Author: Marshall Schott

With the growing popularity of homebrewing has come a ton of novel products to make the process both more convenient and less likely to lead to poor results. A perfect example of this can be seen in the sheer number of fermentation vessels available today as compared to just a decade ago, many or which are miniature versions of what professionals use on a much larger scale. When I got my start in 2003, I didn’t anyone who used anything other than a plastic bucket or glass carboy, in fact it wasn’t until 2012 that I made the move to PET carboys, which seemed ingenious to me at the time.

Nowadays, there are myriad styles of fermentation vessels ranging in size, material, and features. With numerous past xBmts producing results that suggest different types of fermentation vessels may in fact produce unique characteristics, I thought it would be good to compare the popular glass carboy to the relatively new Speidel HDPE tank.

| PURPOSE |

To evaluate the differences between beers produced using the same process where one was fermented in a glass carboy and the other in a HDPE plastic vessel.

| METHODS |

I chose a really simple German Pilsner for this xBmt tod allow for any differences caused by the variable to shine.

Boondoggle

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 32.7 IBUs | 4.5 SRM | 1.049 | 1.010 | 5.1 % |

| Actuals | 1.049 | 1.01 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lager Malt (Muntons) | 9.5 lbs | 95 |

| Vienna Malt | 8 oz | 5 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 11 g | 60 min | First Wort | Pellet | 11.2 |

| Perle | 11 g | 25 min | Boil | Pellet | 8 |

| Hallertauer Mittelfrueh | 80 g | 10 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Super Special (Ü) | Bootleg Biology | 81% | 46°F - 70°F |

Notes

| Water Profile: Ca 70 | Mg 1 | Na 10 | SO4 84 | Cl 62 |

Download

| Download this recipe's BeerXML file |

I made a starter of a super secret Bootleg Biology yeast a couple days ahead of time.

The evening prior to brewing, I collected the full volume of filtered water and adjusted it to my desire profile.

I then weighed out and milled the grains.

My heat stick began heating the liquor a couple hours before I woke up, which meant it was nearly at strike temperature when I started brewing.

Using the no sparge method, I added the milled grains to the full volume of water.

After a couple minutes of stirring, I checked to make sure I’d hit my target mash temperature.

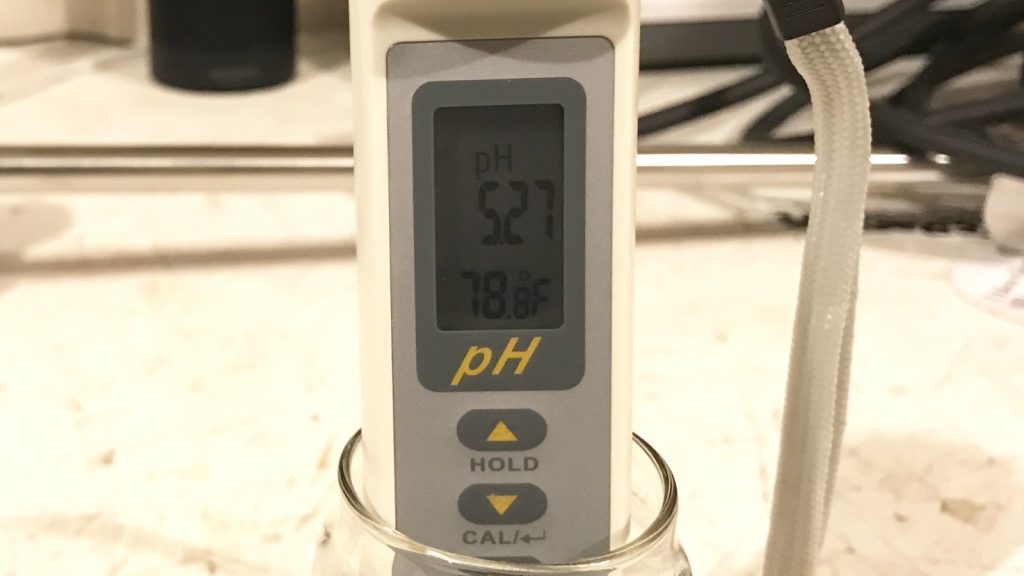

A pH reading 15 minutes into the mash showed it was right on target.

Once the 1 hour mash was complete, I began collecting the sweet wort.

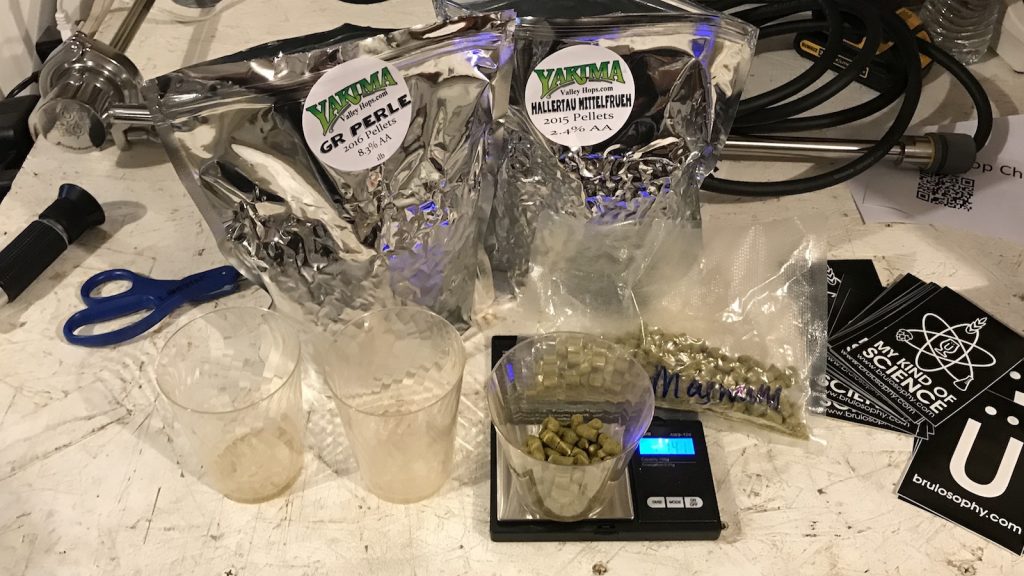

The wort was transferred to my kettle and I began heating it up, measuring out the hop additions while I waited for it to reach a boil.

I boiled the wort for 60 minutes with hops added per the recipe.

At the end of the 60 minute boil, I quickly chilled the wort to a tad warmer than my groundwater temperature.

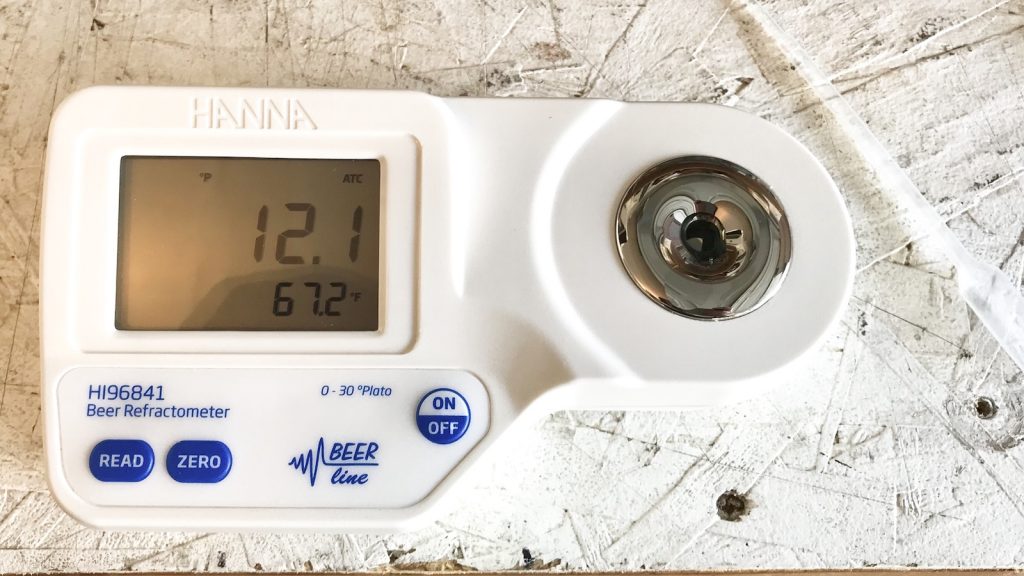

A refractometer measurement showed I’d hit my target OG.

I proceeded split the wort evenly between a glass carboy and a plastic Speidel fermentation tank, racking 5.5 gallons/21 liters of chilled wort to each.

The filled fermentors were placed next to each other in a chamber controlled to my desired fermentation temperature.

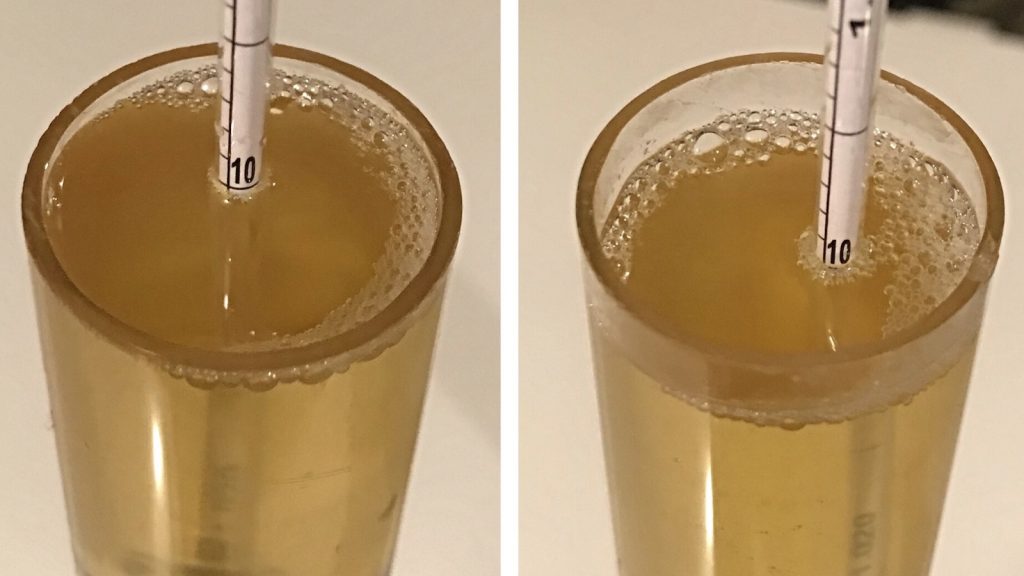

It took 4 hours for both worts to stabilize at my desired fermentation temperature of 65°F/18°C, at which point I split the yeast evenly between the batches. I noticed airlock activity from both just a few hours later and fermentation progressed similarly in each. With signs of activity dwindling 4 days later, I raised the temperature to 72˚F/23˚C to encourage complete attenuation. After another 3 days, I took a hydrometer measurements showing FG had been reached.

I let them sit for 3 more days before I proceeding with cold crashing, fining with gelatin, and kegging.

The filled kegs were placed in my cold keezer where they were burst carbonated for 15 hours before I reduced the gas to serving pressure and allowed them to condition for another few days before collecting data.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer fermented in the glass carboy and 2 samples of the beer fermented in the HDPE vessel in different colored opaque cups then asked to identify the sample that was unique. At this sample size, 11 tasters (p<0.05) would have had to select the unique sample in order to reach statistical significance, though only 6 (p=0.70) made the correct selection, suggesting participants were unable to reliably distinguish a German Pilsner fermented in a glass carboy from the same beer fermented in a plastic Speidel vessel.

My Impressions: These beers were exactly the same to my palate in every respect, there was nothing distinct about either, which explains my no-better-than-chance triangle test performance– in 8 attempts over 2 weeks, I was correct 3 times, and I’ll admit each one was a random guess. The beers were surprisingly tasty, I was glad to have 2 kegs around because it was an easy go-to lager when nothing else sounded appealing. Light, crisp, and thirst quenching with a really nice noble hop character that came off as more pungent than I expected based on the hop schedule. Definitely worthy of a re-brew!

| DISCUSSION |

This is the now the sixth xBmt we’ve completed that’s been focused on fermentation vessel and the third in which tasters were unable to distinguish a difference between the beers. I’d hypothesized that one potential explanation for prior significant xBmt results on this topic was headspace and geometry differences between vessels. However, seeing as though glass carboys, Speidel tanks, and Ss Brew Buckets aren’t necessarily identical in size and shape, it would appear my hypothesis was likely wrong. Another thought I had was that the material the vessel is made of somehow impacts a beer’s characteristics, perhaps leeching certain compounds into the beer that subtly effect its flavor. While I can’t be certain this isn’t happening, the evidence at this point seems to suggest something else may be at play.

There are a couple things I can think of that all of the fermentation vessels used in the non-significant vessel comparison xBmts have in common– they are highly impermeable to oxygen and they were all relatively new at time the xBmts were completed. Anyone who has ever stored a sour beer in a plastic bucket or PET carboy knows that they let in more oxygen than other types of vessels based on how quickly a pellicle forms, and given the significant results of our recent cold-side oxidation xBmt, it’s possible this ingress has a perceptible impact. It also seems like the stuff that stains well used plastic fermentation vessels could also impact beer flavor, carrying over whispers of flavor from past batches that ultimately combine to have an impact on the overall character of beer.

I’ve personally taken a strong liking to the Ss Brewtech Brew Buckets for their durability and overall ease of use. Being stainless, they’re essentially impermeable to oxygen and don’t stain, making them safe from either of the aforementioned issues. I also really like the Speidel plastic tank for its very thick HDPE wall and screw on lid that will also keep oxygen out, though I am curious about how the plastic will hold up over multiple batches. I have a buddy who has been using Speidel tanks for awhile and they’re definitely a different color than my new-ish one. I suppose a good future xBmt will involve comparing a new plastic fermentor to one that’s been well used.

If you have thoughts about this xBmt, please feel free to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

21 thoughts on “exBEERiment | Fermentation Vessel: Glass Carboy vs. Plastic Speidel Tank In A German Pils”

Congratulations for a new exbeeriment. I think there are two mistakes in writing. You say that you split the beer in brew bucket and plastic speidel. You also put that add dry hops in the beer.

One question: In the brew bucket do you feel the smell of previous batches like in plastic fermeters?

Cheers

Here is a link to oxygen permeability of different polymers: http://www.faybutler.com/pdf_files/HowHoseMaterialsAffectGas3.pdf. As you can see the permeability of HDPE is 10x that of PET. So, I would say that oxygen ingress is insignificant in both cases.

I think it is possible that previous batches can affect it. I have a BSG bucket that i used for Skeeter Pee (lemon wine) primary. I have soaked, washed and sanitized it several times with hot water and chems, lightly scrubbing, but it still smells lemony.

I later tried to use it for water transport on a brew day, and we could still barely detect the lemon in a cup of water. I guess its now dedicated to skeeter pee.

Can you post the recipe for “Skeeter Pee” and the process used somewhere? Please? I think that would be interesting to try. Thanks.

Do you often dry hop Pils? I’ve thought of doing it but didn’t want to risk making a batch that was over the top. How much do you dryhop a Pils with to get a little more jolt to the hop flavor? Any varieties work particularly well? I read about NZ Pils in BYO Mag and thought they sounded very nice with the NZ hops.

Oils, proteins and other compounds bind easily to plastic and overtime this could reduce the overall concentration? It’s a common issue in biochemistry labs whereby plastic/glass can lead to decreased concentrations. Over the course of several days you could get a film of oil etc forming, although I am not sure how much influence it would have on the final taste. Plastic is more hydrophobic than glass and can be highly charged. Generally drugs are stored in glass vials for this reason, it could also lead to precipitation of these compounds as they reach high concentrations on the wall of the fermenter.

It’s the only thing I could think of, that would lead to differences between glass and plastic, afterall it’s almost impossible to get a beer smell out of a plastic fermenter whereas glass is easy to clean, so plastic must be adsorbing something from the beer in high concentrations.

The only way I think you could test this is to do two batches of beer sequential and not clean the fermenter in between and see if you get any flavour changes between the beers… risky to do though and you could get some funky beer if it gets contaminated. However in theory the wall of the fermenter shod be saturated after the first beer so will adsorb significant less from the second batch?

I have the MiniBrew 6.5 XE by HobbyBeverage https://www.minibrew.com/products/6-5x-gallon-conical-fermenter?variant=25674595014 Which is made of HDPE. The amount of O2 permeability for making beer would be in a nearly negligible number. Oxygen impart takes time and porosity. There simply is not enough time to impart any significant amount of O2 to the beer through the plastic. You would get more air from opening the lid, transfer, sampling, etc than any that you could garner permeating the High Density plastic. One thing about HDPE over SS is it’s visible, both beer levels (or wine) as well as with the conical fermenter, the level of trub in the cone. It is also safer then glass. Yes, glass can be dangerous if dropped. Near our winery is another winery run by “Jim L.” who has been making high end commercial wines for several yeast. Last year I saw him show up at our winery to pick up some chemical or other ingredient he was needing for his immediate use on his wine. This is a commercial enterprise, both where I work and his. His arm was in a sling, and he had over 30 stitches in his arm from going up a stairs, dropping a 5 gallon glass carboy that broke and landing on the glass pieces. It just missed his brachial artery, which may have been deadly. So, when I speak of glass as somewhat dangerous, it is real. 99% of the time, our cellar crews move wine into and out of 5 gallons “small” containers for storage or blending with our processes, and most I have heard was just breaking a 5 gallon glass carboy with no injury.

My Conical HDPE comes out of the stand by just lifting when empty and easy to clean in the bathtub as it is light weight, has a nice 6″ opening at the top and I can reach all the way to the bottom. Even though it is somewhat opaque, and you can see levels, it is actually impervious to UV light and so light does not have a chance to change the character. That cannot be said as much about PET containers as they are crystal clear and would filter very little UV light, as would also clear glass carboys.

So, clear glass carboys, depending on where and how they are stored, could potentially effect flavor a LOT more than HDPE in the UV light reacions.

Vernon

Hi Marshall,

Do you plan on experimenting with Fast Ferment HDPE conical fermentors?

I’ve been using one for a few years now and I’m quitte satisfied with it.

Keep up the good work. Love reading you 🙂

Potentially, just gotta figure out a ferm temp solution— they don’t fit in chest freezers.

I agree, you should try using a Speidel that has been around the block a few dozen times. I have several of them and they all have various stains and aromas that I just can’t seem to remove regardless of different and harsh cleaning methods. It may be because I am not blind to the variable within my fermentors, but I can definitely sense off flavors/smells from brew to brew in my Speidels especially since abandoning them in favor of glass. I will be moving to stainless in the near future and trashing these expensive and fancy versions of the buckets you get in entry level homebrew kits.

On the list!

I pop mine in a old regular size refrigirator I have in my basement.

As for cleaning up a discolored HDPE plastic container, I use a mild solution of javel water very diluted (100 ml in 25 litres !!!) with hot water and soak it for a day. After it looks like new and retains no smell after good rinsing. Just as a reminder, javel is a desinfectant but also a powerfull detergent.

Cheer’s,

Robert

Thanks for the xBmt. I’ve been contemplating a Speidel. However, what really interests me is the super secret Bootleg strain! Give us a hint! Was it something you isolated yourself or a beta strain Jeff has in the works? I love their products and get excited when something new comes along. Inquiring minds want to know!

Hint: it’s something Jeff and our crew have been working on together… 🙂

Is the water profile you have listed including the elements from your tap water or is that just what you are adding? Looked like you just run your tap through a carbon filter so most elements from your source will still be present. Just curious.

Awesome post! Cheers 🍻

All of us use different starting water and the profiles we list in the recipes account for that plus any mineral additions.

Do you have any plans to replicate any of these ferm vessel xbmnts that have come out significant? I know it seems like that time could be spent answering other interesting questions, but given how odd/funky this particular line of research has gone thus far–and knowing what an issue absence of replication can be (psychologists in the house?)–perhaps it would be worthwhile?

I have the SS brew bucket and a Speidel. I love the brew bucket for lagers because the lower temp fermentation never requires a blow-off tube. I love the Speidel for ale temp beers because the fermentation lock is huge. No blow-off needed for a six gallon ale fermentation batch. I got an extra SS brew bucket thermowell and drilled the Speidel too for optimum temp control (you can get the drill bit from SS brew tech – worked perfect). The Speidel with the handles and thickness is super easy to carry around as well. If the Speidel needs a more thorough cleaning (for the ring at the top) I use PBW and soak it upside down. Hint, buy the stainless steel faucet option for the Speidel – it’s pretty solid and leak proof. If you’ve ever had a glass carboy crack – which I have (around the bottom), you will never go back to glass. You can also cold crash in a speidel without the shrink issues of a plastic big mouth bubbler. If I had to chose one fermenter, it would be speidel, hands down. This experiment also shows that you aren’t suffering from any flavor loss with plastic too!

I think the cool ferment would tame the flavours you might normally extract from a new vessel, plastics outgas at temperature. Try filling a new hdpe drink bottle with water leave it in the hot sun for a few hours then back in the shade to cool. See how it tastes.

Also every plastic is different, whenever you have used PET the tasters have picked it.

Great exbeeriment as always. I just finished kegging a batch using this recipe today and it tastes great. Can’t wait to get it carbonated and in the kegerator. The only difference was that I used Saflager W-34/70 but the gravity targets were both within a point, so I was happy with that. I’ve been brewing ales exclusively for several years primarily because I don’t have the space for temp controlled fermentation beyond using wet towels or space heaters. So I have been really excited to try a lager using essentially ale temps. I think that’s one of the most significant results out of all these exbeeriments – fermentation temperature. It’s at the very least put a lot of lagers into play for people like me without the capacity to actually ‘lager’ in the traditional sense.

Many thanks to everyone everyone at Brulosophy!