Born and raised in Southeast Michigan, Mike Neville currently lives, works, and brews exBEERiments in Dearborn, MI with his wife and daughter. Mike earned his bachelor’s degree in Secondary Education from Central Michigan University, but decided to pursue a career with one of the Big Three Automakers. Since 2015, he has been an active member of the Motor City Mashers Homebrew Club where he has served as President, Vice-President, and Education Chair. As a BJCP Certified judge, Mike regularly enjoys judging competitions in Michigan and surrounding states.

Born and raised in Southeast Michigan, Mike Neville currently lives, works, and brews exBEERiments in Dearborn, MI with his wife and daughter. Mike earned his bachelor’s degree in Secondary Education from Central Michigan University, but decided to pursue a career with one of the Big Three Automakers. Since 2015, he has been an active member of the Motor City Mashers Homebrew Club where he has served as President, Vice-President, and Education Chair. As a BJCP Certified judge, Mike regularly enjoys judging competitions in Michigan and surrounding states.

| ABOUT MIKE |

How did you get into brewing?

Late in my college career, I frequented local craft breweries and became very interested in the brewing process. I was gifted a basic starter kit and brewed my first batch, which was essentially undrinkable (more about that later). I put the kit away for a few years and for reasons I can’t remember now, decided to pull it back out and give it another go. In the beginning, I frequented resources like The Brewing Network and Northern Brewer’s Brewing TV. After about 20 batches on my own, I attended my first Learn to Homebrew Day at Adventures In Homebrewing where I met Ray Bilyk, the President of the Motor City Mashers at the time. Ray took me under his wing and introduced me to the rest of the club. That’s when I really fell in love with homebrewing; not just the brewing process and what is produced, but the comradery of my club members, some of which are my closest friends today.

What was your first batch and how did it turn out?

Yes, back to this…

My first batch was an Irish Stout extract with steeping grains recipe, and from what I recall, the brew day went okay. I brewed up my concentrated wort, added it to the fermentation bucket, topped-up with water, pitched, and waited 2 weeks. During fermentation, I collected a variety of used bottles then used the one step cleaner included in the kit to prepare them, not knowing they also needed to be sanitized. After bottle conditioning, I was left with a variety of outcomes– it was a new adventure every time I opened a bottle. Some were gushers, some flat, some had unusual floating particulate, and nearly all were downright undrinkable. Needless to say, most were dumped down the drain.

How did you get involved with Brülosophy?

After serving as Vice President and President of my club for 4 years, I wanted to take a step back and serve as Education Chair. As an avid reader of Brülosophy, I was always envious of the tasters who were able to take part in the xBmts. I wanted to be able to taste the effect of the variable being run, so I essentially copied everything Brülosophy was doing and brought it to my club as the educational piece of our meetings. I reached out to Marshall to ask about the process he used on the triangle test, just to make sure I wasn’t missing anything, and he basically said if I was serious about doing this, there was an open spot to fill. After more discussion and a lot of questions on my part, I jumped at the opportunity to join the crew!

What xBmt has surprised you the most?

The xBmts that have surprised me the most are those dealing with mash temperature and fermentation temperature. When I first started brewing, and even still today, it was beaten into my head that mash temp and fermentation temp, no matter how small a difference, will have a perceptible impact. While I acknowledge that every xBmts provides a single point of data, it just seems over and over that these particular variables might not matter as much as traditional homebrewing dogma suggests.

Have the xBmts influenced your current brewing perspectives?

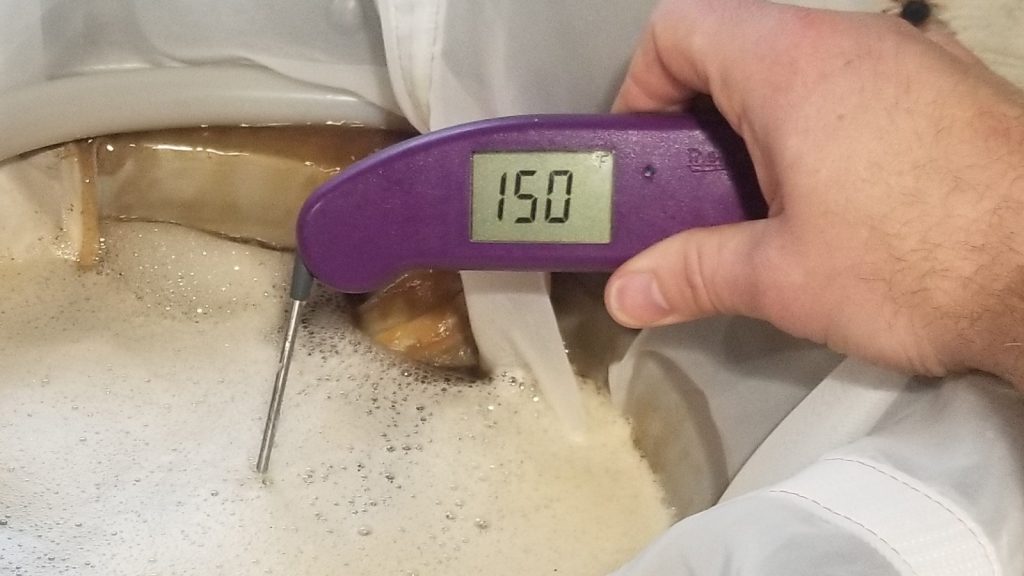

The xBmts have definitely influenced my current brewing perspectives. If I’m targeting a mash temp of 150°F/66°C and it reaches 154°F/68°C, I worry about it way less than I used to. Same goes for fermentation temp– if a beer dips below or drifts above my target, I don’t really worry about it all that much. The water chemistry xBmts have solidified in my head that water matters. I’ve also really enjoyed the xBmts done on base malt and subbing portions of base malt for others, whether it be for cost savings or malt availability. Brewing has been described as a very robust process with a lot of built-in forgiveness, and the xBmt’s that come back non-significant have shown me that it may be even more robust and forgiving than originally thought.

What are your 3 favorite styles of beer?

Kölsch

To me, it doesn’t get much better than Kölsch. I love brewing and drinking this crisp, clean, thirst-quenching style. Good for any situation.

German Pils

Much like Kölsch, German Pils falls in the same pale, refreshing category that is good just about any time. Whether golfing, doing yard work, or having a couple slices of pizza, the bready maltiness and firm hop bitterness is hard to pass up.

American Pale Ale

American Pale Ale is the style that made me fall in love with craft beer. This style can showcase an array of different hop varieties from tropical and citrusy to piney and resinous, all supported with a firm malt backbone. I’m also a big fan of experimenting with new hops to create different flavors of Pale Ale.

What are your favorite ingredients?

Malt: Weyermann German Pilsner malt

Crackery, doughy, white bread, the classic German Pilsner base malt perfect for all those delicious German Lager beers.

Hops: Saaz

Saaz is my current favorite hop variety just based on the types of beers I’m brewing most these days. I use it in my Kölsch, German Pils, and just about any other clean German lager beer I brew, as I love the mild floral and herbal notes it contributes.

Yeast: Imperial Yeast G03 Dieter

Sensing a trend? It’s all about Kölsch for me! Dieter is by far the best Kölsch yeast out there, in my opinion, and it has range– I’ve used it for American Pale Ale, IPA, Cream Ale, Helles, Pilsner, Cal Common, American Amber, and American Brown Ale, just to name a few.

What’s your desert island beer?

This is a tough one for me, but Founders Solid Gold is the bomb. Crisp, clean, easy drinking. I can drink this beer just about anytime, anywhere.

What music do you listen to while brewing?

NOFX, Teenage Bottlerocket, Street Dogs, The Pogues, The Dubliners, Dropkick Murphys, The Tossers, Gaelic Storm, Flatfoot 56, Flogging Molly, Me First and the Gimmie Gimmies, Against Me!, Alkaline Trio, Reel Big Fish, Ramona, The Lillingtons, Social Distortion, Bayside, The Bouncing Souls, Pat The Bunny, The Briggs, Rancid, Green Day, Brand New, Say Anything, Senses Fail, Primus, Sublime, Sigur Ros, Wheeler Walker Jr., Old Crow Medicine Show, Lucius. Sometimes I listen to Your Mom’s House Podcast, The Monday Morning Podcast, or The Pat McAfee Show, and on those fall Sunday brew days, I usually watch the Detroit Lions lose.

What else do you enjoy doing besides brewing?

When I’m not brewing, I enjoy playing golf with my Sunday golf bag at least once a week in the summer. I’m also a big fan of cooking, grilling, and have more recently been going down the meat smoking rabbit hole. I love going to concerts and traveling with my wife. I also love spending time with my young daughter and have been very lucky to be around for most of her firsts since I’ve been working from home.

If you could go back, what brewing advice would you give yourself?

Just chill dude. Maybe it’s because I spent so much time worrying in the beginning, which solidified my process, but when things don’t go as planned, I’ve realized I don’t need to worry about it too much. That doesn’t mean I’m careless, it just means when I miss my volumes, gravity, mash temp, or ferm temp, I just roll with it and adapt.

| BREWING GEAR & PROCESS |

While I’ve done a majority of my brewing on a 15 gallon kettle and propane burner that I later converted to electric, I’m currently using a pair of 10 gallon Bräu Supply Unibräu systems.

Pre-Brew Preparation

I start every batch by designing a recipe in Brewfather, which I’ve found is incredibly intuitive and has all the tools necessary to ensure a precise brew day.

My local water comes from Lake Huron and the Detroit River, which I simply draw from the tap and add a Camden tablet to before adjusting with minerals to my desired profile. Once that’s taken care of, I weigh out the grain with the Smart Weigh Postal Scale then run it through my Barley Crusher mill.

I typically prepare my water and grains the night before to make for a smoother start to my brew days.

Brewing

After collecting the water and adjusting it to my desired temperature, I flip the switch on the controller to get the water heating for the mash.

When the water reaches strike temperature, I drop the grain basket lined with a fabric filter from The Brew Bag in and stir to incorporate the mash.

Next, I use a Thermapen Mk4 to check the mash temperature.

It’s usually during the mash rest that I weigh out the kettle hop additions.

Following the mash rest, I lift out the grain basket and let it drip until I’ve reached my target pre-boil volume, after which I boil the wort then chill it with my JaDeD Brewing Hydra immersion chiller.

Next, I rack the chilled wort to my Spike Flex+ and attach it to my glycol rig, which is regulated with an Inkbird controller, before pitching the yeast.

Before fermentation is complete, I often cap the fermenter to build up some CO2 pressure before cold crashing.

Packaging & Serving

When the cold crashing step is complete, I transfer my beer to CO2 purged ball lock kegs.

Filled kegs are placed in my 4-tap keezer where I typically hit burst carbonate by hitting them with 40 psi for 16 hours before reducing the gas to a serving pressure of 10 psi. Using this method, my beers are usually ready to serve 2-3 days after packaging.

My keezer has a simple 4-way manifold for gas distribution to each keg and I serve through Stainless Steel Intertap Beer Faucets.

Cleaning & Sanitation

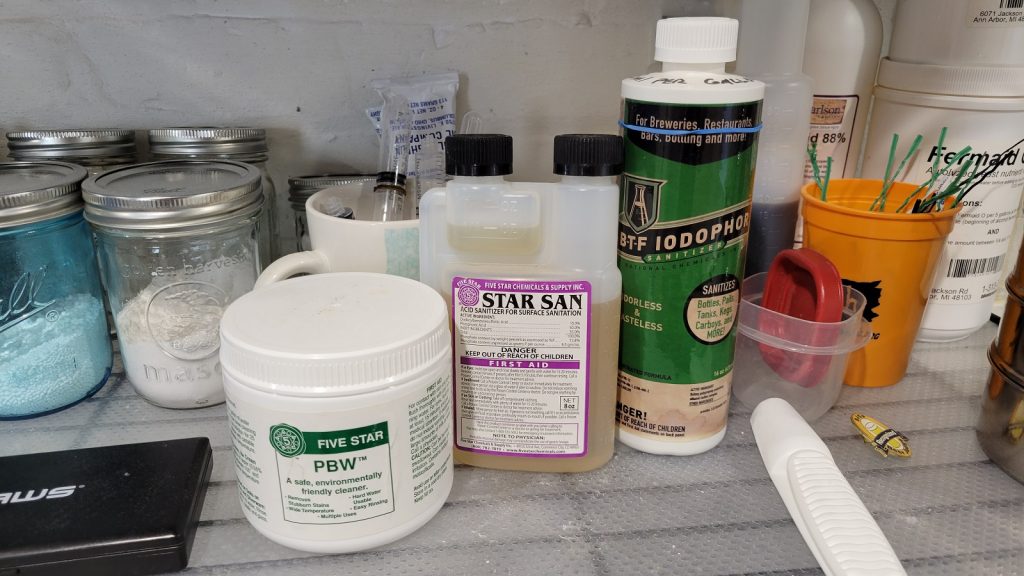

I clean my gear with PBW and sanitize my cold-side equipment with Star San, though I occasionally use Iodaphor to mix things up.

I do all of my cleaning immediately after brewing so as to avoid having to do it later. I’m fairly neurotic about keeping things as clean as possible, so every piece on my kettle is broken down and soaked in PBW after each brew session.

Other Stuff

I’m a big fan of canning beer, as cans are lightweight, impermeable to light, and nearly unbreakable, which is great for shipping. I’ve got an Oktober BenchMK Drill-Powered Can Seamer that makes canning beer super easy. In addition to Oktober making high quality gear and offering great customer service, they’re based out of my home-state of Michigan.

Contact Mike via email at mike@beerconnoisseur.local and feel free to leave any questions in the comments section below!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!