Author: Marshall Schott

Of all of the xBmt variables tested, the one that has stumped me the most and had me scratching my head in confusion has been fermentation temperature. I allowed myself to be convinced by fellow skeptics that the non-significant result of the first ferm temp xBmt was likely due to my use of the super clean WLP029 German Ale/Kölsch yeast used in my slightly roasty May The Schwarzbier With You recipe. So I repeated the xBmt using the notably more characterful WLP002 English Ale yeast, which produced significant results by a pretty small margin, something a few chalked up to the small-ish sample size. Regardless, I thought we might be onto something. For the third iteration of the xBmt, I used WLP800 Pilsner Lager yeast in a light lager fermented at temps far enough apart to all but guarantee a distinguishable difference.

Except that’s not what happened.

A bunch of people I view as having at least decent palates were unable to reliably distinguish a Bohemian Pilsner fermented at 50°F/10°C from one fermented at 66°F/19°C. Not only that, but comments about the beers were congruent with what you might expect from this style with nary a mention of any of the off-flavors commonly associated with higher fermentation temperatures. Stumped doesn’t begin to explain how I felt after this.

As a lover of all things lager and loather of complication, I would love nothing more than to know I could produce great tasting beer without the extra effort commonly accepted as required for the lager styles. As much fantastic lager beer as I’ve made using the quick lager method, I’d happily forgo the additional chilling and temp ramping if I knew it’d consistently produce a product of equal quality. Resisting the urge to jump to a conclusion, I decided it best to repeat this xBmt using a the world’s most popular lager yeast strain.

| PURPOSE |

To evaluate the differences between 2 beers of the same recipe split into separate fermentors and fermented with the same yeast with half fermented at traditional lager temperatures (50˚F/10˚C) and the other half fermented much warmer (70˚F/21˚C).

| METHODS |

Since my intention with this xBmt was to accentuate any possible perceptual differences, I designed a pale beer with a simple grist and hop schedule.

German Helles Exportbier

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 29.5 IBUs | 3.6 SRM | 1.053 | 1.011 | 5.5 % |

| Actuals | 1.053 | 1.008 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 17 lbs | 85 |

| Vienna Malt (Gambrinus) | 2 lbs | 10 |

| Cara-Pils/Dextrine | 1 lbs | 5 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 30 g | 60 min | Boil | Pellet | 11.2 |

| Select Spalt | 30 g | 20 min | Boil | Pellet | 3.1 |

| Tettnang | 20 g | 10 min | Boil | Pellet | 5.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Download

| Download this recipe's BeerXML file |

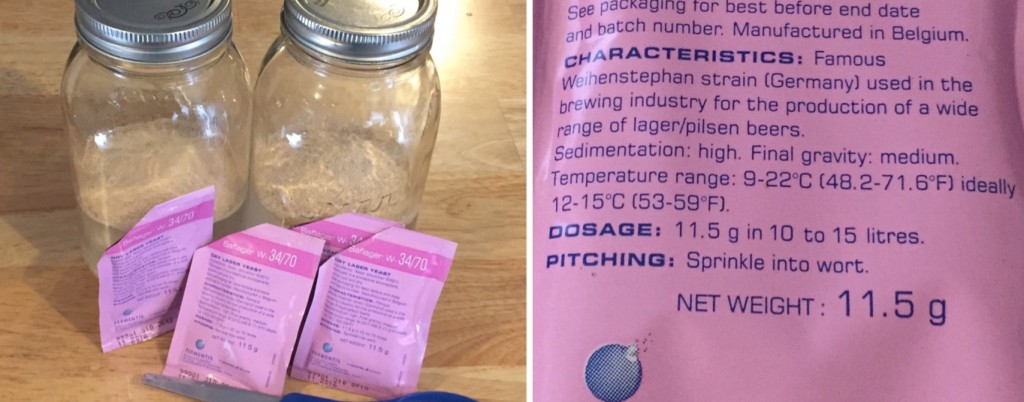

A starter wasn’t necessary since I was using Fermentis’ Saflager W-34/70, widely known as the Weihenstephaner strain (WLP830 German Lager, WY2124 Bohemian Lager). This brew day began the afternoon prior to brewing when I began water collection using HbrewO’s BrewRO system for the first time, it runs at just about 3 gallons per hour.

Real quick, this RO filtration system works incredibly well and was a cinch to get hooked up. Unfortunately, HbrewO has put a halt on production for various reasons. I’d encourage anyone interested in making RO brewing water at home to contact Mike and let him know!

I just heard from Mike at HbrewO who said he’s heard from many readers interested in the BrewRO system. He informed me they have plans to start selling it again sometime in April!

I let my kettle fill with water while I grabbed a few pints with friends at the House of Pendragon taproom. A hair under 4 hours later, the full volume of pure brewing liquor collected and the sparge volume split off, I proceeded to weigh out and mill the grain.

The following morning, I awoke early, hit the flame under my strike water, then mashed in about 15 minutes later.

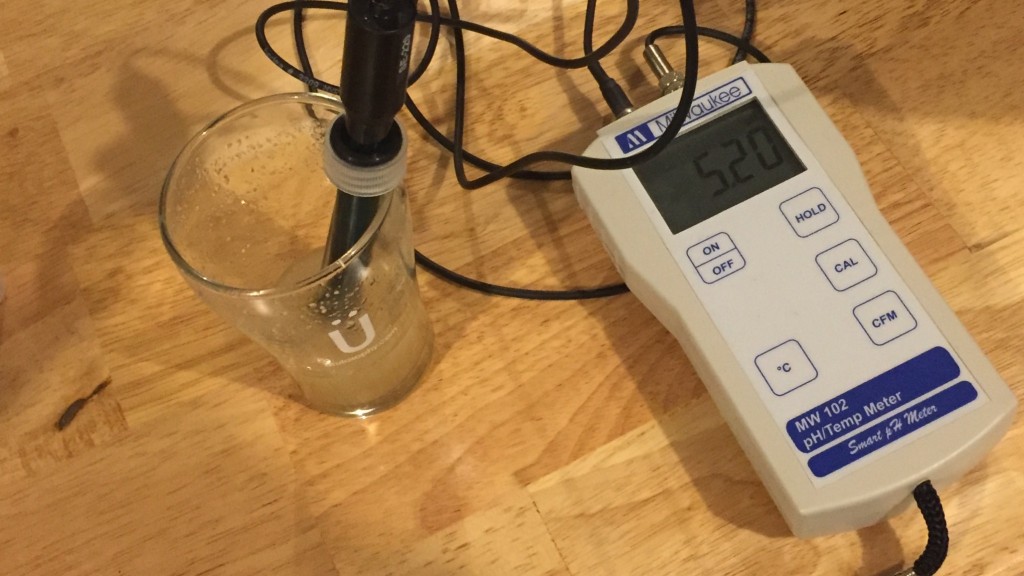

While I don’t do it every time, I occasionally take pH readings about 10-15 minutes into the mash to confirm the Bru’n Water Spreadsheet prediction. As always, it was spot on.

With the 1 hour mash complete, I collected the sweet wort and quickly brought it to a boil.

The small amount of hops were added at the appropriate times during the 1 hour boil, after which I quickly chilled the full volume of wort to 70˚F/21˚C, cut the water, then transferred 5.25 gallons to a 6 gallon PET carboy.

I then turned the water back on to chill the wort even more, it got down to 60˚F/16˚C due to my unusually cool groundwater this time of year. The warm ferment batch was placed in a chamber controlled to 70˚F/21˚C where it remained un-pitched while the cool ferment batch finished chilling to 50˚F/10˚C in another chamber, this took about 4 hours. With both worts sitting at their target fermentation temperatures, I prepared the yeast by rehydrating 2 sachets per batch in warm water for 15 minutes, all shared the same expiration date. It was at this point I noticed for the first time that Fermentis’ recommended fermentation temperature range is far outside of what I expected.

71.6˚F/22˚C… seriously?! This took me a bit by surprise and made me wonder how they came up with such a wide range. The rehydrated slurries were pitched. At 24 hours in, the warm ferment batch was showing signs of activity while the cool ferment beer was not, which wasn’t necessarily unexpected.

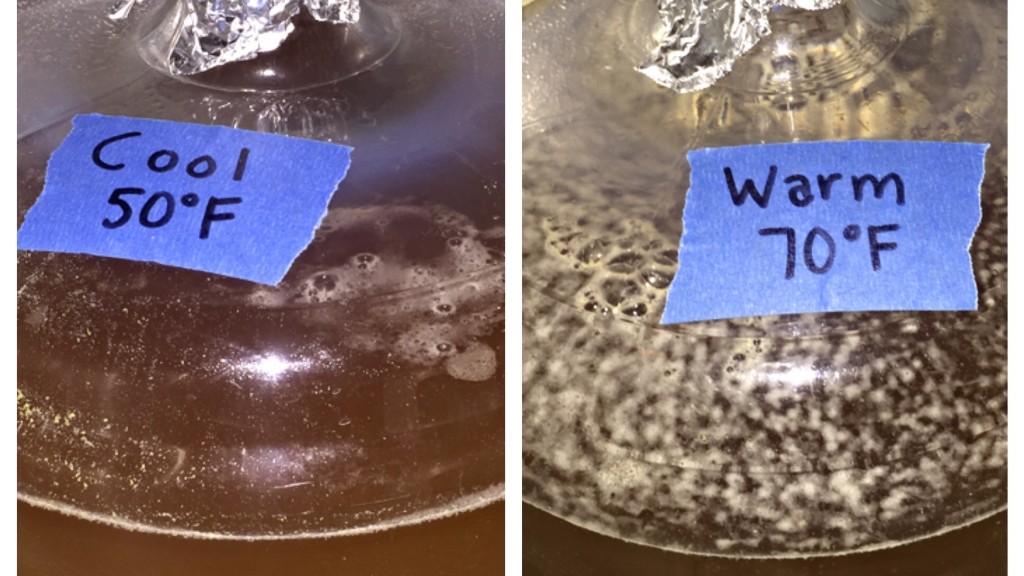

Things had really started kicking for the warm ferment beer at 36 hours post-pitch, the cool ferment beer appeared unchanged.

I began to notice some kräusen formation on the cool ferment beer around 48 hours after yeast was pitched then it finally seemed to kick into high gear around day 3.

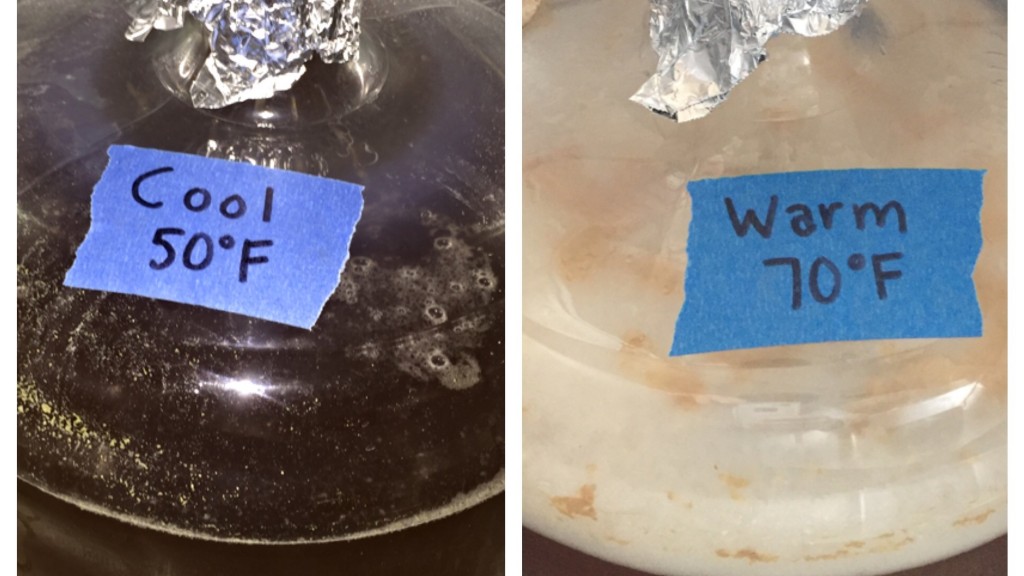

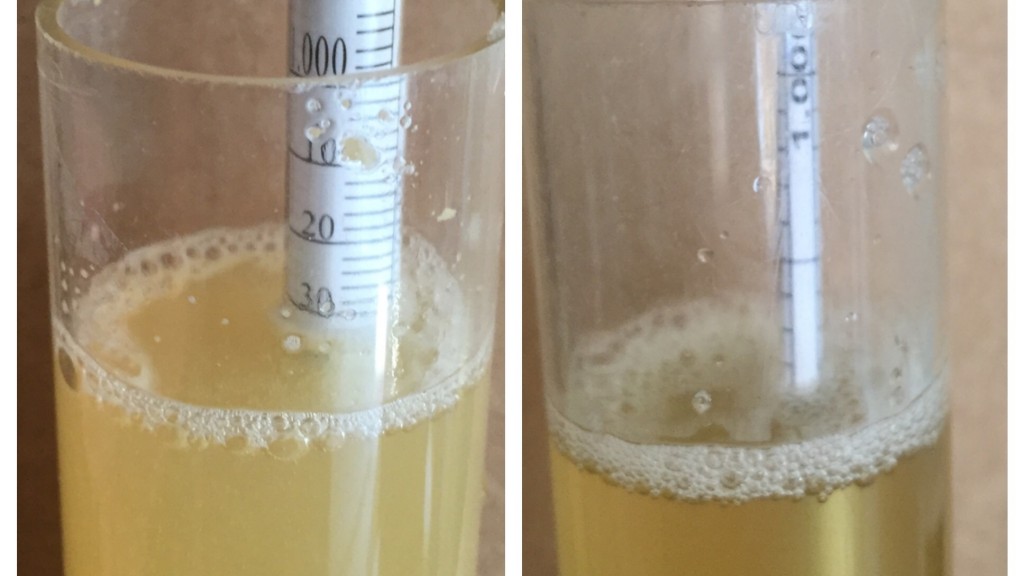

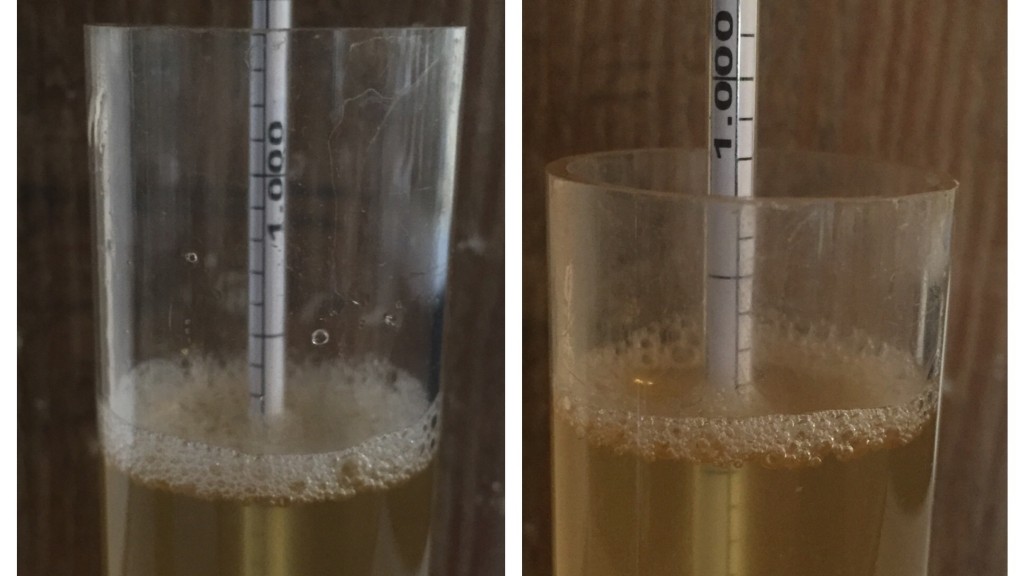

At 1 week fermenting at their respective temperatures, the kräusen on the warm ferment batch had completely dropped while the cool ferment batch still maintained a nice white cap. It was at this point I decided to measure the SG of each beer and discovered another difference.

With the cool ferment beer was sitting at 1.032 SG, slightly over 50% to my target FG, I moved it into the chamber holding the warm ferment batch, which had dropped to a steady 68˚F/20˚C once active fermentation was complete.

It took 2 full days for the cool ferment batch to stabilize at the warmer temperature, then I let the beers hangout for another 5 days to encourage complete attenuation and clean-up of any undesirable fermentation byproducts. I took a second hydrometer measurement at 2 weeks post-pitch.

Both the warm and cool ferment beers were sitting at a beautifully dry 1.008 SG. After 2 more days in the warm environment, I took a final hydrometer measurement that confirmed fermentation was indeed complete, then I cold crashed and fined with gelatin.

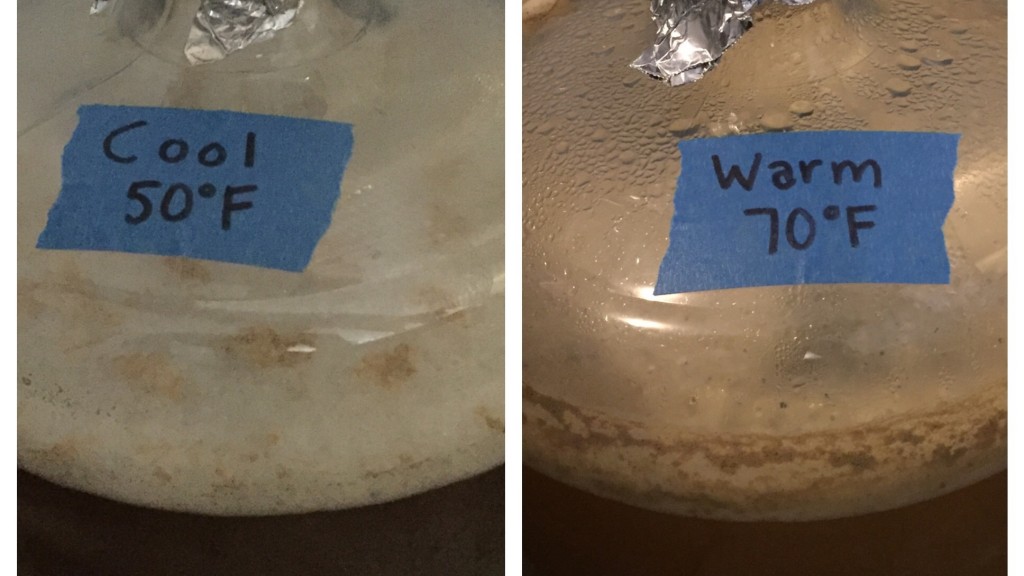

The beers were kegged 3 weeks after being brewed, hit with 45 psi of CO2 for 18 hours, and tasting pretty damn good a few days later. I let them “lager” another week or so before presenting them to tasters for evaluation, they were looking quite delectable.

| RESULTS |

The participant pool for this xBmt consisted of 26 people including BJCP judges, experienced homebrewers, craft beer enthusiasts, and a few Brewcasters. Each participant was blindly served 2 samples of the warm ferment beer and 1 sample of the cool ferment beer in different colored opaque cups then instructed to identify the one that was different. In order to achieve statistical significance given the sample size, 13 participants (P<0.05) would have had to correctly identify the cool ferment sample as being unique, while only 12 (p=0.083) were capable of doing so, meaning 14 tasters selected one of the other samples. Although close, these results suggest tasters in this xBmt were unable to reliably distinguish between pale lagers of the same recipe fermented 20˚F/11˚C apart.

The 12 tasters who were correct on the triangle test were subsequently asked to complete a brief evaluation comparing only the different beers while still blind to the variable being investigated. Since this xBmt failed to achieve statistical significance, I’d caution anyone from putting too much weight on this data. That said, I sure found it interesting. In terms of overall preference, a majority of 10 tasters chose the warm ferment beer as the one they liked most, while the other 2 preferred the cool ferment sample. When asked to select the beer they thought was fermented cool, 11 participants incorrectly chose the warm ferment beer.

My Impressions: I first had a friend triangle test me on these beers about a week after they were kegged and I was able to get it right, an example of the prowess of my palate, indeed. At this point, I experienced the differences as incredibly subtle, almost unnoticeable, with the warm ferment beer possessing a character that was slightly cleaner and crisper than the cool ferment beer, which had more of what I thought to be Pils malt character. Then over the following week, I failed 3 subsequent attempts. The realization I was unable to reliably distinguish these beers after initially guessing right was tough to accept, and perhaps predictably, I maintained a slight preference for the cool ferment beer, despite nearly every correct participant selecting the warm ferment beer as the better one. Why? Bias is my best guess, and ultimately, I enjoyed both just fine.

| DISCUSSION |

The variable of fermentation temperature continues to fascinate me. Having accepted, and still refusing to abandon, the idea that it’s one of the most important components of making good beer, particularly when it comes to lagers, these results are confounding and raise more questions than they answer. Perhaps the character expressed as a function of fermentation temperature is yeast dependent, with some strains such as 34/70 and WLP800 performing similarly without such tight constraints. Or, as Warren on The Session suggested, maybe the difference would have been more stark if the cool ferment beer had been left to completely ferment out at the lower temperature rather than ramping it up after 50% attenuation. Of course, we won’t be able to say for sure without more testing, which is certainly planned, but I’m personally inclined to defer to a possible explanation I often do lately, that much of what we claim to know as homebrewers was gleaned from the professional world, and perhaps issues associated with fermentation temperature are more a matter of scale than anything else. I really have no clue.

As for now, with 3 out of 4 fermentation temperature xBmts failing to achieve significance, my conviction that precise control is imperative to making good beer has weakened. I won’t be selling off my temperature controlled chambers or anything drastic like that, but I’ll certainly be worrying less about chilling my lager wort to exactly 50˚F/10˚C before pitching yeast. That’s just me.

I know I’m not the only one who finds these results very surprising, please share your thoughts, concerns, and ideas for future iterations on this variable in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

138 thoughts on “exBEERiment | Fermentation Temperature: Fermentis Saflager W-34/70 In A German Helles Exportbier”

Mind blown…again. I think you’re right, though. On a home-brew scale, there has to be a different set of variables than what the pros deal with. I can’t imagine a for-profit commercial brewery would continue to do stuff ‘just because’ if it involved all kinds of expensive extra equipment, which making lager does.

I suspect that having temp control helps even at higher temps. Most of us started home brewing with many dubious practices, under pitching, no temp control and poor sanitation. My guess is that you would see more of a difference with no temp control. It seems likely that a constant temp produces less yeast stress and fewer off flavors. It would be interesting to see if you would end up with a solventy off-flavored mess with an otherwise solid process without temp control.

I am definitely trying this.

They did a ‘no temperature control’ experiment: https://brulosophy.com/2015/01/19/fermentation-temperature-pt-1-exbeeriment-results/

Exactly what I was going to say. Sometimes I think the key is more about maintaining constant temps than it is about what those temps are (at least for our scale of brewing). I know my beer quality drastically improved once I got temp control, but I think that’s mostly because, prior to temp control, I was fermenting my beer in the garage where the temp would vary by about 10 degrees between night and day. Definitely a strain on the yeast.

From what I have observed on pre vs post temperature control and the fact that I sometimes don’t temperature control.

A constant temperature might be something that helps. I’ve run in to a couple of yeast strains that I at least think seem to be very temperature temperamental. Belgian strains (at least WLP500 and 530) seem to be highly temperature dependent on how they behave. They do not like cool temperatures. Hefe yeasts do seem to change character dependent upon warm vs cool part of their temp range. Highly “characterized” yeasts seem to show temperature dependent results, which yeasts without a whole ton of character (IMHO, lager yeasts, west coast and yes, I consider most English yeasts not to be SUPER character imbued, not like Hefe and Belgian yeasts are) don’t seem to respond as much to temperature differences on fermentation results.

What I have found as my fermentation area is my basement, which is 65F on the slab in the winter and about 70F on the slab in the summer is that I can get in to more of the sweet spot with some yeasts. Belgian yeasts I’ve found do NOT like fermenting in the middle 60’s, they like it warm. I can’t do a Saison justice, since I use Belle Saison yeast and that seems to like it around 80F, without temp control. I couldn’t do a kettle souring, as I needed to keep temps around 115F, without temp control. In the winter time, even some of my plain ale yeasts have issues at 65F, again the Belgians, but even some of the English strains slow down and seem to have trouble finishing if I can’t bump the temp up to around 70F for a couple of days, say 5-7 days in to fermentation.

I can also cold crash, which has a nice positive effect on clarity and reduction on sediment getting in to the bottle.

I was holding out to brew a lager because I dont have any controlled temperature room. This just convinced me I should try it.

I know ‘Ill be crucified by purists, but I’ll forward them this article.

Who says you even have to tell the purists about the process? Let them try your beer “blind” first then blow their minds 🙂

This is so machiavelic I already have goosebumps!!!

I am fermenting a pilsner very similar to your recipe right now at 64 degrees. It’s done fermenting and in the process of cold crashing and fining with gelatin. No off flavors thus far and it tastes very similar to when I did the same beer at 55 degrees.

It’ll be interesting to see what the guys at the homebrew club think when they try it. They liked the last batch, so we’ll see. I think it tastes great and has the hallmarks of a classic pilsner. Thanks for your work on this, it’s really fascinating stuff.

I agree, tell them you got a fermentation chamber set up and did it cold. See what they say!

Wow. Three experiments showing fermentation temp doesn’t affect lager flavour. I don’t think that’s coincidence.

Perhaps fermentation temperature does matter in some contexts. Cold fermentation certainly suppresses bacteria and wild yeast, which is part of the reason lager is traditionally brewed that way. But I do think the contribution of temp in making “clean” vs “estery” beer is wildly exaggerated by homebrewers, especially by those who’e invested money, time and space in brewing fridges and temperature controllers. A recurring claim on brewing forums is that “temperature control is the single most important upgrade” to improve quality. I’ve always suspected an element of emperor’s new clothes in these claims – post-purchase rationalisation and placebo effect at work.

The comments show that a few brewers are already repositioning – now it’s consistency that matters, not temperature. So I reckon that’s the next myth, but of course I could be wrong.

Nice work.

Do it! W-34/70 is what I used to brew a lager for the first time a solid year before I had temperature control. I brewed an Oktoberfest and it turned out very yummy. It was mid September at that point and my basement was starting to cool for the winter. It was about 68F ambient, but I am sure the temp in the carboy probably free rose 2-3F warmer than that and it turned out really nice. As this experiment showed, that strain seems to tolerate high temperatures pretty well. I mean, if you can’t get temperatures below 70F or so, I’d think twice about it, but you don’t necessarily need to get down to traditional lager temperatures for it to turn out okay.

F’ing amazing! Of course, you have to do the solid and steady 50F fermentation over 4-5 weeks VS the 70F fermentation. Hard to compare them exactly too though, as they will be so far apart in time, unless you brew two separate worts, but that is another variable. Awesome work!!

Could the “No chill” method work to preserve the wort for the warm ferment batch?

Potentially, but I’m not sure it’d make a difference.

Really, really interesting, especially the reproducibility you’ve found. For me, this must be one of the most important findings you’ve shown.

I’ve avoided making lagers in my small appartment with no space to refrigerate anything other than a couple of bottles in the fridge (no cold crashing for me!). The lowest I can ferment is about 18C (controlled on the warming side only). I’d contemplated splashing out on a immerson cooler for my FV, pumping iced water, but it’s expensive and a hassle, However, going on these results, I’m more tempted to give it a go and get a tasty lager ready for summer.

What’s your aeration process, Marshall? Just curious because oxygen is supposed to limit ester formation, as is pitch rate.

Anyway, I am fascinated by this series. I think I speak for many homebrewers when I say “This is really interesting, but I’ve also had the ridiculously estery fermentation….” Lived experience tells me that fermentaion is an important part of the process, and that one and the same strain can give pretty variable results. The funny thing is, whe don’t really understand very well why.

I don’t actually mind the aspects of fermentation management, and having already invested in the whole friggin kit (I actually got the fridge for free and the warmers were necessary back when I fermented on my porch in the winter), so I probably won’t be changing much. Still, our lack of real understanding is perplexing.

As above, I have yet to attempt a lager. My “temperature control” consists of the seasons, and different parts of the house. Now maybe I’ll make a lager at my coolest setting: winter basement floor. Thank you.

I’ve used 34/70 in the low 60s for years. never had a problem with it. I even wrote about it over on my site. A weird thing is happening in home brewing where “best practices” are being proselytized as canonical laws of home brewing. “thou must ferment lager at 50 F” “thou must lager for 2 to 3 months”. We used lager yeast in the low 60s in the 1990s because we didn’t know any better. The beer came out just fine… we kept doing it. I think cool temperatures, and consistent temperatures are more important than exact temperatures or very low temperatures. Just because it can ferment at 50 F, doesn’t mean it needs too. I suspect with most yeasts, but especially with lager yeasts, that the temperature swings have a more profound impact on off flavor production.

I think you might be right. The first time I tried to make a lager was in Lebanon during the winter of 2010. Thinking that cold was better than warm, I put it on my balcony where it got in the 40s at night and the 60s during the day. It wasn’t THAT bad but it didn’t taste like a proper lager. That’s just an anecdote, but I’ve never made a bad lager since using a temperature controlled chamber.

How was the overall profile of the beer? Was it good?

It was simple, easy drinking.

The same palate prowess, that thinks your helles(kolsch) tastes like HB?

I said if I was forced to choose one, that’s probably the one I’d say it was closest to. Goodness…

After reading this post — and most of your other posts on the topic of lagers — as well as brewing a few lagers of my own with decidedly mitigated success so far…

I Wonder how the kegging vs bottling question is important for lagers. Because my lagers so far mostly range from “underwhelming” to “fruit bombs”. Granted, the later only has 22 days in bottle (or had at last tasting, at least) and might not be completely ready, but I’ve absolutely never seen (more like, tasted) a beer that was so far from being ready after 22 days).

My conditionning temperature is mostly in the hi-50ies, lo-60ies by now. Ferm Schedule was mostly your lager Schedule @50-53, with the 2nd part at 65/68F, followed by a week in the fridge at 38F. The pre-bottling samples were really clean, hence why I’m wondering about the role of bottling in all of this.

Fruitiness is probably an ester. Esters are formed by yeast when they combine an acid and an alcohol. In the presence of oxygen, however, the most prominent acid in wort, Acetyl CoA, is used for cell growth rather than esterification.

Alcohols are less easy to perceive than esters, for the most part.

The hypothesis suggested, and I have no way to test this, is that fermentation during bottling converted fusels to esters, while the esters were not present at flavor thresholds before bottling.

If I were in my BJCP role taking a test, I would recommend pitch rate increase and temperature reduction to reduce the problem. Note that oxygen will increase fusels precursors as well. My thought is to reduce fusels before bottling, and a recognition that fusels are less apparent to the senses than esters. Whether this will work, I don’t know.

I’m convinced many people confuse hop fruitiness for esters.

@Philosofool

Humm… Interesting. I thought lager yeasts were really low producers of fusels to begin with. When you’re talking about reducing temperature, I guess you meant the bottle conditionning temperature….? Isn’t 60F a bit already on the “low” side?

Also, I’m already pitching at 1.5/1.75M ml/plato.

@Marshall

That wasn’t hop fruitiness at all.

I’ll never know!

@Marshall 11:13 am

“I’m convinced many people confuse hop fruitiness for esters.”

-1pt for assumption.

-2pt for being convinced of assumption. 8^)

That was an opinion, one I’m convinced of.

@MXD I wasn’t very clear. Either (1) there’s something in the beer prior to bottling that’s important to the fruitiness you’re experiencing or (2) there isn’t and it’s all happening in the bottle. If (1) try to reduce potential undetectable compounds from prior brewing and fermentation; fusels are the most likely candidate.

It sounds like your fermentation practice is pretty solid. Are you confident of temperature control, that is, fluctuations?

More in reference to Marshall’s assumption. I think in this case he (Marshall) is likely correct. In reading the scientific literature regarding esters and lager fermentation, the main one produced at levels detectable by humans is isoamyl acetate (banana). If someone smells a lager and thinks “fruity” but not “banana”, then maybe hops is more likely.

Marshall, obviously there was no difference in mouthfeel between the beers, right? I asked White Labs a question about lager vs ale chemistry, since if the thing that distinguishes the two, other than process, is “cleanliness”, and WLP001 is as clean or cleaner (according to their miniferment data) than most of their lager strains, why not just brew with the clean ale yeast and call it a lager? The response from someone in their analytical lab was that apart from the sulfur-containing compounds released by some lager strains, one other difference is that ale yeasts tend to release glycerol, which gives a slicker mouthfeel to the beer.

There’s a lot of talk of clean ale yeast vs. lager yeast. I don’t think it’s just a matter of a lager being clean. To my taste, a lager also imparts a “lagery” character to beer. Maybe the most important is that it super accentuates the maltiness or malt character of the beer. I can’t imagine an ale yeast ever tasting like a lager yeast, at any temperature. again, that is my experience.

Try 029…

Agreed. Love that yeast!

@Philosofool

If by “stable fermentation temperature”, you mean ” assuredly kept in a range of 3 or 4 degrees”, then yeah.

My main fear is about what happens in the bottle. I guess I’ll just wait a bit and see what happens. The good thing is — it was possible to tell the beer wasn’t quite ready just by looking at it. So it might change a lot. On the other hand, I’ve never seen a beer so far from being ready after 22 days. On my third(!) hand, it wasn’t fined AND I used some wheat, so it’s something of a very hazy lager. Dunno if that has anything to do with possible off-flavors.

Great information, much appreciated. I’ll just add a recent related experience for the broadening of our information base. I recently brewed a Blue Moon Wheat clone recipe, second time I’ve brewed it. On both occasions use Chico yeast, temp controlled, yeast starter, etc. So to my knowledge all variables were very similar. The first iteration was just what you’d think in terms of yeast flavor contribution, very clean. The second batch, fermented off the charts in terms of vitality. I was blown away at the activity and the result was more like a true hefewiezen or witbier, in test flavor contributions, albeit a little less potent. IE: Cloves, esters etc.

Here’s the thing, ferment temps were the same both batches … so clearly there was another variable involved. What it was is up for theorizing, but wasn’t temp ferment schedule.

I also think perhaps if you had kept the fermentation temperature of the cold ferment at the colder temperature longer than 50% attenuation there may have been a more noticeable difference.

I have homebrewed lager for over two decades and used a lot of tradition methods, such as decoction brewing, which I believe can make a difference in flavor that cannot be exactly matched by using a different malt and no decoction. Personally I won’t brew lager if I can’t keep the primary fermentation temperature below 52F, and I usually prefer 46-48F. In the Pacific Northwest that usually means late November through February as I use ambient temps in my garage with a water bath to balance any fluctuations.

Having said this I’m surprised with the results. Maybe the length & temperature of lagering have a greater effect on flavor profile, though I know that you can also cheat on the lagering process. The traditional one week per one degree Plato probably never happens anymore and I rarely do it unless I have the patience. I do suspect that a proper procedure where the fermented beer is chilled slowly as to not stun the yeast and then held at a consistsnt lagering temperature for an extended period is more important than the primary temperature, though I assumed 70F would be far higher outside the acceptable range and would not be able to produce a beer that fit the lager flavor profile.

I know that I can tell the difference in a beer which has been brewed using more traditional methods (colder ferment and reasonable lagering) versus your “normal” Pacific Northwest lager, which in the helles style normally tastes like a cream ale. It’s because your standard American ale brewery doesn’t have the time or space to make a proper lager. They may as well make lambic with a single ale strain and package within a month of brew day. Understanding this process better can only help these breweries who “cheat” a lager into making improved products.

I’ve made a few decent ‘lagers’ by fermenting at 62-65F with Saflager S-23, then kegging and cold conditioning at 40F for 2-3 weeks. They had none of the off-flavours traditionally associated with brewing lagers at higher temperatures, and were very lager-like in the flavour profile.

You usually oxygenate the wort for lager with pure oxygen? How long time do you recommend purge O2 in wort with high OG (> 1,060) ?

Great job !!!!

I don’t ever use pure O2, it’s never been an issue.

I remember reading that there’s no point to adding O2 when using dry yeast so any speculation about O2 addition or not making a difference may not apply in this case with the Saflager product.

Hi there,

I have read you experiment and first of all that’s great. Good job and good variable control, at least for the purpose in cause! I have experience with that yeast (W 34-70) and i think that temp control is indeed a challenge but you got to have it for lagers. What I do is to pitch the yeast at a good temp, for example 14-15ºC is ok and maybe 18ºC I don’t worry, a good start like this is ok. But after 4/5 days of fermentation I drop the temp. to 10ºC for more 4/5 days or even a full week. Next I do a diacetyl rest by letting the temperature go until 20ºC or more for 2/3 days, to allow diacetyl to be fully removed. This is the most important because without the not so good (for some people) diacetyl taste in beer, we will have a crispy and clean malt flavour and hops as also. I find diacetyl rest one of the major components of making lager beers! Then drop again to maturation temperatures (2/4ºC) for 1/2 weeks. Within 3 weeks i have a good “green” lager with good malt flavour!

Of course in homebrewing it’s not so easy to control temperature but if you change the thermostat of you frig. you can manage to do that ;)!

I wonder if the use of gelatin in these experiments is somehow stripping off-flavors from the warm ferment batch. Just a thought.

If so… YAY GELATIN!!

Hi Marshal,

Once again, congrats for another welcome experiment.

2 questions:

1- how did you got a FG=1.008 (apparent atenuation of 85%)?

2- did you ever bottle condition/carbonation with dextrose/DME and gelatin?

cheers

luis

Thanks!

1. 34/70 always attenuates well for me when I use a simple, mostly Pils malt grist mashed low.

2. I only keg, no bottle conditioning.

Cheers!

Some quotes from the web:

“Fermentation temperature control is the single most important thing you can do that will make the most dramatic improvements in your beer.”

“First time brewers often rush to buy their first lager kit, planning to brew the beers they have always tasted at home. Alas, most of these projects end in disaster since true lagers can’t be fermented properly without refrigeration in the mid to low 50 degree F (around 11-12 C) range.”

“Controlling the temperature of your fermentations is one of the best ways to improve the quality of your beers”

“gaining the ability to control your fermentation temperatures is the most important upgrade that any brewer can make”

“Fermenting at room temperature results in an excess of esters (fruity or spicy), fusel alcohols, diacytl (butterscotch), and sulfur flavors.”

“Without temperature control, it’s simply impossible to brew most beers correctly. Many homebrewers underestimate its importance and therefore are doomed to brew mediocre beers.”

What do all these writers have in common? None of them have actually tested their claims empirically. All of them simply regurgitating rubbish they’ve read somewhere else.

To be fair, I’ve done plenty of regurgitating myself…

I love this site and read it immediately after every email alert. Having said that, we are talking about correlation of one variable. I suspect given the data from most of the experiments that a series of factors are at play and that they compound.

I don’t think you can say the fermentation temps don’t matter. The data doesn’t say that. What you can say is that lager yeast don’t always need low fermentation temps to produce good beer. If you read the site you can detect the skepticism of the authors themselves when confronted by these unexpected results. You will notice that they are only cautiously and slowly changing their processes.

To me, the power of this site is that it calls into question the importance of any single part of the brewing process. I hope it acts to quiet brewers that assume there is one way to do things. Here is the big question, what were the factors that moved good brewers from barely drinkable batches to brewing the good stuff?

As you said, few of us have made wholesale process changes (yet) due to single variable testing.

What some of us have suggested, a theory which I personally subscribe to, is that perhaps compounding variables may have an effect greater than two performed separately. Perhaps, when no O2 and warm ferm temp are performed together then those variables rear their “ugly” heads. Who knows.

“I don’t think you can say the fermentation temps don’t matter. The data doesn’t say that. ”

Agreed, but all the quotes I pasted go much further that that. They say temperature control the most important aspect of brewing and that disaster ensues if you attempt to make beer without it.

Even more interesting is that the three lager yeasts tested in brulosophy experiments all yielded indistinguishable warm- and cold-fermented beers. A single significant result would unreliable, buy when three tests point in the same direction you have to take seriously the possibility that conventional wisdom about lager fermentation is untrue.

Don’t know who the quotes are from, but I will say at a few of the writers/ authors that I’ve come to learn mote about have tested (some of) what they prescribe – perhaps not exactly as we do, for better or worse,

That’s most likely referring to consistency of temperature throughout fermentation. Not necessarily what that temp is supposed to be. These experiments suggest the former “may” be more important than the latter.

If I wanted to use Wyeast 2124 at ale temperatures, do I have to pitch like a lager or will pitching like an ale work?

As always, great article!

Cheers

I’d pitch at ale rates.

This xBmts made me wonder if it is possible to tell Wy1056/wlp001 appart from w-34/70 fermented @ mid 60F? Have you done this before? Are we really able to differenciate lager from a neutral ale yeast?

The IGORS from Experimental Brew just did that one.

I only saw their experiment on the 1056 vs 001,

What I meant is an experiment to test the taste/aroma of an ale vs lager yeast for example: 1056(clean ale) vs w34/70 (clean lager) with a pale lager recipe fermented @ 66 like you did for this Xbmt. Will the testers able to discern the difference?

Thanks again Marshall and your team for your great work and as a Master student, I appreciate your rigor during the experiments.

Ahh, good idea!

Damn it! Why did you have to go and do this to me? I just brewed my first lager, a nice Budejovice clone, using WLP 802. I worked so hard to keep the fermentation at 50 F for three weeks. I even bottled all 5 gallons with these really festive American Flag caps thinking that I was going to lager the whole batch at 34 F until Memorial Day or possible 4th of July. Sons-a-bitchen! Is nothing sacred anymore?Warm lagers, cold ales. My head hurts. I need a beer.

Great xBmt, by the way. I’m thinking along the lines of others here, keep the temps within a consistent range and you should be OK.

Well, certainly have not claimed all yeast strains will behave the same. Nor will had it been claimed the results will be the same every grist/ hopping bill. But so far….. results have certainly raised a few more questions.

With your experiments showing that fermentation temp for lagers (with the yeast you’ve used) does not have an effect on taste and perception, seems like the next step could be to test pitch rates, ie., using 1 packet of 34/70 vs 2 packets at cool temps, and then repeating the same experiment at warm temps, to see if any noticeable differences arise.

Similar to a previous Xbmts https://brulosophy.com/2015/07/28/yeast-pitch-rate-pt-3-ale-vs-lager-in-a-kolsch-exbeeriment-results/.

No brewing myths were harmed in this experiment. This is well known amongst lager brewers- BrewingTV did an episode at least 4 years ago recommending the Weihenstephan 34/70 strain for lager attempts without temp control as do countless threads on HBT and the wyeast site even lists it as an option for cal commons. You picked a lager yeast known for it’s forgiving temperature tolerance (its even printed on the pack) so I’m not surprised by the results. That said, I’ve used the strain for dozens of beers and I do think there is a detectable difference in a pale beer. I know you’ve addressed the accusation of “shitty palates” but I’d trust this result more if the panel included members of lager brewery sensory panels rather than “craft beer enthusiasts” (craft beer enthusiasts are by definition lager haters). People who taste pale lagers for a living will be able to taste the difference.

I’ve done it with WLP800 as well.

Kind of a dick reply, but it is an interesting idea to do a lager-off exBeeriment and use only self-professed lager aficionados as the judges. Could be interesting.

Sorry if that sounded dickish. The person I linked to this from had referred to it as “another brewing myth shattered”. I’m actually happy you got those results as it confirmed what I had suspected. If you do a replication with professional lager tasters, maybe go lite american lager. The less flavor, the more fermentation differences will stand out and I do think the differences will be subtle.

What if we let only unicorns judge the beer. Maybe that would get a significant result. 🙂

Maybe, but most people are not brewing beer for lager brewery sensory panels. If only a small percentage of highly trained individuals can detect a difference in a beer, then does it really matter?

I do like the idea of 001 or nottingham vs 34/70 at 66F (and ideally vs 34/70 in normal lager conditions). If the sole point of the whole lager brewing process is to brew clean beer, and this can also be accomplished using a clean ale yeast at normal ale temps, then fuck it. Who cares about purity of process if the net result is the same (at least to people who are not on lager brewery sensory panels)?

Exacly! I’m wondering if using lager yeast is really necessary to have ”that clean crisp taste of lager”.

Further to this point, I was looking at the mini ferment data for wlp001, 029, 800, and 830, and for the compounds they looked for, 001 is as “clean” as 800. Of course, there’s no data for “crisp” though.

I think I’ll split a batch between Chico and lager yeast at 66F and see what my beer-loving, scientist but not brewing scientist palate thinks.

I’m just used to people (including myself) chiming in about how things would be different IF. It’s healthy skepticism, but I think we are really forging into new ground with these exBeeriments. Do some for yourself and see if you are as good at detecting differences as you think you are.

I used to religously separate trub from my wort. Then, I read the trub exBeeriment, and it has changed my brewing practice. My beers are at least as good as before, probably better now that I ferment on the trub. I also read about a very controlled german pils exbeeriment in germany in which they did some cloudy mash vs non-cloudy and truby wort vs non-truby, and the results are very counter to common wisdom.

Oh, and that didn’t SOUND dickish, it WAS dickish! Just kidding, dude. Brew on!

Its good that people chime in, if this is science you need your skeptics to peer review. I have little desire to do rigorous experiments but anecdotally, in the last 6 months alone I’ve brewed the german pils recipe from BCS 7 times and split batched most of them. I know I can’t tell the difference between most of them but I have run them by a homebrewer who worked at a lager brewery and he was scary good at telling the differences – I’ve had ranked bjcp judges not call out US-05 vs lager yeast but he called it as “tasting like US-05, not wy1056 but US-05”. I scored 80% on the BJCP tasting exam but I’m a total fraud. These things to me are 1 part tasting to 2 parts cold reading and believe me, memorizing the style guide can take you most of the way to a good score on the tasting exam. But I have witnessed some great tasting. I guess what I’m saying is I believe it doesn’t matter much for homebrewers (you have shown that you can bend the rules and very few beer judges will bust you on it) but Macro brewers have been bastardizing lager traditions for a century and as far as I know, they are still cold fermenting. If they could get away with something easier I’m sure they would.

Right, but you compared something different (a pilsener fermented with an ale yeast) than what Marshall did (not saying you didn’t know this, but it is significant). But supposing that BPCL judges could tell the difference, even if that were the case then there’s not reason for large lager breweries to not adopt the practice, since most people probably couldn’t.

Like todd, I’m now questionning my abbility (and others) to really differenciate us05 vs lager yeast. I started a thread on homebrewtalk of ale vs lager http://www.homebrewtalk.com/showthread.php?t=571958

I think it may have already been mentioned but it would be interesting to see if temperature stability is a factor ie having a brew fluctuate 5 degree C each day vs stable temp

It’s on the list!

I’ll offer another vote for a test based on temperature changes – this would be a very important test to run IMO. Perhaps a 3-way exbeeriment? One at 10C, one at 18C and one that fluctuates from 10 to 18 each day. By making the limits of the fluctuating beer the same temps as your cold & hot beers you would isolate the effect of change in temperature from temperature itself. Might make your tasste testing a bit more complicated but I’m sure you can do it!

It’s coming!

Haha…don’t mean to rush you, just excited about the results!

I personally pitch much warmer for lagers and then throw it in to my fermentation chamber. I generally pitch at about 58-62F depending on what my ground water can get it down to in a reasonable amount of time. I then pitch my starter and let the fermentation chamber bring it down over the next 24hrs. I have a plain STC1000 controlling my minifridges (2 of them) and I’ll generally set it for 56F right away and then the next morning or that night (whatever is roughly 12hrs later) I’ll set it down to 50F on basically all my lagers (I use WLP830 on almost all my lagers, but I do use Oktoberfest and bock yeasts on rare occasions) which usually ends up hitting equilibrium a few hours later.

I like to try to encourage the yeast towards a bit faster start then pitching at 50F. The couple of times I’ve done it at 50F, even with a fresh starter only cold crashed for 24hrs before pitching it often takes 12-24hrs to get noticeable activity going with my lagers. If I start it at 58-62 and ramp down, it is often only 4-12hrs before I see noticeable activity. I also do the warm ramp, but I let my lagers and ales chill till it seems like activity is pretty much done, which tends to be 6-8 days for lagers and 3-5 days for ales. Then I’ll increase the temp to room temperature or 68F, whichever is cooler for lagers for 2-3 days before I drop it to 40F for 1-2 weeks or with ales I raise it to 72F or room temperature, whichever is cooler (except Belgian yeasts which I crank to 75F) also for 2-3 days before I cold crash at 40F for 2 days and then bottle.

How long it is left warm, when I ramp it warm and how long it is lagered or cold crashed depends on when I brewed and when I can bottle. Sometimes cold crashing is only 24hrs, sometimes it is 4 days. Sometimes I lager for a week, sometimes it is 2-3 weeks if life gets in the way. Sometimes I leave it warm for 2-3 days, other times it is a week.

The only real temperature fermentation tests I have done, more by accident is Belgian yeasts. Regular White Labs Belgian ale yeast I’ve found is NOT a fan of cooler temps. Fermented it once at 65F and it produced massive amounts of H2S that took a couple of months to dissipate. The next time I brewed with it (same culture line) and kept it up around 72F, very little H2S production.

This would ostensibly have implications for the required starter size for lagers.

Do/did you add any mineral additions or pH adjustment to your RO water?

Yeah, I built it up to Bru’n Water’s “Yellow Bitter” profile with 5.2 pH.

This is merely an anecdote, but contributes to the discussion all the same. I used to manage a small homebrew shop in NYC and when we would run out of Wyeast 2112 Cal Lager (Anchor Steam) for our Cal Common kits I would always suggest a packet Saflager 3470 and just tell them to “keep it as cool as possible”. Several people took me up on the suggestion but I never got to taste the finished beer. One person did bring in our kit, brewed around 70F (no temp control) and I was dumbfounded. It tasted like a clean lager (and kind of like anchor steam mostly because of the ingredients). I made everyone in the store taste the beer because I thought I was nuts.

Very interesting experiment, and thank you so much for sharing the results!

I am wondering how well you liked the SAFLAGER W-34/70 yeast.

Would you consider it slightly “inferior” to the liquid equivalent? How about doing a dry yeast vs liquid yeast comparison for this strain?

Keep up the good work like always!

-Frank

I’ve compared the 2 in the past informally (i.e., not an xBmt) and don’t recall telling much of a difference. Considering the fact Russian River and Firestone-Walker both use 34/70, I’d say it’s probably a good strain. One thing you might consider is harvesting slurry and repitching that in subsequent batches, I believe Vinnie once said he has good luck doing this for his lager beers.

Thank you for the prompt response!

I am currently brewing with WL002 and plan to re-pitch it 3 or 4 times, and after that moving onto a Kolsch, schwarzbier, and then an Oktoberfest-style beer. Initially I planned on using WLP029 and buying a stir plate. However, noting your experience with the 34/70 I’ll go for it instead and forego the started/decanting and ferment in the 50s.

Keep the experiments coming! Such a great site indeed!

I’d be interested to see how this experiment fares with a much lesser hopped lager. many recipes I’ve seen which replicate bland lagers seem to be around the 15-20 ibu mark. I wonder whether high ferments would still work. I tried it, and was incredibly careful with every process, and my w34/70 gave off lots of harsh pear esters.

Brewing is not as picky as people think it is. I’ve screwed up a lot of beers that still came out fine. Time heals everything

I recently brewed a slightly modified version of the “Bia Hoi” recipe from the Speed Brewing book and she recommends lager yeast at very high temps.

Recipe was 3 gal batch with 3 lb pilsner extract, 8 oz rice syrup solids and .25 oz hallertau hops. 60 min boil. I used S-23 dry lager yeast and set the fermentation fridge at…. 76 F!! Cold crashed and used gelatin. Guess what, it was AMAZING!!!! Super clean flavor and a perfect summer beer.

I have a 5 gal batch fermenting now that I did with a 20 min boil (first time doing one that isn’t 60 min) with 1 oz hallertau and used some magnum to get where I wanted. I’m usually a by the book all grain brewer but these exbeeriments really get you thinkin’.

Last winter I brewed a Doppelbock with S-23 at cool-ish temps in a guest bathroom. No water bath, no temp control, just in a spare shower that hung out between 65-68 most days. I called it Approximator.

I will say two things – I think I was a the top end of the alcohol tolerance for the strain (so it started a bit sweet), and it was a little estery, probably due to that extra stress, so the first couple bottles weren’t great. But after just an extra week of conditioning, it was fantastic.

With this xBmt somewhat supporting my anecdotal results, I won’t be afraid to try it again this winter with a few different lager styles.

Am I crazy or was the recipe originally included on this post?

Something appears to be wrong with the BeerXML program we use, I’ll get it fixed up soon!

Awesome! Thanks much! I was thinking about brewing a 10gallon batch of this over the weekend.

It was super simple, something like 95% Pils malt and 5% CaraPils, all noble hops, and 34/70 yeast.

I was checking to see if I wrote it down correctly. Here is what my notes show.

11 gallon batch

OG 10.51

IBU 30

17 lb Bohemian Pilsner

2 lb Vienna

1 lb Carapils

1 oz Magnum (60min)

1 oz German Spalt Select (20min)

1 oz Tettnanger (10 min)

Liquid is not dead Urquell vs 34/70 on the same beer produces very different results

I mean, the closest we can get to “Urquell” is WLP800 or Wyeast 2001, and since we haven’t pitted either of those against 34/70, I don’t really know. But I wouldn’t be surprised if they were more similar than you presume.

I was wondering, would the 34/70 fermented at the higher temps be able to achieve the 2 week turn around like the WLP029?

– Thanks!

Definitely! At least in my experience.

After seeing these fermentation temperature exBeeriments, I’ve finally decided to try making my first lager – a German Pils. My basement is a pretty steady 63-65 degrees, so I think this 34/70 yeast will work just fine.

Report back!

Thanks again for another great piece of information. Having read a many of your X-beeriment results, it seems that:

1) Under-pitching or over-pitching doesn’t affect beer taste

2) Fermentation temperature doesn’t affect beer taste

3) Hot side aeration doesn’t affect beer taste

4) Yeast strain (playing in the same league) doesn’t affect the beer taste

I’M just wondering, is there anything that affects beer taste ? There must be because I have succesfully brewed very bad beer in the past and maybe not so long ago…

Maybe sanitation and the grain bill are the only thing that matters after all.

If one was to plan a “warm” fermentation say like low to mid 60s based on these results do you think 2 packets of 34/70 is still necessary? Can’t really figure out the yeast calculators for that scenario since it’s a lager yeast but ale temperature. Thanks!

No, it doesn’t mean these things don’t affect taste, it just means the delta between 2 beers is below detectable when everything else is equal. You are assuming there is some sort of transitive property but individual tests don’t prove that (and human perception generally doesn’t work that way). The tests don’t show that if A + B = A and A + C = A then A + B + C = A. Consider the extreme example: I can throw a tsp of baking soda in a 5 gallon batch and not notice it, I can throw a tsp CaCl into a 5 gallon batch and not notice it, but put both in the same batch and some noticeable chemistry will happen. All of those things probably matter, just not as much as people originally assumed given everything else is equal. …except hot side aeration which is only cold side aeration denialism (it only ever afflicts brewers who bottle condition and don’t purge their transfers)

OK. I finally got around to trying this myself, and brewed up a batch this Sunday just gone (Aug 27th). Kept things nice and simple. 10lbs of 2-row from my local maltster, single infusion at 150F, no sparge, 90 minute boil with 25IBU at 90m and 2oz of Czech Saaz added at 5 minutes. Whirlfloc, 15 minutes of hot whirlpool and then knockout into the conical at about 85F (warm groundwater sucks)

Chilled down to 66F using the glycol and pitched one pack of rehydrated 34/70. Nicely fermenting away at a pretty steady 66F the next morning. Pulled a gravity sample this evening (Aug 30th) and it’s sitting at 1.011 (temp bumped up to 72F to get that final point or two of attenuation).

Moment of truth: the sample tastes damn near perfect. There’s a touch of residual sweetness (to be expected), a slight tang from the suspended yeast but no hot alcohol, no phenolic or ester driven off flavors, no diacetyl or acetaldehyde, no nothing.

I am really looking forward to getting this into the keg and on gas, even now theres a really lovely bready malt flavor (Epiphany craft malt 2-row) with Saaz flavor for days. Once this gets some gelatin and a couple of days cold it’ll be easy drinking all day long.

Awesome! Looking forward to hearing how the finished beer turns out.

Could it be temperature fluctuation that is the problem?

Start brewing in garage, cupboard, back of the kitchen. Temp all over the shop. Ropey beer.

Invest in temp control, nice constant temp. You dial it cool as you heard you should, great beer.

2 variables changed. Perhaps you are looking at the wrong one…

Perhaps the Safalle folks have developed a strain (whether knowingly or not) that is able to produce a clean beer at a variety of temperatures because *that’s how homebrewers brew*.

It might be more instructive to develop a screening design experiment of 1-gallon batches given a number of different variables. Knowing what to look for and how to score would also be very important in the evaluation.

I get similar results from Imperial, White Labs, and Wyeast versions of the same strain.

This is very interesting indeed, I am about to try to make my first pilsner style lager (and second beer ever) in the UK where my garage is south facing so could fluctuate in temperature from about 5°C (40°F) to 15°C (60°F) lower as the winter gets in to its stride (and lower fluctuation as fewer daylight hours) – I need to actually take measurements on this, it all depends on people’s heating in the flats behind and above the garage.

I brewed my first lager/Pilsner after reading this. Pretty basic Pilsner malt backbone with a little Vienna malt. Willamette and cascade hops during the boil to the amount of around 20ibus. W-34/70 yeast. Fermented at 62 for 4 days. Tested at 1.016 and raised temp to 66 for 4 days. Finished at 1.010. Moved to keg, carbed and left for 3 weeks at 35 degrees. Poured and boom, amazing Pilsner taste and flowery from the hops.

Never wanted to upgrade equipment to lager, but I can ferment in low 60s. Thanks for the article and info!!

Oh and also- I only used one pack of yeast and did not have a starter or rehydrate. Just added oxygen and sprinkled on top.

I’d just like to mention that I’ve made 20 x 1 gallon brews with W34/70 using Morgans lager kits and various enhancers, half using in the refridgerator @10C and the same in a tub of water at 20C. That was four months ago and it’s been a hot summer down here and both seem the same to me,ie. delicious. So I’m thinking the latter is a lot less work.

By way of ps. why did I make 20 x 1 gallon? It was for a contest with a decent prize sponsored by Morgans for using their kit. I used the three different Coopers enhancers plus combos with Hop Teas both cold and warm fermented and in some cases the wort cold crashed before hand. I then selected the two most promising brews to enter. Alas it was for naught. Gushers and churlish judges left me among the also rans. But it’s been very good for my summer.

RHAHB!

Hi, I’m relatively new to home brewing and only just started all grain brewing. I’m planning on making a pilsner next. I was going to use saflager S-23 but after reading this thread I’m going to try the 34/70. Am I correct in saying that (all things being equal) I can hope to make a decent beer by fermenting with 2 x 34/70 at 18°C in an approx 22L batch for about three weeks. Then bottle for about two weeks, leaving at room temp to carbonate, before storing in a fridge at lowest temp setting?

Thanks in advance for any advice. Mick.

Hi Mick, I believe all of us have fermented delicious lager styles using 34/70 at ale temperatures. Only way you’ll know, though, is to give it a go yourself!

I will certainly do that, thanks. I’m happy enough to give the fermentation side of things a bash.Can you tell me if the 2 weeks in bottles at room temp followed by fridge part sounds about right?

I might move 1 bottle to the fridge first, let it chill then open it to ensure carb is right before moving all to the cold. My guess is 2 weeks will be good enough.

Fair play. Thanks for the advice.

One thing to keep in mind about bottle conditioning is there’s room temperature and there’s the temperature of your room. In full disclosure, I haven’t bottled in 5+ years since I started kegging. However, when I used to bottle, I’d keep them in my basement which stayed pretty cool. It would take about 4 weeks for my bottles to carbonate up properly. Being an impatient new brewer, I started storing them in a water bath in a Rubbermaid bin with a fish tank heater and aquarium pump to circulate the water, keeping the water about 72F. Bottles were upright and submerged approximately halfway. They would be carbonated pretty well in 2-3 weeks, but if I’m being honest, it still took about 4 weeks total until they seemed “ready”.

My winter temp control consists of my concrete floor in my utility room and the counter of my workshop. Living in Canada the concrete floor is 13C or 55.5F from November through April and is the ideal heat sink. I brew extract with steeped grain recipes. Always pitch under 20C or 68F. Have tried a dozen yeast products including WLP liquids, K-97, US-05, Notty, 34/70, S-23, T-58, Windsor etc. 34/70 is the least obtrusive strain by far for my “mock” lagers. US-05 is second place. My best recipes have been a Mill Street Tankhouse Ale clone using US-05 and a Creemore Springs lager clone with 34/70. Same method. Pitch at 66F then ferment at ambient 56F for 35+ days racking to secondary at 21 days. 4 oz of dextrose at bottling (per 5.5 US gallons) and minimum 6 weeks carbonation at 56F. Any beer I have pitched above 76F has been estery.

In summer the floor is 18C or 64F. Beers made last summer are noticably more estery. Still good!

Far out, what a great xBmt! Thanks for sharing this pearl. In saying that, I reckon I’m still not willing to ferment a lager at warmer temps… the wait time versus risk of dumping a batch because of esters is unpalatable!

I think the true test of this xBmt is to try the beers after months (maybe a year) of cool/cold storage. As noted by most people, lagers tend to age okay for awhile, but ales tend to go down quite fast. I know you serve from the keg, but bottle a few and let them sit for awhile and then serve them again…and tell if there is any difference when you age them.