Author: Ray Found

In Yeast: The Practical Guide To Beer Fermentation, authors Chris White and Jamil Zainasheff posit,

One of the most important measurements, especially in terms of fermentation, is pitching rate. Without consistent pitching rates, flavor can change significantly from batch to batch. What are the consequences of overpitching or underpitching? In general, underpitching affects flavor more, while overpitching negatively affects yeast health more over generations. However, both can result in a less than ideal fermentation with high levels of diacetyl, acetaldehyde, and low attenuation.

One of the most important measurements, especially in terms of fermentation, is pitching rate. Without consistent pitching rates, flavor can change significantly from batch to batch. What are the consequences of overpitching or underpitching? In general, underpitching affects flavor more, while overpitching negatively affects yeast health more over generations. However, both can result in a less than ideal fermentation with high levels of diacetyl, acetaldehyde, and low attenuation.

Indeed, making yeast starters to dial in precise pitching rates has become a norm with many brewers attributing significant improvements in the quality of their beers to the practice. The existence of myriad calculators designed to help brewers determine what size starter is required to propagate specific cell counts is evidence of this shift in understanding, and the beer people are producing today is ostensibly better than it’s ever been, so it must be working!

Interestingly, results from a previous xBmt found participants were unable to reliably distinguish an ale fermented with a single pack of yeast (~56 billion cells) from the same beer fermented with yeast propagated in a starter (~237 billion cells), suggesting underpitching may not be as detrimental as many believe in otherwise ideal conditions. This is likely possible due to advancements in the yeast manufacturing process that has allowed brewers to use remarkably pure and viable cultures.

Unlike ales, lagers demand clean yeast character and subtle flavors, which in addition to the fact they’re traditionally fermented at cool temperatures, has led to the largely accepted notion that they “require” a ton of yeast, around double the recommended amount for ales. As a lager beer brewer myself, I’ve often wondered about this purported requirement, namely whether it’s really necessary to double up on yeast to achieve the results I’m after, but also what impact overpitching might have on my beer. Unable to find satisfactory answers elsewhere, I decided to test it out for myself!

| PURPOSE |

To evaluate the differences between an underpitched and overpitched lager beer of the same recipe.

| METHODS |

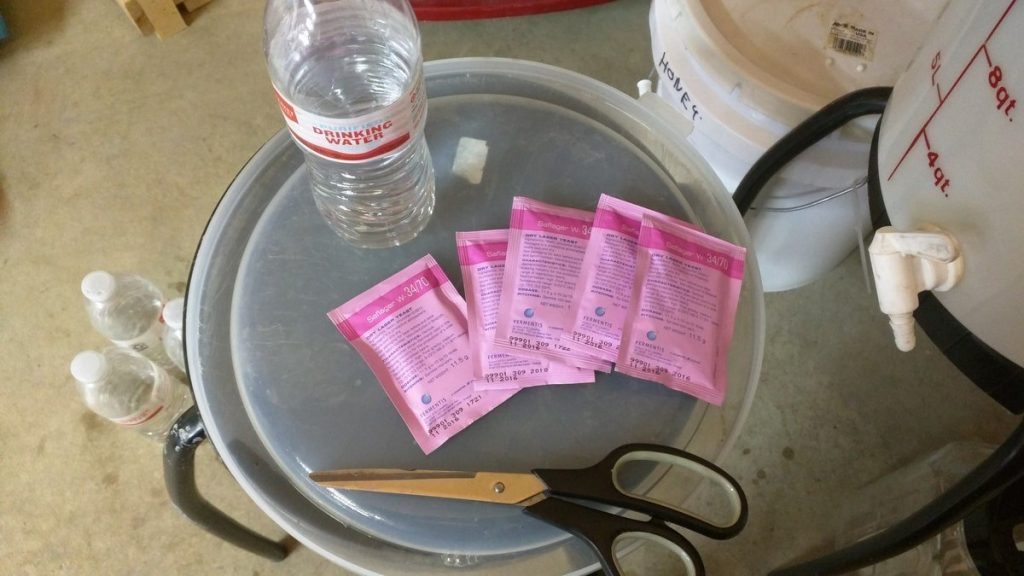

Saflager W-34/70 was chosen for this xBmt not only because it’s known for being the most popular lager yeast strain in the world and thus applicable to many brewers, but the fact it is a dry yeast would presumably make cell count predictions more accurate. While researching dry yeast for this xBmt, I discovered there seems to be some confusion over how many cells are actually contained in each pack. While Fermentis reports 69 billion cells per pack of yeast (6 billion per gram), counting exercises such as the one performed by Sean Terrill suggest a count closer to 230 billion cells per pack (20 billion per gram), which supports Jamil’s claim that Fermentis’ counts are a lower-bound guaranteed amount. I deferred to the latter for this xBmt.

Since a version of my Märzen recipe is frequently on tap at Stone Church Brewing, I don’t feel the need to make it for myself, so I’ve been gradually adapting the recipe towards the Festbier style, a style I figured would highlight any differences caused by the variable in this xBmt.

Festbier 2016

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 33.4 IBUs | 7.0 SRM | 1.056 | 1.013 | 5.6 % |

| Actuals | 1.056 | 1.013 | 5.6 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, 2 row (Gambrinus) | 7.625 lbs | 64.89 |

| Vienna Malt (Gambrinus) | 2.375 lbs | 20.21 |

| Munich Light 10L (Gambrinus) | 1.375 lbs | 11.7 |

| Honey Malt | 6 oz | 3.19 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 14 g | 60 min | Boil | Pellet | 12.1 |

| Saaz | 60 g | 15 min | Boil | Pellet | 3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Download

| Download this recipe's BeerXML file |

I started the day prior to brewing by turning my highly chlorinated, rock hard Corona City water into nearly pure, mineral devoid RO, perfect for building a water profile upon.

The following afternoon, I weighed out and milled the grains for a single 11-gallon batch while my strike water heated.

Once it reached a few degrees above the recommended temperature, I poured the strike water into my mash tun for a brief pre-heat then added the milled grain and gave it a good doughball bustin’ whisking.

Mash-in complete, I found the temperature settled just above my target.

I set my mash timer for an hour then took the downtime to make up a “hop kit” so that each addition was ready to go. I also drank a Swami’s IPA… mmmmm, Swami’s.

After the mash rest, I transferred the sweet wort to my kettle where it was boiled for 60 minutes.

At the end of the boil, I quickly chilled the wort to just above the temperature of my groundwater then took a hydrometer measurement showing I’d hit my intended OG.

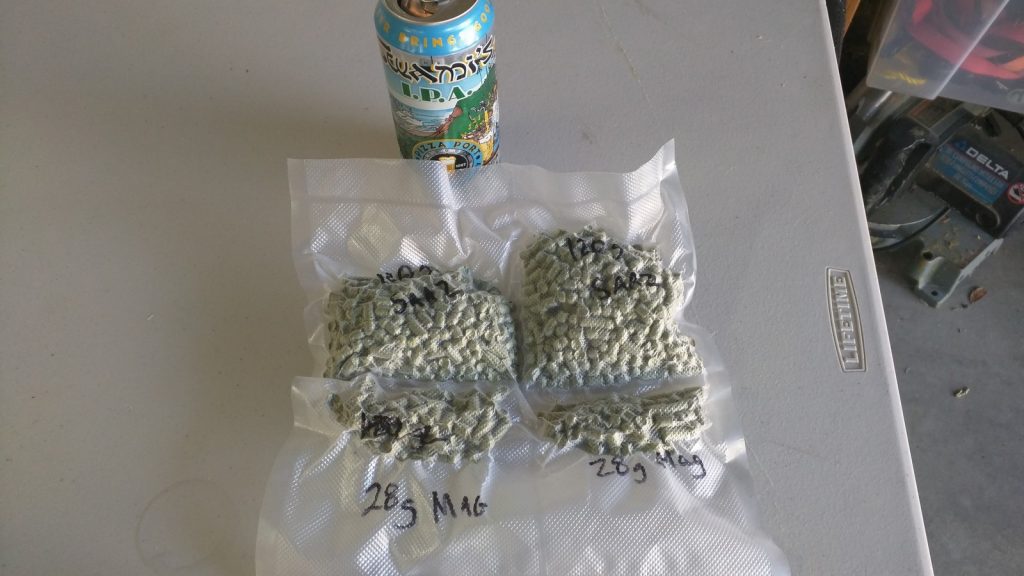

The 6 gallon PET carboys were placed in my cool chamber where they remained overnight to drop to my target fermentation temperature of 56°F/13°C. With the temperatures stable, it was time to introduce the variable. Various yeast pitch rate calculators recommended around 430 billion cells for 5.5 gallons of 1.056 OG lager wort. Assuming the 20 billion per gram estimate is correct, a single pack of yeast contains would lead to a 50% underpitch while 5 packs would result in a 250% overpitch. I prepared both sets of yeast by rehydrating them in 95°F/35°C water then allowing to cool to around 60°F/16°C before pitching.

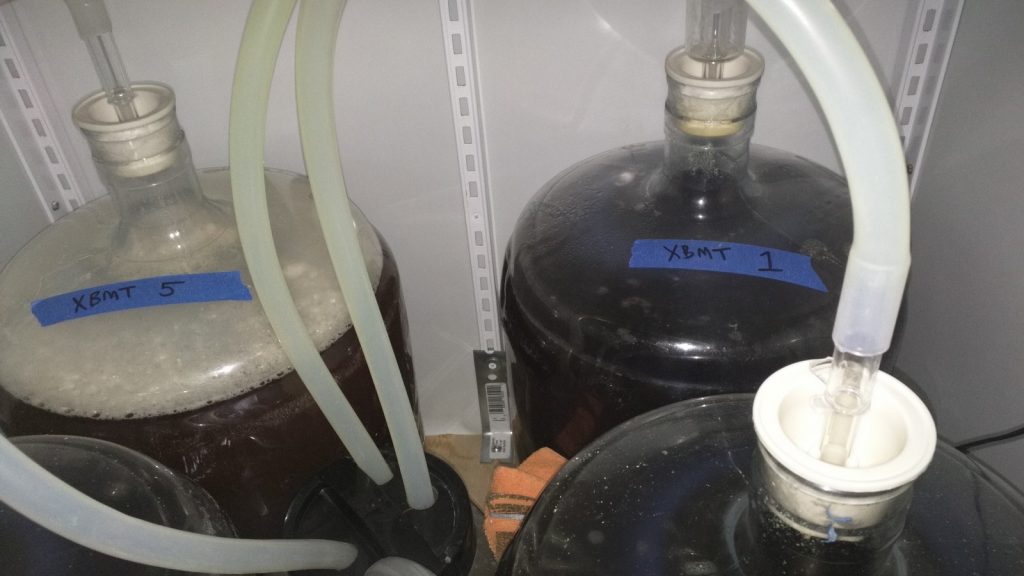

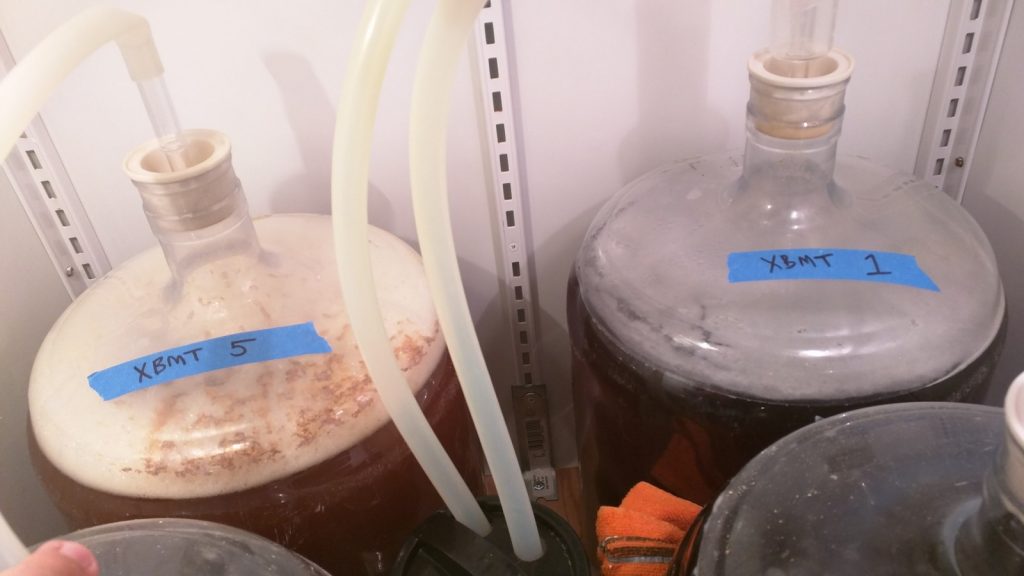

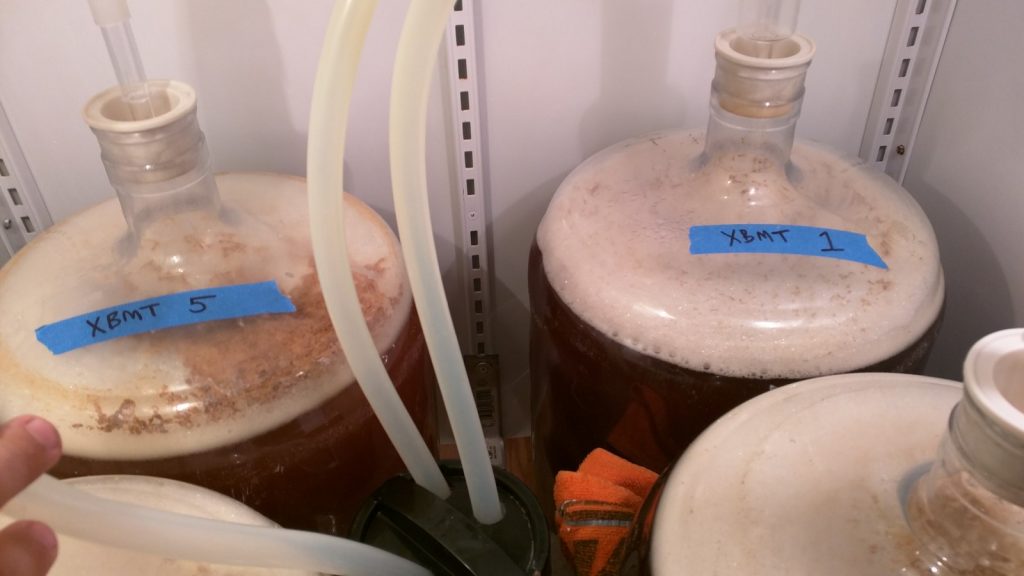

The overpitched batch was beginning to develop a kräusen about 30 hours post-pitch while the underpitched beer still looked eerily like wort.

Another day later, the overpitched beer was in full-swing as the underpitched batch appeared as though little was going on.

The underpitched beer was finally making some progress by the third day, just a couple days behind its overpitched counterpart.

Both beers were fully engaged and ripping along nicely 4 days post-pitch, which is when I began inching up the temperature to promote a complete fermentation.

I observed no visible signs of activity in either batch at 12 days from the kettle and took hydrometer measurements revealing both had reached the same predicted 1.013 FG.

The beers were cold crashed, fined with gelatin, racked to kegs, then burst carbonated. By data collection time, both had cleared equally well and shared a pleasing amber hue.

| RESULTS |

A total of 15 people of varying levels of experience participated in this xBmt, many during a BeerMe Brew Club meeting, and all blind to the variable being investigated. Each taster was served 1 sample of the underpitched beer and 2 samples of the overpitched beer in different colored opaque cups then asked to select the unique sample. In order to reach statistical significance with this number of participants, 9 (p<0.05) would have had to make the accurate selection. In the end, only 5 (p=0.60) were able to do so, which is exactly congruent with chance, suggesting tasters were unable to reliably distinguish a lager fermented with approximately 50% the recommended amount of yeast from a similar lager fermented with nearly 250% the recommended amount of yeast.

My Impressions: I keep tricking myself-– on a few occasions, I’d pour myself samples of both beers to evaluate, initially think I could tell a difference, then wait a few minutes before taking more sips only to find what I thought was different had switched cups! My performance on “blind” triangle tests was, wait for it, 1 out of 3, exactly the same as participants. I could not reliably distinguish either beer from the other, even in side-by side tastings, even after tasting them as different then simply shuffling the cups, forcing me to accept that any differences I thought I perceived were likely in my head.

| DISCUSSION |

I’ve fermented many batches of lager with a single pack of dry yeast, which by conventional standards means I’m underpitching, yet my experience has been hugely positive. No major off-flavors, I’ve even won a few awards. In chatting with the other contributors about these results, I learned I’m not alone in this camp. While I’ve little doubt yeast pitch rates are important for healthy fermentation, it seems to me the relationship between cell count and quality of the finished beer including attenuation and overall character isn’t as linear as I once thought. Especially since several yeast pitch xBmts have yielded non-significant results, and this direct comparison of pitch rates is similarly insignificant.

Despite the fact tasters were unable to reliably distinguish between the underpitched and overpitched beers, there were some differences. For example, the underpitched batch took nearly 2 days longer to show signs of active fermentation compared to the overpitched batch, which may be viewed by some as reason enough to pitch more yeast in order to decrease the risk of contaminants having their way. A more practical difference can be seen in price– at $6.00 per pack of yeast, the underpitched batch cost $24.00 less than the overpitched batch. Of course, the amount of yeast used in the overpitched batch is unreasonably high, the fact it was perceptibly no different than the underpitched batch suggests pitch rate may be an area of diminishing returns.

Admittedly, I’ll use these results help to assuage the twinge of guilt I feel when pitching a single pack of yeast into a batch of lager when all calculators agree it “requires” two packs. This is in no way a recommendation that others follow suit, as this is a single data point using a specific strain of yeast and thus the results may not be generalizable. But hey, $6.00 is $6.00!

Please share your thoughts on pitching rates or the results of this xBmt in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

37 thoughts on “exBEERiment | Yeast Pitch Rate: Underpitch vs. Overpitch In A Märzen”

I’ve been waiting to see regular pitch vs 5-10x underpitch (so much so I’m trying it myself this winter).

Great experiment! Thanks!

BTW I’ve seen some papers in the literature that say overpitching increases diacetyl. Others talking about esters. Inconsistent though, and probably strain dependent.

O tend to believe the 200 billion cells for each pack since everytime I use Brewers Friend’s calc with the rated 110 billion cells, I get all the characteristics of overpitching. Like a lag phase of only 2 hours in a lager or complete attennuation in 48h on ales.

Interesting xbmt guys. I can’t help to wonder if you’d see more pronounced differences with a liquid yeast strain. One of the biggest sensory differences reported between liquid and dry yeast is the expression of ester flavor and aroma compounds. Additionally stress, or lack there of, associated with under and over pitching can lead to detectable differences in ester profile. Seems like this might make for a interesting test.

Also, it would be interesting to see similar testing with more flavor yeast of any kind.

You guys have turned Monday into my favorite day of the week. It’s not the beginning of the work week anymore. It’s xbmt day! I have had good results doing one pack of 34/70 per batch but I do a 1500ml starter with it and my lag time is more like your overpitch batch that way.

I love the effort of this one and I agree with the conclusions except holy hell, who charges $6 for W34? I sell it for $4.25 https://www.brewhardware.com/product_p/saflagerw34.htm. You did hit on the point about reducing lag time. If I’m noting being lazy I’ll rehydrate a single pack of W34 otherwise I pitch two packs so that I don’t do a 5 gallon wort stability test.

I bought some at one of my LHBS and they charged $7.20, I would have gone somewhere else but I was there and didn’t have time to go to another store. It amazes me how 34/70 is so much more expensive than other dry yeasts at many stores

I really wonder about this. Conventional wisdom states that the yeast should get stressed out and produce all kinds of undesirable things, but its very difficult to argue with empirical evidence. Great job.

Yes, because one experiment which was fermented at naughty temps and where will also didn’t actually taste the beer because hey, it’s one and done. / :-/

WTF is naughty temps?

Possible that the underpitched batch simply was not underpitched enough to generate significant stress.

There was some time ago a series of blog posts about weizen that has tied specific characteristic with underpitching in an experimental manner. I couldn’t find it now, but it’s somewhere there.

It’s quite often recommended to under-pitch for styles like Hefeweizen as it supposedly stresses the yeast and causes more by-products that produce esters or peachy flavours (if that’s the profile you are after).

Since I have used using the Mr Malty calculator I have not had any stalled or under attenuated beers. The size of these starters also lets ale yeasts grow to five to eight times the amount pitched, while lager yeasts increase three to five times without stress.

It sounds a bit like you prove that underpitch yields the same results as “proper” pitch as found by some calculators in your discussion. But that was not REALLY what you were investigating, was it? Overpitching is said, by the same authors you quote in the beginning, to give non-optimal results too.

It appears to me the under pitch was not low enough. Under pitch was 1/2 the estimated correct pitch rate whereas the over pitch was 5 X. These are not equal. Based on the results I would expect a 1/2 to 2X to have no difference, but what about 1/3 to 3 or 1/4 to 4 or 1/5 to 5? Also 34/70 aggressively reduces diacetyl and one reason it is so popular. Also the ferment temp and pitch was on the warm end for lagers and raised after 4 days. Why not try WY2000 or 2001 which are more cold tolerance and produce more diacetyl, allow to ferment at 50F for two weeks, taste for diacetyl and then raise the temp. I used to pitch one XL pack per 5 gallons with 2124 and it worked well. Other yeasts not so much. I also believe those yeast that produce and have trouble with reducing diacetyl would not fare very well with the Narziss? ferment process.

I haven’t really looked at pitching rates, I’m still working on some other aspects of my brewing (2.5 gallon batches, 1 dry yeast packet ea). Are we talking about a linear relationship for proper pitch rate?

nice XBMT – I don’t do alot of Lagers, but when I do I always try to overpitch (essentially an additional yeast pack on top of the calculator suggested.

but, I’m actually more interested in US-05 pitching rates.

as probably the most popular Yeast on the planet (at least in a homewbrew sense)

I’m interested in the affects of an underpitch v overpitch, and at a specific temp/

i.e – under pitch and ferment low without a D-Rest

– underpitch and ferm higher (20 Deg C) no D-Rest

– overpitch witht he same temps/consitions

– overpitch same conditions

Have you thought about a pitching rate experiment on an IPA? I’ve heard that overpitching an IPA alters some of the hop character because the excess yeast bonds with the hop oils, causing a biotransformation in the flavor compounds of the hops. I’ve heard that it can either decrease the perceivable hop flavor, or the biotransformation will create a whole new set of flavors (like the soft and juicy hop characters from NEIPA’s). This is probably also yeast strain dependent, but it would still be a cool experiment to try out.

Another hoppy yeast experiment would be pre and post fermentation dry hopping. Scott Janish has covered this a little, but I haven’t found much in the way of a true comparative analysis on the differences in flavor. I’m actually running something similar to this myself at the moment, where I brewed 20 gallons of a hoppy pale ale. Two carboys we dry hopped at the start of fermentation. The other two were dry hopped after fermentation had ceased. I’m yet to try them, and am really curious to try the results!

https://brulosophy.com/2015/06/29/yeast-pitch-rate-pt-2-viable-cell-count-vs-vitality-exbeeriment-results/

This was closest.

I like so many of the xBeeriments but this one is kind of dogshit. I think liquid yeast would be a better bet and can you guys try and brew a lager at correct temps? You should really talk with Fermentis about using 34/70 at hight temps. I have with a lot of their yeasts about variying ferm temps. I’d also like to see this done on a Barleywine or something with a high gravity and an ale. Anyway – cheers!

I don’t think your rude tone justifies a response, but here goes:

the notion of “correct” temps is hilarious to me. Look, you don’t have to like my beer (not that you’ve ever tasted it), but to sit behind a keyboard and call someone else’s process “wrong”, when it produces subjectively good results is asinine. I have been personally happy with my lagers in the 50s, this is homebrewing afterall.

Also, worth noting that fermentation temp was the same on both, so it is irrelevant from the standpoint of the variable being tested.

I have evaluated pitch rate in another way on a high gravity DIPA:

https://brulosophy.com/2015/06/29/yeast-pitch-rate-pt-2-viable-cell-count-vs-vitality-exbeeriment-results/

I will loudly admit the results of any xbmt are single data point, and may not generalize to other conditions (temperature, gravity, strain, etc…). Additionally, a lack of evidence is not conclusive evidence for lack. That being said, have you performed controlled experiments that contradict these results? Are those shared with the brewing community at large anywhere? I would love to see any more data on the subject.

The closest seems to be this one (http://seanterrill.com/2010/05/09/yeast-pitching-rate-results/) , which was on a different style, and the beers had a notably different appearance, not sure how they controlled for that (we use opaque cups). Even still, at p=0.167, it should likely be taken with a great deal of salt.

Wow, what a jerk! Maybe Ray can just quit his job and do this sort of thing full time for free, huh?

I enjoy the way that you guys poke the bear, but I wish that each “data point” you present was less predicated on past experiments (quick lager method, higher-than-usual ferment temps, etc). Because now what I’ve learned is that in a lager that I am not actually lagering, that I am fermenting hotter than usual, and with a recipe that is relatively nontraditional (honey malt), I can get away with one packet of lager yeast, instead of a starter. That’s awesome info, but I can’t really use it.

…or you could perhaps save 2 bottles of your triple decoctioned, all Bohemian floor malted, 6 months lagered lager and invest some § in yeast and malt to test the above and see if you indeed perceive a noticeable difference. The result could even be shared right here – all in the sprite of home-brewing 😉

Your exaggeration is the problem with too many home brewers who take these results as gospel to cut corners; They think lager “purists” mean a decoction and obscene lagering time (incidentally, I know of no lager brewery that lagers for six months or employs triple decoction mashes anymore). I am talking about the methods of modern German lager brewing, not some overcomplicated mess. Step mash, four to eight weeks lagering, using modern modified malts. It’s how virtually all “traditional” lagers are made now, and there’s a reason they haven’t stopped doing it that way. Lagering/cold conditioning time matters, their own exbeeriment showed that.

I really prefer lower lag times, so I love my starters. While I have never had an infected batch, the more assurance a starter and more yeast gives me is worth the extra time and money of making a starter. I also feel more connected to the process, so I’ll keep doing it for that. These experiments do make me progressively less nervous to try brewing my first lager.

I’m also interested to know how these hold up if bottled. See how they develop with a few months behind them. Then doing another side by side to see how they’ve matured.. A thought

I would really love to test the difference of pitching rates in ester heavy beers like belgian tripple or heffewizen that really benefits from correct pitch rates.

With all due respect to the love of IPA/APA/Lager there are better styles to test that kind of assumption.

All in all, love your experiments and insights! I’ve learned a TON.

Unrelated question.. why did you use the SS brewtech kettles and not your “new” Spike? Is there any particular reason for the switch?

Different authors! Jake has Spike, Ray and Marshall have SS. I’m not sure what Malcolm uses and I’m too lazy to check.

By looking at BOIL VS. NO-BOIL BERLINER WEISSE | EXBEERIMENT RESULTS! Malcolm has Spike.. just FYI 😉 thanks for pin pointing the one line in the EXBEERIMENTs I do not read

I’d think the problems with underpitching and overpitching wouldn’t become terribly apparent except with reuse 2-3 generations later. Assuming that you either always underpitch or overpitch for whatever reason, you would continue to put poor selective pressure on the yeast which would result in more pronounced off flavors.

Hi guys! Thx again for your endeavours! One question: I can’t really get the expiration date on the yeast packages. To me it looks like Nov 2016? In this case, according to Fermentis FAQs, the yeast would be manufactured two years ago. Taking into account a loss of 4% of vital cells per month (-62% of vital cells), mrmalty would suggest using 5 packages for optimal fermentation. So no overpitching?

Yeast aren’t stressed by underpitching. They are stressed when essential resources are in short supply, the temperature is too high or low, or the cells are overcrowded. Undercrowding is not a cause of stress.

I’m not surprised by the result. More nonsense and pseudoscience permeates discussions about pitching rate than any other aspect of brewing. Low pitching rate can spoil beer if the wort is contaminated with wild yeast/bacteria that get a toehold before yeast cells monopolise the wort. It can also spoil beer if the wort is insufficiently aerated or the starter contains insufficient O2 or ergosterol for the yeast to finish attenuating without stalling early.

The idea that yeast are stressed by being surrounded by sugar and free of competition from other yeast cells is just plain nonsense.

I think this is the real story behind under pitching. And it’s nothing to do with the yeast. It has everything to do with the lag time and the contaminants from poor practices.

Held at temperature too long allowing lactic acid to permeate, acetobacter from a little tiny fruit fly that sneaked in. Those are what I think contribute the off flavors previously blamed on low yeast counts.

off topic sorry. Just found this site, fascinating. Have you guys tried the drop of olive oil in lieu of oxygenation? (big brewers are using olive oil to add antioxidants) I have great results just using a little plastic aerator cone on hose. It slows down wort transfer and I do 40gallon batches. I would love to take aerator off, it gets blocked by occasional hop leaf anyway. Thanks, Ill try to compare on my next batch. BTW Ive split packets off yeast before in 5 gallons still good results. I have also reused yeast for a year and find it gets cleaner after second pitch. I assumed this was because I was pitching at higher rates from lees. (I store yeast under beer and never wash it)

I know this is a few years ago but this is a really great article. I’ve been playing with underpitch lever myself, the beer style you have used is perhaps the best to understand the effect since standard advice with Lager is to overpitch. cheers!