Author: Jake Huolihan

A method that has seemed to experience a bump in popularity over the last few years, perhaps as a result of the growth of the Brew In A Bag (BIAB) movement, no sparge brewing involves eliminating the sparge step by mashing with the full volume of brewing liquor. As far back as 2002, John Palmer discussed the merits of this simplified all-grain approach to beer making in an article he penned for Brew Your Own, in which he states:

At the end of the continuous sparging process, the mash pH typically rises to around 6 as the sugars are extracted and the buffering effect of the malt and wort is replaced by water. This rise in mash pH tends to extract greater proportions of tannins, polyphenols and silicates into the wort that have a dulling effect on the taste. Batch sparging (in which first, second and even third runnings are combined to produce the wort) can exacerbate this effect because all of the wort is drained away, including the majority of the buffering capability, before adding the next sparge volume. (Skip the Sparge!, J. Palmer, BYO, May/June 2002)

In the interest of both speeding up my brew day and producing a beer with more malt character, I’ve tried my hand at the no sparge method numerous times, all successful to the extent that I made beer. As is often discussed, my no sparge batches tend to yield slightly lower efficiencies compared to when I batch sparge, but I can’t say I’ve ever noticed the finished beers as being all that different in terms of malt character or overall quality. However, I’ve never compared beers made using either method side-by-side, and since it seems more brewers are making the switch to no sparge methods, I figured it was good time to test it out!

| PURPOSE |

To evaluate the impact different mash methods have on beer, the same recipe was brewed simultaneously using either batch sparge or no sparge.

| METHODS |

Something about the warm Summer had me yearning for low alcohol yellow beer, so I decided to brew an easy drinking Kölsch for this xBmt, figuring it was light enough to allow any potential variable dependent differences to shine through.

German Kölsch

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 25.7 IBUs | 2.9 SRM | 1.050 | 1.010 | 5.3 % |

| Actuals | 1.05 | 1.006 | 5.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 row) (Gambrinus) | 9.5 lbs | 95 |

| Cara-Pils/Dextrine | 8 oz | 5 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Saaz | 29 g | 60 min | Boil | Pellet | 3.8 |

| Saaz | 29 g | 30 min | Boil | Pellet | 3.8 |

| Saaz | 15 g | 10 min | Boil | Pellet | 3.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| German Ale/Kolsch (WLP029) | White Labs | 75% | 65°F - 69°F |

Notes

| Water Profile: Ca 58 | Mg 5 | Na 8 | SO4 73 | Cl 68 |

Download

| Download this recipe's BeerXML file |

A few days beforehand, I prepared a traditional starter with a very fresh pack of WLP029 German Ale/Kölsch yeast, which turned into one of the milkiest starters I’ve ever spun.

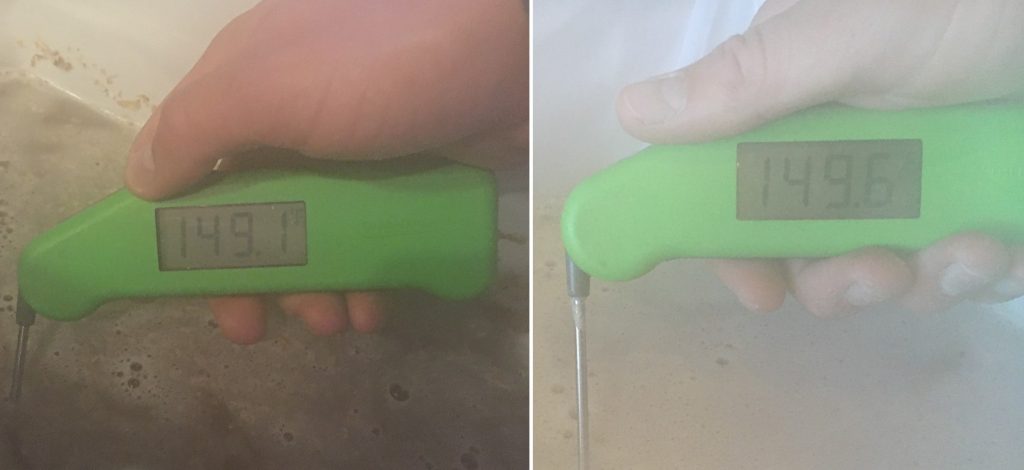

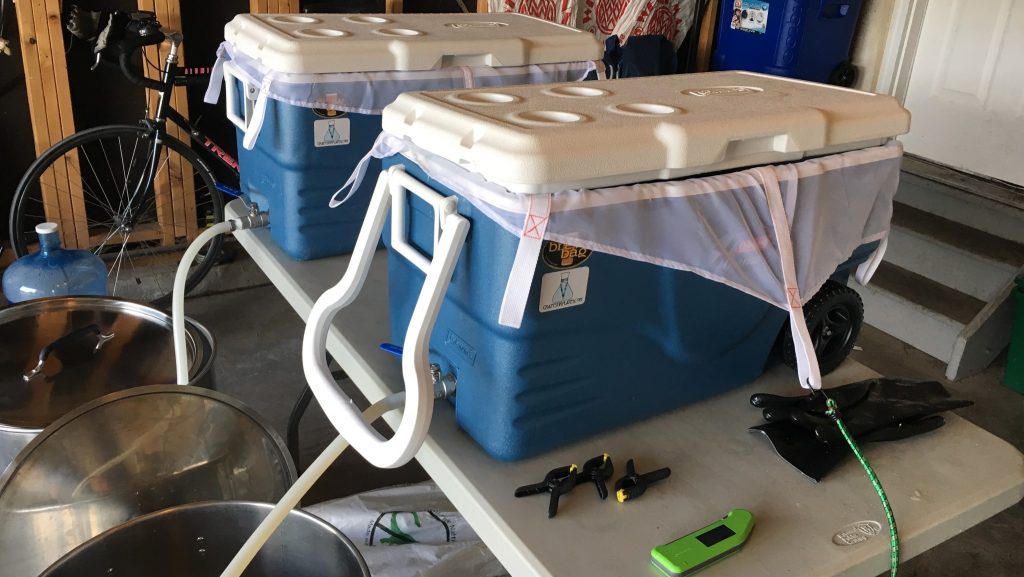

The night before brewing, I gathered all of the ingredients required for each batch including the brewing water, which required different volumes given the variable. For the batch sparge batch, I went with a fairly common liquor to grist ratio of 1.5 quarts per pound of grain, this amounted to 3.75 gallons while the full volume of no sparge water took up 8.75 gallons of kettle space. Immediately upon waking early the following morning, I began heating strike water, staggering the start of each batch by 30 minutes. Similar mash temperatures confirmed I’d input everything into BeerSmith accurately.

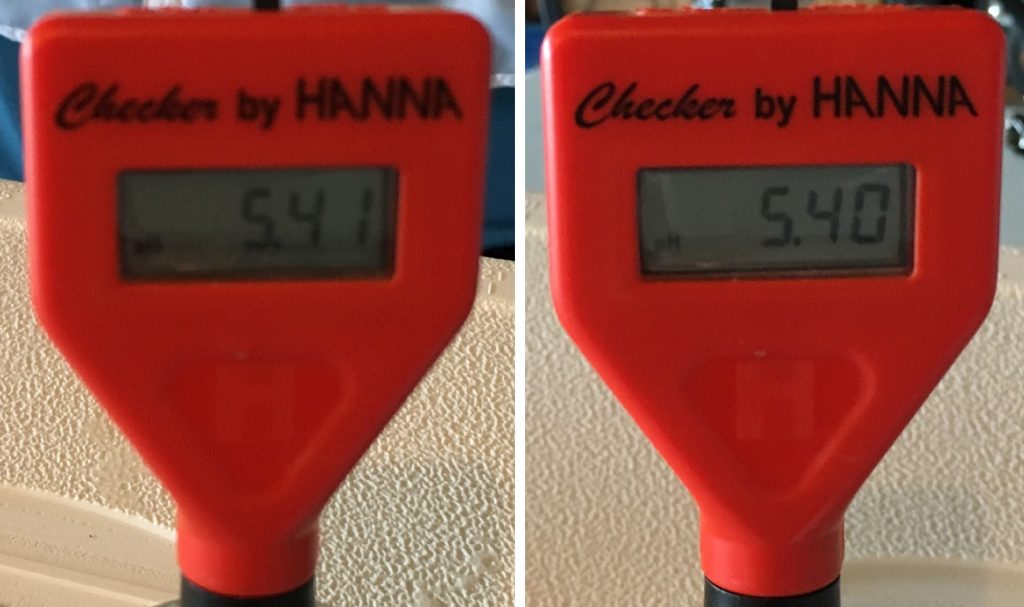

I was pleased to see that pH readings from both batches settled in right where Bru’n Water predicted based on the adjustments I made.

Note that the no sparge mash required quite a bit more acid (34.7 mL of 10% phosphoric) than the batch sparge mash (13.1 mL of 10% phosphoric) in order to hit the same mash pH, so to minimize any potential flavor impact, I added the difference of 21.6 mL of phosphoric acid to the sparge water for the batch sparge batch. Both mashes were left alone for 60 minutes.

I began heating the sparge water soon after mashing in on the no sparge batch. Once the batch sparge mash was complete, I collected the first runnings, added the sparge water to the MLT, stirred, then collected the rest of the sweet wort. When the no sparge mash was finished, I simply drained the entire volume of wort into its own kettle. All said and done, the batch sparge process took approximately 20 minutes longer than the no sparge process, which to me is a solid amount of time! I proceeded to boil each wort for 75 minutes, adding hops at the times listed in the recipe.

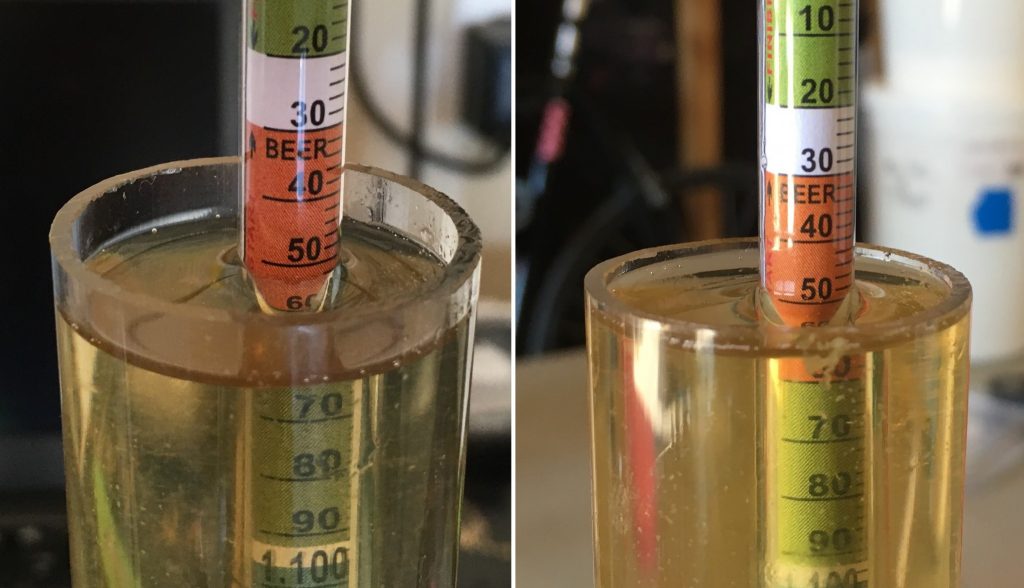

At the end of each boil, the worts were quickly chilled to my preferred fermentation temperature then transferred to separate fermentors. Hydrometer measurements showed the batch sparge wort was at a slightly higher OG than the no sparge wort, which amounted to a 3% difference in brewhouse efficiency (74% and 71%, respectively).

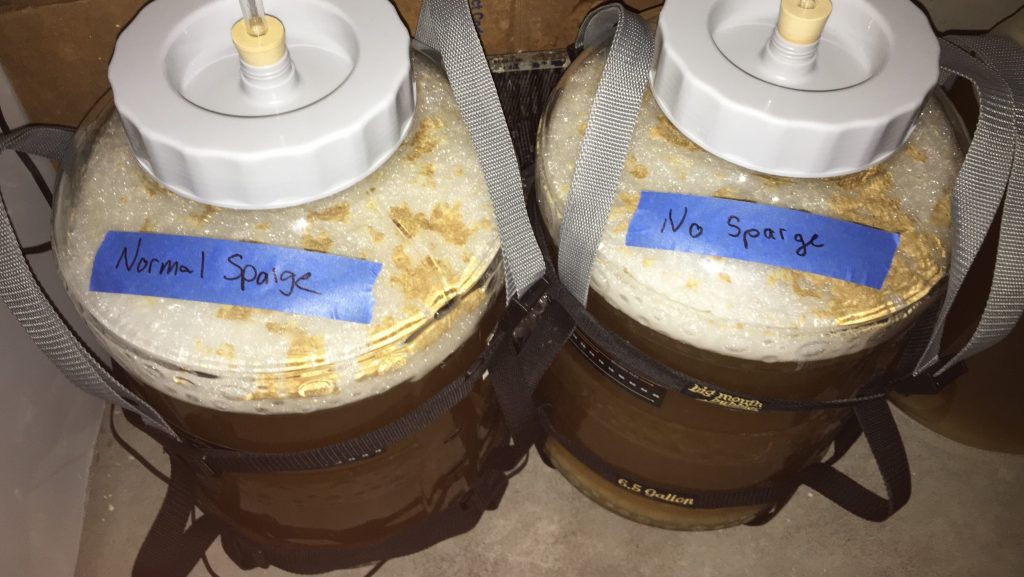

After placing the fermentors in my 68°F/20°C fermentation chamber, I decanted and evenly split the yeast between each fermentor then dosed both 60 seconds of pure oxygen. I observed similar fermentation activity 12 hours later.

From this point on, the beers appeared exactly the same. After 2 days of fermentation, I began gently ramping the temperature over the course of a few days to encourage complete attenuation and clean up any off-flavors. While fermentation appeared to be complete in both beers at the 1 week mark, I let them sit another week for good measure.

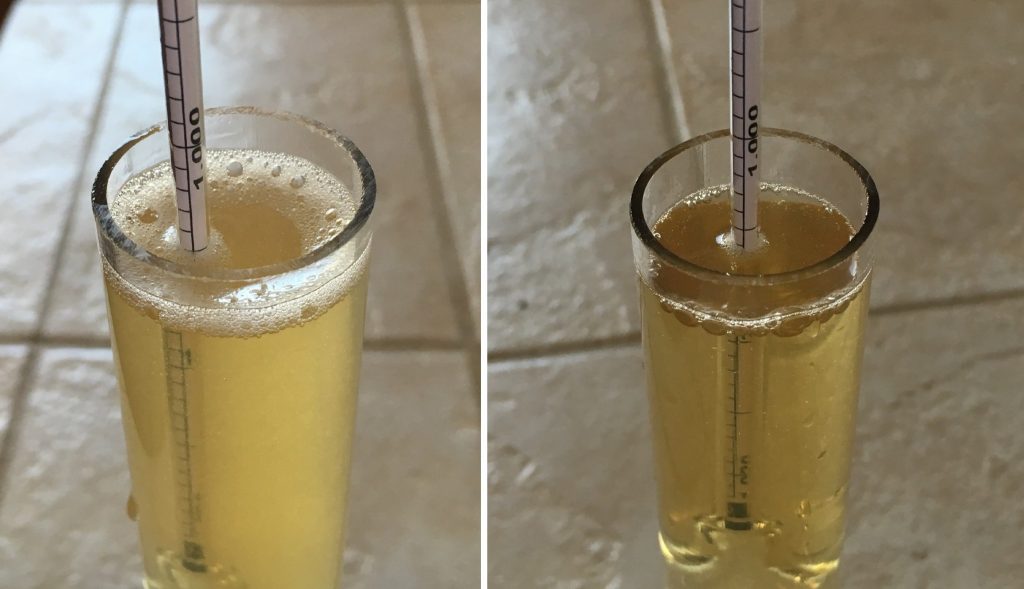

Hydrometer measurements taken 2 weeks post-pitch showed the batch sparge beer fell to a similar FG as the no sparge beer.

It was at this point I cold crashed, fined with gelatin, then kegged.

The kegs were burst carbonated in my keezer then left to condition for a few days before being served to tasters. It appeared the no sparge beer dropped slightly clearer than the batch sparge beer.

| RESULTS |

A panel of 26 members of the Aurora City Brew Club participated in this xBmt. Each taster, blind to the variable being investigated, was served 2 samples of the beer made using the batch sparge method and 1 sample of the beer made using the no sparge method in differently colored opaque cups then instructed to select the unique sample. Given the sample size, 13 tasters (p<0.05) would have had to correctly identify the unique sample in order to achieve statistical significance, while 14 (p=0.02) were able to do so. These results suggest participants were able to reliably distinguish a beer made using the batch sparge method from one produced using the no sparge method.

Following completion of the triangle test, the 14 tasters who correctly identified the unique sample were asked to complete a brief preference survey. Still blind to the nature of the xBmt, 7 tasters said they preferred the batch sparge beer, 3 liked the no sparge beer more, another 3 said they had no preference despite noticing a difference, and 1 person reported noticing no difference.

In chats with tasters after completing the survey, those who were correct on the triangle test had difficulty putting their finger on what about the beers were different. Some said they perceived the batch sparge beer as having a slightly different mouthfeel and “thinner” flavor than the no sparge sample. Another person noted the batch sparge beer left a slight lingering flavor in the back of their mouth.

My Impressions: I began tasting these beers sooner than the participants and I’ve never been able to distinguish them, despite knowing the variable. Obviously, this doesn’t align with the results, which is either an indication of my shitty palate or the fact these beers really weren’t all that different, just enough to be reliably distinguished by participants. Visually, the beers are clearly different, in fact the batch sparge beer remained hazier than the no sparge version until the kegs kicked. I found both to be fine and easy-drinking, but they had a slightly stronger fruity ester than I typically prefer in this style, something I’m inclined to attribute to fermenting on the warmer end of recommended temperature range. Kölsch being one of my favorite styles, I’ll certainly be brewing more, though in future iterations I plan to add a touch more Crystal malt and ferment a tad cooler.

| DISCUSSION |

Based on my multiple experiences with these beers, I was admittedly surprised by the results showing participants were able to reliably distinguish the batch sparge beer from its no sparge counterpart. While they didn’t share similar levels of clarity, they weren’t that different and looked identical when served in the opaque cups we use for data collection, which makes me think the differences tasters perceived were not a function of appearance but rather the different mash methods.

Speaking of appearance…

I’ve used gelatin to fine many beers, it works beautifully the large majority of the time, though occasionally a beer will remain hazy despite my best efforts. If the haze in the batch sparge beer was an actual result of the variable, it would seem to provide support for the idea that the sparge process extracts more “tannins, polyphenols, and silicates,” as Palmer and others have pointed out, which perhaps is what allowed tasters to tell them apart. However, the fact is I’ve made many crystal clear beers using the batch sparge method, hence I’m left wondering what’s really going on.

While these results appear to confirm the notion that the batch sparge method produces a qualitatively different beer than the no sparge method, more exploration on the topic is warranted before anything conclusive can be said. And even if the difference is real, the method one chooses to use remains wholly a matter preference, as stellar beer can be made either way. I will continue to use the no sparge method for 5 gallon batches because it’s easy, it works well, and I’m okay exchanging a minor hit to my efficiency for the time savings.

Please feel free to share your thoughts and experience with the difference mash methods you’ve used in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

53 thoughts on “exBEERiment | Mash Methods: Batch Sparge vs. No Sparge In A Kölsch”

the no sparge beer dropped clearer, right. there’s an error in the text right above the picture of the beers in the glasses

By changing the PH prior to the mash didn’t you eliminate one of the primary differences in the types of Spages? I haven’t made the leap yet into water adjustments other than a carbon filter so please forgive my lack of understanding here. But aren’t you adjusting the variable out of the equation resulting in a similar beer vice letting the variable do its thing keeping the initial water properties the same?

It’s one of the proposed differences, one we thought it best to control for this first time around. In future iterations of the xBmt, we may not. Cheers!

It makes more sense to make sure you make each version of the beer the best you can rather than from the get-go hinder one of them, IMHO. Glad you added phosphoric to the sparge water as well, good thinking.

Well, depends on what the point of the xBmt was. The premise of the “Skip the sparge” Palmer article was to say that sparging raises the pH which is bad for the quality of the beer, therefore do no-sparge for better beer. If the purpose of the xBmt was to find out if traditional batch sparging really produces a lower quality beer, then acidifying the sparge water kinda negates that (because it corrects the problem the article said existed). However, since many xBmts seem to be about “can we make just-as-good beer more easily,” then it does make sense to keep the acidity equal so the only variable is the simplicity of the process.

You don’t say if you squeezed either batch bag. Typically the water retained by the grain after squeezing is 7.5 oz or so, while the no-squeeze will result in 14-16 oz depending on the grain plus whatever is left in the tun. In addition, squeezing yields more sugars into the boil kettle; in this case 70 oz or just over two quarts, which would have made up for the difference in the gravity readings. However, adjusting for this must be done when calculating the strike water volume.

I don’t squeeze the bag. I’m pretty much performing a normal mash with the amazing benefit of the easiest clean up ever

Squeezing the bag improve the efficiency a lot, I almost guarantee above 80%, and change for sure the final beer. That is a suggested xbrmt.

Maybe the wlp 029 is the cause off the haze in both beers even post gelatin. It takes a minimal off one month at cold conditioning to clarify well. Just dont know why this little difference between both samples tested.

Could be, I just wonder why one was perfectly clear nearly right after kegging and one never cleared. I’m inclined to think it’s a result of the variable being tested but who knows

There is a temperature variable to consider as well, assuming that the batch sparge water was heated above the mash temp water.

With traditional full volume BIAB, you use a full volume of water in the mash – which happens in the brew pot (not a separate cooler / mash tun). So it is a continuous sparge…with full volume of water in the mash. The beauty of it is not that there is “no sparge”, rather that there is no extra sparge needed, because it is already happening because your mash is at full volume.

Variations like this where you don’t mash at full volume will wind up with low efficiency if you don’t include a separate sparge. Full volume BIAB mashing has much higher Brewhouse Efficiency / EIB.

Whats the difference between a full volume mash in a cooler and a full volume mash in the kettle? Either way its a full volume mash, I don’t see what you’re getting at.

Most of the “BIAB” type processes we read about that have “not so good” 70ish efficiency always seem to happen when people try to deviate from traditional full volume BIAB (i.e. using a smaller pot than normal, and then sparging). Biggest discrepancy that pops out in this example is the additional 20 minutes of time of grain contact that the sparged grain received. That is important. Does using the cooler make a difference? Maybe not, not sure…logic would say “no”…but perhaps lack of a mid-mash stir could. (?)

My BIAB bag is a flat bottom bag – no cone shaped, and I believe that helps by not compacting the mash. Also I do a 90 minute mash followed by 90 minute boil. So for those traditional 3V brewers that do a 60 minute mash followed by a 30 minute mash – this is identical grain contact time. I stir really good when mashing in, and at least once in the middle of the mash (I partially pull the bag to heat the water – stirring really good before partially pulling and again before covering it back up). Pot gets covered with blankets and sleeping bag when mashing… With the cooler for mashing, I wouldn’t think anyone would stir in mid-mash because of losing heat. Does that matter? I don’t know… Also I squeeze the bag at the end. Easy to do with a brew pot BIAB bag when using a pulley. Does that matter? Not sure, but I tell myself that I’m getting an additional point or two… 🙂

My “Efficiency Into Boil” (aka “Brewhouse Efficiency”) can vary depending on the batch, recipe, etc., BUT the norm is honestly 82-84%. Think the lowest ever was around 80, and the highest was around 90…but average in low to mid 80s… I conduct my BIAB by the “traditional full volume method…” Besides being meticulous in record keeping, cleanliness and using good equipment, I don’t know anything else that is all that special.

Yeah it says 8.75 gal went into the no sparge batch…. Sounds like full volume to me. There’s no difference between doing it in the kettle and doing it in the cooler as long as temps don’t fall…

I have always thought the higher PH of the second and third batch sparge methods was where the tannins were coming from. Even stated from the quote from Palmer. By adding the difference in acid to the sparge water I am unclear what was being tested in this xbeeriment. By quoting Palmer I was thinking the test was about extracting the tannins etc. using a batch sparge vs. a no sparge.

You will still get more tannins and other stuff into your wort if you do a batch sparge with pH-adjusted water. One could argue that the best possible batch sparge method is to run off, refill with pH-adjusted water, and then run off. To me, this is a comparison of the best method for doing a batch sparge vs the best method for doing a no sparge.

Well, you basically say that by modifying the pH, there should have been no differences. The beauty of this exBeeriment, at the end of the day, is that there *is* a difference, and we’re left wondering where it comes from.

Did you vorlauf both of the batches before running off? How was the clarity in each? I am surprised that the batch sparge beer is not the clearer one. I have noticed in the past that my fly sparged beers seem to clear up much slower than my batch sparged beers. I always assumed this was due to more stuff in the beer that can pull out the yeast after fermentation. I would expect more stuff in the batch sparged beer compared with the no sparge beer, and thus that the batch sparged beer would be clearer. Did you measure the post-fermentation pH?

So did you measure the pre boil wort pH of each batch? I’m curious about the effect adding the extra acid to the sparge water had. If brun water predicted the same mash pH with the different amounts of acid based on water volume, then wouldn’t the pH of the pre boil wort of each batch then be the same? Wouldn’t adding additional acid to the sparge water then lower the pH of that batch below the other one? Perhaps that is the reason for the noticeable difference between the beers? Or maybe I’m missing something…

I did measure pre boil ph for both beers and it was the same according to my ph meter (5.37 and 5.39). I imagine the mash effectively buffered the ph in the sparge water similar to how it did so in the no sparge.

The first time I used BIAB I had really low efficiency. I think it was because the grind was to course. A lot of literature suggests that double grinding will increase the efficiency for BIAB beers. How were the grains crushed for this eBmt?

They were crushed at my LHBS using their mill.

Aaron, sometimes brewers mix methods without taking advantage of using a fabric filter. Without adjusting the mill gap down, the second pass of milling has little impact on the result. The key to BIAB is a combination of finer grinding, as low as the mill will allow, and increased water to grain ratio – as high as the final results call for but anything over 2.5 is when the magic happens.

Just curious, did you squeeze the bag from the full volume sparge to extract absorbed wort?

I usually squeeze that thing like it owes me money, helps with efficiency.

Did not squeeze either batch. I never have in fact.

Not squeezing leaves behind about 7 oz of same gravity wort per pound. You need to figure this in the water calcs. Doing so increases kettle volume and efficiency as there is no unnecessary dilution used to move the wort from the mash tun to the kettle.

what was your HCO3 or CaCO3 ? cheers

Really interesting to see that the no-sparge beer is clearer. I agree that the cause is probably the variable being tested. When I batch sparge the runnings after the sparge are much milkier and cloudier than first runnings – the hot water and disturbed grain bed clearly pull some murky stuff into the wort.

One great advantage of no-sparge brewing is that the mash holds its temperature well due to the high thermal mass. This makes this method ideal for overnight mashing. I’d love to see an xBmt comparing an overnight mash to a standard mash to see if there’s any difference in taste or efficiency.

To be honest, I think dudes who have spent a lot of time and money on the sparge process and whatever kind of E-HERMS stainless 3 vessel system they’re running have trouble accepting the fact that you can either add all your acid to the full volume or split it between the mash and sparge water, and you’re going to get a very similar result. If you’re recirculating a full volume mash your efficiency will only increase. IMO the only issue could be with using a large amount of partially modified malt, whereby with big water/grist ratios you destabilise beta amylase with too much starch dilution. In this instance you would want to keep your mash temps lower otherwise you’ll really create very hostile conditions for beta. This of course wouldn’t apply to well made, highly modified malt.

BTW that Ph meter is only rated to work under 122 degrees, so ? the accuracy unless you cooled a sample.

Correct the samples were cooled to ~70 degrees prior to taking a reading.

Can I ask, what beersmith profile do you use for MIAB? I am about to start, but confused if I should use BIAB profile, single infusion etc

Thanks

Another excellent topic. To work around the sparging issue with higher pH water, on my last two batches I’ve drained my mash tun down to about an inch or two of wort above the grain bed. Decocted ~70% of the remaining grain for 20 minutes, added it back to the mash tun, stirred, rested for 15 minutes, then drained what was left. I have to say, I feel better decocting the grains then sparging them; even using neutral water.

I love this stuff!

Great experiment and discussion. Can i try the thc beer! Figured you were from colorado. I try not to, but i just have to squeeze my sack. I feel like im throwing away a dollar or something. Some of the best looking wort comes out of the squeeze, but i bet it hurts clarity. Makes sense that not squeezing it would yield a very clear beer. It has the full volume draining through a filter bed in that clever setup of yours. I would vorlauf in that setup as well if i wasnt squeezing. I have always felt not vorlaufing is a disadvantage of biab.

Consider that when you vorlauf you’re introducing pure water which dilutes the wort. If you mash full volume and squeeze, the wort is 100% same gravity and leaves only 6-8 oz in the grain and none in the tun, whereas when sparging, the grain holds 14-16 oz per pound of grain plus the remaining lower gravity wort not released into the boil kettle.

I no-sparge when I brew 6g batches. I batch sparge for 12g batches (since my 15g kettles can’t accommodate the grain and full volume of liquor). I have a pump that recirculates during the mash and I stir at least once, usually twice. With these practices, 6g no-sparge batches consistently produce an efficiency of 65%; 12g batch-sparges reach 70%

Because of the different expected efficiencies, I scale the grain bill as needed.

In order to reveal the qualitative differences in beers produced between the two methods, beyond OG, such as tannins, polyphenols and silicates, shouldn’t you have scaled the grain bills, so that they each reach a consistent OG?

I am curious to know why a fly sparge was not also included? As far as clarity did you measure the pH, SG and temperature of the final batch runnings? These are the variables that leach tannins etc.. What was the pH of the final worts prior to fermentation? This may affect attenuation and clarification. One final comment on batch, no, and fly sparging and clarity. In batch sparging if the mash is not recirculated between draining it will naturally be cloudy each time wherea no sparging will be fairly clear if recirculated and it not it still will filter more particulates in the grain bed. With fly sparging one recirculates for about 10 minutes to get clear wort than flush for 45 minutes to collect 15 gallons.

For my system I will no sparge will always require adding water to the boil as my batches yield 15 gallons of pre boiled wort from a 15 gallon mash tun. With fly sparging I add water for SG 1048 or under as sparging to the full volume would exceed grain weight to sparge volume limits and the final sg of about 1008 – 1014..

So I conclude no spare result offers insurance against over sparging small beers, but reuqiers a much larger mash tun than the boil to be utilized for most SG’s.

Adding a third variable would disallow use of the triangle test. We’ve done fly vs. batch sparge in the past, we’ll get to fly vs. no sparge at some point as well. Cheers!

I’d really like to see an experiment for water to grist ratio with a grain bill using a more traditional, less modified and less enzyme-rich base malt such as Munich or Vienna, or at least if using modern 2-row then a high percentage of adjuncts such as wheat, rye or oats.

This would really put a high water-to-grist ratio to test, because it would seem that beyond ratios of around 4 or 5 to 1 (L/KG), fermentability drops off as beta amylase becomes more unstable due to the the relative unavailability of substrate in a very diluted mash.

Had to chime in here because my last brew was just that…. I had a water to grist ratio of 3.2 lb/L of 100% vienna malt and it really had a hard time converting. It was Wyermann. I’ve never had that much difficulty converting before that brew. I came in well below my target pre boil gravity and had to add DME to the kettle.

Sorry I meant qt/lb not lb/L

How are you certain you didn’t have conversion? Did you perform an iodine test? I’ve never had problems with conversion in full volume mashing and have used it nearly exclusively since this article.

Most of the time when I’ve seen people who get poor conversion or efficiency it’s actually a volume issue.

@Jake Huolihan

I converted to 1.030 using a refractometer. Beer smith had me calculated at a 1.045 pre boil gravity. I just couldn’t get that last third out of the mash even after 90 minutes.

Really interested to hear a reply to this question. I would like to know the same:

charliwest

August 30, 2016 at 1:10 pm

Can I ask, what beersmith profile do you use for MIAB? I am about to start, but confused if I should use BIAB profile, single infusion etc

Thanks

I use my batch sparge profile, it works perfect.

With that setting do you mash then with the smaller amount of water beer smith suggests or just put the full amount in?

If I’m doing batch sparge, I do the split amount; for no soarge, I adjust the strike to full volume.

My one observation is that you should have received information of the malt you used which would have let you calculate the maximum extract you could have recovered from your malt charge in litre degrees/pound, and compared it with what you actually recovered to compared the efficiency of your extract recovery methods. Would be interesting to have seen those results.

I do a recirculating BIAB mash in an electric urn, kind of like RIMS, and consistently get around 83% kettle and 75% brewhouse efficiency.

Nowhere do you actually tell us the volumes of water used! How can anyone reproduce this experiment without vital statistics? You told us the amount of grain and the amount of water in the initial mash for the batch sparge, but you didn’t tell us the volume you added the second time, nor did you tell us the total volume you collected, nor did you tell us the total volume water you added for the no-sparge method. Give us numbers !!!!

Sorry water numbers are fairly system dependent so likely wouldn’t be the same for you.

Don’t recall total volume used in each off the top of my head, however 1.5 qts/lbs was used to mash for the batch sparge brew, the full volume was used for the no sparge brew, total water between the two was the same. Should be roughly 9.75 gal each, give or take some.

Just the liquor:grist ratio for each presentation should suffice.