Author: Greg Foster

As an admitted hophead, a badge I’ve worn proudly since I started brewing, there’s little I won’t do to improve the hop character of the beers I make. A few years back, during one of many haphazard Google searches for tricks to help take my IPA to the next level, I happened upon a fascinating thesis on dry hopping written by a well regarded hop researcher called Peter Wolfe. While a ton of interesting information is contained in this 79 page behemoth, there was one experiment that particularly piqued my interest. Mr. Wolfe tested the intriguing variable of agitating beer during the dry hop stage, which he discovered led to the quicker extraction of hop oils, accomplishing in mere hours what most believe requires days.

If a little agitation after adding dry hops could produce more hop aroma in less time, you better believe I was going to give it a try!

After engineering a couple wonky contraptions, I eventually realized the best solution to keeping my beer moving after adding dry hops was something I’d already done in a prior xBmt— toss a stir bar in a keg of beer, add the hop charge, and put it on my stir plate! I figured this might be an ideal way to employ this novel method without the complexity of extra pumps and hoses. Only one question remained: would agitation during the dry hop stage lead to amazing aroma in a significantly abbreviated amount of time? Time to find out for myself!

| METHODS |

I designed a simple Pale Ale for this xBmt with the intent of imparting most of the flavor and aroma characteristics from the dry hop.

Whirly Bird Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 45.0 IBUs | 6.7 SRM | 1.056 | 1.016 | 5.4 % |

| Actuals | 1.056 | 1.011 | 5.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| ESB Pale Malt (Gambrinus) | 10.5 lbs | 90.32 |

| Munich Malt - 10L | 1.125 lbs | 9.68 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Yakima Valley Hops Extract | 4 g | 60 min | Boil | Pellet | 61 |

| Cascade | 18 g | 10 min | Boil | Pellet | 5.5 |

| Simcoe | 18 g | 10 min | Boil | Pellet | 13 |

| Cascade | 38 g | 4 days | Dry Hop | Pellet | 5.5 |

| Citra | 38 g | 4 days | Dry Hop | Pellet | 12 |

| Galaxy | 38 g | 4 days | Dry Hop | Pellet | 14 |

| Simcoe | 38 g | 4 days | Dry Hop | Pellet | 13 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

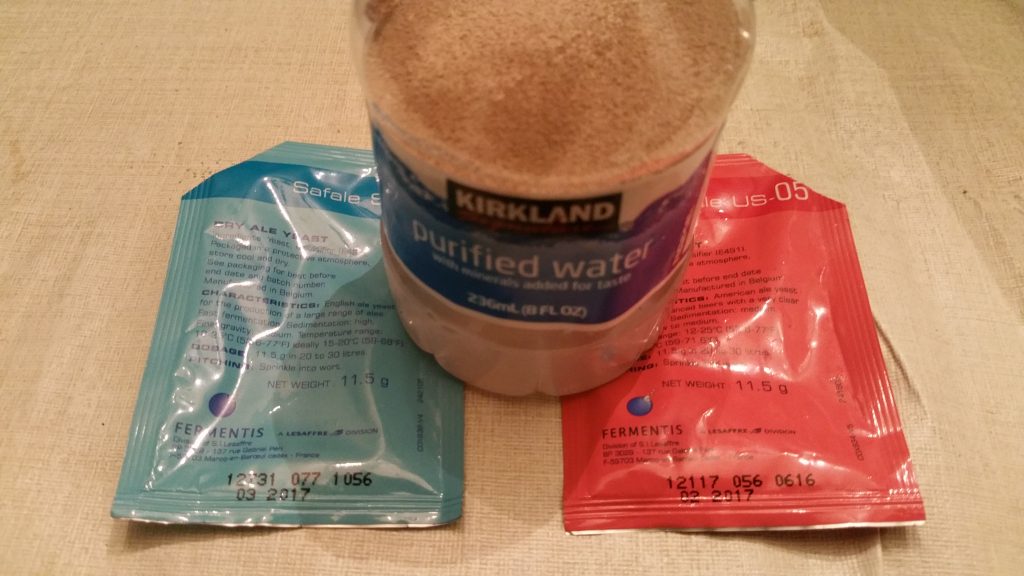

| SafAle English Ale (S-04) | DCL/Fermentis | 73% | 59°F - 75.2°F |

| Safale American (US-05) | DCL/Fermentis | 77% | 59°F - 75°F |

Notes

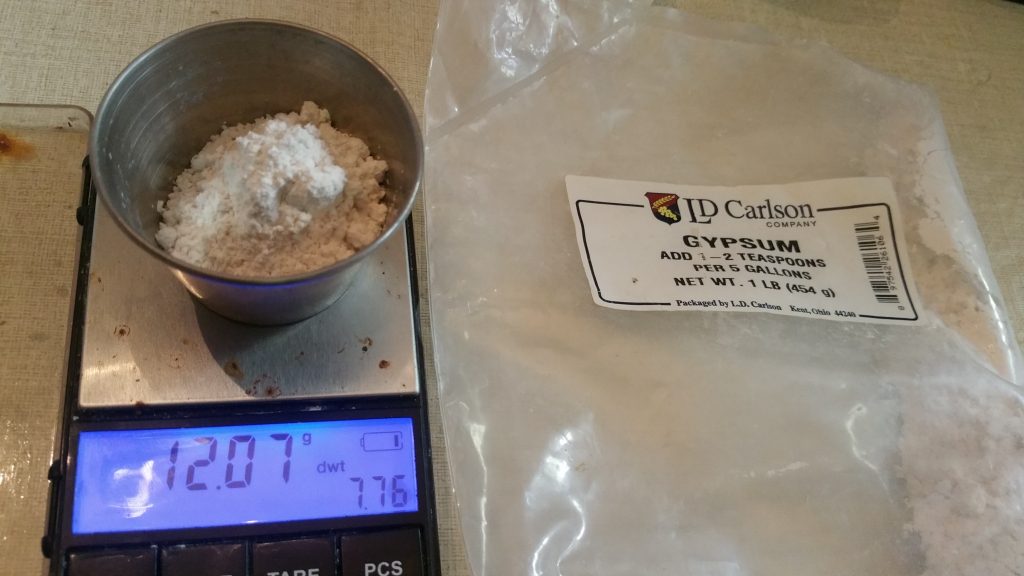

| Water Profile: Ca 108 | Mg 0 | Na 0 | Cl 35 | SO4 217 |

Download

| Download this recipe's BeerXML file |

My brew day began with the usual ritual of weighing out and milling the grain.

I poured the pre-heated RO strike water into my mash tun, powered on the heating elements to maintain my target mash temperature, then added minerals and acid to achieve my desired water profile.

Next, I incorporated the crushed grain into the strike water, stirring gently before checking to make sure I’d hit my target mash temperature. I let my RIMS recirculate for a 60 minute sacchirfication rest.

With the mash complete, I transferred the sweet wort to my electric keggle, performed a batch sparge, and cranked up the power to bring it to a rolling boil, at which point I squirted in a syringe of slightly gross looking hop extract.

I left the wort to boil for 50 minutes before adding Whirlfloc and a modest amount of kettle hops, then 10 minutes later I proceeded with chilling the wort as quickly as possible.

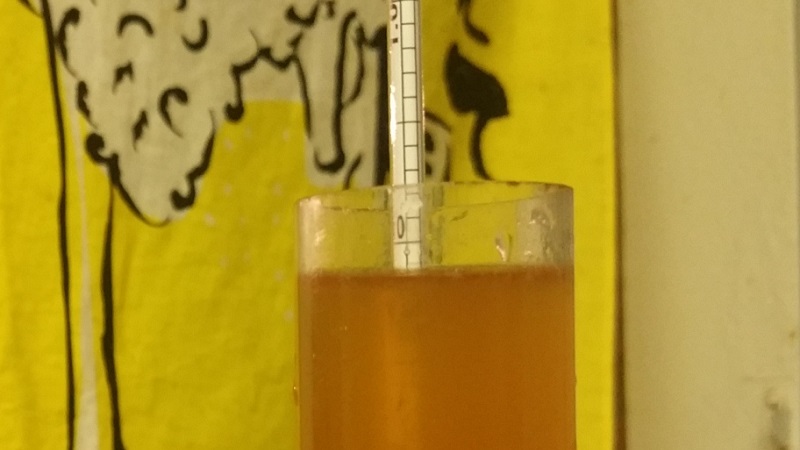

A hydrometer measurement at this point showed the wort was at a respectable 1.056 OG.

I transferred the entire volume of cool wort to a 10 gallon corny keg and placed it in my temperature controlled chamber. I’d made a starter of harvested WLP001 California Ale yeast but for some reason it never really got going, so not wanting to risk a stalled fermentation or off-flavors, I improvised and went with a combination of US-05 and US-04 yeasts, which were rehydrated before pitching. Best of both worlds, dry yeast edition perhaps?

The yeast was pitched and the beer left to ferment at 65°F/18°C for 3 weeks before I took a hydrometer sample confirming FG had been reached.

In order to remove as much particulate as possible prior to introducing the dry hops, I cold crashed the beer for a few days, transferred to new kegs, then let them warm back up before moving forward. Time to introduce the variable.

I started by sanitizing two 3 gallon kegs and installing a stainless mesh filter around either dip tube before adding equal quantities of hop pellets to each vessel.

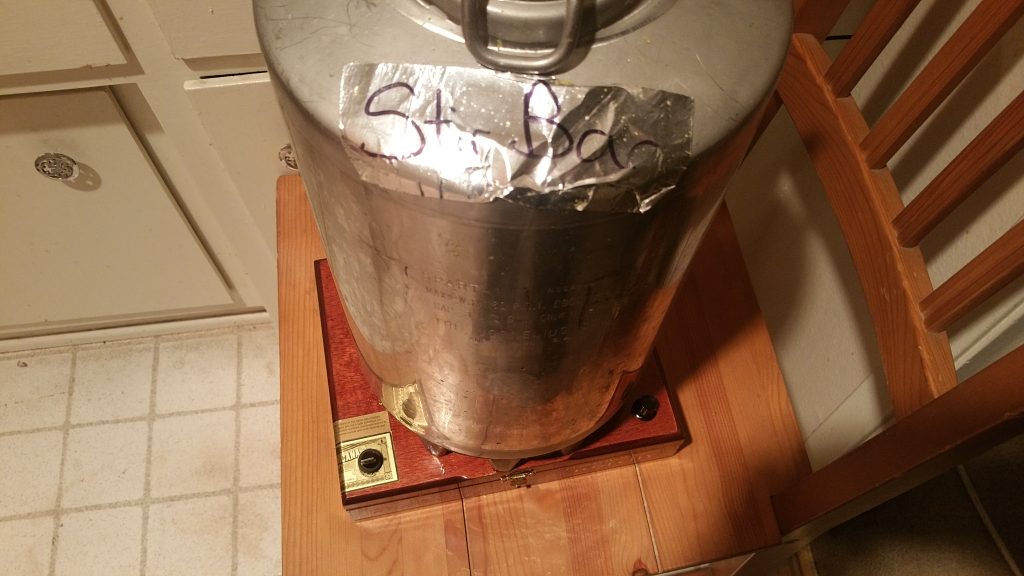

A stir bar was then dropped into the keg that would be agitated then both were sealed and purged with CO2 an unreasonable 15 times, my way of mitigating the anxiety of swirling already fermented beer. At this point, I used new gadget I’d recently constructed to transfer equal amounts of beer to both kegs simultaneously. It worked like a charm!

Of the various ways to test this variable out, we settled on the one thought to be a good starting point that involved immediately placing the agitated dry hop beer on the stir plate and leaving it for a mere hour.

With the spin cycle complete, I pressure transferred the agitated beer to a freshly sanitized and CO2 purged serving keg, which I held at room temperature. One batch down! The other beer was left unperturbed at room temperature for 4 days before I pressure transferred its contents to a similarly prepared serving keg, the stainless mesh filter doing an excellent job of preventing hop matter from clogging the dip tube.

Both kegs were placed in my keezer where they were allowed to slowly force carbonate over the following two weeks. By data collection time, they were looking quite nice!

| RESULTS |

A panel of 19 Strand Brewers Club members with varying levels of experience participated in this xBmt.

Each taster, blind to the variable being investigated, was served 1 sample of the agitated dry hop beer and 2 samples of the standard dry hop beer in different colored opaque cups then instructed to select the unique sample. While 11 correct selections would have been required to achieve statistical significance, only 3 tasters accurately identified the unique sample (p<0.05; p=0.96), indicating participants in this xBmt could not reliably distinguish a beer dry hopped for 1 hour with agitation from from one dry hopped over 4 days without agitation.

For those wondering if a significant portion of tasters chose either of the other 2 samples– nope. Of the 19 participants, 9 chose the red cup (p=0.15) and 7 chose the green cup (p=0.46), both of which contained the same exact beer. Randomness can be so random at times.

My Impressions: When I initially sampled these beers side-by-side, I thought I could tell the difference between them by smell alone, perceiving the standard dry hop beer as having a stronger hop aroma while the agitated dry hop version seemed to be missing some hop punch. Despite my confidence in being able to tell these beers apart, I proceeded to triangle test myself “blindly” 4 times for the sake of scientific rigor, carefully analyzing both smell and taste each time. As it turns out, my initial impression was completely wrong, I simply could not tell them apart, despite fully knowing what the variable was. Thankfully, both were also equally delicious.

| DISCUSSION |

It’s true that a non-significant xBmt result doesn’t prove that a certain variable doesn’t matter, we make it a point to say this often, as there’s always a possibility the thing tested would have a more noticeable impact in different situations. Then again, there are times where a statistically non-significant result actually holds some weight, particularly when the variable tested is purported to have a similar effect as the control to which it was compared. Such is the case with this xBmt.

Corroborating Mr. Wolfe’s prior findings that agitation of beer during the dry hop stage leads to rapid extraction of aromatic hop compounds, participants in this xBmt were unable to reliably distinguish a beer using an agitation method from one dry hopped without agitation for 4 days. It’s possible agitation didn’t actually play a role and that a non-agitated beer dry hopped for an hour would have extracted the same aromatics, something we intend to test out, though this would contradict prior xBmt findings showing dry hop duration does impact the perceptible characteristics of beer. I’m personally compelled to believe agitation made a difference, and while I’m not prepared to start touting its merits just yet because it is only a single data point, these results leave me feeling cautiously optimistic about the ability for agitation to allow for drastically reduced dry hopping and, consequently, grain to glass times.

This xBmt definitely leaves me wanting for more, in particular I’m curious if the hop character in the agitation dry hop beer might have been stronger immediately after the hour on the stir plate, maybe even enough that tasters would have been able to tell it apart form the standard dry hop sample. Yet another variable added to the list!

If you have thoughts about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

43 thoughts on “exBEERiment | Dry Hop Length: 1 Hour with Agitation vs. 4 Days Undisturbed In An American Pale Ale”

are you sure the stir bar was spinning? didn’t the screen impede it?

Haha, yes I was sure. I occasionally tilted the keg a little bit to make the spinning stir bar thump against the keg. The dip tub was bent so the screen was adequately out of the way.

I suspect the stirring caused some degassing of the CO2 which could have blown-off some hop oils, hence the lower aroma.

Hmm… I’d think the fact the keg was capped the entire time disallowed for the blowing off of aromatics, but perhaps I’m wrong.

Greg:

Nice exBeerment.! Would you mind sharing how you made/attached the dip tube screens?

Roy Ventullo

Yes! I originally got the idea of using the stainless screen from this article: http://www.bear-flavored.com/2014/09/how-i-dry-hop-my-ipas-with-no-oxygen.html . I wanted to use the lid, so I drilled a small dip tube sized hole in it. Then I just pulled the dip tube up and lowered it into the stainless hop blocker. I should note that I also bend my dip tubes so they pick up from the edge of my kegs, not the center.

Great experiment. I had read that thesis myself and was also struck by the findings around the duration needed to extract dry hop aroma. Unfortunately I don’t keg, so I’m a bit stuck on how to introduce agitation without oxidising the beer.

I’ll be interested to see any follow up experiments to this one.

The stir bar method would probably work if you were using a glass carboy. Plastic, probably not a good idea.

Like Aaron, I wonder whether the stir bar was really spinning. I guess you tested that prior to the exbeerimnt itself. But even so, seen the great amount of hop matter in the keg, did it really spin?

Also, it would be interesting to see if a 4 day with agitation improves things.

Cheers!

Greg isn’t free to respond this morning, but he assured me the bar was spinning. How crazy would it be, though, if the bar wasn’t spinning and a 1 hour dry hopped beer tasted the same as a beer dry hopped for 4 days? New xBmt idea added to the list!

How long was the stir bar?

1 inch

This was my first thought. Need to do 1 hour of dry hops with no agitation vs. 4 days dry hopping. Thanks for the Xbmt!

Yes, stir bar was definitely stirring away. I could hear it thumping against the keg wall if I tilted the keg a bit. I definitely want to see if longer durations improves things.

Was the agitated beer on CO2 while spinning? Seems like another way to attempt to minimize O2 ingress and potentially speed up carbonation without having to use the burst method.

Assuming the next exbeeriment with 1 hour agitated vs 1 hour un-agitated shows significant difference, I think the next step would be to set up increments of un-agitated beers to determine exactly how many hours/days agitation can save. Is there a difference after 12 hours? 24? etc.

I like the way you think!

It’s probably the sleep deprivation talking, but when I read the title of the Xperiment, I thought “agitation” involved shouting insults at a secondary dryhop carboy for an hour!!

Also, if you already have a hop screen basket, why not just put the hops in that, save the messy clean up out of a keg?

I wanted maximum contact between the hops and the beer. I was worried leaving the hops in the screen basket might slow down hop oil extraction.

Similar question as above, i guess. What screen are you using? All of the screens i’ve seen recommend using whole hops instead of pellet due to clogging. Always contemplated using a hop bag and screen combo. Didn’t know if the bag would plug the screen.

The dry hopper was purchased here http://www.stainlessbrewing.com/Dry-Hopper-with-twist-cap-currently-out-of-stock_p_155.html , but they are cheaper now on Amazon. I have had clogging with this method before when done in the primary with the trub. I think the combination of yeast trub and pellet hops was the problem. Definitely would be less likely to clog with whole hops.

website no longer exists

I LOVE Abalone!

ME TOO! I love introducing people to it because no one has ever heard of it.

Dude that is wild. I 100% expected a different result. I mean, one measly hour!? Not that I doubt the results. My mind is just kind of blown right now. Good stuff.

Try the same experiemt again but have them both sit for 4 days dry hop?! If 1 hour gave similar results to a 4 day dry hop, could it possibly add a better punch after 4 days on the stir plate?

Do you think the 2 week carbonation time had any effect on the perceivable “hoppiness” of the beer?

I connect co2 to the bottom of my conical fermenter a couple of times daily for 3 days when I dry hop. Maybe something for another exbeeriment?

My only concern/comment would be that past experiments have shown testers have a tough time distinguishing hopped beers apart even though they’ve been shown to taste different. I wonder what the results would be if a group of people were told to rate the hop level of beer A from 1-10 and another rated beer B.

How would they have been shown to taste different if testers have a tough time distinguishing them? Isn’t that how you show they taste different?

Have you guys thought about (or perhaps already done) an experiment comparing the beer from recirculating vs conventional steep mash processes? looks like you already have the equipment!

I’d love to see an XBMT testing if agitation can reduce the quantity of hops required to achieve the same hop character. Could shave a few dollars off.

I bet Peter Wolfe wouldn’t be surprised by these results. 🙂

I kind of wonder if pellet vs whole leaf is the bigger issue when it comes to dry hops and time. Once the pellet hops break apart, they have a pretty high surface area to volume ratio. Interesting reading about the dry hopping method, I wouldn’t mind upgrading from bags at some point. When cleaning your kegs, do you disassembly the beverage out post to clean out the filter seperately? Do you use a keg washer?

Great experiment.

I’m curious how the yeast mix of 05 and 04 turned out in terms of taste?

Thank you!

I am actually not surprised by this. I have been dry hopping straight into the keg for, I would say the last 4 or 5 dry hopped beers I have done and by the time I finish force carbonating them they seem to have the aroma I am looking for and no noticeable gains after that point.

MHO: Stir rod too small. If you could some how automate a Mixing Mate Paint Can Lid, then you’d have something. MHO.

Love the tee fitting to transfer to both kegs simultaneously. Great time sav and I alr Andy have the parts to make that work!

You could dry hop, seal up the corny and put it in the back of your car and drive around for an hour – that would definitely mix things up. 🙂

I wonder if the NEIPA style has such great aroma due to similar hop agitation in the fermenter seeing as you add hops during active fermentation. The hops are swirled all throughout the wort similarly.

Ok…I have what I believe a novel thought about this. Would it work to draw some wort of prior to yeast pitch into a beaker and add your hops to that using the stir plate agitation method for an hour or so, then add them back to the pitched wort?

Side question – why the Whirfloc? Thought you guys had proved it was of no benefit…

This xBmt came before the Whirlfloc xBmt, for one, but I still use kettle finings because (a) I have a bunch lying around and (b) it may help with clarity.