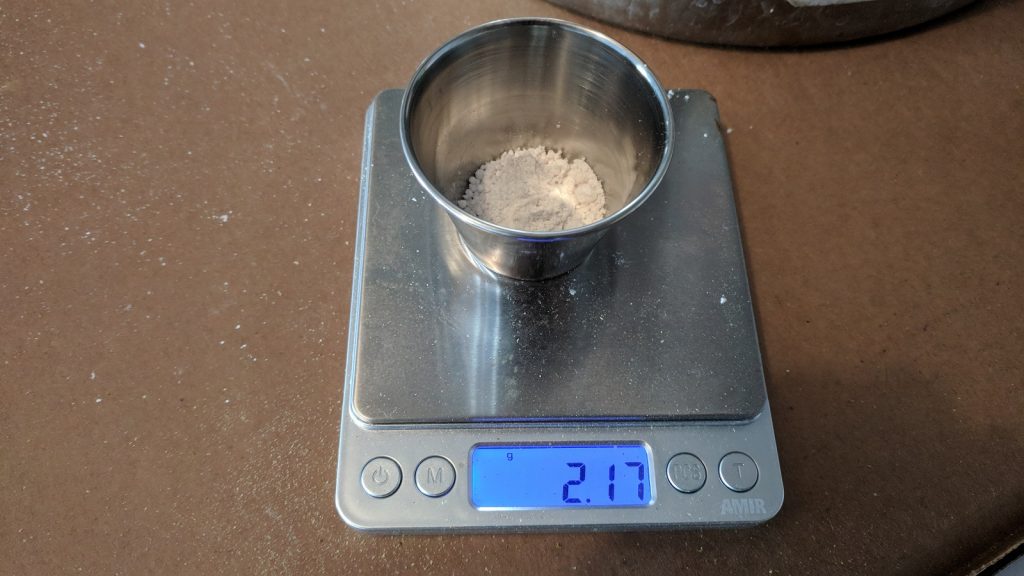

While the water was heating, I weighed out the minerals I’d previously determined would get me to my desired profile using Bru’n Water Spreadsheet, then added them to one batch.

I then weighed out and milled two identical sets of grain.

Once strike temperature was reached, I mashed in before checking to ensure each batch was at the same initial temperature rest of 146°F/63°C.

Twenty minutes into each mash, I began raising the temperature to 160°F/71°C and stole some samples for pH measurement. I had adjusted both batches with a small amount of lactic acid in order to control for pH.

After an additional 40 minute rest, I removed the grains and began heating the worts. Both batches were boiled for 60 minutes with hops added as stated in the recipe.

When the boils were finished, I quickly chilled the wort by running it through my counterflow chiller directly into sanitized fermentation vessels.

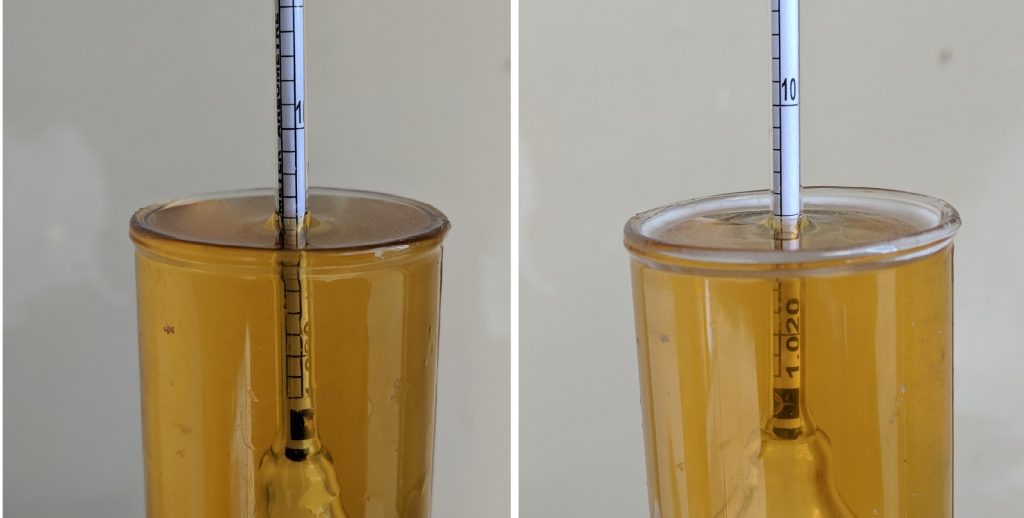

Hydrometer measurements showed the batch made with pure RO water came in a couple SG points lower than the batch made with adjusted RO water.

The filled fermentors were placed in temperature controlled fermentation chambers where they were left to finish chilling.

Once stabilized at my desired 48°F/9°C fermentation temperature, I evenly split the yeast starter between each batch. The following morning, both beers were bubbling away. After 8 days of cool fermentation, I racked the beers to kegs, onto which spunding valves were attached, then raised the temperature to 68°F/20°C for a few days.

After a few more days, I pulled samples to confirm FG was reached in both beers before reducing the temperature.

Curious to see how lack of minerals impacted clarity, I decided to forgo my usual gelatin fining process and let the beers lager in my kegerator for 2 weeks before serving them to participants!

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with unadulterated RO water and 1 sample of the beer made with adjusted RO water in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, while a total of 14 (p=0.003) made the accurate selection. These results indicate participants in this xBmt were able to reliably distinguish a Czech Pilsner made with unadulterated RO water from one made with RO water built up to desired water profile.

The 14 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 3 reported preferring the beer made with straight RO water, 7 liked the beer made with adjusted RO water more, 3 had no preference despite noticing a difference, and 1 person reported they perceived no difference between the beers.

My Impressions: I attempted 5 semi-blind triangle tests and was able to identify the odd beer out 4 times. To me, the beer adjusted to my desired water profile had what I can only describe as a more full flavor with a more expressive hop character in the aroma. While the straight RO beer was also really enjoyable, it seemed to be less characteristically clean as far as the style goes. In the end, I really enjoyed both of these beers, I just thought the minerals produced a more well defined flavor profile.

| DISCUSSION |

At the 2007 National Homebrewers Conference, John Palmer presented on an experiment he performed that demonstrated how different water profiles impact beer. Since April of 2015, we’ve published the results of numerous water chemistry xBmts that corroborate Palmer’s findings, and I’ve personally noticed improvements in my own beer that I believe is due to water adjustments. For these reasons, I didn’t necessarily find shocking the fact that participants in this xBmt could tell apart beers made with either straight RO water or RO water built to particular profile. These findings add to the growing evidence that adjusting brewing water with minerals has a qualitative impact on beer.

With RO water being essentially absent of all minerals, including those deemed to effect more than just beer flavor, I was curious to compare other more objective aspects of these xBmt beers. One area I expected to see a difference was in conversion efficiency, and while the adjusted water beer did have a slightly higher OG, it wasn’t by much, just a couple SG points. Since calcium is known to play a role in beer clarity, I also wondered if the adjusted RO water beer would drop clearer than the straight RO water beer, which didn’t seem to be the case.

All in all, these results leave me feeling even more confident that the mineral profile of the water we used to make beer matters. While I’ll absolutely continue to pay attention to my brewing water chemistry, I look forward to exploring the use of various profiles for particular styles, as given the subjective nature of preference, it’s possible what’s ideal for me may not be what I read somewhere else.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

26 thoughts on “exBEERiment | Water Chemistry: Straight vs. Adjusted RO Water In A Czech Premium Pale Lager”

Thanks for this. I have been building my water from 100% RO water for awhile now, but still don’t entirely understand it all. I have always wondered what unadjusted water would be like in a beer, and now I don’t have to brew it because you did.

Cheers,

Chris

I’m in the same boat as you! I’ve been doing RO water adjustments for about 6 months now and was contemplating doing one with an unadjusted water profile but this exbeeriment just proved what I needed to know as well.

I would love to see one however with a stout or porter for comparison in regards to maltier beers

Thanks for taking the time, Matt!

It would have been nice to have the mineral analysis of the beers to know what the differences were. You will get minerals from the malt, so it is not a comparison of nothing vs something. it is interesting to see that in your experiment, relatively minor amounts had a significant effect. Also, kudos for the beer, to pick up that small difference you must have brewed a great beer and your process was certainly tight.

Cheers!

Hey Lup!

Yeah totally agreed, and in addition to that it is RO water which, in theory, also isn’t “nothing”. So there’s definitely something to the non-adjusted profile, though the malt would (I think) contribute the same minerals to each batch. If anything, I think this just suggests what most literature and breweries have reported for a long time, water profile matters. Definitely want to keep exploring this one.

Interesting, a club member performed a similar experiment last year and concluded he liked brewing with RO (No minerals added). Our water is fairly hard, so his filter brought it down from ~400 ppm to about 40 ppm TDS. Have you checked your water with a TDS meter? Kind of hard to make a conclusion for his I didn’t have a mineral profile to take a look at for his, but I thought he might have been getting enough residual minerals. I’d love to see this repeated with distilled water, but it seems so clear that water adjustments matter it’s hard to justify it compared to other experiments.

Any chance there’s a review for the Anvil fermenter coming up? The price point is very nice compared to the SS Brewbuckets.

A friend (who is now a pro-brewer) made several batches of stout with all RO water and they’re always amazing. I think it’s likely contextual more than anything, but there’s room to explore there. And same as you, I definitely would like to see this with distilled water. My RO water for this was purchased though, and a TDS meter check (I’ll need to grab the number when I get home) was incredibly low in mineral content. I’ll update this comment tonight.

I’m really enjoying the Anvil so far, but I’ve only had a few uses out of it. Overall really solid. no change in beer quality which is great. Only issue so far is the large horizontal profile with the spigot. Totally worth the price.

FWIW I have the Anvil too but that soft silicone bung it came with got destroyed after two uses. After buying a new #7 bung I used a Dremel to polish that hole in the lid now it doesn’t seem nearly as sharp.

It looks like it fixes one or two issues I have with my SS Brewtech Mini-tiny orings that get cut on the racking cane, and a permanently attached base. I’d love to know if the 4 gallon fits in a minifridge, makes it super cheap to get a nice lagering setup.

Any reason why you add Mg and not Na? From my understanding, malt will provide all the Mg needed for fermentation, and Na can provide a flavor boost.

I actually use two single port brew kettles I picked up on sale for $30 each as fermenters. They work great. They are easy to clean and if one is paranoid you can cycle them with your actual brew kettle so all the nooks and crannies get sterilized. I use plastic wrap over the top with the O ring seal from a 5 Gal. bucket lid to hold it tight. It has enough stretch that it just inflates like a balloon at peak fermentation and then settles down as fermentation ends. Plus you get to peak without opening anything up. My plan had been to use non ported kettles and syphon but the one ports came up for a lot less so…

I don’t use a dip tube on the port. It turns out that the bottom of the port is just about exactly the above the height of the turb. Sometimes I will tilt the fermentor a touch if the turb is lower.

I always enjoy the articles Matt, great work! Could you share the minerals that were added?

Thanks!

Definitely! I can add the exact measurements once I get back to my PC, but this particular profile was adjusted with Gypsum, Epsom Salts, and Calcium Chloride. Lactic acid was used for pH adjustment in both batches.

Thanks for posting those measurements! I just started working with water adjustments recently so any information is always helpful.

Nice work Matt! I love these water xbrmts. I did have a question about your mash schedule. I noticed you used 146 for 20 and 160 for 40 minutes. What was your reasoning behind this choice of schedule? I now have the ability to step mash and have been reading a lot about the subject. It’s confusing how so many books tell you to mash and others say don’t waste your time. Just wondering if it’s worth the trouble for classic styles like pils and Hefs? Thanks for the xbrmt 🍻

It looks like he did a Hochkurz mash

What about using your local water source for brewing? To me, that is part of brewing. I have an advantage of reasonable local water hardness (hardness in the teens). I understand using RO if you have really hard water or other issues (I run mine through a carbon filter to eliminate chlorine). I also 50/50 dilute with RO for soft water beers, like your pilsner. Suggest an experiment of local water versus RO, both adjusted with minerals. Bet it wouldn’t be significant.

If you ever want to automate your mineral ad back check out waterdynamix.net. it goes though RO and other filters then adds back minerals at custom rates

I’ve always found the water experiments to be very interesting. Water chemistry is probably the area most lacking area in my own brewing “expertise”. I use RO and add a bit of this or that because it’s what you’re “supposed to do”. But I am always gratified to see these experiments come up significant, because they are the ones that really seem like they SHOULD make a noticeable difference. After all, water is the biggest portion of the finished product.

It’s somehow gratifying when a change that is supposed to make a notable difference actually does…. thanks!

What I am dying to know is can you achieve the same with post additions. If you made the additions after fermentation to the clean batch would anyone tell the difference, would the beers become identical, does the profile affect the mash much or is it just the flavour of the water, or do certain minerals bring out certain flavours. It’s important, because if I can make additions post, then I can trial a range of different profiles on a single batch and really dial things in.

I agree with Jack, how about an evaluation of the effect of post-fermentation adjustments to water chemistry!

Fantastic write up. I have really enjoyed your work. I am never too surprised to see water play a massive role. I think the merits of water considerations remain to buried. Beer is clearly almost entirely water. I tried spring water and am now very inspired to start adjusting ro thanks to you. I have been wanting to for a while, but this is helping me get there. Last brews i made were with my denver tap. With camden added I am surprise how good it is. Denver city water has a brewer page anyone know what this tap water would be naturally good for? Anyways thanks for the awesome work.

Matt,

Are those the Anvil brewing bucket fermenter? How do you like them?

Curtis

Hey Curtis!

They are, the 7.5 gallons. So far, I like them a lot. I was fermenting in pin lock kegs before, which also have their pros and cons. So far, the major pluses of the Anvil’s are the ability to see into the fermenter and access the inside easily for cleaning. Lid holds well, ball valve doesn’t leak, and it is really easy to change out the barb on the ball valve to put a closed line in place for the a keg. Durable, light weight, really great for the price overall.

Only issue so far is the horizontal profile. The ball valve adds some space, my 7.5 cubic foot chest freezer can’t fit two.

Thanks for the input Matt,

I’m looking forward to using mine as well. It should be arriving tomorrow in time for brew day this weekend.

I finally switched to stainless since my last couple batches had some off flavors I’m attributing to using the same plastic fermenter for a few years now.

Great exBEERiment, Matt… I am on about batch 20 of my brewing career but water chemistry is something I have chosen to stay out of so far; believing virtually any fresh water will make a good beer… maybe not the “best” but certainly perfectly good. In a typical 8.5 gallon water requirement for a batch of beer, I use a combination of my Southern Maryland well water (about 1.5 gal) straight form my tap in combination with commercially bottled Deer Park spring water (7 gal). Cheers.

Thank you for conducting this experiment. While I don’t deny the importance of adjusting the salts in the water profile, I have seen a study which indicates that, for many of the salts, the great majority of the salts in the resultant beer actually comes from the grains used as well as the hops (for example, in the study, 56% of the sodium, 60% of the sulphate, 96% of the magnesium and over 99% of the Phosphorus and Potassium came from the grains and hops used alone! That is quite substantial. I have only seen two such studies to date, which is quite surprising considering the incredible importance of the contributions that malts and hops make. I have not seen any studies which show how much of the salts that hops alone contribute. Are you planning any such experiments in the future? I would be most interested!

I would like to see an exbeeriment where the variable is the water source. Hard Tap Water (with necesarry mineral adjustments) vs RO Water (with necessary mineral adjustments). Would people be able to tell the difference if both are adjusted towards the same water profile? Or does an RO water starting point yield better results?