Author: Jake Huolihan

From the book Yeast by Chris White and Jamil Zainasheff:

When the brewer has an appropriate pitch of healthy yeast available, and has the ability to chill the wort down to fermentation temperatures within a reasonable amount of time, the better course for beer quality is often pitching at or slightly below fermentation temperature. The brewer allows the fermentation temperature to rise over the first 12 to 36 hours, until it reaches the desired temperature. The benefit of this process is controlled yeast growth, which often results in better overall yeast health, less leakage through the cell membrane, and thus a cleaner beer profile.

When the brewer has an appropriate pitch of healthy yeast available, and has the ability to chill the wort down to fermentation temperatures within a reasonable amount of time, the better course for beer quality is often pitching at or slightly below fermentation temperature. The brewer allows the fermentation temperature to rise over the first 12 to 36 hours, until it reaches the desired temperature. The benefit of this process is controlled yeast growth, which often results in better overall yeast health, less leakage through the cell membrane, and thus a cleaner beer profile.

Like many, I was a rather staunch adherent to this advice and truly believed it helped me avoid many of the fermentation related off-flavors I so despise, which made the non-significant results from the first pitch temperature xBmt all the more surprising to me. I began worrying a little less, particularly when it came to ales, which I’ve pitched at around 72°F/22°C without noticing any noticeable detriment to the resultant beer. However, lager styles have become more of a focus for me lately, which led me to wonder about the impact wort temperature at time of yeast pitch for a more delicate style might have.

I tend to ferment right around 50°F/10°C when using most traditional lager strains, and since this is about 20°F/10°C cooler than I can chill my wort throughout most of the year, I’m forced to hold off on pitching for a few hours until my chamber drops the wort to my target fermentation temperature. As annoying as it is to have to return later to finish the job, I’m most concerned about the potential for a contaminant to have its way with my vulnerably fresh wort before the yeast takes hold. Curious for a solution, I decided to test the merits of pitching cool in a fairly extreme way!

| PURPOSE |

To evaluate the differences between two lager beers split from the same batch where one had the yeast pitched at 48°F/9°C while the other was pitched at 80°F/27°C.

| METHODS |

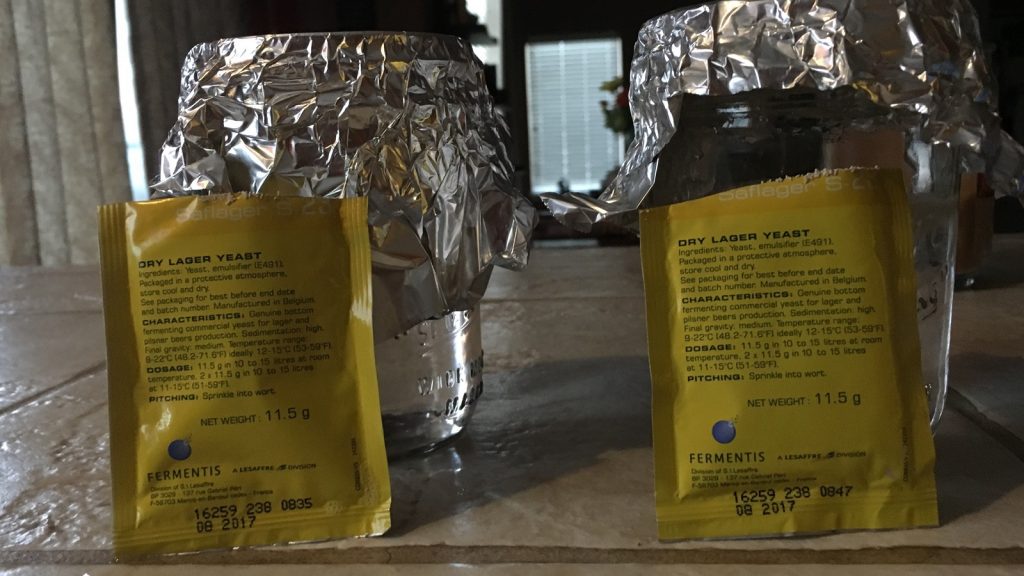

For this variable I decided to go with a simple Munich Helles in hopes of emphasizing any differences caused by the variable. After some consultation with the crew, I decided to use a yeast strain other than the hearty Saflager W-34/70 I’d be relying on so much and went with Saflager S-23 instead.

Munich Helles

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 43.8 IBUs | 4.8 SRM | 1.048 | 1.013 | 4.6 % |

| Actuals | 1.036 | 1.01 | 3.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Weyermann Pilsner Malt | 12 lbs | 99.79 |

| BlackPrinz | 0.4 oz | 0.21 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 15 g | 60 min | Boil | Pellet | 12.5 |

| Hallertauer | 90 g | 30 min | Boil | Pellet | 2.4 |

Notes

| Water profile: Yellow Balanced from Bru’n Water Spreadsheet |

Download

| Download this recipe's BeerXML file |

I started my no sparge brew day by lighting the flame under my kettle of brewing liquor that had been previously adjusted to my target profile.

As the water was heating, I measured out and milled the grains then placed the grist in my empty converted cooler MLT.

Using the underletting method, I transferred the slightly overheated strike water to my MLT before checking the mash temperature, which was a skosh higher than my 152°F/67°C target.

After an abbreviated 30 minute mash I drained my mash tun completely to collect the full volume of sweet wort in my boil kettle.

The wort was then boiled with hops added as laid out in the recipe.

I began chilling the wort at the end of the 60 minute boil.

Once the wort reached 90°F/32°C, I gently stirred to ensure homogeneity then racked 5 gallons into a fermentation keg that I sealed and set inside my warm house. I then turned the water to my IC back on and continued chilling the remaining wort to 58°F/14°F, which is slightly warmer than my cold winter groundwater here in Denver, CO.

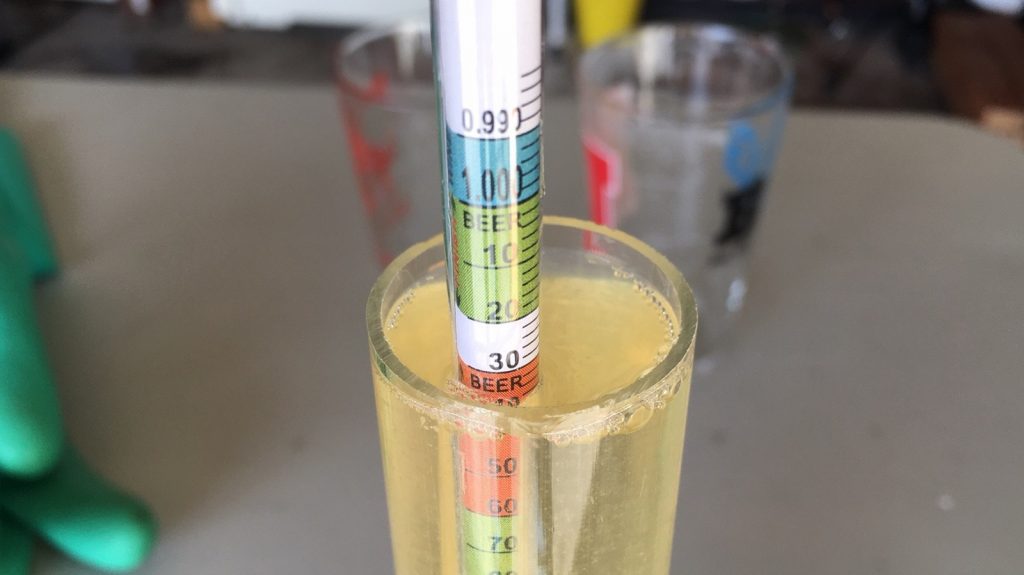

I placed the cooler wort in my fermentation chamber controlled to 48°F/9°C, my target pitch temperature for this batch, to finish chilling. A hydrometer measurement at this point showed my efficiency was disappointingly low, an issue I’ve regularly experienced when using methods to reduce oxidation during the mash. Oh well, I figured it might actually serve to emphasize any differences caused by the variable.

It took 2 hours for the cool pitch wort to stabilize at 48°F/9°C, at which point the warm pitch batch was at 80°F/27°C. I rehydrated two packs of Saflager S-23 dry yeast for each beer before pitching.

Once the yeast had been added to each beer, I placed the warm pitch keg next to the cool pitch batch in the cool fermentation chamber. While I’d normally sandwich the temperature probe between the two fermentors, I was concerned the warm beer would cause the compressor to stay on long enough to reduce the temperature of the cool beer too much. My solution involved letting the probe dangle in the chamber with the controller set to my target fermentation temperature of 50°F/10°C in order to let the warm pitch beer finish chilling before placing the probe between the kegs.

I returned a few times to check on the beers over the following 24 ours and observed bubbling from the warm pitch beer a mere 8 hours after pitching the yeast. I noticed the first signs of activity from the cool pitch batch around the 24 hour mark, which is also when both beers had reached the same temperature and I placed the probe between the kegs. Both beers appeared to be done fermenting after 10 days, presumably due to the lower OG, though I noticed the warm pitch batch did slow down a couple days prior to the cool pitch batch. An initial hydrometer measurement showed the cool pitch beer had attenuated to 1.010 SG while the warm pitch beer was sitting at 1.008 SG. I raised the temperature to 56°F/13°C and left the beers alone for a few more days before taking another round of hydrometer measurements that revealed no change, indicating FG was reached.

I pressure transferred the beers into sanitized and purged serving kegs, which I placed on gas in my keezer to carbonate.

To hasten clarification, each keg was injected with gelatin fining and left to condition for a week before I began serving them to tasters.

| RESULTS |

A panel of 20 people with varying levels of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the beer that was pitched cool and 1 sample of the beer that was pitched warm in different colored opaque cups then instructed to select the unique sample. While 11 correct selections would have been required to achieve statistical significance, a total of 15 tasters chose the different beer (p<0.05; p=0.0002). These results indicate participants in this xBmt were capable of reliably distinguishing a Helles where the yeast was pitched into 80˚F/27˚C wort from the same beer where the yeast was pitched at 48˚F/9˚C.

A brief comparative evaluation of only the two different beers was completed by the 15 participants who made the accurate selection on the triangle test, all remaining blind to the nature of the xBmt. The cool pitch beer was preferred by 7 tasters, 5 reported liking the warm pitch beer more, and 3 had no preference despite noticing a difference.

My Impressions: I experienced these beers as being pretty darn similar, much more so than I originally expected. However, with some effort, I was able to consistently identify the odd-beer-out in multiple semi-blind triangle tests. To me, the cool pitch beer had a slight hint of sulfur that was absent in the warm pitch beer, and while neither were offensive, I preferred the one pitched warm for its cleaner, crisper, and unexpectedly more lager-like character. The beer itself was okay, drinkable, but certainly nothing special, which may have been due to my efficiency issues.

| DISCUSSION |

An undebatable truth – yeast activity is positively correlated with temperature, which makes the results of this xBmt showing tasters were able to reliably distinguish between lagers where the yeast was pitched either cool or warm somewhat unsurprising, not to mention it aligns with the conventional wisdom. More interesting to me is the data on preference as well as my own subjective impressions of the beers.

It’s not a far stretch to presume a beer fermented with a traditional lager strain pitched at 80°F/27°C would end up with a stronger ester character than the same beer pitched at 48°F/9°C. This is certainly what I expected, but that’s not how things went down, I actually thought the warm pitch beer had more lager-like characteristics than the cold pitch beer, to the point I chose it as the one I preferred when sampling blind. If the distinguishing factor was indeed sulfur, as I perceived, it’d lend credence to the idea that said element is a standard and, perhaps for some, preferable component of traditional cold fermented lager.

It’s worth noting that the wort from the warm pitch batch was hit with yeast at a temperature quite a bit warmer than most homebrewers chill to; it’s entirely plausible a smaller delta in pitch temperature between the batches would have resulted in differences that were even more subtle, possibly to the point of being indistinguishable.

But that’s for a later xBmt! For now, I’ll rest a little easier pitching yeast at whatever reasonable temperature my chiller is capable of bringing my wort down to.

If you have any experience pitching yeast into warm wort or thoughts about this xBmt, please share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

35 thoughts on “exBEERiment | Yeast Pitch Temperature: Cool vs. Warm In A Munich Helles”

Brilliant partial chill method, I’m doing this from now on. That’s a huge time savings on brew day.

Matt that’s an OK idea for certain yeasts like cry havoc, some Belgians, or s23. But if you do that with s04/5 or most other strains you are going to produce some very nasty esters and phenols. Source: personal experience.

So the couple hours going from 80 to 68 in a fermentation chamber creates nasty esters? Is that what you tried with other yeasts?

How does that differ from no chilling? I used to put my wort into the cube at very hot temp , then left to slowly cool overnight. Never had a problem with off flavours , and most of my batches used 05.

I think it would likely differ by the pitch temp. My understanding of no chill is you don’t pitch til at ferm temp

The .4 Black Prinz listed in your recipe, remarkably, had little effect on the SRM. I suspect a misprint at work. 🙂

Nope, Jake used a touch of BP purely for color.

Is this a LoDO attempt? Reduced mash oxidation (SMB?), SS chiller, s23 instear of w34/70, fermented in kegs… sounds a lot like it.

Jake is definitely interested in LODO and has been exploring the method since the PDF was released. However, this particular xBmt was not LODO focused.

Any thoughts on what part of LODO contributed to low efficiency? Is it no sparge, or insufficient mixing of the malt? Any plans on a LODO XMBT? It seems like ton of work , and very easy to mess up.

It’s on the list, I’m not sure what causes the lower efficiency in my case to be honest.

A theory we’ve been discussing is SMB potentially denaturing/inhibiting enzymes of a sort but honestly that’s just guess work.

He underlit the grains and didn’t sparge. Pouring grains into your strike water and sparging are known to be major O2 injection sites. I’m leaning towards the no sparge technique as being the culprit.

Jake:

Sorry if I missed this in the notes…. How long did the “warm” keg stay “warm”? I would guess that it would drop to 60 in a few hours. (If there was a fan in the chamber I would expect the two kegs to be about the same temperature after 8 hours)

Good information to prove that the first few hours are not as critical as expected. All these tips put together can really make the overall process much friendlier, especially for brewers just starting out.

Tom

Both kegs sat in ambient 50 for 24 hours, I didn’t measure how long it took to go from 80 to 50, I would venture to guess roughly 10-16 hours though

I am surprised to see a difference. I always err on the side of caution and cool the wort just below target fermentation temperature before pitching yeast (either using a bag of ice to add to circulating water in the last 5-10 min of chilling, cost about $5 per 10Gallon batch but can speed up the day by good 30min to 3 hours, depending on your approach – or, as Jake does, place it in a pre-cooled chamber and let it cool over a few hours – this takes quite a long time though and I do wonder about risk of contamination).

The reason I am surprised at the results is that I always assumed that the lag that most yeast experiences – often between 2-3 hours and sometimes as long as 12-24 hours, would make the whole pitching temperature irrelevant, as long as you get to the right temperature before fermentation really starts. But I guess I was wrong?

This also makes me wonder about controlling temperature of a starter – I always make my starters at 65-70F, should I start making them cold (for lagers) to avoid off-flavors?

Since the purpose of a starter is simply growth and not beer I think you’re fine doing all starters at that range.

What about considering that the difference between starter and wort at pitch may be relevant. Dropping a starter into a wort that is ~20oF cooler is likely to stress the yeast and result in unexpected characteristics. At a minimum I would suspect that attenuation % could be impacted. I typically cool my lager starters to near fermentation temperatures after growing up the desired cell count. I follow a protocol typical of lager processes in which the fermented wort is chilled to lagering temperatures (~32oF) at a -5oF per day rate and then pitch when starter and wort are at the same temperature. As always, different strains and possibly OG magnitude may yield different results.

Yeah I’m not sure. Imperial recommends pitching their yeast cold which I’ve always done and the performance has been amazing

Isn’t the lag you observe due to cell division prior to visible fermentation (with a little bit of that time being the cells assessing the wort composition and adjusting gene expression levels)? I haven’t conducted cell counts vs time, so this is just my assumption based on observing unstirred starters (3 spoonfuls of slurry in 1L)… cell mass at the bottom increases with no visible bubbling, then once a critical mass is achieved, the culture starts producing visible CO2 bubbles.

Warmer pitch=quicker cell division=shorter lag to visible signs of fermentation.

I think/thought you are right but then why should there be any flavor difference between warm pitch and cold pitch (as above)?

Nice article, Jake, thanks. 3 batches ago I was running out of time so I pitched rehydrated m54, Californian lager, at 32°C and couldn’t find any off -flavor. So, in the next two batches I did it again on purpose with US05, since my goal was to brew as fast as possible. Again, no off-flavor was detected and the 3 batches attenuated as expected.

I’ll split the next batch to evaluate if there are noticeable differences between pitching US05 at 17°C and 32°C, besides the expected differences in bittering and aroma from the longer cooling time. Water here has reached very high temperatures as the summer goes by in southeastern Brazil, with thermometers reaching 38°C under shade… Cheers!

Cheers thanks for reading

Congratulations Jake. The level of significance you achieved is the hallmark of a well-conducted experiment.

Can you please share the qualifications/ experience of the 15 people that were able to distinguish the beers?

As we don’t chase results I’m not sure significance denotes a good/bad xbmt.

For the tasters: https://brulosophy.com/2016/01/21/investigating-the-bad-palates-argument-a-graphical-look-at-xbmt-performance-based-on-experience-level/

One of my clubs that I belong to had a Microbiologist/homebrewer come in to speak to them about yeast health. He suggested something that I have been doing essentially ever since. I chill my wort to around 85* and then add the yeast (mostly from a starter) directly to the kettle for more even distribution and then will fill my fermenters and chill down. I have noticed activity within 2-6 hours and have not detected any off-flavors. Side note, I have not done a comparison such as this.

To me the most interesting thing is the fact that the warm pitch beer dropped 2 points lower; is that because the few hours it took for the beer to warm is the “growth phase”, so that yeast was able to ferment slightly more? This may also explain why you perceived that beer as cleaner, right? Got me wondering if the fact that I normally pitch in the mid 70’s (warm, California groundwater) is the cause of my consistently low FG…

Great xbmt – 1 question.. Have you shortened the dip tube in your fermenation keg so that you don’t suck up all the yeast when transferring to your serving keg?

Thanks!

No it’s bent so it rests where the bottom meets the side. You could shorten it though

Awesome.. I’ve been meaning to use one of my kegs as a primary sometime.

This makes me feel better. For about a year now, I’ve been pitching when the temp hits +5F over my fermentation temp and letting either the chamber or my basement walk the temp backwards into the range I want. Usually within 6 to 8 hours everything is good to go.

Also, best purchase from a garage sale: 35lb ice machine.

What was the reason for switching to s23 from 34/70m for this experiment?

Availability– he had a bunch on hand. I’m not Jake, but we did chat about it beforehand.

Hello Jake. I’m resurrecting the post (I hope you see it 🙂 ). I’m looking for a information in the pitch process so far I have not find neither here nor in other posts.

I saw that you investigated the influence of the wort temperature during pitching but one thing is not clear to me is: what was the yeast+water temperature at pitching time? Guessing you re-hydrated it at 30-35C and let it rest for 30min, have you pitched at whatever temperature it was or have you cooled it down to the same wort temperature?

Do you think this yeast+water (or in the case of a starter) temperature has any influence on final results?

I’m asking this because I always hear about yeast being stressed due to big temperature delta. Pitching the 30C yeast+water into a 10C wort sounds more stressing to me (so bad I can not ask to the yeast 🙂 ) rather than doing it at 27C wort. The yeast got almost “instantly” cooled down a delta of 17C, instead of cooling down same delta temp during a couple of hours…

Hope this is not a too dumb question 🙂 (I’m a beginner) – It’s been a couple of weeks I’m looking for this info for my first lager batch, I’m always looking for ways of improving my brewing process, and for this special point I’m still not decided what to do…

Similarly, I can’t help but note the apparent lack of a starter in this example. I always pitch a starter for all lagers, regardless of gravity. So as an additional explanation of the “cleaner” taste of the warmer pitch, it would be this: Both samples were under-pitched for brewing a lager. The warmer pitch had time to grow population in its first day, while the cold pitch never grew much and remained under-pitched. The low pitching rates are a known stress factor that contributed to esters and phenols in the cold pitched keg; perhaps compounded with the apparent temperature change from the warm hydrated yeast to the cold wort.

I’d like to see this again with 2 quality starters of appropriate size (1 L?) and chilled to match the temp of each respective sample of wort. Overall this xbriment is a great attempt to answer a persistent question For home brewers, with anything but a consistent “answer” or even a best practice / protocol.

See Houlihan above:

“I rehydrated two packs of Saflager S-23 dry yeast for each beer before pitching.”

That equals 23 grams of dry yeast per 5 gallons of 1.036 wort. The number of cells per gram is debated. (Zainasheff says 20B, Troister says 8B-18B, Brewers Friend says 10B, Fermentis says 6B and Danstar says 5B). Depending on whose number you choose the pitch rate was somewhere between being ~150% and ~75% of what is recommended. If you account for some cell death due to age and the mean of the range given you end up – more or less – at 100% of the recommended pitch rate.