Author: Marshall Schott

My wife hates beer. Every once in awhile she’ll nurse a taster glass of Flemish Red, but for the most part, beer “just taste like beer” to her. But she absolutely enjoys a good hard cider. So a couple years ago, I researched different cider making methods, ultimately stumbling upon a very popular Apfelwine recipe that recommended the use of store-bought apple juice. I gathered my ingredients, swapping the dextrose for brown sugar, and had my first batch going in little more than 20 minutes. Three weeks passed and the concoction appeared to still be fermenting, which multiple hydrometer readings over 3 days confirmed. After another 3 weeks, the golden liquid had dropped very clear and the SG had stabalized… it was then that I realized I’d just made a 9% ABV apple wine. Even with nearly 3 volumes of CO2, my wife could barely stomach the stuff. I’d failed… and I certainly had no plans to drink it. Thank goodness for my brother-in-law who spent a few good evenings pounding glass after glass of the stuff so I wasn’t forced to shamefully pour it down the drain.

Without returning to the web to do any research, I made another batch with a couple changes in hopes of retaining more apple flavor and keeping the ABV a tad lower. I used the same store-bought apple juice, threw it all into a sanitized carboy, and fermented it with a quick working ale yeast. No sugar, no wine yeast, just juice and ale yeast. Three weeks later, I kegged and carbonated what ended up being a 5.4% hard cider that was pretty damn tasty!

Alas, the cider was far too dry for my charming companion. At 1.004, this is understandable, though I had no problem at all ripping through that keg. When it kicked, I threw together the same simple recipe, only this time I added 4 lbs of mixed berries. It came out better than I expected, another easy drinker, though still not exactly what the woman of my dreams was seeking. She deserved better than this.

With a big 4th of July/1st year birthday party approaching, I figured now was the perfect opportunity to try my hand at a technique still foreign to me. We’d recently shared some Ace hard cider, which my wife claimed was her favorite. I now had something to aim for and I knew for certain I’d have to back-sweeten my cider to get anywhere close to the flavor of Ace’s offerings. I’d read about back-sweetening numerous times, but always felt a little wary working with the chemicals required to halt the yeast. Anyway, I swapped my panties for big boy britches and forged ahead. Here’s how simple it was:

| INGREDIENTS |

– 5 gallons preservative-free Apple Juice (or cider, if you prefer). I usually get whatever’s on sale, which happened to be Tree Top on this occasion. I’ve used Best Yet brand apple juice and it has always worked well.

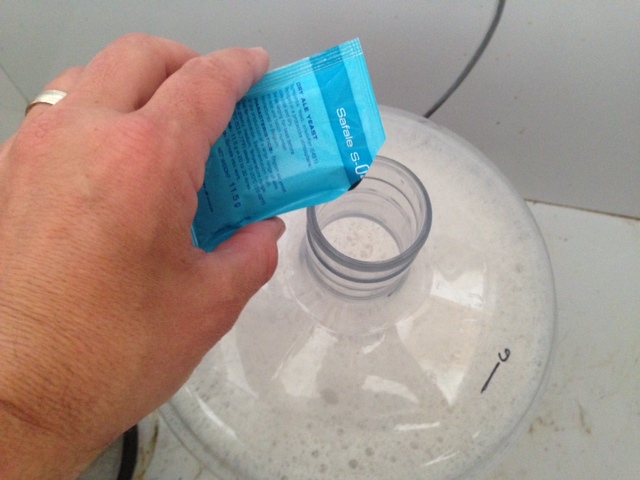

– 1 sachet SafAle S-04

– 0.5 tsp Potassium metabisulfite (Campden tablets)

– 2.5 tsp Potassium sorbate

| PROCESS |

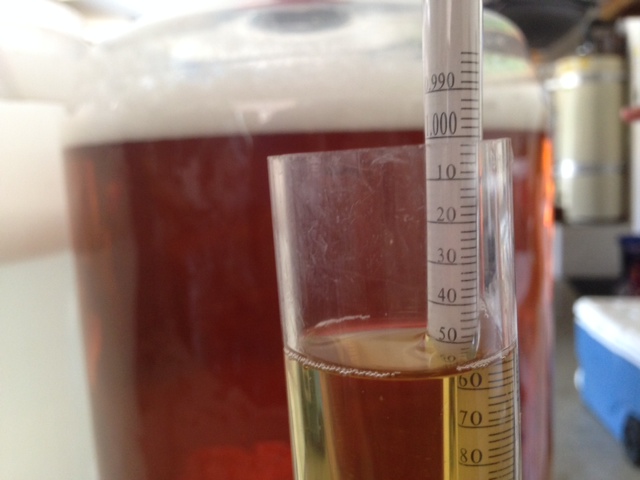

Step 1: Measure the SG of the AJ in order to later calculate ABV.

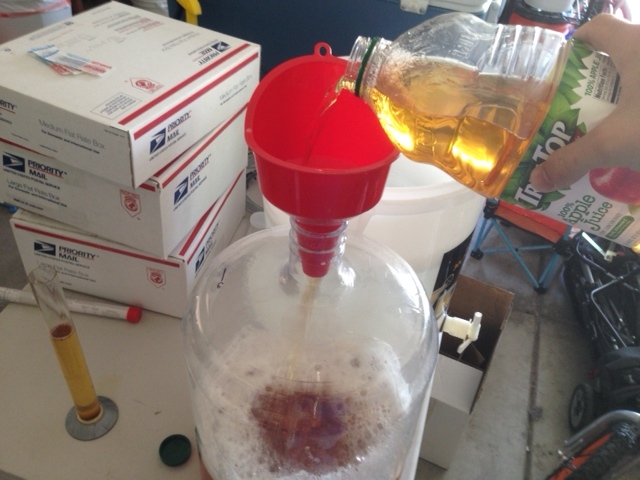

Step 2: Dip top of AJ bottles in sanitizer before opening then pour into sanitized carboy.

Step 3: Sanitize top of yeast sachet then sprinkle on top of AJ

Start to finish, the brew day took less than 11 minutes… a nice change of pace from the typical 4-6 hours it takes me to make the same amount of beer!

Step 4: Ferment at 64°F to suppress ester formation, producing a very crisp and clean final product.

Step 5 (optional): Once fermentation activity has settled down a bit, which usually takes about 3 days, I like to bump the temp up a few degrees to encourage the yeast to finish a little faster. Since I had to use my fermentation chamber for beer, I moved the cider into my 74°F degree guest bathroom (the “sour shower”).

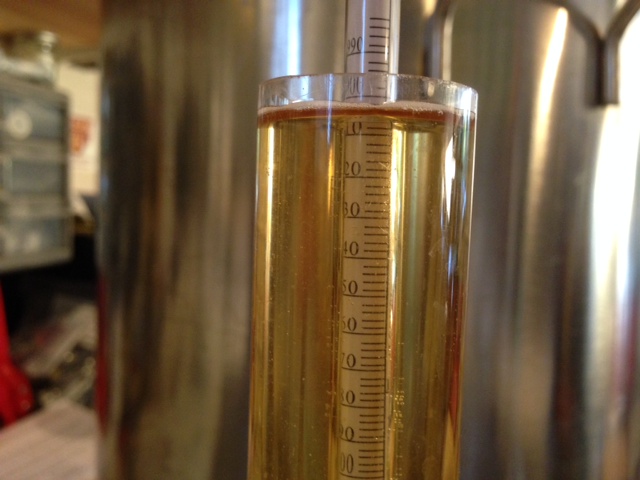

As is often the case, the krausen reappeared after the move, but only stuck around for a couple days. I took an initial FG reading after 11 days of fermentation.

I measured the gravity again 5 days later and found it had dropped a bit more.

Step 6: Add potassium metabisulfite and potassium sorbate to cider, swirling the carboy gently to incorporate, then allow it to sit for 24 hours. Some people prefer to rack out of the primary fermentor into a secondary carboy with the aforementioned chemicals. I’m a fan of single vessel fermenation, but whatever floats your boat will work here.

Step 7: Back-sweeten and package. I used 2 bottles of 100% apple juice concentrate that were totally thawed, just poured them into the sanitized keg and racked the finished cider on top of it.

Step 8: Carbonate to your liking. I prefer my hard cider sparkling and let it sit at 30 psi for 48 hours before decreasing the pressure. After another day at 13 psi, the carbonation was just right.

From bottled apple juice to delicious hard cider in just about 3 weeks, not too shabby. The best part is… SHE LIKES IT! I’ve succeeded in making a beverage my wife actually enjoys, even more than some commercial varieties. Besides adding a very pleasant sweetness, the concentrate also seems to have imparted some body to the cider, as it just feels more full than the drier versions I’ve made in the past. I have a feeling this keg will be one of the first to blow come July 4th!

| UPDATE 10/2016 |

I’ve made many batches of hard cider using store bought apple juice since writing this article and I’ve made a couple changes:

– I now use Danstar Belle Saison yeast almost exclusively. It seems to require a little longer to fully finish fermenting, but I really like the character it adds. With this yeast, I start fermentation around 68˚F, leave there a couple days, then let it ramp up naturally to anywhere between 75˚F and 78˚F.

– Because my wife enjoys it, I almost always add either mixed berries or tart cherries once fermentation is done, they get tossed directly into primary and left for another week before packaging.

Besides that, the process is about the same, couldn’t be much simpler.

| FOR THOSE WHO BOTTLE |

If you do not keg, making a sparkling back-sweetened cider can be a little more difficult due to the fact the yeast used to carbonate in the bottle have been made inactive by the potassium metabisulfite and potassium sorbate. The easiest option is to skip adding those chemicals altogether, bottle and carbonate the dry cider (which is actually very tasty), then sweeten it at the time of serving. The biggest benefit with this is that you can tweak the level of sweetness to each drinkers liking. My wife really enjoyed mixing about 25% 7-Up and 75% dry hard cider, though we also successfully experimented with blending different fruit juices into the cider. If you’re okay with still cider, you’ve nothing to worry about. Or, you can always just back-sweeten with non-fermentable sugar alcohols (e.g. Xylitol, Stevia, etc).

| SUGGESTED READING |

The Everything Hard Cider Book: All you need to know about making cider at home by Drew Beechum

The New Cider Maker’s Handbook: A Comprehensive Guide for Craft Producers by Claude Jolicoeur

Cider, Hard & Sweet: History, Traditions, and Making Your Own by Ben Watson

If you’ve been toying with the idea of making hard cider at home, I strongly encourage you to give this very simple approach a shot! The resultant refreshing beverage will surely please you and your friends. As always, please do not hesitate to ask any questions or leave comments. Cheers!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

| Read More |

18 Ideas to Help Simplify Your Brew Day

7 Considerations for Making Better Homebrew

List of completed exBEERiments

How-to: Harvest yeast from starters

How-to: Make a lager in less than a month

| Good Deals |

Brand New 5 gallon ball lock kegs discounted to $75 at Adventures in Homebrewing

ThermoWorks Super-Fast Pocket Thermometer On Sale for $19 – $10 discount

Sale and Clearance Items at MoreBeer.com

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

34 thoughts on “Simple Summer Sipper | A Hard Cider How-To”

You didn’t rehydrate the yeast!? You monster!

Want to really make it special, add some oak, a pinch of tannins, backsweeten with honey (cyser). You seem to be adding 2X the amount of sulfite as normal, standard is 1/4 tsp/5 gal, since you are already using pasteurized juice and wash everything like a good beer brewer I think you are pretty safe dropping the sulfites down a little. The level you have it now is what we use when pressing apples that have a few spots on them.

This mismatch great info, thank you! I looked everywhere for a recommendation as to how much sulfite to use and couldn’t seem to find a definitive answer. 1/4 tsp is what I’ll stick with from now on!

So true, I just spent several hours of company-paid time trying to find out how much sulfite to use. Cider novices like me are hurting for more clear info.

Here’s a silly question–do you need to add both sorbate and sulfites? I ask because my husband and I are sensitive to sulfites, and I’ve got a ‘for fun’ gallon of Whole Foods cider fermenting alongside my latest brew (used the same yeast, just tipped about 1/8 cup of the starter into the jug) that I’m now wondering how to kill off the yeasties when it comes time to enjoy it.

I will say that I think I’ll be making a jug o’ cider every time I make beer from now on–it’s stupid simple, and will be a fun way to explore the yeast in different ways since I’ll be using the same yeast from the beer in the cider.

My understanding is that sulfite kills the yeast while sorbate stops it from reproducing. I’ve heard the sulfite isn’t necessary, for what it’s worth.

It’s more like sulfite stuns the yeast (but kills bacteria), they’ll become active again ~24 hours or so after adding the sulfite; this is why you can’t rely on sulfite alone to prevent refermentation.

You can also stove top pasteurize to kill and stop the yeast. If you bottle then you should also bottle one plastic beer or pop bottle so you can use that as a gauge for the carbonation level. I like to back sweeten with frozen apple concentrate and light brown sugar. This makes it carb up in as little as 3-4 days. Hence the plastic bottle and pasteurization to stop the fermentation. Don’t want any exploding bottles!

Very cool idea… just a tad risky for my liking.

Quick question: was there added ascorbic acid in your juice?

I believe so…

I have a similar cider (juice, brown sugar, and Nottingham) that has fermented down to 1.004, right about where I want it. I’m not going to backsweeten, so I think I’ll just cold crash and/or rack and then keg it at 40 degrees. Shouldn’t that put the yeast to sleep and effectively stop fermentation? If you’re cold crashing and kegging are the chemicals even necessary?

I know folks who just cold crash, I was just being extra cautious. I have definitely had some beers that I kegged a little early continue fermenting once in the keezer, so…

Well, the great thing about cider is that it’s so easy and relatively cheap to make, it encourages experimentation. Guess I’ll see how it turns out. Thanks, great blog.

This is a great article: now I’m thinking of doing this over the weekend! Since I’ll be bottling, I’ll forego the potassium additions, prime with sugar and since I do have lactose, use that to back-sweeten. I’m not aiming for a very sweet hard cider anyway, so I think it could do the trick – unless I’m missing something. Thoughts?

Sounds great!!

What would you recommend to boost the abv my juice is only 1.040og. ? I’ll be meeting.

I’d used table sugar, 1 cup in 5 gallons ought to get you closer to 1.048 or so.

Honey, it gives body as well as sweetness and you can call it cyser, we make more of a cyser than cider using it to boost the alcohol and it gives a much better flavor then just sugar. WVMJ

How long will this stay good in a keg at 65 degrees ? I have no fridge space at the moment and the cider is done. Fyi 2.5 gal apple juice 1/2 lb sugar, 1/2 lb corn sugar added 1/2 gallon water. I havetwo cocontrate ready to back sweet with.

Hey Ron, I would imagine it’d be fine for 6+ weeks.

I just tried some before adding the potassium’s. I add 1\4 regular cider to the coke bottle filled with the fermented cider set to 40 psi with a carbonater cap a shook like crazy for a couple of minutes. Wow the only side I had that is better than this is beak and skiff. Thanks for the blog I will save a ton of money!

Can you expand on Step 7? The concentrate you refer to is missing from the ingredients list. What is the size and of concentrate? I’ve never seen it in bottles, only in cardboard tubes.

The cardboard tubes work fine as well, they’re the smaller size ones, I’m not sure the exact fluid ounces though. I just backsweetened some hard cider yesterday, added 3 of the smaller cardboard tubes to the keg and racked the fermented cider right on top.

Hey all, I hate to resurrect old posts, but I just made my first cider and have a few questions.

My recipe:

5 gallons of apple juice

4 lbs brown sugar

2 lbs organic honey

1 lb dextrose

Wyeast Cider Yeast-I forgot which one I used

I left it I’m the primary for about a month them transfered to a secondary to rest a while.

It’s super dry and strong. I did not take a sg reading(dumb, I know)

My questions are about backsweetening.

1. For a 5 gallon batch, with plans to back sweeten with Apple juice concentrate and then keg the final product, should I use Potassium metabisulfite (Campden tablets) and Potassium sorbate to halt the yeast? Or do you think the high abv has killed the yeast?

2. When I keg it do i need to worry about fermentation kicking back up with all the new sugar?

All help is greatly appreciated as this is my first cyser and I think I may have gone for a real high abv with all the sugars.

Cheers all!

Laz

1. I’ve done it both ways and have had more success adding the PM and PS.

2. Not if you add PM and PS 🙂 The 3 times I didn’t, I’m pretty sure fermentation kicked back in.

Cheers!

I have made several batches using this technique. One thing I do different is pour the packet of yeast into one bottle that I poured about half a quart out of as a starter. Then 24 hours later I mix that with two other bottles to step up the starter. Then a day later I put one of those bottles in the refrigerator to save for next time and pour the other two in the carboy with my batch.

Marshall,

I’m looking at brewing your simple summer cider, but backsweetened, with apple juice, for the Angry Orchard fans.

I’m wondering about the flavor impact of campden and potassium sorbate. If I keg it and keep it cold, I’m not worried about referment. However, If I bottle, I’ll add the sulfite and the sorbate.

Any thoughts on flavor from campden and sorbate ?

Yo Mike,

I haven’t noticed any impact on flavor whatsoever, my ciders are always a hit and I always sorbate and sulfite… except for that one time I thought keeping the keg in my keezer would eliminate further yeast activity after backsweetening. It absolutely did not! The cider was clear at kegging but within 3 days in my keezer it had become very hazy and overcarbonated, despite dropping the gas down to a serving pressure of 8 psi, a sure sign fermentation was happening. I’ll never rely on temperature like that again, chemicals do the trick beautifully.

Thanks Marshall,

Hi

I´ve been reading the articles about hard cider with great interest, however there is one question I can´t find the answer to.

I don´t have the possibility to keg my cider, so I have to bottle it. How can I bottle the cider and at the same time carbonate it, without the risk of having exploding bottles?

Cheers

Jacob

I’ve never done that and have heard it can be tricky with backsweetening. This is something we’ll have to look more into before I’m comfortable giving suggestions.

Thanks for the great information above and your podcast on cider! I’m from the US living in China and haven’t been able locate apple juice concentrate to back-sweeten an apple cider. I was wondering if you had any suggestions/methods/alternatives to back-sweeten a cider without concentrate.

Thanks for everything you guys do for us homebrewers!!!

Felix M.

So I’ve made around 40 gallons of this stuff and absolutely love it. This time I have 10 gallons fermenting and I’ve used Danstar belle saison for the first time. I rehydrated and tossed into two separate vessels. My basement and parts of my house is has been overrunned by farts! Haha. The sulphur smell this is producing is crazy! I started fermentation 3 days ago at 68 and brought it up to 70 now. Is this sulphuric smell normal or is something going wrong? I would love to have this drinkable by March 2nd but I doubt that’s possible? I’m making 5 gallons of black cherry and the other 5 strawberry. Any input would be greatly appreciated! Thanks so much for all you do.