Author: Marshall Schott

Of all of the xBmt variables tested, the one that has stumped me the most and had me scratching my head in confusion has been fermentation temperature. I allowed myself to be convinced by fellow skeptics that the non-significant result of the first ferm temp xBmt was likely due to my use of the super clean WLP029 German Ale/Kölsch yeast used in my slightly roasty May The Schwarzbier With You recipe. So I repeated the xBmt using the notably more characterful WLP002 English Ale yeast, which produced significant results by a pretty small margin, something a few chalked up to the small-ish sample size. Regardless, I thought we might be onto something. For the third iteration of the xBmt, I used WLP800 Pilsner Lager yeast in a light lager fermented at temps far enough apart to all but guarantee a distinguishable difference.

Except that’s not what happened.

A bunch of people I view as having at least decent palates were unable to reliably distinguish a Bohemian Pilsner fermented at 50°F/10°C from one fermented at 66°F/19°C. Not only that, but comments about the beers were congruent with what you might expect from this style with nary a mention of any of the off-flavors commonly associated with higher fermentation temperatures. Stumped doesn’t begin to explain how I felt after this.

As a lover of all things lager and loather of complication, I would love nothing more than to know I could produce great tasting beer without the extra effort commonly accepted as required for the lager styles. As much fantastic lager beer as I’ve made using the quick lager method, I’d happily forgo the additional chilling and temp ramping if I knew it’d consistently produce a product of equal quality. Resisting the urge to jump to a conclusion, I decided it best to repeat this xBmt using a the world’s most popular lager yeast strain.

| PURPOSE |

To evaluate the differences between 2 beers of the same recipe split into separate fermentors and fermented with the same yeast with half fermented at traditional lager temperatures (50˚F/10˚C) and the other half fermented much warmer (70˚F/21˚C).

| METHODS |

Since my intention with this xBmt was to accentuate any possible perceptual differences, I designed a pale beer with a simple grist and hop schedule.

German Helles Exportbier

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 29.5 IBUs | 3.6 SRM | 1.053 | 1.011 | 5.5 % |

| Actuals | 1.053 | 1.008 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 17 lbs | 85 |

| Vienna Malt (Gambrinus) | 2 lbs | 10 |

| Cara-Pils/Dextrine | 1 lbs | 5 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 30 g | 60 min | Boil | Pellet | 11.2 |

| Select Spalt | 30 g | 20 min | Boil | Pellet | 3.1 |

| Tettnang | 20 g | 10 min | Boil | Pellet | 5.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Download

| Download this recipe's BeerXML file |

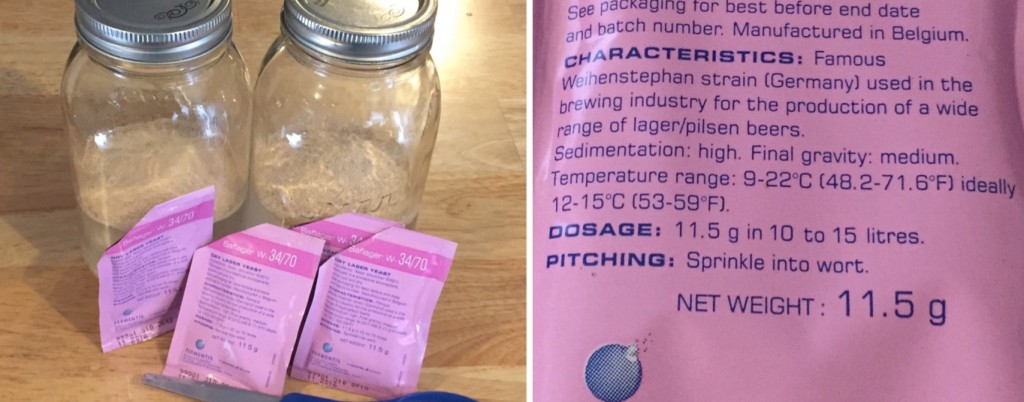

A starter wasn’t necessary since I was using Fermentis’ Saflager W-34/70, widely known as the Weihenstephaner strain (WLP830 German Lager, WY2124 Bohemian Lager). This brew day began the afternoon prior to brewing when I began water collection using HbrewO’s BrewRO system for the first time, it runs at just about 3 gallons per hour.

Real quick, this RO filtration system works incredibly well and was a cinch to get hooked up. Unfortunately, HbrewO has put a halt on production for various reasons. I’d encourage anyone interested in making RO brewing water at home to contact Mike and let him know!

I just heard from Mike at HbrewO who said he’s heard from many readers interested in the BrewRO system. He informed me they have plans to start selling it again sometime in April!

I let my kettle fill with water while I grabbed a few pints with friends at the House of Pendragon taproom. A hair under 4 hours later, the full volume of pure brewing liquor collected and the sparge volume split off, I proceeded to weigh out and mill the grain.

The following morning, I awoke early, hit the flame under my strike water, then mashed in about 15 minutes later.

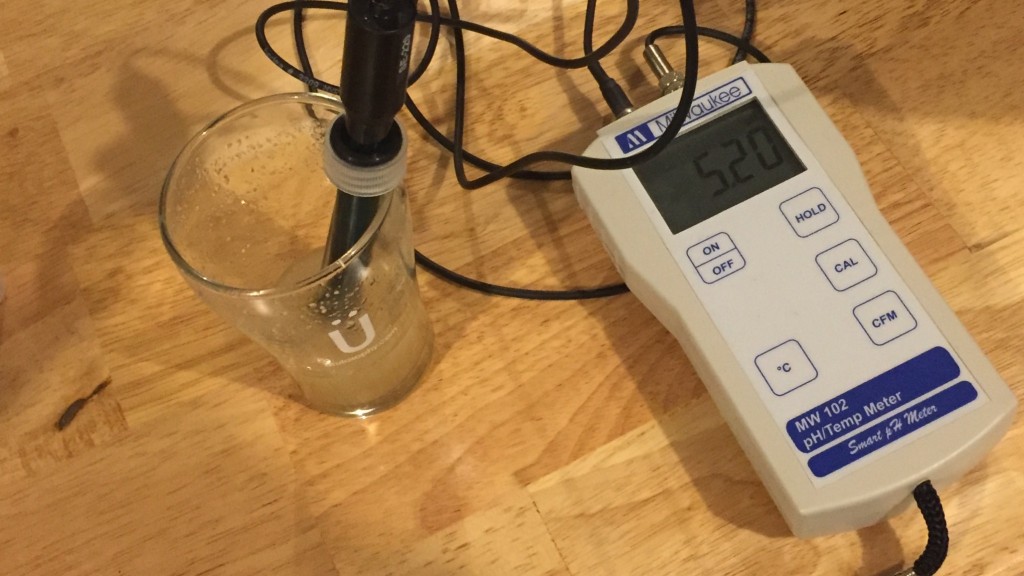

While I don’t do it every time, I occasionally take pH readings about 10-15 minutes into the mash to confirm the Bru’n Water Spreadsheet prediction. As always, it was spot on.

With the 1 hour mash complete, I collected the sweet wort and quickly brought it to a boil.

The small amount of hops were added at the appropriate times during the 1 hour boil, after which I quickly chilled the full volume of wort to 70˚F/21˚C, cut the water, then transferred 5.25 gallons to a 6 gallon PET carboy.

I then turned the water back on to chill the wort even more, it got down to 60˚F/16˚C due to my unusually cool groundwater this time of year. The warm ferment batch was placed in a chamber controlled to 70˚F/21˚C where it remained un-pitched while the cool ferment batch finished chilling to 50˚F/10˚C in another chamber, this took about 4 hours. With both worts sitting at their target fermentation temperatures, I prepared the yeast by rehydrating 2 sachets per batch in warm water for 15 minutes, all shared the same expiration date. It was at this point I noticed for the first time that Fermentis’ recommended fermentation temperature range is far outside of what I expected.

71.6˚F/22˚C… seriously?! This took me a bit by surprise and made me wonder how they came up with such a wide range. The rehydrated slurries were pitched. At 24 hours in, the warm ferment batch was showing signs of activity while the cool ferment beer was not, which wasn’t necessarily unexpected.

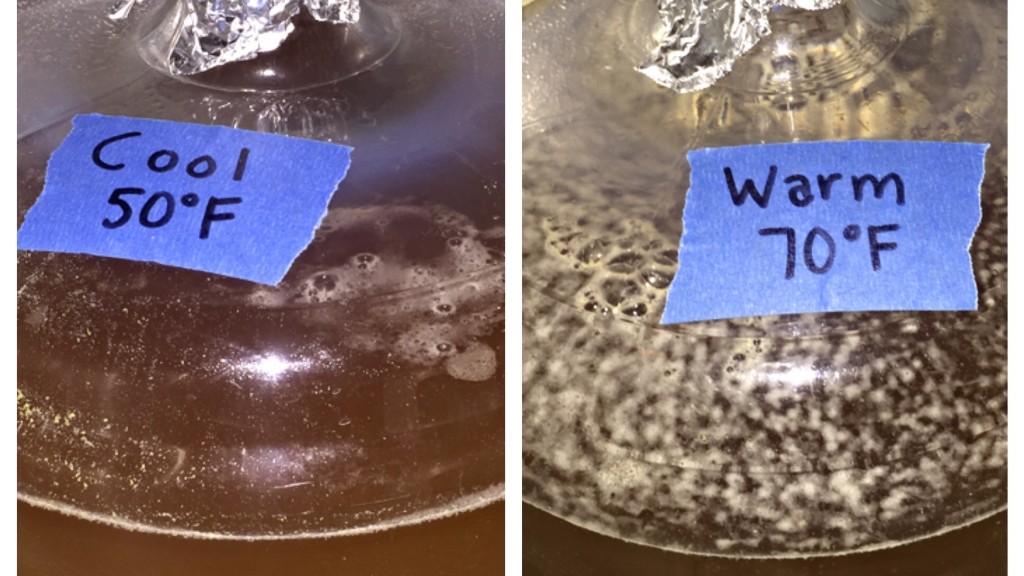

Things had really started kicking for the warm ferment beer at 36 hours post-pitch, the cool ferment beer appeared unchanged.

I began to notice some kräusen formation on the cool ferment beer around 48 hours after yeast was pitched then it finally seemed to kick into high gear around day 3.

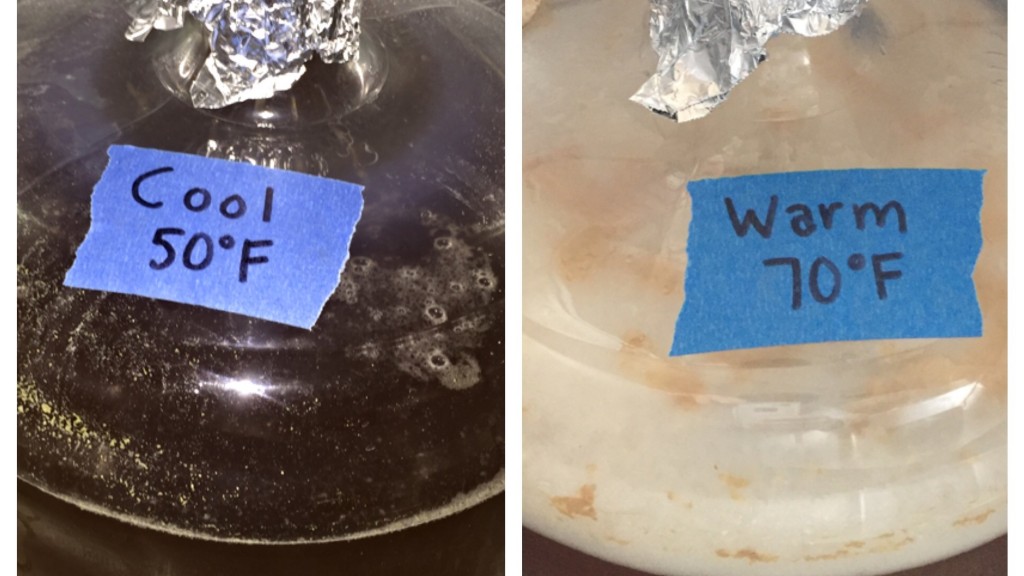

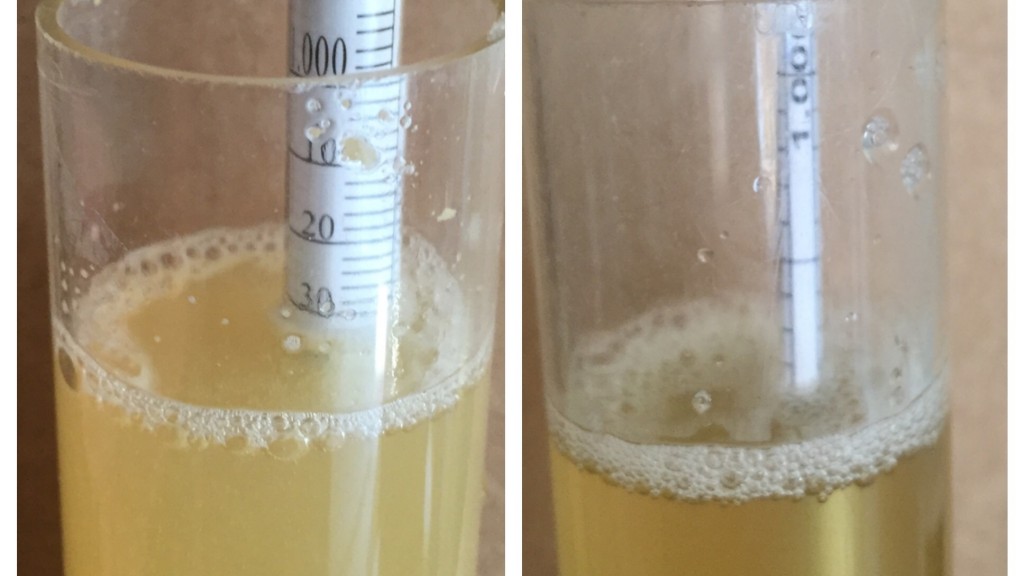

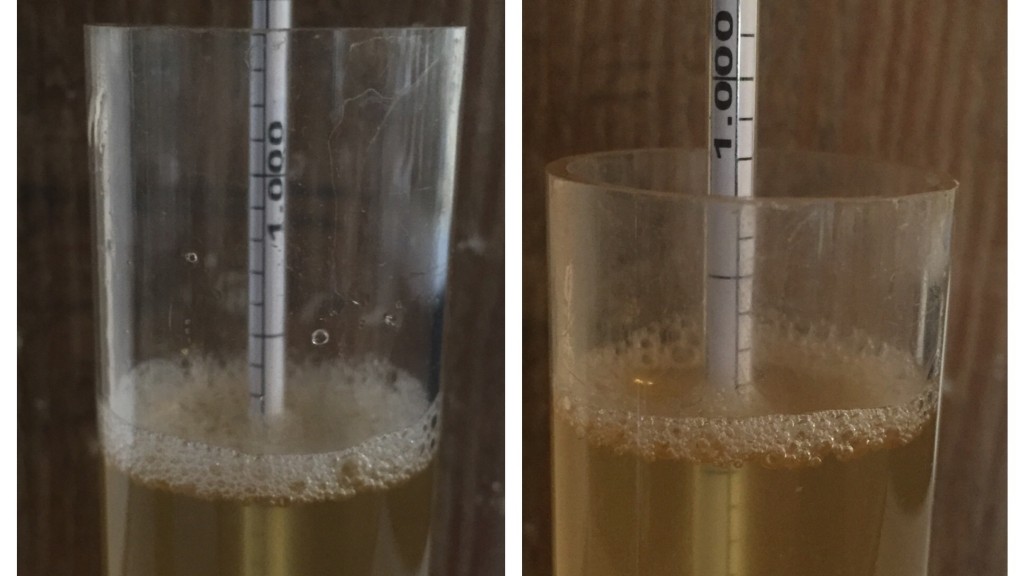

At 1 week fermenting at their respective temperatures, the kräusen on the warm ferment batch had completely dropped while the cool ferment batch still maintained a nice white cap. It was at this point I decided to measure the SG of each beer and discovered another difference.

With the cool ferment beer was sitting at 1.032 SG, slightly over 50% to my target FG, I moved it into the chamber holding the warm ferment batch, which had dropped to a steady 68˚F/20˚C once active fermentation was complete.

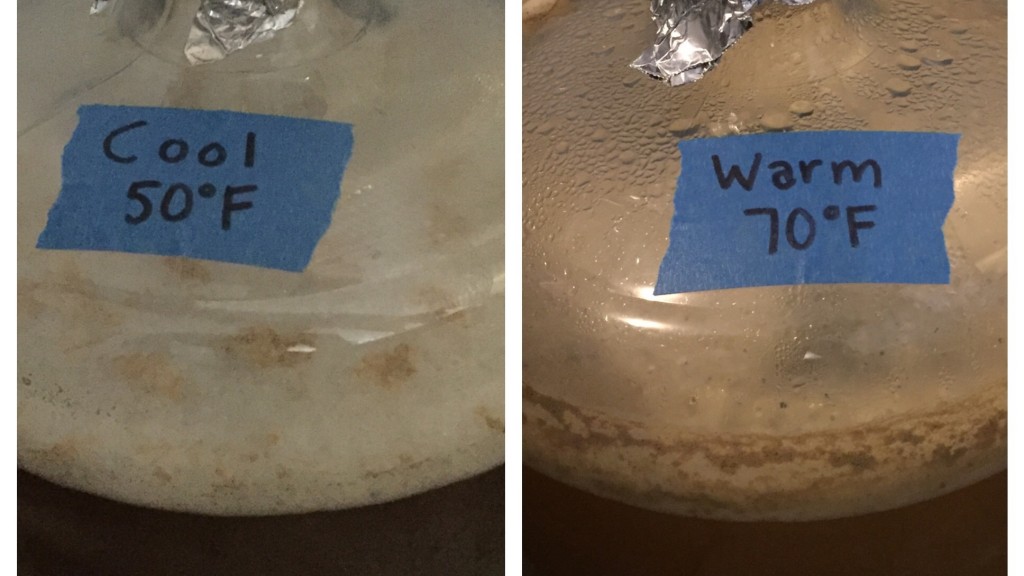

It took 2 full days for the cool ferment batch to stabilize at the warmer temperature, then I let the beers hangout for another 5 days to encourage complete attenuation and clean-up of any undesirable fermentation byproducts. I took a second hydrometer measurement at 2 weeks post-pitch.

Both the warm and cool ferment beers were sitting at a beautifully dry 1.008 SG. After 2 more days in the warm environment, I took a final hydrometer measurement that confirmed fermentation was indeed complete, then I cold crashed and fined with gelatin.

The beers were kegged 3 weeks after being brewed, hit with 45 psi of CO2 for 18 hours, and tasting pretty damn good a few days later. I let them “lager” another week or so before presenting them to tasters for evaluation, they were looking quite delectable.

| RESULTS |

The participant pool for this xBmt consisted of 26 people including BJCP judges, experienced homebrewers, craft beer enthusiasts, and a few Brewcasters. Each participant was blindly served 2 samples of the warm ferment beer and 1 sample of the cool ferment beer in different colored opaque cups then instructed to identify the one that was different. In order to achieve statistical significance given the sample size, 13 participants (P<0.05) would have had to correctly identify the cool ferment sample as being unique, while only 12 (p=0.083) were capable of doing so, meaning 14 tasters selected one of the other samples. Although close, these results suggest tasters in this xBmt were unable to reliably distinguish between pale lagers of the same recipe fermented 20˚F/11˚C apart.

The 12 tasters who were correct on the triangle test were subsequently asked to complete a brief evaluation comparing only the different beers while still blind to the variable being investigated. Since this xBmt failed to achieve statistical significance, I’d caution anyone from putting too much weight on this data. That said, I sure found it interesting. In terms of overall preference, a majority of 10 tasters chose the warm ferment beer as the one they liked most, while the other 2 preferred the cool ferment sample. When asked to select the beer they thought was fermented cool, 11 participants incorrectly chose the warm ferment beer.

My Impressions: I first had a friend triangle test me on these beers about a week after they were kegged and I was able to get it right, an example of the prowess of my palate, indeed. At this point, I experienced the differences as incredibly subtle, almost unnoticeable, with the warm ferment beer possessing a character that was slightly cleaner and crisper than the cool ferment beer, which had more of what I thought to be Pils malt character. Then over the following week, I failed 3 subsequent attempts. The realization I was unable to reliably distinguish these beers after initially guessing right was tough to accept, and perhaps predictably, I maintained a slight preference for the cool ferment beer, despite nearly every correct participant selecting the warm ferment beer as the better one. Why? Bias is my best guess, and ultimately, I enjoyed both just fine.

| DISCUSSION |

The variable of fermentation temperature continues to fascinate me. Having accepted, and still refusing to abandon, the idea that it’s one of the most important components of making good beer, particularly when it comes to lagers, these results are confounding and raise more questions than they answer. Perhaps the character expressed as a function of fermentation temperature is yeast dependent, with some strains such as 34/70 and WLP800 performing similarly without such tight constraints. Or, as Warren on The Session suggested, maybe the difference would have been more stark if the cool ferment beer had been left to completely ferment out at the lower temperature rather than ramping it up after 50% attenuation. Of course, we won’t be able to say for sure without more testing, which is certainly planned, but I’m personally inclined to defer to a possible explanation I often do lately, that much of what we claim to know as homebrewers was gleaned from the professional world, and perhaps issues associated with fermentation temperature are more a matter of scale than anything else. I really have no clue.

As for now, with 3 out of 4 fermentation temperature xBmts failing to achieve significance, my conviction that precise control is imperative to making good beer has weakened. I won’t be selling off my temperature controlled chambers or anything drastic like that, but I’ll certainly be worrying less about chilling my lager wort to exactly 50˚F/10˚C before pitching yeast. That’s just me.

I know I’m not the only one who finds these results very surprising, please share your thoughts, concerns, and ideas for future iterations on this variable in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

138 thoughts on “exBEERiment | Fermentation Temperature: Fermentis Saflager W-34/70 In A German Helles Exportbier”

Have you tried this experiment with a proper lagered version. This one had OG 1.053 so atleast 5.3 weeks before testing?

I like the 34/70 yeast, it gives me reliable results. I’m consistently brewing a larger with added hops and grains.

My problem – I have a supply issue, not enough beer! (common problem I would think) And don’t want to outlay the cost of another temp controlled pressure fermenting vessel.

My solution – Purchase a much more cost effective non temp controlled pressure vessel and ferment in an airconed environment. Hence I am also experimenting with higher temp fermentation. At pressent I’m fermenting at 21°c I’ll let you know the results.

While the experiment is interesting, it is completely invalid. The temp on the cold ferment should have been left at 50 until FG was achieved.

At best you have a hybrid, which obviously is equal to the ale like ferment temp of 70 degrees.

Mostly unrelated. In 2010 I had some three year past use date bohemian lager yeast and decided to smack the pack just to see what happened if anything. Then take a whiff out of curiosity to learn what bad yeast smelled like. Didn’t smell bad at all. Made a starter (3 times). When I figured it was built up enough I abused it some more and made an ipa with it at 65 degrees. Beer turned out great with 75% attenuation. Will I do it again? I’m going to try not to. But obviously this yeast is very, very forgiving

I made a dunkel last year with S-34/70 after reading this. I decided to ferment it warm to see how it would go. I used a fairly large starter (based on a yeast calculator) and it went berserk. It ended up fermenting at 74F and it finished fermenting in less than 5 days. It was kegged and drinkable in 2 weeks. And it turned out fantastic. I shared it with many of my homebrew friends and they were floored how hot I fermented it, how quickly it was finished, and how there were absolutely zero off flavors.

I’m about to repeat this with a Helles and Oktoberfest. I can’t wait to taste the results!

and?

I again made a starter, 2L per 5 gallons. They were actively fermenting within 8 hours of pitching. They both fermented around 70F and were kegged within 10 days. After a week of carbonating, the Helles tasted great.

The Oktoberfest was underwhelming. It wasn’t bad, but it was missing the roasty caramel flavor that I associate with the style. However, it just needed to age a bit. It’s been in the keg for over a month and the flavor is much better (compared to Spaten or Paulaner).

I absolutely love this yeast. I’ve had great success with it and there have been no off flavors that I can detect from the hot ferment.

Chris, I did the same thing(a Dunkel with a large starter) and afterward I found out you’re not supposed to make starters with 38-70- just dry pitch. My kräusen looked like what could only be described as “fart blisters). The verdict is still out on the beer.

I stumbled upon this article when looking for inspiration for an Oktoberfest (Festbier) recipe with the 34/70 yeast. Do you mind sharing your recipe Chris?

I’m curious. What kind of setup do you have for fermentation chamber? What do you use for heat?