Author: Marshall Schott

Awhile back, I started thinking about converting my kettles into e-kettles. With everything priced out and in my Amazon cart, I had an electrician friend over to give me a quote on installing two 240 volt outlets to run the elements I had settled on. He came over, gave my “brewery” the once over, and provided what I felt was a reasonable price (~$250). Then he asked if I’d considered natural gas. I said I had but that I thought electric was… well… cooler? He was quick to point out how much cheaper natural gas was*, giving me estimated monthly costs for each option. It wasn’t a difficult sell, particularly since my NG meter was on the same wall I’d recently built my brew bench into. We got to work.

I started snapping photos later than I planned. Prior to making any connections, we turned the gas supply OFF! Please, if you’re going to do this, turn your gas off first. If you’ve no clue what you’re doing, pay someone, it probably won’t cost you more than about $150 and could save you trouble, a house fire, and potentially your life.

In the pic above, notice the nice looking grey tee connector, this had a plug on the end that is now connected to the 90˚ elbow. It took about 5 minutes to measure out how much black steel we would need, which my buddy just happened to have in his work truck. Once we mocked everything up, a 1″ hole was drilled in my garage wall and everything was plumbed.

I secured the longer pipe to the wall, just in case.

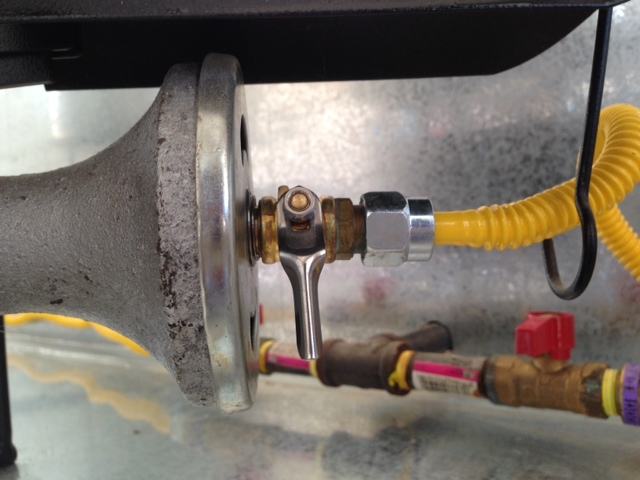

Don’t forget to use the yellow teflon tape when connecting your pipes to ensure no leaks. Once everything was connected outside, we moved into the garage. We had to remove the bench deck to install the tee and gas valves.

We used 2″ nipples on either side of the tee to provide enough room to open/close the valves, then we attached standard gas line to the other side of each valve. While I used the more rigid yellow gas line, I’d recommend spending a little more to get the flexible stuff, it’s just easier to maneuver, a nice feature when you’re trying clean-up after a boil over.

Once all the plumbing was connected, we made sure all valves were off then turned the gas back on. While no leaks were heard, we still checked every connection using dish soap- if it bubbles, something isn’t right, turn the gas off and ensure all connections are well taped and tight.

To get my Bayou KAB-4 burners to work with natural gas, I discovered I had 2 main options- bore out something called an orifice or buy a LPG to NG converter valve. I chose the latter… I don’t like boring out orifices.

For $8 a piece, these converters from William’s Brewing are the way to go. No guesswork, just screw on and boom, natural gas works.

I have a 2 burner system that allows me to make 2 x 5 or 10 gallon batches side-by-side. I’ve been using this setup for over a year and can honestly say that the $120 I spent to convert from propane to natural gas was the absolute best investment since I started making beer at home. No more running out of propane halfway through a 90 minute boil, frozen tanks in the dead of winter, or that terrible sound tanks make when they scrape across the garage floor. When I’m ready to brew, all I have to do is turn a couple knobs, click a lighter switch, and I’m up and running.

I was pretty stoked to see how the burners looked in the dark.

And I brewed the following day, it worked beautifully!

For those who are curious and have read that natural gas is less efficient than propane (basically doesn’t burn as hot)- I regularly heat 7.5 gallons of strike water from 65˚F to 165˚F in 20 minutes or less, which is actually better than I was getting with propane. After collecting all of my sweet wort, I’m usually at a full boil within 20 minutes. Plus, natural gas is remarkably cheaper than propane.

If you are considering this type of conversion for your home brewery, please do not hesitate to ask questions! If you’re uncomfortable doing this type of work, check Craigslist for local electricians, they are usually certified to plumb natural gas as well. Cheers!

*In California, at least the Central Valley, the power company charges for electricity using tiered rates, meaning homeowners pay a higher price per kWh once certain usage thresholds are passed… meaning we pay way too fucking much for electricity in California. My typical monthly Summer bill runs ~$400.

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

| Read More |

18 Ideas to Help Simplify Your Brew Day

7 Considerations for Making Better Homebrew

List of completed exBEERiments

How-to: Harvest yeast from starters

How-to: Make a lager in less than a month

| Good Deals |

Brand New 5 gallon ball lock kegs discounted to $75 at Adventures in Homebrewing

ThermoWorks Super-Fast Pocket Thermometer On Sale for $19 – $10 discount

Sale and Clearance Items at MoreBeer.com

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

88 thoughts on “Propane to Natural Gas Conversion”

Best decision I ever made. I’m glad you got on the bandwagon. One of the two best investments to my brew system (the second being a plate chiller)

You were an inspiration, my friend. Second best decision I’ve made: ditching my plate chiller/pumps for a nice IC and learning to use it correctly 🙂

What are you implying when you say “learning to use [the immersion chiller] correctly”? What could one possibly do wrong with them?

It would seem most folks simply put there chiller in the hot wort and turn the water on at a slow to moderate rate, perhaps gently stirring the wort until it is chilled, which can take upwards of an hour. Using the following techniques with a 50′ x 1/2″ IC, I can chill a 5 gallon batch in ~5 minutes and a 10 gallon batch in ~10 minutes:

1. Turn the source water on full blast.

2. Ensure hot wort is constantly in contact with the cold coils by vigorously stirring and/or moving the IC around in the wort.

That’s all I meant 🙂

Black iron pipe outside? Did you get an inspection? You need to use only galvanized.

Did you need to add any ventilation? Does natural gas produce as much carbon monoxide as propane?

Ventilation is a good thing to consider, though I’m not sure it’s something to fret too much about. In my research, I’ve found that the primary byproduct of burning propane is carbon monoxide(CO), which will kill you, while the primary byproduct of burning natural gas is carbon dioxide (CO2) and water vapor. Now, I’m not saying ventilation is unnecessary, I always have my garage door, the window above my kettles, and the side door open when brewing, but considering many homes use natural gas as their primary heating/cooking energy source, like I said, it’s nothing worth worrying too much about.

I know I am a couple years late to the party but are you concerned about the state of the finish above the kettles, I mean are you worried about paint chips falling from the ceiling or is steam not an issue?

Has never been an issue

I will reinforce one notion – if you don’t know how to do the gas plumbing, the calculations needed to determine whether or not you have enough pressure to feed the targeted burners, etc – for the love of Pete, don’t do this yourself. Get a guy who’s been doing it to help you.

YES!!! I will reinforce Drew’s reinforcement. Professionals have very simple ways of ensuring gas pressure, ways most of us DIY folks don’t have on hand, hence my calling a friend to help. The entire project took about an hour and if you pay an expert, you won’t be paying full price for all the plumbing, so it will likely end up being a decent value.

Is this guide assuming that natural gas is already in use at the home? Seems like something is missing.

Well… yeah. Having the city come out and plumb just your house with NG would likely be a bit more costly.

I paid the city to run NG to my house with a meter and it cost me about $800. It was probably a 40 foot trench and took them about a day. Fyi

Great info! I was curious how much something like that might cost, $800 seems somewhat reasonable to me.

A NG conversion is currently at the top of my to do list!! what size black iron pipe did you use? and what size is the yellow flex hose? I am using banjo burners as well was always worried about not having enough NG pressure, but you answered that question here.

Great write up, Many Thanks

Chris

Thanks! Like I said, NG has been easily the best brewing investment I’ve made. I forget what the exact size of my pipe is, whatever is standard on most houses I suppose… probably 1/2″ to 3/4″ (this is just a guess). I do believe we used a reducer somewhere in the chain, probably from the meter to the first pipe.

I’m doing this! Screw refilling propane tanks!

Any regulators? Do you get the 11″ W.C. recommended by Williams Brewing ?

The dude I had come out and help, he’s a certified gas plumber, said 11″ W.C. is standard in my area. Whatever it is, it works so incredibly well!

My utility will only provide higher than 7″ on request. Probably a fee. You’re a lucky man. Wondering how I’d get the power you do with the least amount of moolah. Perhaps borrowing drill bits and up-sizing the orifice until I’m happy?

1/2″ is for a single appliance. Always run 3/4″ and install a Tee with a shut-off valve so that you can branch something else off of it. This, of course, is a mute point if you are branching off of an existing 1/2″ line.

I am on the verge of going natural gas as well. I must say, however that I find electric very intriguing. TANKS SUCK. And the 100 lb. tanks are not cheaper per pound (propane).

I’ve been thinking of adding a couple electric elements to my setup as well, a hybrid of sorts 🙂

Great write up! Suppose I want to buy regular NG burners…anyone have any recommendations?

Regular NG burners? I’ve not seen burners designed specifically for NG, but the conversion orifice is only $7, making the KAB4 I link to in the article a great price.

the burners themselves? ebay or amazon.

The best price I could find is on Amazon (http://amzn.to/1JwOaqA), $85.99 + free shipping (2 days with Prime).

The KAB4 is an awesome burner. As I’ve debated with myself, I’ve considered the 32 jet (plugging some of the jets with bolts) or 23 jet burners for a fraction of the price. But again, if money isn’t tight, the KAB4 is cool too.

For anyone interested in regular NG burners, checkout The Bayou Boiler (www.bbqguys.com)!

LOVE the outdoor toilet. Keep the drunks from stumbling through the house! LOL.

HOLY CRAP! This would work perfectly in my garage… how did I never think of it?

Question for you: Do you have a write-up for the bench you built? Couldn’t find one in search… I would love to look at that as a guideline for building something similar.

PS: I randomly found your blog a few nights ago on r/homebrewing (which I’m new to) and I have been reading every word and missing out on sleep — great writing, great information… thanks for sharing so much and so well.

I’m so glad you like the site, thanks! I never really considered writing up the bench build, and since it’s already together it wouldn’t include many photos, but I might consider at least sharing the dimensions and my thought process when building it. Until then, feel free to shoot me an email with what you’re thinking, I’m happy to chat!

Based on your photos, it appears you are simply using the incoming natural gas pressure with no regulator, and allowing the 1/8 inch orifice valve to do the pressure reducing work, correct? Also, I’m assuming that running the KAB-4 burner on natural gas does not cause any concern for overheating the bottom of your brew pot.

Correct and it doesn’t.

I found this write-up about one hour after I posted questions about this. This is awesome. Thanks for posting this.

Cheers!

Can you adjust the amount of flame with the valve on the converting fitting or is it more of just on or off?

It allows you to the adjust the flow of gas, absolutely. I usually bring my wort to a boil with it fully open then back off a touch to maintain a rolling boil.

Great thanks for the info!

Do you use the valve on the fitting, or the valves on the gas line?

The valve gets screwed directly onto the plate on the burner, where the propane line usually goes, then you attach the propane to that. Very simple.

I was reading about your LP to NG conversion. It looks like you went from a 1/2″ to 3/8″ flex hose. Do you happen to have videos of your burners on full blast? I’m curious if 3/8″ is good enough. I was thinking of doing 1/2″ to a 23 tip burner (23 tip burner is much cheaper than the kab4). How fast are you getting your temps up? Any empirical data?

Thanks.

No video, but I happened to time things last weekend. 9 gallons from 56F to 165F in 22 min, 7.25 gal from about 148F to boil in 15 min.

Awesome. Thanks.

I am about to move to a new home and will miss my natural gas connection. On the bright side I will greatly increase my brewing space!

My question for you is, it looks like the valves are all in the back, if you ever had a boilover or some kind of flareup, you would have to put your face in hot lava to shut the gas off, is that right?

They are in the back, but I have access to them from the sides of my bench. But… I don’t have boilovers, ever!

I don’t see a regulator between the natural gas line and the burner. Would a regulator even be necessary in this case?

The hurricane LP to NG valve had the following in the description: “THIS VALVE OPERATES AT 11″ W.C. OF PRESSURE. IT IS IMPERATIVE THAT THE APPROPRIATE REGULATOR IS UTILIZED”

I had a professional gas plumber help me install it, he swore it was totally fine. I’m pretty sure the gas source acts like a regulator, he actually told me the gas was coming in at 11″ W.C., fwiw.

I’m not trying to argue with you here, but residential gas is much lower than 11″ WC. It’s more like at ~7″ WC – unless you’ve got major work done to get it at 11″ WC. 11″ WC is for LP.

Your gas meter is like it’s own regulator. If/when I decide to plumb mine, it’ll be similar to brulosopher’s setup, but I’ll be using 1/2″ all the wall to the 23 tip burner.

I appreciate the comment! It was awhile ago, it’s likely I misheard something, but he assured me it was kosher. I use it a lot, so far so good.

Thanks. I ordered a Bayou Classic SQ-14 but I’m not sure the Hurricane valve will work with it as the hole in the burner head may not be 1/4″ like the KAB-4. Might be worth a shot though.

I believe I’ve heard of someone using that valve with a SQ-14, but I’m not too sure. Definitely worth a shot!

Not sure how to edit my comment above about residential NG being 7.5″ WC. I think I misspoke, I’ve read that NG is 3.5″ WC. I used this website as a resource (including the comments) for my future setup, so I wouldn’t want someone to make a mistake based off of my misinformation.

I think the pressure will vary by utility. For example, our local gas utility’s tariff states: “For general purposes, the average pressure normally maintained at the meter on the Customer’s service is six (6) inches of water column (w.c.) and gas will be supplied at not less than five and one quarter (5.25) inches nor at not more than eight (8) inches of w.c. pressure. The direct reading will be the basis of billing for gas used when pressures are in the above range; i.e., five and one quarter (5.25) inches to eight (8) inches w.c. pressure. “

Do the converters fit the KA6B burner?

Yep!

I’ve purchased this burner and am currently using it with propane in my garage. However, I have a decently sized portion of my basement that is separate from the finished portion. If I were to convert to natural gas and use this inside, is there any reason why this might be unsafe?

With adequate ventilation, you should be fine.

There is a set of bilco doors maybe 15 feet away from where I would do it. Would this be sufficient? Or would I need to install some sort of vent and duct system/chimney for the exhaust. My other option is to run gas to my garage for a set up similar to yours, but with a brew table that will fold back up into the wall so I can still park a car in my garage.

I just keep my garage door open and I’m still alive. I also don’t fancy myself a gas expert…

if you HAVE TO do it (basement), get a carbon monoxide detector. costco has 10-year ones for $35.

I was thinking of doing this in my garage. I have a simple formica laminate table as a work space – would you suggest covering in with stainless steel plating like you did? Does the burner generate a lot of heat to the surrounding area?

Thanks!

Hey Marshall…what is the countertop height you have there? Standard?

For the brew bench? I forget the exact height, and I’m not home right now, but I made it so that my cooler MLTs fit with about 2″ headspace.

Yes…I have a 10g SSBREWTECH pot and yet to grab the KAB4 burner. Since I do BIAB, when doughing in, I dont want the countertop too high to prevent having to use a step ladder.

If I have a gas dryer, would I be able to T off the pipe and have one line running to the dryer and one line running to a burner? Obviously wouldn’t use both simultaneously.

I really have no clue, I’d recommend consulting with a plumber or contractor before trying it out.

it depends on your supply line. assuming it’s residential, it’ll work, but it won’t be optimum. meaning, you won’t get full BTU’s/utilization of your burner’s full capacity. i’m not sure what will be the result, but if i were you, i’d probably do it and then if needed, supplement with a heatstick.

Thanks, I might just swap out the connections as needed since I don’t need the burner constantly plugged in.

that’s an option, but i don’t like screw and unscrew gas connections often. it increases chances of leaks, cross threads, etc. maybe use a Y splitter with a valve and a quick disconnect?

That’s reasonable. I’d like to avoid any big changes if possible since I’m a renter.

Wanted to say thanks for the article. I read your article and purchased a Bayou KAB4. I never even tried it on propane. I bought a natural gas coupler/hose kit from Lowes. I T’d into my 3/4″ natural gas line for my garage heater with 1/2″ line and ran it down the wall to near the floor. I installed the quick coupler there wother a 3/8″ ball valve. I drilled the orfice on the heater to 1/8″ and everything works perfectly. With the valve wide open its got tons of heat. Heated 5 gallons of winter cold strike water to 155F in 10min and brought that to boil in 5 min. The ball valve worked perfectly to adjust the flame. I also had a CO detector in my garage and it never made a peep.

I’m super stoked about it. Because NG is so cheap in Alberta that the equivalent cost in to propane is literally $1 per 20lbs. And right now the cheapest place for a 20lbs fill is Costco at $7.49. That’s a 700% savings and I don’t have to drive across the city for it. Or in a pinch a gas station exchange bottle is $25 per 20lbs!

Thanks again!!!

The yellow gas line and fittingthat connects to the gas conversion valve – did you purchase those two items yourself or did your plumber supply it? I’m doing the same thing now and my plumber is trying to source those parts. Thanks.

I bought the propane to natural gas valve from William’s Brewing and the hose was the cheapest I could find at Home Depot. I’ll likely be swapping the hose out for something more flexible, as the corrugated yellow stuff is pretty damn rigid, which makes moving my burners around difficult.

Thanks, Marshall. I have the same valve from Williams Brewing. Did the chrome-looking fitting connecting it to the hose come with the hose

or did you find it at Home Depot, too?

Happy to help! All I bought was the hose and the valve in the proper sizing, it all fit together.

Hi Marshall. Did you have any soot issues from using the KAB4 with Williams valve ? I recently converted my SP10 to natural gas by adding a 23 tip wok burner. It is not a good application. Flame is not that efficient and it puts soot on my kettle. My kettle has to be super high above the flame and it still burns yellow in spots. Thanks !

No soot whatsoever.

Thanks Marshall. I Love reading your posts. It has become a Monday morning ritual followed by a Monday afternoon discussion with my homebreweing brother. Thanks for all your contributions to the hobby. Prost!

I noticed that a gas regulator was not used in this application of converting a Bayou Cooker KAB-4 from LP to NG using a 1/4″ NPT Hurricane valve.

Should I use a regulator?

Why or why not?

If so, what size water column regulator with this cooker?

Thanks!!

NG to home is regulated, I use gas ball valves to regulate flow.

I not that Williams Brewing says that conversion valve ‘operates’ at 11″ WC pressure. My local utility in San Francisco boasts a delivery of 7″ WC with 50% variability. Is any of that a problem?

I know people in SF who use NG using this adapter, but I’m not an expert…

I am ready to do this. Can you adjust the intensity of the burner or is it simply on or off?

Oh I see you said you use gas ball valves…

You can definitely adjust intensity!

Yes, it’s adjustable. There’s a small valve that control the flow of gas.

I’ve been using this and I’m very pleased with it.

That “nice looking tee connector” that had a plug in it was put there for a reason. Your professional plumber eliminated the purpose of that tee. it’s there so the gas company can put a probe in it, shut off the riser valve and feed your house gas from a separate source while work is performed on the meter, regulator, valve or the fittings in between. Most plumbers understand this and add another tee for their job. yes, natural gas is delivered at 7″ wc to your house. Propane is usually regulated at 11″ wc.