Author: Jake Huolihan

In the not so distant past, dry yeast was all that was available to homebrewers, usually in the form of a small packet attached to the underside of the lid on a can of liquid malt extract. It turned wort into beer, but as many a veteran brewer experienced, it wasn’t always of the highest quality. Thankfully, as our knowledge of fermentation grew, companies were formed that provided brewers with high quality, fresh yeast that came as a liquid. Better beer was being made and it seemed a new standard had been set– liquid yeast was king. Thanks to the work of a few dedicated yeast labs, the tide is turning and dry yeast’s negative reputation is being challenged. Labs such as Fermentis, Lallemand, and Mangrove Jack are producing various dry yeast strains of high quality, expanding the options brewers have available to them.

There are many benefits to using dry yeast such as the fact it tends to be less expensive and generally contains more cells than a pack of liquid yeast, which has led to the widespread belief dry yeast doesn’t require a starter. In fact, Jamil Zainasheff and John Palmer state as much in their fantastic book, Brewing Classic Styles:

There are many benefits to using dry yeast such as the fact it tends to be less expensive and generally contains more cells than a pack of liquid yeast, which has led to the widespread belief dry yeast doesn’t require a starter. In fact, Jamil Zainasheff and John Palmer state as much in their fantastic book, Brewing Classic Styles:

You generally don’t want to make a starter for dry yeast. It is usually cheaper and easier to buy more dry yeast than it would be to make a starter. For dry yeasts, just do a proper rehydration in tap water; do not make a starter. (p. 285)

I’ve never had reason to doubt this advice and adopted the practice of skipping starters when using dry yeasts, doing as they recommend and rehydrating it in warm water prior to pitching. It has always worked fine, though I’ve noticed the lag between pitching and visible signs of active fermentation are longer when using dry yeast compared to when I pitch liquid yeast from a starter, often by 12 or more hours. Not terribly concerning, but I certainly appreciate reduced lag and recently began wondering if I might be missing something by not making starters with dry yeast. Might the unpleasant character some brewers say they perceive in beers fermented with dry yeasts be ameliorated by first propagating it in a starter? The financial argument against starters with dry yeast seems less valid today versus a decade ago, as per my calculations, the cost of DME used to produce a 1 liter starter ($0.96) is quite a bit lower than the price of a pack of dry yeast ($4.00), which even for larger starters seems a small sacrifice if it results in the payoff of faster fermentation and better quality beer. This with the thought of pitching yeast of higher viability was incentive enough to motivate me to try it out for myself.

| PURPOSE |

To determine if two beers fermented with dry yeast were reliably different from one another if one was innoculated from a dry yeast starter compared to simply rehydrating a pack of dry yeast.

| METHODS |

Having always thought it looked tasty, I decided to whip up a slightly adapted version of Tiny Bottom Pale Ale for this xBmt, making changes to the hops based on what I had available as well as the yeast.

Tiny Bottom Pale Ale-ish

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 39.6 IBUs | 8.8 SRM | 1.046 | 1.010 | 4.8 % |

| Actuals | 1.046 | 1.01 | 4.7 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Briess Pale Ale Malt | 8 lbs | 77.58 |

| Weyermann Vienna | 11 oz | 6.67 |

| Victory Malt | 8 oz | 4.85 |

| Caramel/Crystal Malt - 10L | 6 oz | 3.64 |

| Caramel/Crystal Malt - 20L | 6 oz | 3.64 |

| Caramel/Crystal Malt - 60L | 6 oz | 3.64 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 15 g | 60 min | Boil | Pellet | 12.2 |

| Perle | 13 g | 25 min | Boil | Pellet | 8.6 |

| Mandarina Bavaria | 7.5 g | 10 min | Boil | Pellet | 8.5 |

| Mandarina Bavaria | 15 g | 2 min | Boil | Pellet | 8.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Safale US-05 (US-05) | DCL/Fermentis | 77% | 59°F - 75°F |

Notes

| Water Profile: Ca 68 | Mg 0 | Na 8 | SO4 97 | Cl 51 | pH 5.3 |

Download

| Download this recipe's BeerXML file |

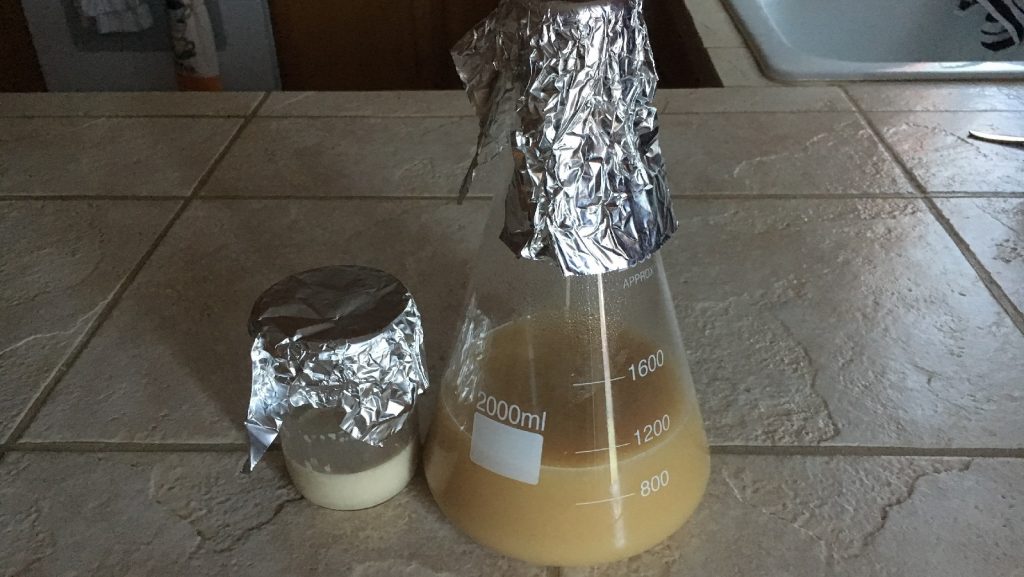

I made the Safale US-05 starter a day ahead of time, rehydrating the yeast before pitching it into the starter wort in order to ensure any differences between the batches were a function of the variable.

I started my brew day by getting the flame going under my mineral adjusted RO brewing liquor.

As the water was heating up, I milled my grains.

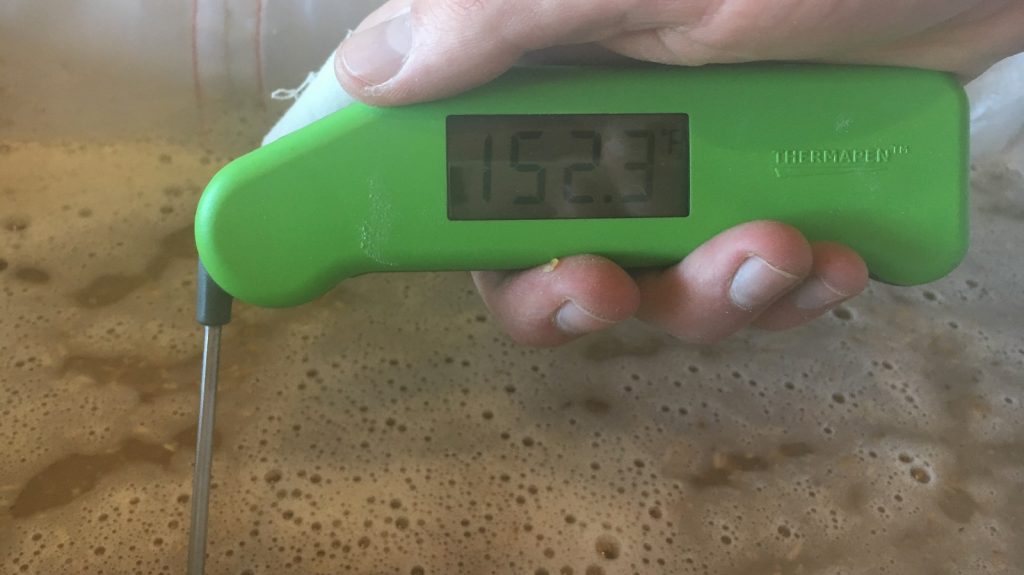

Once the water was a few degrees above strike temperature, I transferred it to my cooler MLT for a brief period of preheating then stirred in the grains to reach my target mash temperature.

I let the mash rest for 60 minutes before I began collecting the sweet wort utilizing a standard batch sparge method.

The wort was then boiled for 60 minutes with hops added at the times noted in the recipe.

I quickly chilled the wort to slightly warmer than my groundwater temperature immediately after the boil was complete.

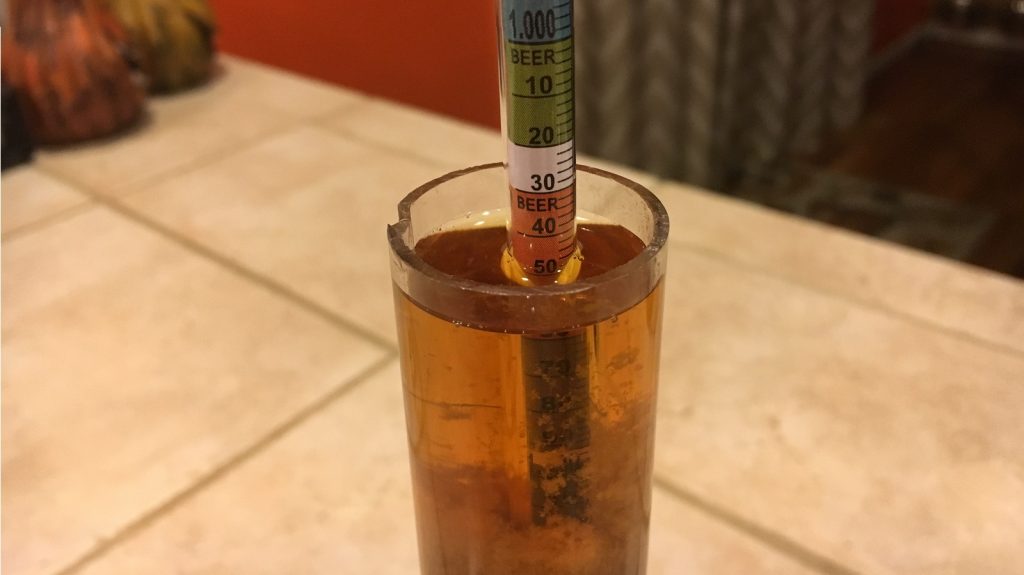

A hydrometer measurement at this time showed the wort was at a slightly lower than expected 1.047 OG.

The wort was split equally between two 6 gallon PET carboys that were placed in my fermentation chamber to finish chilling down to my desired fermentation temperature of 66°F/19°C. In preparation for pitching, I boiled enough water in a mason jar to equal 10 times the weight of a dry yeast pack, allowed it to cool to 95°F/35°C, then added a pack of Safale US-05 for rehydration.

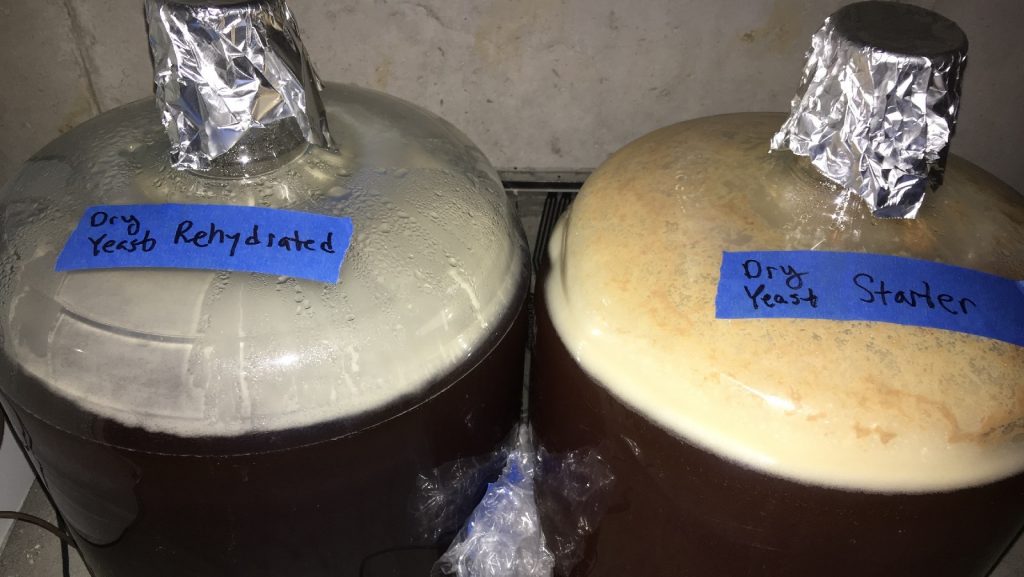

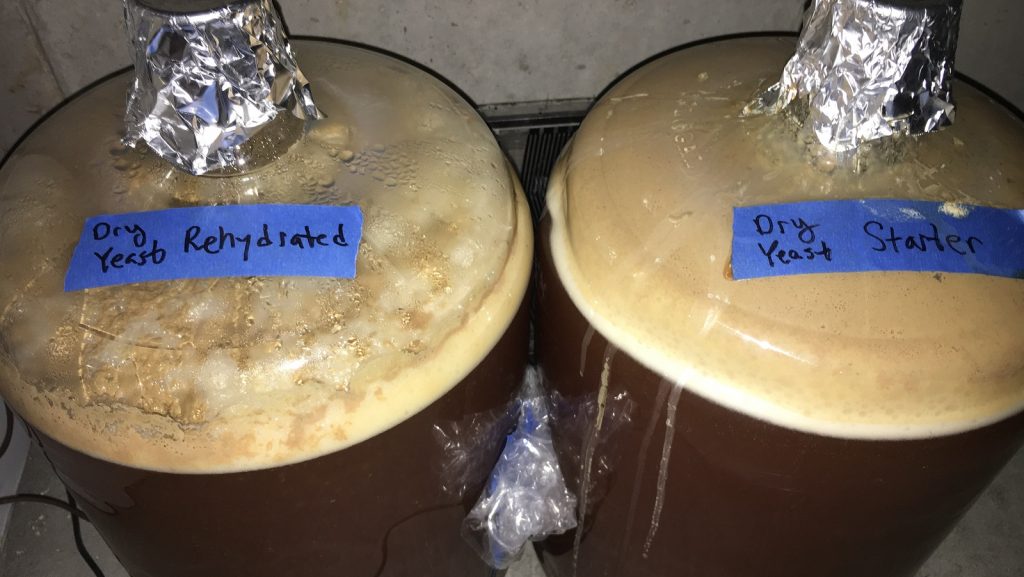

The full contents of both the rehydrated yeast and the starter were pitched into separate carboys of wort. I checked on the beers 24 hours later to find both showing signs of activity, though one seemed a bit further ahead than the other.

After 48 hours, the kräusen on the yeast starter beer had begun to leave the carboy, and while the rehydrated yeast batch was visibly more active than before, it was still a few steps behind.

After a week in the chamber and a slight bump in temperature, the yeast starter beer looked to be done fermenting and had dropped fairly clear while the rehydrated yeast beer still appeared to have yeast in suspension.

Despite hydrometer readings at this point showing both beers to be at similar SG, which interestingly enough was the target FG, I let them sit another 3 days to ensure full attenuation and clean-up of any off flavors.At 10 days post-pitch with both beers appearing the same, another hydrometer measurement confirmed the beers had stopped fermenting at the predicted FG.

I proceeded to cold crash and keg each beer.

The filled kegs were placed in my keezer and burst carbonated overnight, after which I fined them with gelatin. Within a few days, they were carbonated, clear, and ready to serve!

| RESULTS |

A panel of 25 Fermentologists club members of varying levels of experience participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the beer fermented with rehydrated yeast and 1 sample of the beer fermented with a yeast starter in different colored opaque cups then instructed to select the unique sample.

Given the number of participants, a total of 13 would have had to accurately identify the unique sample in order to achieve statistical significance (p<0.05), though only 6 tasters (p=0.89) made the correct selection. These results indicate participants were unable to reliably distinguish a beer fermented with rehydrated dry yeast form the same beer fermented with dry yeast that was first propagated in a starter.

My Impressions: My wife served me 3 semi-blind triangle tests, switching up both the unique beer and the color of the cup the unique sample was in, and despite full knowledge of the variable, I was unable to get it right a single time. This left me completely stumped, as I expected to perceive at least some of the off flavors often cited when discussing dry yeast and pitching rates, but that wasn’t the case. As for the beer, cheers to Marshall for designing this recipe! Even with the changes I made, my version of Tiny Bottom Pale Ale had a nice malt character that balanced the hops, and while Mandarina Bavaria may not be my choice if I were to brew it again, the beer was very tasty.

| DISCUSSION |

Indeed, the results of this xBmt failed to support the hypothesis that fermenting with rehydrated dry yeast would produce a qualitatively different beer than fermenting with dry yeast propagated in a starter, at least based on participants’ general inability to reliably distinguish them from each other. But that’s not the whole story, there was some obvious observable differences– not only did the yeast starter beer become active sooner than the rehydrated yeast batch, but it fermented with more vigor as evidenced by the larger kräusen and blowoff. Whether this is enough to justify the practice of making starters with dry yeast is up to each brewer.

As with every xBmt, the generalizability of the results is limited by certain factors, and one in particular that comes to mind has to do with the fact the beer I brewed was of moderate OG. Is it possible fermenting a higher OG beer with dry yeast built up in a starter might produce a greater difference, maybe even be beneficial?

The pitching rate dogmatist is admittedly reluctant to abandon the practices I’ve gleaned from trusted sources, mostly because they’ve never let me down. But I like the idea of reduced lag times and more vigorous fermentation, so even if it doesn’t have a positive qualitative impact on the finished beer, I plan to continue making starters with dry yeast. Regardless, it’s nice to have at least some evidence that either path may lead to the same destination.

What’s your experience with dry yeast? Do you sprinkle, rehydrate, or prop in starters? Please share your thoughts in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

47 thoughts on “exBEERiment | Yeast Pitch Rate: Starter vs. Rehydration With Dry Yeast In An American Pale Ale”

it should cost about $1 for a 1 L starter if you buy 3 lbs of DME at a time.

Depends on what the DME costs for you I guess

That’s exactly what I was thinking. Also, you can make too much and save some for a later batch.

You’re right, that part in the article has been edited to reflect more common prices (i.e., MoreBeer).

I’m not trying to be a dick, just want people to realize that rejuvenating yeast with starters is a VERY cost-effective way to go. I use Marshall’s yeast harvesting method to grow up starters and save yeast for later pitches. I have saved a lot of money on liquid yeast, get great, healthy yeast, etc. Really no down side other than more storage space required and a little time to make a starter.

No worries! I think I had used the local price for one pound of DME in my initial calculation. Regardless at around a buck a liter starters are much cheaper and at least in this comparison improved performance.

First I’m fanatic of make beer and Brulosophy, thanks for your great work.

Could you consider make an experiment pitching dry yest directly in the carboy whitout rehydrating vs pitch re rehydrated yest.

In a argentine forum they make a cell counting of w-06 yeast and the result says there are more available cells in non re hydrated yeast: 10.8M cells/ml vs 10.4M cells/ml

https://groups.google.com/forum/#!searchin/cervezapropia/no$20re$20hidratar$20w06%7Csort:relevance/cervezapropia/hZvd_bOGH_8/gVafGpWL2OwJ

Sorry for my shity english.

We definitely need to repeat the xBmt using a triangle test, but here’s a comparison we did a couple years ago.

I agree. I was able to talk to one of the Fermentis Yeast guys at AHC in 2015. He stated that he no longer bothers to re-hydrate as the amount of yeast death is < 10% so you can easily compensate during pitching. A beer with smaller OG would easily only need a single packet. Bigger beer… just use a scond packet (or so that was my take-away). What's a packet or two among friends 🙂

seriously.. I have always wanted to test the starter, re-hydrate, rip&pitch all side by side.

My experience with dry yeasts and different methods to pitch…

When I rehydrate, then everything starts slower and fermentation last a bit longer…

When I sprinkle, then fermentation starts faster and ferment a bit faster.

I never make a starter with dry yeast. Why, because I think then I must make a huge starter or use only part of a pouch. Why? Because if I understand right, normally 1g/liter is good practice with dry yeasts. So If I use 10g pouch, then I must make a 10 liter starter. And if I make smaller then I got fever healthy cells than if I use 1g/l. There cannot be that much lipids to feed huge amount of hungry yeast cells if I use example 2 or 3 liter starter with 10g of dry yeast. But ofcourse, everything is relative. You can use even 6g of dry yeast with 20l batch and you can get drinkable beer. But what I think, if you use 1g/l then there is really good change that your fermentation starts relative fast and fermentation is quite “optimal”, if you can control your fermantation temperature.

There is one option with starter, if you pitch your starter to your main wort soon enough, then maybe your yeast can start grow better because it is rehydrated and feeded and you give food to cells before they starts starving.

But I think it is much easier to give 1g/l and wait to yeast miracle =)

I’ve gone full circle in a short period of time. I am not sure if it is my fridge, or practices in storing it, but I did dry yeast exclusively for my first 16 months of brewing, then liquid yeast only for 18 months and now I am back to do mostly dry yeast.

With the liquid I was making oversized starters and saving the yeast. I found after 3-4 re-uses the yeast was dying. Probably not sufficient live cells for viability and I don’t brew often enough. At one point I had 6 different liquid yeasts in test tubes in my fridge. I am lucky if I brew once a month, so 6 months sitting around for a liquid yeast, not good.

I also realized most of my financial savings in brewing was using bulk grains, the reuse of the yeast was just a fraction. Now what I do is about 80% dry yeast, with the occasional liquid yeast when I need a specific strain for something, like an Oktoberfest or a Dopplebock, that sort of thing. Otherwise, it is buy half a dozen dry yeast packets at my LHBS once or twice a year and use those. I DO make starters for my dry yeast if I think I might brew a similar style again soon, then I’ll save off a test tube of yeast and make a start out of that later. Sometimes I’ll do things like this fall I made an Amber with S-05, then an Oktoberfest with Whitelabs liquid Oktoberfest yeast, then I made Pumpkin Ale with the saved off yeast from the starter I made of S-05 for the Amber (making a starter from that saved yeast of course). I didn’t keep a test tube from the Amber as I know I likely won’t brew another S-05 appropriate yeast for a few more months.

The dry yeasts, especially the increase in different varieties, lets me have a lot of options on hand on what I can brew and no worries about viability as they’ll keep in my fridge for basically a few years before going too stale. Compared to a liquid yeast where I pretty much have to make a starter/brew with it within about 3 months, maybe 4 or so at the outside (unless I want to make step starters and culture up from the few remaining viable cells).

comparing yeast – I wonder if maybe you could choose a style that is not so hopy in nature. bitter or kolsch or belgian

This beer was definitely not very hoppy.

Maybe I was misunderstood: I meant that adding hops for flavor and aroma kinda mask the yeast profile

It certainly could, I tend to think at least in this case any differences were so subtle that the data was not affected by recipe choice.

A more vigorous fermentation is not necessarily better. Too vigorous and you may end up with excessive acetaldehyde and other by-products. The same goes for lag times, shorter is not always better.

With US-05 I always get a lag time less than 12 hours, and enough vigorous fermentation. Without either starter nor rehydration.

I’m not sure visible signs of fermentation are reliable indicators of yeast metabolic activity given that in one fermenter you’ve added a volume of solution with dissolved CO2 metabolic byproduct which may contribute to the “earlier signs” of fermentation given that the “signs” you’re pointing to are krausen/bubbles (aka dissolved CO2 breaking out of solution).

I’ve used Safale US-05 in dozens of batches and never even considered re-hydrating. I fill the fermenter about 1/2 way with wort, add in the dry yeast, then continue adding the remaining wort. The dry yeast ends up hydrated and well distributed. I’ve noticed longer lag times than when using starters, but I’ve been happy with the final beer.

I use starters for liquid yeast or propagating a friend’s Conan slurry when I want or need the variety, but otherwise the ease of use for dry yeast has been a big time saver.

I bought a 500g brick (a bit bigger than a pound) of US-05 for $53 on my brew club’s last bulk grain order. I then used my vacuum sealer to parcel it off into 40 individual 12 g packets +/- 0.5g each, and stuck them into the feezer. So each yeast packet now costs me $1.33! I used to collect and wash my yeast in Mason jars out of my Fastferment conical at least 3-4 times per yeast packet. Now the yeast is so cheap I can’t justify my time to wash yeast. It took me about 90 min to measure and re pack the yeast one evening so I think I am winning. I don’t make as much lager so I still wash some yeast to save the strains and start with more colonies. I buy grain by the 50lbs bag and hops by the pound. PBW by the 50lbs pail and Star San by the gallon jug. One vacuum sealer and suddenly I am the guy who always has supplies in the club. I more than recupe the costs from my intial purchases by selling or trading with club mates and they still get better than retail deals. Organize a bulk buy, you’ll be amazed at the savings.

Just curious… has anyone ever had a bad beer result from a longer than expected lag time? My longest lag was four days (yes, four days), after pitching a tube of expired 002 directly into a batch of bitter (Brulosopher’s Best, actually). It took four days to amass enough cells before the carboy went crazy in the usual 002 way. Beer tasted great. That’s anecdotal, but personally I don’t really think lag is an enemy.

That said, I’ve had US-05 take off in four hours a couple of times. After rehydrating, I added some wort stolen 5 minutes into the boil, and let the yeast hang in that for a few hours before pitching. Obviously they can’t be replicating in the hyper-saturated culture I created, but maybe they activated an appropriate transcriptional program for the wort constituents? Or maybe it was all a fluke? Again, anecdote.

Anyways, I love the yeast-based exbeeriments. Thanks for your work!

https://brulosophy.com/2016/08/15/yeast-pitch-rate-pt-4-vitality-starter-vs-viability-starter-in-a-lager-exbeeriment-results/

That was my longest ever lag time, tasted just fine. I really don’t tend to worry about lag much but if your sanitation isn’t spot on I guess it could be a problem.

I meant Hop Test Bitter, sorry.

I have had a couple of liquid yeast fermentations (without starters) that did not start within 3-4 days, which led me to pitch another (dry) yeast. One of them developed a Brettanomyces infection, one had a weird tastewhich I can not pin point. Anyway, getting the fermenation going is important because non fermented wort is vulnarable.

I’ve been using low gravity beer to propagate yeast count for higher gravity beer. Brewed a vienna lager using 2x rehydrated w34/70, then step up to a BdG, then Baltic Porter, then imperial IPL. Wonder how many generations the yeast cake is good for but the Baltic Porter (3rd beer) is tasting really clean and malty, despite the trub/dead yeast that have been hanging out in the cake. We’ll see how this imperial IPL taste like.

I have some problems with this study. It is effectively a test of pitching rates between 0.5 and 0.75 million cells/ml/°P with a yeast known for its low ester and phenol production. It is therefore absolutely no surprise that you couldn’t tell the difference between the two.

Non-rehydration and making a dried yeast starter have similar detrimental effects to yeast viability (i.e. osmotic pressure destroying cell wall). This has been shown to cause the death of around 50% of cells (https://bkyeast.wordpress.com/2013/03/13/more-on-yeast-rehydration/).

This study is therefore a test of pitching rate in the given beer. If you wanted to pitch at 0.75 million cells/ml/°P for 5.5gallons of 1.047 wort then you would require about 180 billion cells total. If you wanted to pitch at 0.5 million cells/ml/°P then you would require about 120billion cells total.

If we calculate that your dried yeast was 18b cells per gram (11g packet) and you re-hydrated perfectly then you would have 198 billion cells. If we estimate half of the cells died from the starter yeast (leaving 9b cells per gram) then you would have about 100 billion cells total. This leaves you in the ballpark for either 0.75 or 0.5 million cells/ml/°P respectively which in both cases should be adequate to produce a clean beer. The fact that you could not discern the difference between the two is therefore no surprise, especially considering the yeast chosen S05 is not characterful (has low ester, phenol, aldehyde production etc).

If you were to rerun this test I would recommend choosing a high gravity pale beer (OG1.070+) and use a more characterful yeast. Pitch so that one packet of yeast with 100% viability would provide 0.5-0.75 cells/ml/°P.

By my calculation the rehydrated was pitched with ~200 billion cells (1 packet) and the starter was pitched with ~300 billion cells (1 rehy packet on a stir plate). The pitch rates are ~ 0.90m/Plato and ~1.30m/Plato.

I agree that pitch rate is a minor added variable in this case which is a result of doing one sachet either rehydrated or thrown into a simple starter. If there had in fact been a noticeable difference I’d be inclined to retry this trying to keep pitch rates equal. I think it would be interestingness to try in a higher OG beer.

I just want to give a shout out to the Brulosophy team. Whenever I get an email from you guys, I get psyched to see what you guys are up to next. Many of the xBmts you’ve done have been things I’ve wanted to do or thought about doing but just never had the time or resources to pull it off. I really appreciate what you guys are doing for our community. Cheers!

I second this. I’ve bought several of the items used and promoted by you folks, and I’ve implemented several of the processes you all use. My brews have definitely improved because of Brulosophy, and my brew day has gotten shorter. Major thanks.

Where is your airlock? just tin foil? I liked it. 🙂

I switched to an airlock after a few days of active fermentation. Those 6 gallon PET carboys always blow off on me, it’s annoying.

I cut off the bottom of a 3-piece airlock and then bought some silicone tubing with the same ID as the OD of the airlock tube at the top. That seems to work pretty well with the plastic fermentors.

I also used to use foil, but I was doing some hard cider and came back to see that fruit flies had crawled under the foil and died in my cider! Never again with foil!

Great. I will make this way, cause the krausen always goes into airlock. I hate it.

I would never make a starter with dry yeast. To me the dry yeast is synonym of saving my precious time and that is why I even sprinkle it. If I spend time to make a starter it is because I need a specialty liquid yeast.

Hydrated Dry yeast is an oxegenated slight overpitch.

But a starter is just overpitching even more. So you would get more blow off.

In response to the italicized question at the end of the article: I dump the dry yeast in the bottom of my fermenter then let the cooled wort “waterfall” on top of it. IMHO, US-05 is the Terminator of all dry yeasts. I think you would have to nuke it for it not to work. As for liquid yeast, for every 6 months in storage (33 F), I double the next build (1.5 l, decant, 1.5 l) before pitching. Instead of using DME, depending on the age of the stored yeast and how much I need, I’ll “brew” a few pounds of grain (1.5:1 qt./lb), boil it for 30 minutes and then use that wort to propagate more yeast. I never store yeast without another build for more than 6 months, if I can help it.

Another great article.

Greetings,

What this experiment actually is about, is the difference on the quality of the finished beer having different inoculation rate(low to normal and higher inoculation rate).

As it was mentioned in discussion, it’s no surprise that a kind-of low abv beer fermented using an American strain would be almost identical. Maybe the effects of inoculation rate in the quality of the finished beer would be more prominent if an expressive yeast strain was used on simpler (grain and hop wise) and higher OG wort (maybe even in low DO conditions).

In theory there would be quite a difference in yeast character.

I agree that there are definitely two variables at play: inoculation rate and yeast vitality. Had the results been different I’d be inclined to try it with the same inoculation rate. Also agree with your thoughts that it could produce a different beer in a different scenario.

What kind of starter was it? How many cells did it aim to reach? More than the amount of hydrated dry yeast? Was it a 24h / 48h starter followed by decantantion after sitting a few hours in fridge?

I made a starter for dry yest just once: a Rauchbier, that needed 400 Bi cells and I had 2 packages of a 21 months old W-34/70, what should give me around 127 Bi. That was what I got from my supplier, couldn’t see that it was “old” until I got it by mail.

So, the goal was a 3,15x increase in cell count. I have calculated and executed this starter. It took me three days without no SG change to convince myself to use another package of hydrate W-34/70. After 12-14h, there was activity.

The starter seamed good, there was activity and the yeast volume had increased.

I still don’t know why it was taking too long to take off, whether it was the dry yeast being to old (although starter seemed fine and there activity after pitching the third package), or I had “depleted” the potential for it to “take off” for doing the starter (against this major sense recommendation to just pitch more packages).

I’m still not that confident to make another dry yeast starter, although I do it all the time for liquid yeast.

Strategies to save on DME:

* Make more wort and can or freeze what you do not need

* On a quiet evening make some wort, boil it short and freeze it

Due to brewing relatively small amount, I freeze wort in amounts of 200 ml, of which I then first use 20 ml into rehydrated yeast, and then use the rest to build a starter which I try to keep in lag phase until pitching (that’s due to you guys: vitality starter)

Lag time with pitching dry and re-hydrated:

* I pitched dry once and I had a lag time of 24 hrs, but after using the same yeast hydrated, it seems that it is somewhat slower, this is MJ M07. I have used other MJ yeasts, hydrated, which were active in less than 12 hrs.

Starters:

* I do not brew large volumes, so normally I am good with part of a sachet. However, for my Continental Strong Ale with OG 1.100 and S-33 yeast, and for a bock with MJ Bavarian Lager yeast, I both created a starter. In the first case because of the high gravity and because I only had half a sachet of S-33 yeast, in the second case because of bottom fermentation. I got 74% AA on the S-33, the bock fermented six days at 50° F.

For special cases, I definitely build starters, but not for light beers or even tripels. I will build a starter again for a weizenbock, also because I have only half a sachet of MJ M20 Bavarian wheat yeast.

Love the site and all the work you all do,

However, I’m not sure this experiment actually answers the question you intended to ask. You speak a lot about challenging the “conventional wisdom” regarding dry yeast preparation as put forth in Brewing Classic Styles in the quote you included. The quoted text weighs the cost and effort of making a starter, versus simply purchasing MORE dry yeast and rehydrating, to achieve the SAME pitch rate.

To truly test this concept, the straight forward thing to do would be to perform cell counts using a hemocytometer and determine the amount, and cost, of starter wort to achieve the SAME doubling in pitch rate provided by rehydrating a second pack of dry yeast. Given the improved shelf life of dry yeast, associated higher viability, and the likelyhood that only a small starter (1L) would be needed to achieve a doubling in cell counts (based on the research that Jamil performed to construct the formulas used in the MrMalty calculator). It is likely plain to most that a 1L starter will infact be a couple dollars cheaper. Just as rehydrating a second pack of dry yeast along with the first would to many seem like a bit less work.

If you were actually interested in testing any flavor perception differences between rehydrated and starter grown yeast, you could perform an experiment similar to what you have done here but accounting for an EQUAL pitch rate.

What you have tested here seems to incorporate a confounding and unmeasured variable (pitch rate), while testing to see if there was a percievable difference in flavor when all you change is how you rehydrate your yeast (starter vs. water). By pitching a single pack rehydrated in water or in a 1L starter into 5.5g of 1.046 wort, you in effect have compared the standard pitch rate (rehydrated) versus what would be expected to be DOUBLE the standard pitching rate (from the 1L starter). Then you go on to evaluate the flavor perception.

You do mention the change in lag time and the possibility of changing flavor profiles due to this, but it doesnt really seem like your core question. If this was in fact what you wanted to test, perhaps you should elimiante the added pitching rate variable by brewing a higher gravity beer which would require 2 packs of dry yeast, and provide this pitch by either rehydrating 2 packs or adding a 1L started that had a single dry yeast pack added to it?

Just my thoughts, keep up the great work!

I have had great results on not even rehydrating the yeast. Just straight dump dry yeast on wort! Makes me think with a higher gravity beer. Would this stress the yeast enough to make a notable change in flavor over one that is hydrated or started? Don’t get me wrong I have had green apple a few times, but it hasent aways been dry yeast that I have used.

I remember reading something about dry yeast not needing oxygen like liquid yeasts do. Anyone do any experiments with that?

That is definitely the common wisdom.

We haven’t done one over dry yeast with oxygen v not, but i personally am skeptical it’d be different than this xbmt.

https://brulosophy.com/2015/07/13/wort-aeration-pt-2-shaken-vs-pure-oxygen-exbeeriment-results/

An old post but now with increasing number of People brewing lager i thought it needed to be highlighted.

I brew 15 gallon batches of beer (normally wort from 12 to 14 Plato) and a mostly lager according to Narziss method regards temperature typically pitching at 45 deg f. I use mostly fermentis W-34/70 and S-23 which is predictable quality yeast I like and thrust.

To pitch at this temperature Fermentis advice pitching between 200-300g per hektoliter (100 liter) which equals around 150g for 15 gallon (to simplify 10g a gallon or Even 1 sacket pergallon) with 11,5g per sacket this ends up with 13-15 sackets of yeast. I dont know what you pay for W-34/70 but typically prices hover around 6.5 bucks a sacket. Which is easy 85 bucks for a brew in yeast. Cheap? I dont think so, its the most costly part of the brew. For Ale with 3 sackets per 15 gallon well 4 maybe to make sure I see the point in Palmers book with cost but for not for lager, forget it.

I first make a 1.5 liter starter then a 5 liter starter at 10 plato (1.040) to assure a good pitch of at least 1.5 which is minimum for a lager, adjusted according to OG.

This saves me a good deal of cash.

But as a bonus it starts way faster, and finishes off perfect every time. I see no reason to not make a starter, quite the contrary.

Preparing starter. speed up the initial phase of fermentation and insure adding viable cells to the fermentor. If the brew is a big beer the active yeast cells are ready to break down the large amount of sugers right away.

I have been doing the dry yeast starter since 1985, before I even had a stir plate. I have been told I was stupid to do it, then called a genius…usually by the same people years later. I overbuild and save a batch for the next time. I don’t use DME, instead I steal a little bit of mash water from previous batches… Yeast cost virtually nothing….

Was the yeast in the starter rehydrated beforehand or pitched directly into the starter?

I’m planning on using the wort from brew day after 15 minutes or so of boiling to pitch dry yeast, chilled of course, to give them a jumpstart. Good idea?

Cheers!