Author: Greg Foster

A growing trend in homebrewing over the last few years is fermenting in standard corny kegs, which allows brewers to employ certain methods some believe to be beneficial to beer. I started using kegs as fermentation vessels a couple years ago and have found it to be a very convenient way to significantly reduce oxygen from yeast pitch through serving. Admittedly, I presumed oxygen could have been the differentiating factor in the first two fermentation vessel xBmts (plastic bucket vs. PET carboy; glass carboy vs. PET carboy), which was validated by the non-significant results of the third iteration comparing a stainless Brew Bucket to a glass carboy.

However, I recently began to wonder about the impact of vessel dimension, specifically whether fermenting in a tall cylindrical keg produces a qualitative difference compared to beer fermented in other types of fermentors. By observation alone, it’s clear the surface area of the fermenting beer in a standard carboy is greater than in a tall, skinny keg, which means more contact with kräusen as well as whatever oxygen may be contained in the headspace.

Moreover, because of the smaller diameter of a keg, there is less contact between the beer and the yeast cake, which might also have an impact on flavors. It has also been theorized that tall fermentors facilitate more convection, enabling increased yeast contact with the wort that’s said to lead to lower ester production. Admittedly skeptical, given the results of prior xBmts, I was increasingly curious to test this out for myself!

| PURPOSE |

To evaluate the differences between beers produced using the same process where one was fermented in a glass carboy and the other in a stainless steel corny keg.

| METHODS |

I hadn’t had a big Amber Ale on tap in awhile and thought it’d be a good style to use for this xBmt, settling on a slightly modified version of a NHC winning recipe.

Amber Waves of Grain

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 43.0 IBUs | 16.6 SRM | 1.072 | 1.015 | 7.6 % |

| Actuals | 1.072 | 1.012 | 7.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| ESB Pale Malt (Gambrinus) | 14.25 lbs | 90.48 |

| Caramel/Crystal Malt -120L | 11 oz | 4.37 |

| Victory Malt | 11 oz | 4.37 |

| Chocolate Malt | 2 oz | 0.79 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| HopShot | 4 g | 60 min | Boil | Pellet | 65 |

| Cascade | 28 g | 5 min | Boil | Pellet | 5.5 |

| Centennial | 28 g | 5 min | Boil | Pellet | 10 |

| Mosaic (HBC 369) | 28 g | 5 min | Boil | Pellet | 12.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Safale American (US-05) | DCL/Fermentis | 77% | 59°F - 75°F |

Notes

| Water Profile: Ca 83 | Mg 0 | Na 0 | Cl 63 | 118 |

Download

| Download this recipe's BeerXML file |

My brew day began with the usual excitement of weighing out and milling the grains.

With grains prepared, I began heating the full volume of brewing liquor, during which I measure out the mineral additions to achieve my target water profile.

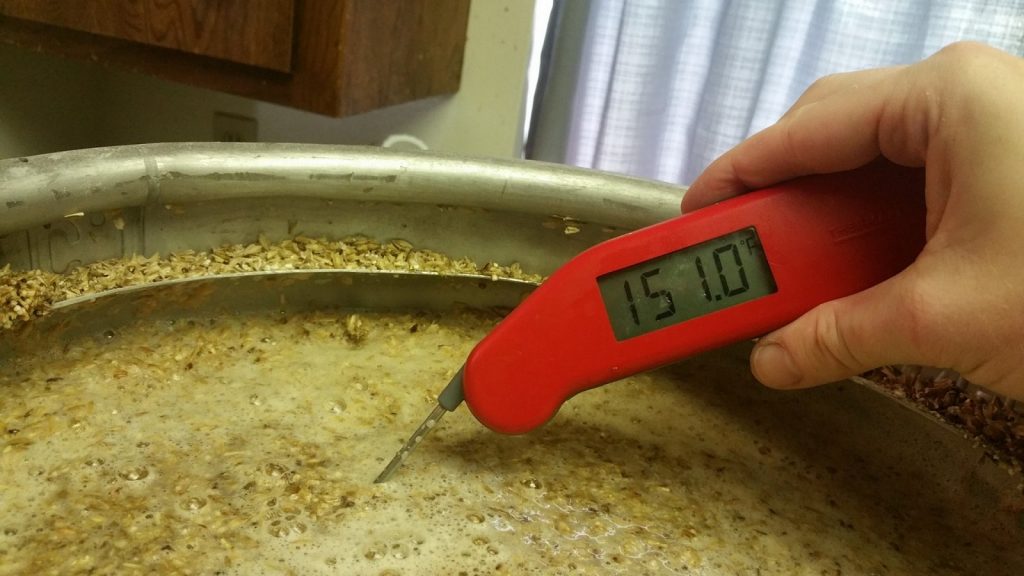

Once strike temp had been reached, I stirred in the crushed grain and confirmed it hit my target mash temperature.

The mash rested for an hour, after which I transferred the wort to a keggle and used my Hot Rod heat sticks to bring it to a rolling boil, adding hops per the recipe. After a 60 minute boil, the wort was quickly chilled.

It was important to me that both vessels receive the same volume of wort, so I weighed both the keg and carboy empty and filled each based on weight, moving the hose back and forth in order to equalize any kettle trub that made it out of the the kettle.

A refractometer reading at this point showed the wort had reached my target 1.072 OG, which by my calculations, “required” about 1.5 packets of yeast apiece based on wort volume. I pitched equal amounts of rehydrated yeast into either batch of wort before placing them in my fermentation chamber controlled to 64°F/18°C.

Dry yeast always seems to take a little longer to become active compared to liquid yeast, which was certainly the case here, as both beers were still 24 hours after pitching. I decided not to worry and let things ride another day before. Sure enough, they were showing signs of fermentation at 48 hours post-pitch.

I slowly began raising the temperature in the chamber to 70°F/21°C a week into fermention in order to encourage complete attenuation. At the two week mark, I observed no bubbles in either of the airlocks and the kräusen on the beer in the carboy had dropped, signifying fermenation was likely complete.

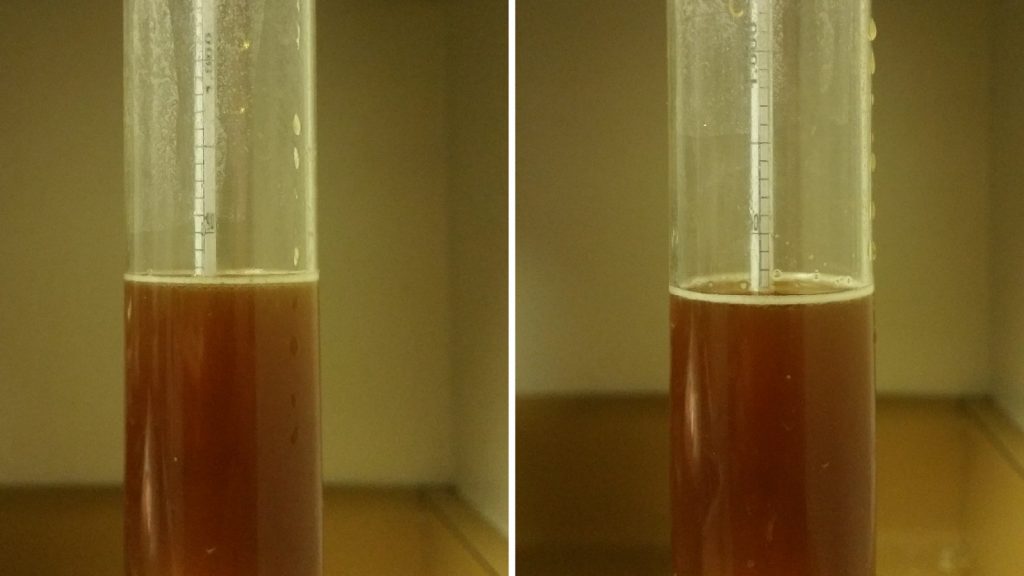

I let the beers sit another few days before taking hydrometer measurements confirming both had settled at a similar FG.

I proceeded to cold crash the beers for a few days before racking to serving kegs. Since the purpose of this xBmt was to evaluate the impact of fermentor type, we decided it’d be best to treat both the same, which meant using CO2 to pressure transfer the beer from the glass carboy rather than using a standard siphon.

I’m not going to lie, I was a little concerned the glass carboy would explode and kill me.

The filled kegs were placed in my keezer where they received a brief burst carbonation before being set to serving pressure for a few more days of cold conditioning. Even without the use of gelatin, both beers looked similarly clear and beautiful when it came time to collect data.

| RESULTS |

A total of 29 people of varying levels of experience participated in this xBmt during a Strand Brewers Club meeting.

Each participant was blindly served 1 sample of the beer fermented in a corny keg and 2 samples of the beer fermented in a glass carboy. While the minimum number of correct responses required to reach statistical significance is 15 (p<0.05), a total of 16 tasters (p=0.013) accurately identified the unique sample. These results suggest participants in this xBmt were able to reliably distinguish a beer fermented in a corny keg from the same beer fermented in a glass carboy.

A brief comparative evaluation of only the two different beers was completed by the 16 participants who made the accurate selection on the triangle test, all remaining blind to the nature of the xBmt. The carboy fermented beer was preferred by 6 tasters, 3 reported liking the keg fermented beer more, 3 had no preference despite noticing a difference, and 4 felt there was no difference.

My Impressions: I attempted 3 “blind” triangle tests of my own, each time carefully smelling the samples before tasting them. My efforts were ultimately unrewarded as I only chose the correct sample one time, an outcome consistent with random guessing, which is exactly what it felt like I was doing each attempt. To my palate, the beers were too similar to tell apart. I do wonder if maybe my expectation that there wouldn’t be a difference somehow biased my performance on the triangle test, especially since participants were able to tell them apart. As for my take on the Amber Waves Of Grain recipe, this is the second time I’ve brewed it and the second time it has come out tasting absolutely delicious! I’d definitely recommend this recipe to anyone who enjoys this style as much as me.

| DISCUSSION |

Of the xBmt variables I’ve tested over the last few years, I viewed fermentation vessel as being one of the most unlikely to produce a distinguishable difference. Yet here we are, 3 out of 4 xBmts comparing different types of fermentors proving statistically significant. Mash temperature, hot-side aeration, cold-side oxidation– all factors I was convinced would have a noticeable impact but didn’t, while such an oft dismissed issue as the type of container beer is fermented in actually appears to have a qualitative impact. Crazy.

As an evangelist of fermenting in kegs, I absolutely plan to continue exploring the impact it has on beer, particularly when employing some of the methods unavailable when using other types of vessels. However, these results have caused me to question the approach, not only because of the statistically significant triangle test data, but because double the amount of tasters preferred the beer fermented in a glass carboy. Is it possible I’ve been making worse beer all this time? I don’t think so, but then again, I really like fermenting in kegs and hence am as biased as they come. Since preference is subjective and I really couldn’t tell the beers apart in my own trials, I won’t be making any drastic changes to my current practices. In the end, if fermenting in kegs somehow changes the character of my beer, so be it, it works for me.

If you have experience fermenting in kegs or have thought about this xBmt, please share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

35 thoughts on “exBEERiment | Fermentation Vessel: Corny Keg vs. Glass Carboy In An American Amber Ale”

this is absolutely fascinating and something I think about. For my brewing, I use a really short and fat aluminum pot (13 gal. size), so the beer gets a lot of contact with the yeast cake and the head space compared to other vessels. And it’s hard not to notice that commercial breweries have tall, slender fermenters. I can’t say I’ve noticed a difference but still.

crazy! seems ferm vessel is one of the most consistent ways to get sig differences in beers!!!

When you ferment in a corny keg, I assume you use co2 to push out the beer. How do you manage the yeast and trub that is in the bottom? I’m guessing you push co2 until it runs clear?

I have a separate set of kegs that I use as fermenters and serving kegs. The difference between the two is that in the fermenting kegs, I’ve cut the dip tubes as to leave roughly a half gallon of liquid behind. This usually accounts for trub when you’re doing a pressurized transfer. That said, I’d be lying to say that I don’t run into (absoutely infuriating) issues with clogged dip tubes from time to time. Ideally, I’d like to have some kind of screen in addition to the shortened dip tibes as to prevent clogging alltogether.

I would probably look at some of those floating dip tube gizmo’s That should avoid the turb.

I fermented in cornys when I was doing 3 gallon batches. I cut about 3/4″ off the dip tube to leave the yeast behind. I loved it, and would do it again if I wasn’t able to brew 6 gallons now.

Like Charles and Dan said, the trick is to shorten the dip tube so you don’t pick up too much trub. There is always a little trub that comes thought, I just push it out with co2 until the beer runs clear. Cold crashing is also important to avoid clogged dip tubes.

Interesting. I brew 11gal batches and have 2 x 15 gal ball lock kegs that I use as fermenters…and I absolutely love them. I can’t say that I have noticed any difference in my beer…and generally have positive feedback from others. I may have to do my own side by side exbeeriment to see for myself.

Aren’t we ignoring the differences in the fermentation temperatures inside the fermenter? This reason alone may change everything.

I was given a 10 gallon (holds 11 gallons) corny keg that I have started using as a fermentation vessel, With the three 10 gallon batches I produced, a blond, an amber and an English brown, all turned out great. I just brewed a huge 5 gallon RIS, that when I brewed previously in a regular 6.5 gallon carboy, I had a major blow up. I was concerned that a large head space would make a difference, an no blow up. time will tell about taste. I did shorten the tube to to keep the cake at the bottom, no problems at all.

One factor that you don’t appear to have allowed for in your xbmt (and possibly previous FV xbmts) is the possible influence of light. The keg is completely opaque, while the glass carboy will allow ambient light to do its work on the brew. A translucent plastic bucket would presumably be in between these two extremes. We know about skunking but could there be other photochemical reactions going on? By definition, anything coloured is absorbing some wavelengths from the visible spectrum and that absorbed energy has to go somewhere, one possibility is driving chemical reactions.

The usual assumption would be that exposure to light is not good. Do commercial open fermenters mean the beer sees more light that closed FVs?

Interesting theory, light could definitely be a factor. The carboy was never in direct sunlight, always in my garage and kept fermenting in a closed chest freezer.

This is very interesting. In commercial brewing, where I have worked, fermenter geometry is taken very seriously and the science behind it is considered settled. Fascinating that the experiments are supporting this. There is a set ratio of cone height to cylinder height for an ideal fermenter. It would be interesting to compare a short, fat carboy to a ferment in a fancy conical that is made to the correct ratio.

It would be fun to know how the fermentor ratio for the keg vs the carboy compare with a commercial setup and what that might bring to the finished product.

You don’t actually describe the differences observed, only the taster’s preferences. What was the difference? Without this information there is little point.

Well, actually, the point is whether taster’s could distinguish between the beers, as that let’s us know the variable has an impact. We share the preference data only because people asked for it, to me it’s largely meaningless, but interesting I guess. We used to ask those taster’s that were correct to explain what was different about the beers, but oddly there was very little consistency between responses, which was exactly the case in this xBmt when Greg talked to some of the participants after completing the survey.

Thanks Marshall for your reply. I love the fact you guys are putting your energy into this and I shouldn’t poke at you… I should have phrased it differently. I’d be interested in what the actual differences are when you choose the between vessel types. Not just that a difference can be detected. Thanks

Thinking about fermenting in kegs, I would love a side by side where both are fermented in kegs, but one uses a blowoff tube while the other is pressure fermented using a spundning valve.

Hey Justin, how’s it going?

They actually did this exact experiment in 2015, I just read it before this one.

https://brulosophy.com/2015/04/27/under-pressure-the-impact-of-higher-psi-fermentations-exbeeriment-results-2/

The results weren’t significant for the flavour comparison, but I think spunding is good for the sake that you can naturally carbonate.

Instead of shortening the dip tube, has anyone thought of using http://www.clearbeerdraughtsystem.com/? I use them for all my serving kegs thought that they might be good also for transfering from fermentation keg to serving keg.

They may seem a bit pricey if bought for each keg, but I bought a 4 of them a few years ago at an NHC booth. I love em. I use them for beers (yeast) that tend to flock slowly and for super hoppy beers that carry loads of hops material during transfer.

How do you take a sample for the hydrometer reading with the keg method?

I usually don’t until the beer is finished, but I can always use a little bit of pressure to push some beer out of the dip tube using a picnic tap

I am also interested in this question. Did you allow oxygen in to the glass carboy to get the sample for the gravity? If so, it may be that the glass carboy received more oxygen at that point where as the keg, which is a closed system, didn’t receive any oxygen at all.

Many breweries have reported changes in the character of their beers when they change the FVs. Lots are moving to SS conicals, but you can imagine what an impact that would have on a brewery that used Yorkshire Squares or the like…

Next would be great to know what type of FV is best for what style and what effects they have 😀

Cannot accurately recall source, gut says Brew Like A Monk, but there was a decent amount of coverage about the troubles some Belgians had encountered when trying to switch from horizontal pill shaped FVs to the upright cylindrical conicals. Two quite a long time before they felt they had made enough alterations in process to accommodate the new geometry.

Yes, Malcolm. I remember that too. I think in the UK it often was mergers and production moving to more modern plants. The recipe, water, process and yeast do not seem to be enough.

Interesting findings. I always used buckets and have switched to SS kettles. So I’m larger diameter. One factor, at least in commercial size FV’s, is the hydrostatic pressure on the yeast. Not sure it would be significant in this case. It would be very interesting to know what exactly the differences are in the finished beer.

As a home brewer I don’t aim for my brews to stay the same batch to batch, though I do aim at having them all good. So for instance I have my “house” IPA recipe but If I have a bunch of X base malt and my recipe calls for Y I don’t hesitate much in making the switch. I will also change up the hops depending on what is on hand or what I feel like.

One big plus for me with the experiments has been that a lot of things one was supposed to obsess about it seems hardly make a difference. One of the few reasons I have been interested in conicals is the yeast harvesting. I’ve been working on some very low ABV beers and they are a lot trickier to get right so if some FV would help it might be significant in really light beers.

Why are the 4 tasters who reported no difference, but correctly guessed the different beer in the triangle test, included in the p calculation? I find it misleading that those that admit, “no difference” are included in the group of tasters that noticed a difference. Perhaps my statistics background isn’t up to par with the reasoning and logic of the analysis?

For this experiment we had 29 tasters. We would expect that 1/3 of those people would randomly get the answer correct, so getting 9.6 out of 29 would yield a p value of p=.5 (50% odds). For every additional person that gets it right, the p value goes down. For this experiment it is not at all surprising that at least 4 people would admit no difference. The p value calculation assumes that people are going to select the correct cup randomly and is taking this into account. What the p=.013 really means is that there is a 1.3% chance of randomly getting 16 out of 29 people correctly guessing the right cup.

I also wonder if you had left the beer to sit on the yeast cake longer, say four weeks, it would have made a difference. This could possibly have closed the gap between the two vessels. I find that two weeks may be long enough for attenuation, but the yeast will continue to work their magic on the flavors for another week or three.

Since more than one year i finished racking my beer from fermenting corny keg to serving corny, instead i simply put the keg straight into kegerator. I no chill, more exactly ‘lasy chill’ that means i let the hot wort directly to the keg, and put the keg to a bigger plastic barrell filled halfway with water to cool. Next day i pitch from stir plated wort in ferm chamber. After about 4-5 days i put spunding valve to get natural carbonization. And after some days and cold crash goes into kegerator. I do not open it after installing the spunding valve. I do not use starsan since then.

If people were choosing completely randomly, with 29 trials according to the binomial distribution there would be a 3.11% chance of getting between 15 and 29 successes. You’ve done 129 experiments at this point right? I love the experiments and the articles, I don’t really know that the statistics are adding much.

wow, what a great set of exBeeriments!

what really amazed me – I think this may have been the most conclusive of all the experiments you guys have run? (at least more than the ones I’ve listened to so far).

With the glass carboy and SS bucket the clear leaders.

what did suprise me more, in the end, when you guys did your own guidance…you suggested it didn’t really matter that much?

now, I agree, if a guy is just getting into it, and wants to limit $$, make some good beer for personal consumption and with friends, then yah, the buckets, the PET Carboy, or glass – all good enough.

but, if someone is going to compete – your data clearly suggests that you’ll stand a better chance to wiin with Glass Carboy or SS bucket -right.

Awesome podcast and exBeeriments – keep it up!

Is the 118ppm of Sulfate correct?

Cheers!