Author: Malcolm Frazer

I’ve been making sour mashed and kettle soured beers for a few years now. In addition to brewing and drinking such historic styles, I also really enjoy the initial research phase. There’s certainly nothing wrong with picking established recipes from trusted sources, but I consider the mystique, romanticism, and small connection to brewing history alluring. Those who have researched Berliner Weisse have likely encountered the same thing I have, namely what written history exists on the style is quite limited. Thankfully, folks like Ron Pattinson from Shut Up About Barclay Perkins and the incredibly dedicated Milk The Funk group have done a lot of digging, arming interested brewers with inspiring information about how to make these delicious styles.

There are many variables brewers have to consider when making Berliner Weisse or any other sour ale that gets its primary character from lactobacillus, many that never come into play with traditional brewing practices. For example, which of the numerous souring methods to use or whether to purge with CO2 during the souring phase. Another variable that has gotten a lot of focus lately has to do with post-souring wort managing, specifically whether or not it should be boiled prior to yeast being pitched. In my exploration of the original Berliner Weisse, I found it was commonly described as having a doughy and fresh bread character, which some have speculated is a function of not boiling the wort, a practice others warn could bring about the DMS boogieman or leave the beer tasting of raw uncooked wort.

| PURPOSE |

To evaluate the differences between two Berliner Weisse beers of the same recipe where one was boiled for 45 mintues while the other was not boiled at all.

| METHODS |

I went with a pretty typical Berliner Weisse recipe for this xBmt, a style I’ve come to use no hops in at all.

Berliner Weisse

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 45 min | 0.0 IBUs | 2.7 SRM | 1.034 | 1.007 | 3.5 % |

| Actuals | 1.034 | 1.007 | 3.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Wheat Malt, Ger | 3.25 lbs | 50.49 |

| Barke Pilsner (2 Row) Ger | 3 lbs | 46.6 |

| Munich 10L (Weyermann) | 3 oz | 2.91 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Ultimate Flora Probiotic | 72% | 64°F - 69°F | |

| SafAle German Ale (K-97) | DCL/Fermentis | 73% | 59°F - 75.2°F |

Download

| Download this recipe's BeerXML file |

My brew day began like most others with water collection then, while it was heating to strike temperature, gathering and milling of the relatively small amount of grain.

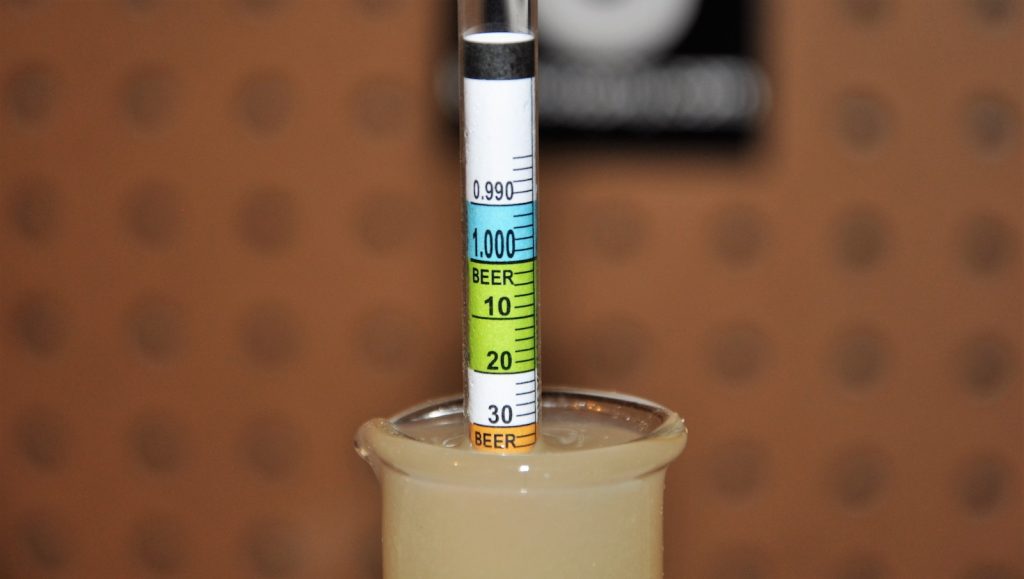

Since the variable wouldn’t be introduced until later on in the process, I performed a single large mash in order keep things as consistent as possible between the batches. With the strike water ready, I mashed in to hit my target temperature and let the mash rest for 60 minutes before collecting the entire volume of sweet wort into another cooler MLT. The also took a hydrometer measurement at this point that confirmed I hit my target.

From here, I used a heat stick to bring the wort to 170°F/77°C for pasteurization.

Once pasteurized, I used my immersion chiller to drop the wort to my preferred souring temperature of 95°F/35°C. As a matter of course, I pre-acidify the wort to around pH 4.5 ±2 when quick souring, not only for the purported foam stability benefits, but because it lessens the overall souring time thereby reducing the potential for unfavorable microbes to take hold.

I opted not to purge the souring vessel beforehand or blanket the wort with CO2 prior to pitching the lactobacillus, which in this case was in the form of an over-the-counter probiotic. Based on what I’ve read and personal experience, I aim for 80-100 billion cells of lactobacillus per 5 gallon batch of Berliner Weisse wort.

While each probiotic capsule contains 90 billion total cells, only 54 billion of those are lactobacillus, so in order to reach my target pitching rate, I sprinkled the contents of 4 capsules directly onto the surface of the wort.

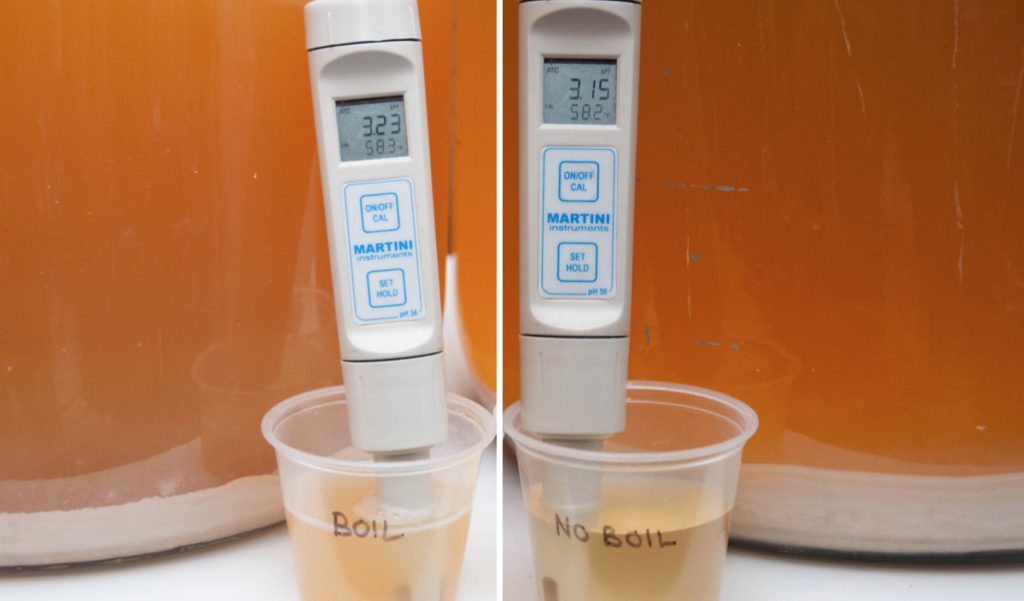

The insulated souring vessel was wrapped in blankets and left alone in my garage. At 18 hours, I found the wort had dropped to pH 3.3, perfect!

Another hydrometer measurement at this point revealed little change to the OG.

The time had finally come to introduce the variable. I started by transferring equal portions of the soured wort to either a fermentor or boil kettle, alternating between them for purposes of homogeneity. I then placed the kettle on my burner and brought the wort up to a rolling boil, leaving it there for 45 microbe murdering minutes.

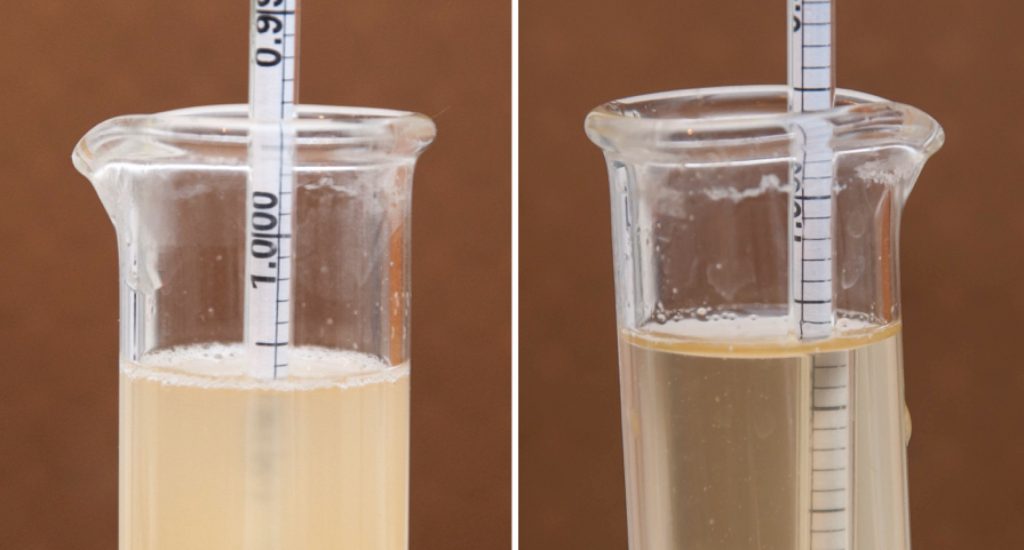

Once the boil was complete, I quickly chilled the wort to 68°F/20°C before adding approximately 1.5 liters of filtered water to equalize the OG between the batches, as we wanted to avoid that being the reason for any perceived differences.

The carboys were placed in a tub of cool water and the beers allowed to ferment in a corner of my garage that maintains a steady 68˚F/20˚C this time of year.

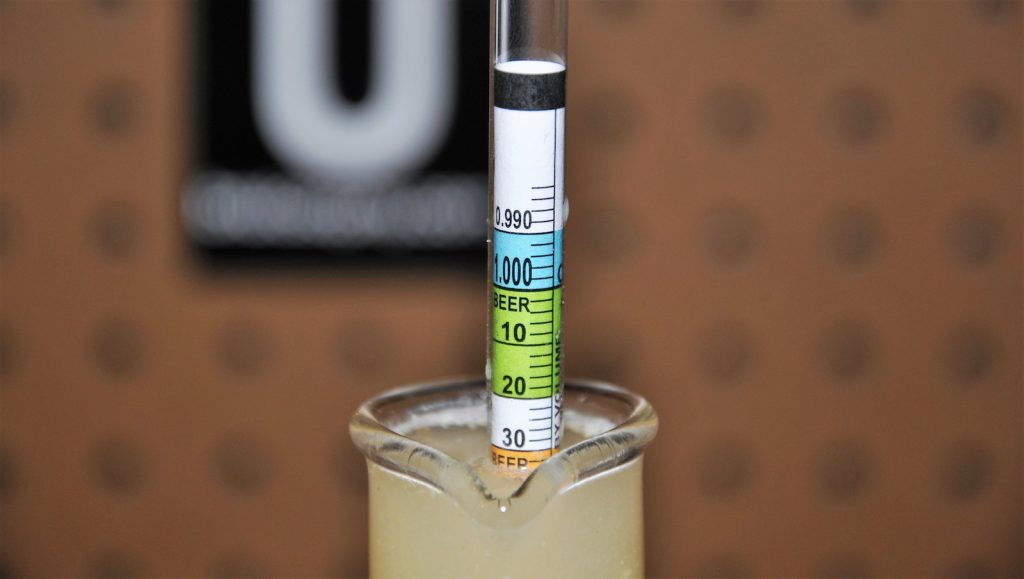

Active fermentation was observed the following day, about 18 hours after pitching the yeast. With such a low OG, fermentation was complete by day 3, but I let the beers mature for a few more days before taking hydrometer measurements indicating both had reached a similar FG.

However, a pH measurement at this point revealed a difference that seemed like it could potentially have a qualitative impact.

Forgoing cold crashing and fining with gelatin, I transferred the finished beers directly to kegs.

I burst carbonated the beers overnight then reduced the CO2 to serving pressure for a few days before I began collecting data. While slight, the color difference I noticed following the boil seemed to carry through in the finished beers.

| RESULTS |

A panel of 37 people with varying levels experience participated in this xBmt. Each blind taster was served 2 samples of the no-boil Berliner Weisse and 1 sample of the boiled Berliner Weisse in differently colored opaque cups then instructed to select the unique sample. At this sample size, 18 tasters (p<0.05) would have had to accurately select the unique sample to achieve statistical significance. Ultimately, 31 tasters (p=0.0000000004) chose the different beer, suggesting participants were able to reliably distinguish the boiled Berliner Weisse from the no-boil sample.

The 31 participants who correctly selected the unique sample in the triangle test were then instructed to complete a brief preference survey comparing only the two different samples, all still blind to the variable. In the end, 15 tasters reported preferring the boiled sample, 13 said they liked the no-boil version better, and 3 people had no preference despite noting a difference between the beers.

My Impressions: As I imagine most brewers do, I began sampling these beers when taking gravity samples and was pretty sure I noticed a difference at this point. The no-boil beer had a distinct aroma of fresh doughy wort, which I found pleasant, in addition to a cabbage-like sulfur with minor tart cheese reminiscent of isovaleric acid, which was not very pleasant. The difference settled out some degree after fermentation was complete, but they were still easily distinguishable to me. Over multiple attempts, both administered to myself and by others, I was able to identify the different beer every single time.

| DISCUSSION |

Over the years, I’ve had numerous Berliner Weisse beers, some boiled and others not boiled, but this is the first time I’ve been able to sample them next to each other. In addition to my personal experience sampling these beers and being able to easily tell them apart, the fact participants were able to reliably distinguish them supports the notion that post-sour boiling has a qualitative impact on the finished beer. I suppose this comes as no huge surprise given the understanding that certain organisms the boil is intended to remove continued working in the no-boil beer.

Perhaps more compelling is the preference data showing that about half preferred the no-boil beer while another half liked the boiled batch better. As someone who has been homebrewing for almost two decades, I’ve know what it’s like to rely on the opinions of others to inform my brewing decisions. These xBmt results reminded me that, while deferring to trusted sources can certainly help make me a better brewer, trying various methods out for myself is the only way to dial in the approach that works best for me.

Please feel free to share your experiences making quick sour beers with or without boiling in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

42 thoughts on “exBEERiment | No-Boil Effect: Evaluating The Impact On A Berliner Weisse”

The listed recipe includes hops, I think that’s inaccurate.

Thanks for another great exbeeriment.

I really enjoy the details of the brew day. That certainly encourages me to try the style.

No hops uses, recipe updated.

Thanks for sharing this really interesting exbeerriment. I really like Berliner Weisse and I didn’t no the no-boil thing…

Do you think that boiling the wort will make easier to have a more stable recipe and increase the reproducibility of a particular recipe?

Cheers

Personally, that’s what I think.

A couple of questions: which did you prefer? And, when you pitched 4 capsules, wouldn’t you have had 216 Billion cells of lacto, rather than the 100B you had targeted?

I’m working to convince my brew mates to do a kettle sour, so thanks for this xBmt!

Each capsule has 90bil total cells, 54bil of which are lacto, thus 2 caps per 5 gal batch is 108bil… since this was a 10 gal batch, Malcolm pitched 4 caps, which is indeed 216bil cells 🙂

I see – that’s what I didn’t understand, since your recipe stated 5.5 gallons. Thanks!

I generally scale recipes down to 5.5 since that’s the batch size it seems most homebrewers make 🙂

Perfect response. Yes. That was the procedure. It was perhaps not as clearly written as it could have been.

Great experiment! Have you had any success using different sources for the Lacto culture? I don’t think we can get that product in the UK unfortunately

Yes. Various probiotics strains have and can been used. Look on the back of the product labels at your local chemist’s for Lactobacillus types. Plantarum is known to be very temperature tolerant and quick acting. Perhaps looking up Milk The Funk and the wiki page for lactobacillus will also give more info. Good luck.

If all else fails, it’s naturally present on malted barley. I’ve had pretty consistent success with my sour mash Berliners with just throwing a handful of unmashed 2row into the sour mash (although it does take longer than their 18hrs).

Take a look at the thread here for a good source of Plantarum in the UK/EU: http://forum.craftbrewing.org.uk/viewtopic.php?t=9662&p=129479

See my comment below for a UK source (for some reason it didn’t show as a direct reply to you – probably user error).

Great study as always. I am curious what the effect would be if you pitched the yeast earlier, I.e., before you reached the desired pH and acidity. Assuming your prediction that other bugs may be causing those unpleasant flavors you noted is true, perhaps pitching earlier would allow the lack to finish it’s job during the years lag time.

Great article.

Do you think the difference between the two had to do with changes from the boil, or the fact that the no-boil continued to be active? Do you think the results would be the same if the no-boil had been pasteurized at 170f again after souring?

It’s a good question and I can just write – I don’t truly know. My guess would be that they’d at least be closer.

Perhaps next time we can try that.

Would you make an educated guess that the carbage-like sulfur was indeed DMS?

That would be my guess. I essentially did everything to promote DMS! But I am married so I am used to being told I am wrong.

Which version did you prefer?

My preference was for the boiled version. But I will need to experiment with K97 a few more times before I can recommend that yeast for this application. My preference as of now is for WLP 029. WLP 001 also works well if it’s a healthy pitch – may experience some additional due to higher acid environment.

Last Berliner I did I used wlp644 Saccharomyces “bruxellensis” Trois. Really nice character. No boil and I defineity had some off flavors in the begining and then all of a sudden it cleared up.

My absolute favorite results have been from the following:

Long low mash with 50% wheat. Ultimate Flora at 95 F, arrested at aprx pH of 3.4 ish. Ferment out with WLP 029. Add Brett Brux to keg or bottles. Brett C is also nice but is sometimes less funk more fruit – which can play well with certain combos. I have only used Brett C once so far.

I have only finished with brett a few times so I cannot say I have it fully figured out but they were my favorites so far as long as the character is nuanced vs bold.

So I emailed White Labs and asked about WLP644. It is not a brett strain but a sach strain. This is the response i got…”You can treat the strain as you would any other yeast strain, no need to worry about contamination! “

Thanks Malcolm! This article inspired me to do my first sour, as you made it so simple. I just pitched the lacto an hour ago. Fingers crossed it’ll be down to 3.3ph tomorrow ready for a boil 🙂 Thanks again guys.

Did it get down?

after 12 hours it’s only down to 4.2 (from 4.6). so I’ll check it again in another six hours or so.

Great article!

It is interesting that you got the almost identical attenuation in both samples. I guess this is because you reach a very high attenuation by means of the lactos anyway.

A couple of mont ago, I did a very similar experiment trying to reconstruct Carynthian Stone Beer, where I also divided the wort and fermented one half unboiled, the other half boiled. Using regular S-33 ale yeast, the boiles sample reached an attenuation of a mere 62%, the unboiled however of 92% due to all the enzymes still being active during the fermentation!

The enrire article about this, including a diagram of the progress of attenuation (German however) is at http://braumagazin.de/article/spiel-mit-dem-feuer-kaerntner-steinbier-rekonstruiert/

And also here, the boiled variant tasted way better due to the DMS present in the raw variant.

That’s correct, Mike. That’s why many will type it as “Brett” Trois or Sacc Trois.

Out of curiosity, what did you use to pre-acidify the wort? Lactic acid or phosphoric acid? What was the source of the type you used?

75% phosphoric. I use food grade sourced from a local brewery.

Probably BSG, so whoever they supply.

https://bsgcraftbrewing.com/phosphoric-acid-haz-1galcs4

Moritz makes a good point that DMS in the no-boil beer likely originates from trace amounts of DMS in the malt (pilsener). It is known that certain types of malt have small amounts of DMS present that was not kilned away, and this is the likely culprit as a mash is not considered hot enough to convert SMM to DMS. This is well covered in the Milk The Funk DMS WIKI page:

http://www.milkthefunk.com/wiki/Dimethyl_Sulfide

I have made several no-boil berliners using 2-row malt, wheat malt, and flaked oats, mashed and inoculated with a handfull of 2-row malt. None of my no-boil beers have had signs of DMS, at least that I could tell. Also, I had no butyric acid or isovaleric acid-type off flavors. A ciscerone acquaintance commented that my berry no-boil was very clean. My experience and your findings suggests two things:

1. Pilsener malt may lead to DMS in no-boil beer

2. Purging the headspace of the souring vessel and keeping out oxygen is critical to reducing unpleasant off flavors.

As for the second point, I suspect that the boil may have driven off any “cheesey” off flavors. It is not clear to me why you opted to not purge the souring kettle, especially when this is a well-recognized practice for making good berlinerweiss beers. I suspect your experiment may have turned out differently had you taken the steps to keep oxygen from undesirable bacteria in the wort. Can you explain your rationale?

Sure, in my opinion and observation the statement “this is a well-recognized practice for making good berlinerweiss beers” is less accurate today as compared to a few years ago.

On the very site you referenced (MTF) many of the active contributors have said they no longer purge their vessels. Some do however! But to say it is generally accepted – I am not so sure. It does appear to be relatively easy “insurance” at the small homebrew scale if it makes you feel comfortable but I question the necessity of the practice at our scale and with a rapid acting healthy bacteria culture. That may seem odd coming off a a bad batch that I shared publically, but I wonder if that had more to due with sanitation (boil?) than the use of CO2 in an attempt to preclude 02. It has been my practice for the last year or so to NOT purge and I have made some fairly tasty kettle sours (my opinion) and ones that have faired well in competitions (comps are subjective, with some luck, but at least they were blind to the brewer).

In this case I think I just made a not so good beer! It happens. I will try the no boil again, perhaps with some variations. Maybe a CO2 purge should also be considered as a variable for an upcoming rendition.

As to the MTF DMS wiki – I have conversed with some of those who contributed to that page – both before and after the experiment! I love MTF, Devin B, Dan P and the awesome community it continues to be. Thanks for referencing them!

Indeed, Brother Malcolm has been an active and valued member of MTF for at least a couple of years. If he didn’t write for Brulosophy, I would hire him to write for the wiki. 🙂

The source of the DMS is really a mystery, unfortunately. As far as I can tell it’s very difficult to figure out the source in a finished beer. Studies have noticed DMS kick up in packaged beer, for example. My hypothesis, as was written on the wiki, is that no-boil beers tend not to give off DMS because the SMM isn’t converted into into DMS because it requires temperatures near boiling to efficiently do so. For every 6°C, the half-life for the SMM to DMS conversion doubles. I still have unanswered questions about this theory… what does SMM taste like? What is its threshold? James Howat once told me that he thought that someone told him the SMM tastes like DMS, but has a much higher threshold. Unfortunately I could never find any other information on it.

When I first read this article, and then listened to Malcolm’s interview with James Spencer, I thought that it was likely that the DMS did come from the SMM. However, I forgot to consider the chances of contamination when only hitting 170°F throughout the entire process. Bacteria can create DMS from the second DMS precursor found in malt, DMSO, and do so at a much higher rate than yeast. Boiling reportedly really helps guard against contamination. When you think about it, all the steam from the boil helps to pasteurize the sides of the kettle. Boiling also has a significantly higher killing rate, according to our friend Bryan at Sui Generis, who is a bonafide “Smart Motherfucker”. So this isn’t a possibility to rule out.

As far as the DMS in the malt, I don’t think (I could be wrong) that this would be the main culprit. DMS in malt is generally considered a non-factor due to the brewing process. Even at mashing temperatures, DMS is volatilized, for example. I suppose it is a possibility, but I would put it lower on the list of suspects.

Cheers,

Dan P.

Have you experimented with the no-boil process outside of Berliners?

Curious of the result produced by BIAB no-boil.

Daniel

We haven’t… yet.

Hi! What do you think of an exbeeriment being in trying pitching the culture vs adding lactic acid directly on the finished beer?

I think it’s worth considering for future projects.

I use the non boil approach but with Brett yeast instead of German Ale

Sounds interesting. I love a touch of brett character in Berliner weisse -type beer.