Authors: Marshall Schott & Malcolm Frazer

When Malcolm and I learned our Homebrew Con seminar submission was approved, we began poring over how to approach serving beer. The obvious choice was to perform a blind triangle test with the audience, but the logistics of organizing such a tasting with so many people forced to consider other ideas. We tentatively settled on brewing a couple good beers with no real purpose just so that audience members would have something to sip one while the two of us blowhards gave our talk.

It wasn’t until we started putting the slideshow together for our presentation, Modern Perspectives on Traditional Methods, that I had the idea to brew a beer utilizing all of the methods we planned to discuss. Of course! I presented it to Malcolm, who had agreed to brew the beer for our seminar given his proximity to the conference location, and was met with a resounding… well, he was hesitant. Malcolm has a strong aversion to serving people shitty beer, and as I imagine is the case for many homebrewers, the idea of cutting so many components of what we “know” to be good brewing practice had him a little worried. Furthermore, he never sampled my prior two Short & Shoddy batches and hence did not share my conviction it would all work out fine in the end.

Pressure was applied and Malcolm eventually agreed to brew what he coined his bad habits beer.

Bad Habits Hoppy Lager

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 20 min | 21.8 IBUs | 3.8 SRM | 1.044 | 1.011 | 4.3 % |

| Actuals | 1.044 | 1.01 | 4.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Floor Malted, Weyermann, Ger | 20 lbs | 91.69 |

| Cara 8 Malt (Carapils) | 1 lbs | 4.58 |

| Cara-Pils/Dextrine | 13 oz | 3.72 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Sterling | 56 g | 20 min | Boil | Pellet | 8.4 |

| Azacca | 28 g | 6 min | Boil | Pellet | 10.3 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Whirlfloc Tablet | 1.00 Items | 15 min | Boil | Fining |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| German Bock Lager (WLP833) | White Labs | 73% | 48°F - 55°F |

Notes

Download

| Download this recipe's BeerXML file |

Anticipating a hectic session given the time limitations and wanting to avoid any accidental lengthening of the reduced mash and boil lengths, Malcolm did a pre-brew walk-through a couple days before tackling the real deal. With a solid plan in place, he made a starter of WLP833 German Bock Lager yeast 36 hours beforehand.

The following evening, once home from work and family obligations tended to, the training wheels came off and Malcolm got going! After collecting the proper amount of brewing liquor and putting it on the flame, he measured out and milled his grain bill consisting of a high proportion of Pils malt.

Not usually one to document the precise amounts of time everything in his process takes, Malcolm did for this Short & Shoddy batch. It took about 45 minutes for his entire volume of brewing liquor to reach the temperature recommended by BeerSmith in order to hit his target mash temperature of 152°F/67°C.

For the first time in Malcolm’s 18 years of homebrewing, he set his mash timer for a mere 20 minutes.

Once the first runnings were collected, Malcolm performed a standard batch sparge to collect just shy of 13 gallons of wort that he noticed was more turbid than usual, perhaps due to the fact he skipped his typical vorlauf routine. This took a total of 17 minutes. With the flame blazing under his kettle, the wort was at a rolling boil only 5 minutes later, at which point he set his timer for another 20 minutes.

Hops were added per the aforementioned schedule, a relatively large initial charge in order achieve the proper level of bitterness, then just like that, the timer was beeping indicating the end of the boil. Having prepared his chilling setup during the boil, Malcolm cranked the water to his Hydra IC and began chilling the wort.

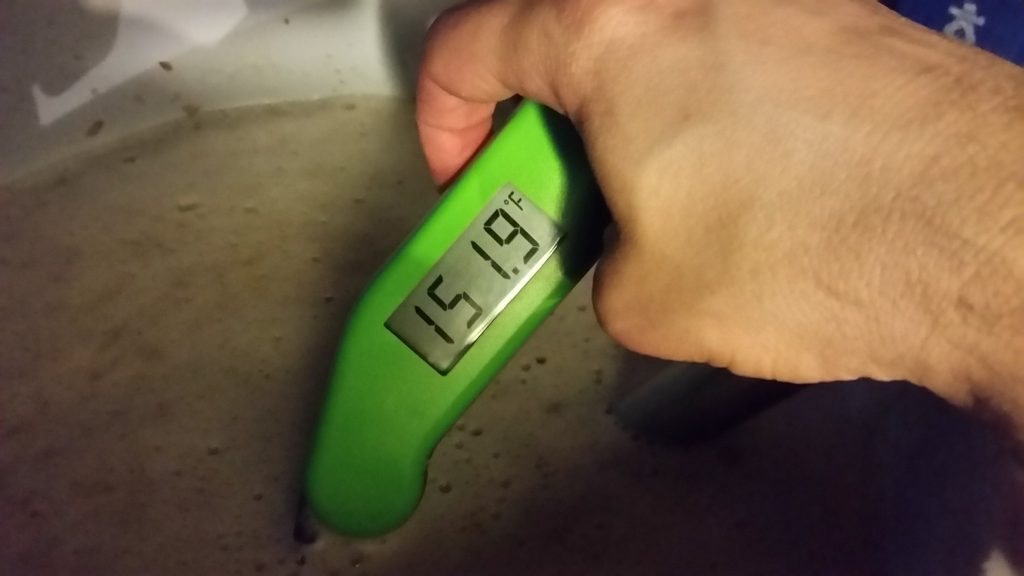

It took about 22 minutes for the entire batch to drop to the target fermentation temperature, after which he racked equal amounts to separate fermentors.

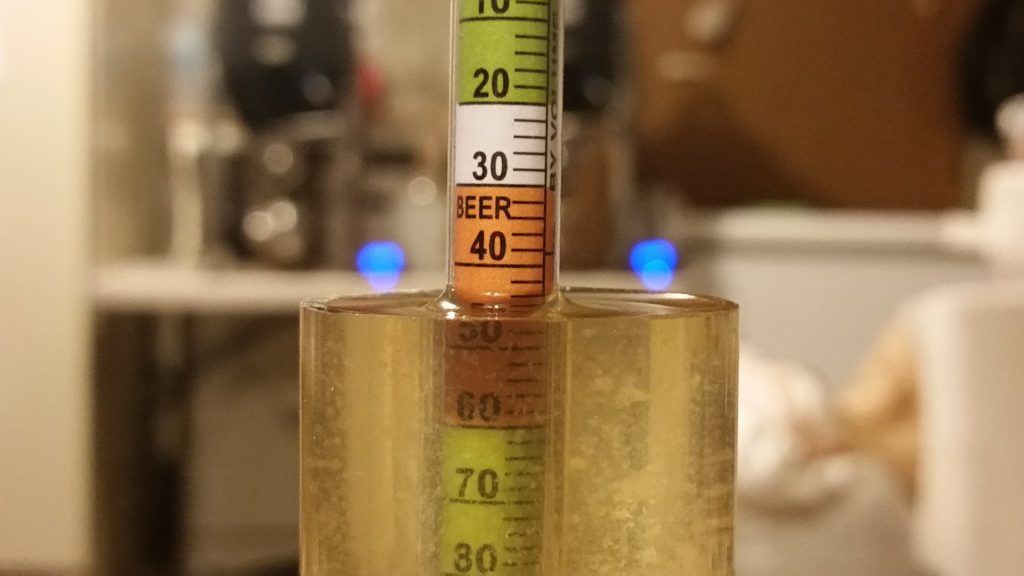

A hydrometer measurement taken at this point revealed the wort was at 1.044 OG, a hair low for a traditional Helles, but just fine for this Bad Habits hybrid version.

He dosed each wort with 60 seconds of pure O2 before splitting the large starter between the fermentors. The beers were then left to ferment at the obnoxiously too-warm-for-lager temperature of 66°F/19°C.

In keeping with the Short & Shoddy nature of this brew, Malcolm made little effort to control fermentation temperature increases caused by the exothermic process and watched as it steadily climbed northward. Hey, bad habits, right? Only 3 days later, hydrometer samples confirmed FG had already been reached. Malcolm shot me a text saying the beer had a very strong sulfur aroma and was still very hazy. We decided to let them sit at 72°F/22°C for a few more days with occasional gentle agitation, reasoning it might help the sulfur dissipate. After 6 days, the FG was the same and Malcolm told me he was still detecting sulfur, but we were out of time, these beers were going to be served less than a week later to unsuspecting audience members during our Homebrew Con seminar.

Malcolm proceeded to cold crash for 1 day before racking the beer to kegs, where they were fined with gelatin. He said he noticed a slight decrease in sulfur at this point, but remained anxious the beers weren’t going to be ready in time for our talk a few days later. He burst carbonated the beers over the next 24 hours then pressure transferred them to clean serving kegs in order to leave behind any gunk that had precipitated out, as they would be going on a long drive and wouldn’t have much time to settle before being served. With slight trepidation, Malcolm pulled himself a sample…

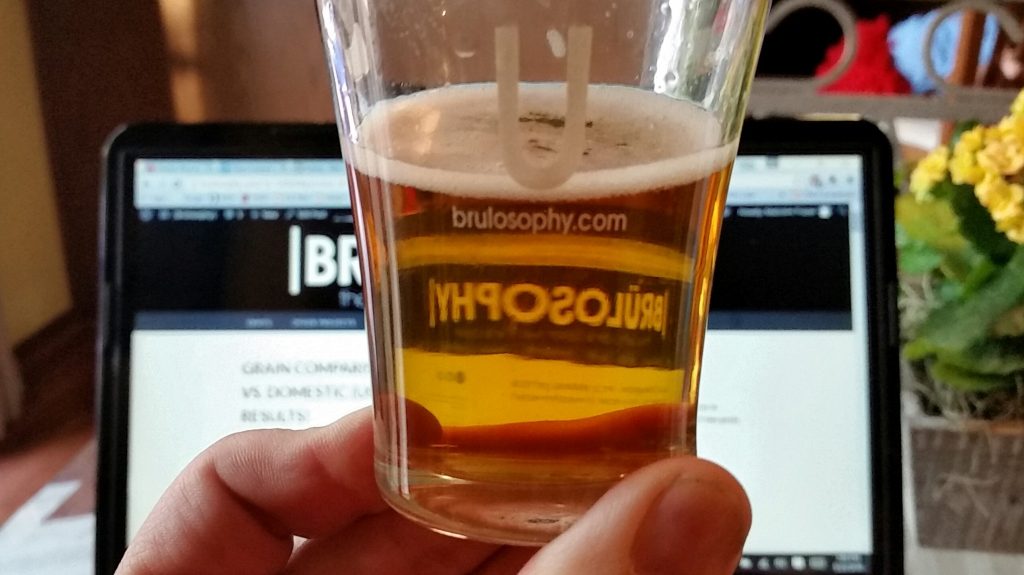

Lo and behold, it was just about ready! Two more days in the cold chamber, 11 since the beer was brewed, and it was about as brite as any commercial lager on the market.

| IMPRESSIONS |

Malcolm admitted some concern the sulfur aroma he detected in the beer might persist, and he wasn’t terribly thrilled with my insistence to serve the beer regardless of whether it was good or not, as I viewed it as a potential learning experience for us and the audience. When we arrived to our hotel, just before turning the kegs into the AHA folks for safekeeping, Malcolm poured me a sample. The first thing I noticed was its clarity and the bright white cap of foam that clung nicely to the sides of my glass. Upon first whiff, it seemed apparent to me that either I’ve absolutely no sensitivity to sulfur or it was no longer present in the beer, as all I noticed was a delightfully bready Pils malt character and somewhat fruity hop notes. I approached my first sip with some expectation something would be off, it feels almost impossible not to with these types of batches, but I was pleasantly surprised to discover it was all for naught– the beer hadn’t just turned out, it was quite delicious! So much so that Malcolm poured himself and me another glass. He’s far too humble to admit it, but I think his Bad Habits Hoppy Lager, while likely a tad too hoppy to fare well in a competition, was of higher quality than many homebrewed lagers I’ve had.

What did others think?

The way we presented this beer to tasters was pretty fun and, I like to think, made for a perspective broadening experience for all involved. At the start of the presentation, we informed the audience we wouldn’t be collecting data on an xBmt during the talk due to how logistically difficult performing a triangle test would be, but that we brought a beer for them to enjoy anyways. We spent the next 30 minutes or so giving our presentation, finishing as most speakers do with a Q & A session. As Malcolm was responding to the first question, I changed the slide to reveal the processes he used to make the beer they were drinking. The bemusement was palpable and we noticed quite a few people go back seeking another sample, no doubt with a different focus.

When we were done and hanging out outside of the conference room, multiple people came by to express how much they enjoyed the beer, how they were shocked they didn’t notice any of the off-flavors they would expect given the methods used to make it, and a few mentioned their plans to try a Short & Shoddy batch for themselves.

| CONCLUSIONS |

Malcolm brought two full kegs of this beer to serve during our seminar, which by our calculations based on the approximate number of people who attended, should have left us with at least a gallon leftover. That wasn’t the case. We waltzed out of the room with two empty kegs. The fact a beer made with a 20 minute mash, boiled for 20 minutes, and fermented warm with a traditional lager yeast was good enough for a group of people to want more than the standard amount, at 10:15 AM no less, might be enough to convince some the Short & Shoddy approach is up to snuff.

However, what speaks volumes to me isn’t the fact blind audience members liked the beer, but that Malcolm, despite heaps of skepticism, thought the beer was good, so much that he told me he plans to use the same approach for a few batches of easy drinking summer brews! As Brülosophy’s longest standing homebrewer and highest ranked BJCP judge (National), I wasn’t sure if this would pass his litmus test, but it did.

One final point– the hit to brewhouse efficiency has been a constant between our three Short & Shoddy batches and is something those considering playing around with reduced brew days ought to consider, if only to ensure they hit their target numbers. For this batch, Malcolm expected a 1.048 OG based on his standard efficiency but came in short at 1.044 OG, which put him at 60% brewhouse efficiency. Not terrible, especially since as homebrewers we have the luxury of compensating by adding pennies worth of extra grain, but it is something to be mindful of.

If you have thoughts about this Short & Shoddy brew, please feel free to share in the comments section below!

New Brülosophy Merch Available Now!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

41 thoughts on “Short & Shoddy | Homebrew Conned (Pilsner)”

Sweet. I’ve been wondering how 833 would fare at room temperature. I just bottled my first batch of room temp 34/70 last night, and plan to do a few more lagers this way in the summer. Thanks for experimenting!

Very interesting! Have you ever done (or considered doing) an experiment comparing a beer brewed with all the “bad” practices side by side to a beer brewed with all the “good” practices? I’ve always been curious if there is some accumulation of tiny benefits that would really come across when tasting.

It’s definitely on the list.

So I was there and got to sample this beer and it was pretty good – Im not sure why, but to me the nose had somewhat of tart note that faded into a nice malty backbone. It was not carobonic in nature (I got the first keg which didn’t have the carb issues). The middle and finish of the beer was great and the hops were nice in this light hoppy lager. But the up front character was just not pleasant to me – enough so that I was sitting there listening and thinking to myself “I wonder which exbeeriment variable they messed with on this one?” Now would I have thought this if I was drinking the beer elsewhere without knowing what you two were all about? Probably not, but the mind plays funny tricks on us! Also the fact that it was only a week old could have been the cause for this character. For some reason I am still leary of the lager yeasts at higher temps, despite the evidence that its not noticeable.

Really enjoyed both talks! I was the guy who asked the question about keeping track of stats and the best time to post in the Bloggers Round Table Presentation. Cheers!

I certainly wonder how expectation of an xBmt impacted tasters’ perception. Thanks for hanging out!

You can chase a sulfur aroma out of a carbonated keg the same way you get rid of excess carbonation. You agitate the keg, vent off some gas, repeat, repeat, repeat. Re-charge your keg with CO2, and you should be golden.

You’re agitating the volatile sulfur compounds out of solution just as you are with CO2.

Seems to have worked great in this case!

I love this stuff. Short and Shoddy, FTW!

My club is having our quarterly “People’s Choice” night tonight, where several folks brew the same style and we pick a winner. I did mine with a 30 min mash and 30 min boil.

As a hair of the dog beer, it was quite enjoyable. Was curious what you guys were up to too.

Always up to something! We intentionally kept the beer very simple, as we didn’t want anyone thinking we intentionally went complex to cover up any flaws.

The only beer I’ve made which received universal acclaim (ie my mom, dad AND wife all loved it) was a blonde ale which I boiled for only 20 mins because I ran out of propane.

Do you think this 30/30 method would be applicable to any style or would some characteristics (IPA-bitterness for example) require longer boil?

Hey Malcolm, have you looked at transferring to the conical hot and then cooling in place?

I suppose the IC method is faster (better cold break), but it would be one less piece of gear to clean.

That may work once I actually set up a mini glycol system but using a cooler and ice or a chilled keg of water in a chest freezer – would not be practical. You’d burn through so much ice or overwhelm the chest freezer.

FYI – the SS BREWTECH website has a great FAQ and answers many such questions.

I think you’re short and shoddy series is one of my favorites. It’s not a controlled experiment, but it is an excellent demonstration of how resilient beer is, and how so much of “common brewing knowledge” is not nearly as important as we think it is (if at all!)

It’s interesting that you consistently hit 60% efficiency on these. The first two had no sparge, so I would suspect that–but this batch did have a sparge step. That really leaves the mash and boil times as the culprits. Which do you think is more important?

This is really close to my brew process, although I’m down to a 10m boil now and I temp control. You can correct for the efficiency issues by stirring a few extra times during 4hr mash, and using a finer crush. Bonus is that it sounds like there was no issue with DMS despite the short boil on a pils malt beer.

That should say “the” not “4hr” (phone keyboard issues)

I’m really glad you cleared that up. I was super confused.

I’m definitely interested in trying a Short & Shoddy brew sometime soon. As a father of two small kids, there’s not always time to set aside 4+ hours for a normal brew day. Having something like a 2 hour brew day (+ grain to glass in 2 weeks!) in my back pocket for those times would be great.

I’ve found them to be pretty fun brew days, a lot more fast-paced, which I tend to enjoy.

I saw a comment up above that you didn’t control the temperature. I thought the temperature was set at 66? or was that just where it started and you let it climb to wherever it wanted?

Pitched at 66F then not really tended to. It ended up getting as warm as about 70F during the first couple days.

We didn’t want to belabor that portion of the article. I set the temp system to 66F. Garage was quite hot (90F days,high 70’s to low 80s in garage). We had a good sized pitch. Yeast makes heat. Instead of fighting the temp rise with more ice, as I would typically do to keep the temp within 1.5 F or so of target, I just let it go up. The temp system was trying to do it’s job and trying to pump cold water into the coils but I didn’t provide enough of a cold water reservoir.

I’m starting to think that the key to the beer coming out good regardless of a lot of these variables is a big, healthy pitch of fresh yeast – whether ale or lager. That’s what seems to be really consistent in these experiments.

The first Short & Shoddy batch was fermented with a very old packet of dry yeast that wasn’t rehydrated, though I suppose it’s possible it was a slight overpitch, which made up for the age.

I guess I didn’t even read that experiment! Looking back, yeah – with an ideal pack of yeast it would be a 2x overpitch by the calculator I am looking at. That dry yeast is built for stability, so potentially that year past due wasn’t a big deal compared to the amount of yeast. Theory rings true a bit!

I am actually going to brew tomorrow, cutting my mash and boil in half (30m each) and see what happens. Even for ales, I use pretty big pitches, so this gives me some confidence.

Thanks!

Justin

I will not yet swear by it, but I do ‘feel’ or believe that healthy vital yeast can compensate for a few other sins. Those buggers are great robust equalizers.

* I should write – or so they seem to be *

You’re welcome for the empty kegs. I got refills every time the guy around, and went up to refill myself a few times. Needless to say, even in the early morning and knowing the nature of the beer, I couldn’t detect any off-flavors.

That’s very kind of you! (we paid him to write that… but not very much.)

Good to hear the short and shoddy method is continuing to shine. I brew 1/2 size batches on a similar schedule regularly, using BIAB it’s a single vessel process. I’ve started putting the wort cooler in to sanitise as the wort is coming up to boil temp as I found with the smaller batches it was killing the boil for a minute or so. I’ve yet to try a lager this way to great to hear it will likely be fine. Cheers

Not really “short and shoddy” but I did reverse a procedure recently to save time. I did a partial mash batch with a prospective brewer. I wanted to show him both extract and grain brewing. I also wanted to make it shorter than an all grain day. I BIABed the mash while the extract portion was boiling in the big kettle. Using only a 30 minute mash and a 45 minute boil, I added the mashed wort to the extract boil with 15 minutes left. My late addition was the partial mash. That batch took under three hours start to finish. (It does help to have another hand for the cleanup) It is still in the fermenter, but I have no concerns about it.

I literally have almost the same beer fermenting now. 34/70 at “room temp” with pale malt and sylva hops. I love bitter hoppy lagers and speed brewing so I try new lager hops each time IE motueka, Merkur etc. Anyways….

I always boil 15 min. No issues. I’ve also tried 10 min – 30 min mashes usually settling on 20 min. Always hit my expected OG like you HOWEVER am always left with “under attenuation”. I believe it 67-70 % consistently. But the beer always tastes great. Just the FG number is high vs when i do a 60 min mash. Why???? You guys never mention this. People I know have the same issues.

PS I’m a national BJCP and critique my beer with others. It’s not sweet or worty. Perhaps just lots of dextrin a balanced with big bitterness…

High FG with 34/70? That’s foreign to me. It always attenuates great for me, regardless of mash or boil length.

We doesn’t answer “why” because… we don’t know ????

Thanks for the quick reply… Forgot to mention, in anticipation of a higher FG as usual, I pitched some amylase enzyme with the yeast to experiment…. Ever use it? I’m wondering if it will increase attenuation but also increase an original gravity??? I mean, if I would have only pitched the enzyme(no yeast) then re took my OG later on, would there be or could there be an increase from unconverted starches? Interesting to think it could go both ways while fermenting….. Thoughts?

I’ve never used it but I have some friends who have and it worked very well.

Have haven’t used 34/70 in quite some time and certainly wasn’t doing quicker mashes then.

I can only speak to my one trial at 20 min, this one, and the attenuation was inline with expectations. 1.044 to 1.010. For 833, White Labs list 80% attenuation I experienced ~77% (apparent) and ~62% actual (calculated).

Maybe (guess) the beer would have or could habe gone down to 1.009 or 1.008 had I mashed longer…

I have played with short mashes inbthe past but wasn’t as big into data collection then. I see hits in efficiency, ability to remove sugar/ extract, but nothing major in fermentability.

Why is FG higher in a 20 vs 60 minute mash? I may be missing something, but do the enzyme need maybe just 10 more minutes to breaks sugars down a bit further?

Well, it seems that time does have a small, but often almost negligible, effect.

My assumption – through some reading and what others, who are more expert than I – have told me is proximity of enzymes to the sugars and the time it takes for the enzymes to fully convert a more complex starch to a less complex sugar that can be fermented by beer yeast before they become denatured. Other have shown that the bulk of conversion occurs withing 15-20 min…. but we seem to eek out a few more percent points of PE between 20-90 minutes.

Wow that’s pretty awesome!! Would never have thought to try this, thanks!

Do you think it would work with saflager dry yeast?

I’ve done it with 34/70 and it works great!

Thanks, I’m so having a go at this!