Author: Marshall Schott

Maybe 6 or 7 years ago, I went for a breakfast visit with my beautiful and ailing Grandma Jan. She’d waited for me to arrive before starting the coffee, as she wanted the Folgers to be fresh for her grandson, a typical gesture of thoughtfulness from this sweet soul. She added the appropriate amount of water to the reservoir and scooped the coffee into the paper cone, then she did something I wasn’t expecting and sprinkled table salt onto the grounds. I thought perhaps her age and illness were responsible, “Grandma, you’re putting salt in the coffee?” She responded, “Yes, dear, steak tastes good alone, but seasoning makes it taste much better.” Touché, grandma. And the coffee was good.

This is one of those memories that comes up often, for no obvious reason I can think of, a bright spot that serves to mentally resurrect the beauty that was my grandma. A couple years after that morning, while preparing a pot for my wife and me, I thought about my grandma’s method and impetuously added a couple dashes of salt to the mound of grounds. It seemed to make the coffee taste different, my wife agreed, then I began to wonder how the different salts I use for making beer might impact the coffee’s flavor. I did some messing around comparing gypsum to calcium chloride and perceived some definite differences.

While this isn’t about coffee and perhaps a bit sentimental, I think the analogy is clear– the chemistry of the water we use to make our beer seems to make a difference. Of all the xBmt variables we’ve tested, those focused on water chemistry have consistently returned significant results, suggesting to me, to paraphrase my grandma, “Beer tastes good alone, but seasoning can make it taste better.” Or at least different.

Over the last year, due mostly to conversations I’ve had with people who know way more than me about this stuff, I’ve focused my water adjustments primarily on chloride to sulfate ratios (Cl-:SO4) and mash pH, which requires the use of 3 simple and cheap ingredients: calcium chloride (CaCl), calcium sulfate (gypsum), and lactic acid. I’ve had great success… when I remember to use them. This xBmt was inspired by forgetfulness, not just my own, but the folks who have emailed me seeking my thoughts on making mineral adjustments to finished beer, those they failed to make earlier in the process. Rather than conjecture, I figured I’d test it out for myself.

| PURPOSE |

To investigate the differences between 2 beers produced from the same wort where the Cl-:SO4 ratio was adjusted post-fermentation, half to 1:2 and the other half to 1:1.

| METHODS |

I’ve never been a huge fan of stereotypically Belgian ale with their high levels of phenols and esters, just not my thing. However, after my friends Sean and Aaron returned from a beer excursion to Belgium, they informed me such character was almost impossible to find in the actual region, explaining the beers they had were crisp and clean with a much more subtle yeast character. Sean made it his mission to reproduce these beers he had come to love, which started with a hunt for the right yeast. After going through nearly all of White Labs’ library of Belgian strains and failing to achieve the results he was looking for, Sean snagged a vial of WLP515 Antwerp Ale yeast, purportedly sourced from the famed De Koninck brewery. Finally, Sean was brewing beers with exactly the character he was after, delicious, crisp, mostly clean with phenol and ester subtleties that made me a believer. Unfortunately, WLP515 is a Platinum strain with a limited window of availability that just so happens to be right now! I’ll get to my impressions on the beer later, but right up front, I love this yeast and encourage anyone interested to grab a vial before it’s too late, the only place I’ve been able to find it currently is Adventures in Homebrewing. With good sanitation, you can easily stretch a single vial out over a year by harvesting from starters, which is exactly what I planned to do.

Inspired by a pale beer House of Pendragon made with this strain, I designed a simple recipe using only the hops a friend from New Zealand brought back to me on her last visit.

Wakatu Belgian Pale Ale

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 11 gal | 60 min | 27.8 IBUs | 4.6 SRM | 1.054 | 1.012 | 5.5 % |

| Actuals | 1.054 | 1.013 | 5.4 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (Weyermann) | 18 lbs | 90 |

| Honey Malt (Gambrinus) | 1 lbs | 5 |

| Vienna Malt | 1 lbs | 5 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Wakatu | 30 g | 60 min | First Wort | Pellet | 7.1 |

| Wakatu | 30 g | 25 min | Boil | Pellet | 7.1 |

| Wakatu | 40 g | 2 min | Boil | Pellet | 7.1 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Antwerp Ale Yeast (WLP515) | White Labs | 77% | 67°F - 70°F |

Notes

| Post-Fermentation Mineral Additions: - Added 1.1 grams gypsum to achieve SO4:Cl- of 2:1 (106:53) | Ca = 93 ppm - Added 1.9 grams CaCl to achieve SO4:Cl- of 1:1 (84:84) | Ca = Ca 83 |

Download

| Download this recipe's BeerXML file |

Two days prior to brewing, I used my preferred online calculator to determine the starter size accounting for the amount I’d steal for later use.

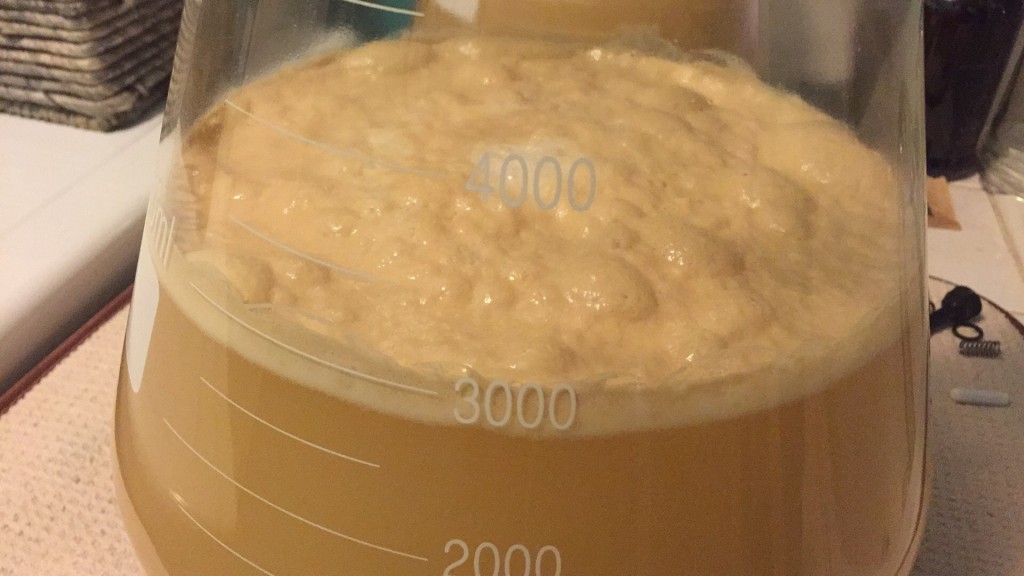

Not even 24 hours later, I observed an odd looking kräusen and the scent of egg fart emanating from the flask.

I consulted with Sean, just to be sure, he said this was perfectly normal. The evening before my planned brew day, I collected my water and milled the grains. Given the blank-slate nature of my water, I added a small amount of minerals to my brewing liquor at this time.

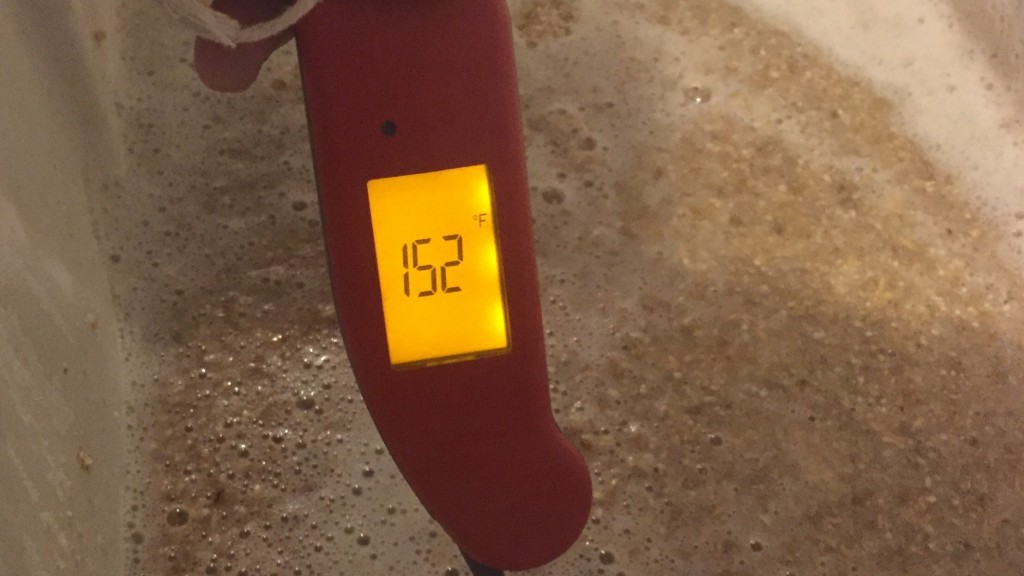

The following morning, I quickly heated my strike water to the temperature BeerSmith recommended, which allowed me to hit my target mash temp dead-on.

Since this was a 10 gallon batch, I used the batch sparge method, collecting the first runnings before adding the hot sparge water then running off the rest of the sweet wort and putting it over the flame.

Hops were added at the appropriate times during the 60 minute boil, then the wort was quickly chilled and racked to sanitized carboys, which were placed in my fermentation chamber regulated to 66˚F/19˚C. I split the yeast starter evenly between each batch and let them ferment a few days before ramping the temp to encourage complete attenuation and clean-up of undesirable fermentation by-products. After about 10 days, with both beers sitting at the expected FG of 1.012, I cold crashed then fined with gelatin. Packaging day arrived and it was time to introduce the independent variable. It probably goes without saying that samples at this point were perceptibly exactly the same. Using the Bru’n Water spreadsheet, I determined a Cl-:SO4 of 1:2 would require the addition of 1.1 grams of gypsum while a 1:1 ratio called for 1.9 grams of calcium chloride. It seemed like nothing. Inconsequential or not, it should be noted the 1:1 batch that was dosed with calcium chloride was calculated as having 10 ppm more calcium than the batch receiving gypsum.

I tossed the minerals in the bottom of separate sanitized kegs before racking the beer on top, gently swirling throughout to ensure the salts fully dissolved.

Once full, the kegs were placed in my keezer and hit with 45 psi of CO2 for 18 hours before being purged and set to my preferred serving pressure of 12 psi. A few days later, I pulled the first finished samples and noticed the 1:1 (CaCl) ratio beer was slightly hazy while the 1:2 (gypsum) beer was crystal clear, it took about 3 days for them to look the same, which is when I started presenting them to tasters.

| RESULTS |

Twenty-one people participated in this xBmt including BJCP judges, experienced homebrewers, and dedicated craft beer drinkers. Each taster, blind to the variable being investigated, was served 2 samples of the 1:1 ratio beer (CaCl) and 1 sample of the 1:2 ratio beer (gypsum) in different colored opaque cups then instructed to select the unique sample. Given the sample size, a total of 11 correct selections would have been required to achieve statistical significance (p<0.05). In total, 12 tasters (p=0.010) correctly identified the 1:2 beer as being different, indicating participants were reliably able to distinguish it from the sample adjusted to a ratio of 1:1 with calcium chloride.

A brief comparative evaluation of just the 2 different beers was completed by the 12 correct tasters. While exactly half (6) preferred the sample dosed with gypsum at packaging, only 2 said they preferred the other sample with 4 noting a difference but no strong preference for either. Following revelation of the nature of the xBmt and a brief explanation of the expected effect, tasters were asked to choose the sample they thought received the gypsum, 7 made the correct selection while 5 chose the wrong sample.

My Impressions: It’s possible I’m becoming sensitive to the impact these minerals have on beer, or perhaps it’s just because of my obvious bias, but I was rather easily able to tell these beers apart in multiple “blind” triangle tests. To me, the 1:1 (CaCl) beer was basically what I expected, slightly malty with a rounded overall character and a softer mouthfeel, while the 1:2 (gypsum) sample was notably crisper with a sharper bitterness that left me with a pleasingly cleaner palate. Both beers were great and more similar than different, but I absolutely preferred the 1:2 beer.

The beer itself was one of the better I’ve made all year, which is really saying something considering it’s mid-December. In addition to the aforementioned characteristics, the interplay of the German Pils malt with the Wakatu hops and WLP515 Anwerp Ale yeast was really something, bready with a hint of fresh fruit and some gentle Belgian spice to back it all up. This beer certainly hit the mark for being full flavored and supremely drinkable, I think I’ll go pull a pint right now!

| DISCUSSION |

As an interesting stroke of coincidence, the January-February issue of Brew Your Own magazine, in which 3 Brülosophy xBmts were covered, had an article on post-fermentation adjustments by Kyle Kohlmorgen where he touches on adding minerals to the keg. Additionally, a Google search on the topic revealed multiple posts in homebrewing forums on the issue of manipulating finished beer by adding salts at packaging. People are obviously curious and with most of what I found being either anecdotal reports of individual brewers’ experiences or discussions about the pros and cons of post-fermentation adjustments, it’s cool to be able to say with at least some impartiality that making such additions did produce a distinguishable difference for this panel of tasters

Briefly, it’s important to consider the impact mineral additions have on mash pH when deciding how to approach such adjustments, as it may work in your favor to make such additions during the mash in order to ensure optimal mashing conditions. Personally, I absolutely plan to continue making mash adjustments while viewing post-fermentation mineral additions as more of a corrective measure. To each their own, of course.

If you’ve messed around with making mineral or even acid additions to finished beer, please share your experience in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

26 thoughts on “exBEERiment | Water Chemistry: Impact Post-Fermentation Mineral Adjustments Have On A Belgian Pale Ale”

Marshall,

You should really look into slanting your yeast strains. It is something I recently got into and it’s a great way to keep strains on hand pretty much indefinitely. A littl slant maintenance is required, but the benefits are worth it!

This is something I have been looking into this month. Where did you go as a guide to get started?

This is great, just timed nicely with my Black IPA finishing up….my ratio was 1:1 as my Bru’n’Water initial profile now I have changed to 1:2 which seemingly requires 4.5g of Gypsum (seems a lot?).

As this recipe here doesn’t require a dry-hop, when would be the best time to do the post-ferm mineral addition? Before the dry-hop or at kegging stage? Would doing this at kegging stage be too late as could it affect extraction of hop flavor during dry-hop?

Hope this makes sense?

I’d do it at kegging. My understanding is the minerals serve only to accentuate flavors, like salt, and won’t impact extraction of hop flavor.

Today I found this links in the comments of a Beersmith article about pH: http://onlinelibrary.wiley.com/doi/10.1002/j.2050-0416.2010.tb00783.x/pdf

This paper shows that minerals/mineral concentration have an influence on alpha-acids retention and composition during boiling. So the effect of salt during dry hopping is something that would be also interesting to investigate.

I have of course done this a lot as a guide to recipe formulation. I only do it as a seat of the pants test and have never used it on beer I was going to serve. I have found useful ratios are from .5:1 to 9:1. A very large range. The results are strongly dependent on hop variety. One day someone should do this test on a series of single hop beers. I can say that for me German hops don’t tolerate as much sulfate as US hops.

Interesting, I’ve been realizing my German lagers have more of that “German character” when I use more sulfate.

That would be a test right up my alley…and probably find a decent amount of volunteers.

“Folks, we need to go through all these hoppy beers and evaluate mineral impact on hop perception”. I guess with anything after a few trials, and after the requisite paper work is introduced, it becomes less exciting – for some.

excellent, thanks!

Water continues to show its importance! I was just catching up on my BYO reading and the Dec 2015 issue states that for malty beers Firestone Walker uses Calcium Chloride (no sulfate) to get to 100 ppm calcium. While for hop forward beers they utilizes a 1:1 ratio of Calcium Chloride to Calcium Sulfate. Then there is evidence floating around of The Alchemist using a ridiculously high amount of gympsum to get close to 750ppm for Heady Topper. Both make great beers.

I was recently told The Alchemist uses crazy amounts of CaCl- for HT… hmm.

I’ve been using Mosher’s Pale Ale profile as a baseline for my IPAs — which has around 300ppm sulfate — but I’ve recently been moving that to 350 and 400. The key, though, and I realized this through experimentation (and failure) is that if the gypsum addition is large, the CaCl addition has to be correspondingly minimal. And i mean, like — minimal. If both are high (which is why the ratio stuff makes no sense to me) then it’s super easy to get a minerally beer. A beer that’s essentially undrinkable (especially when epsom salt is thrown into the mix for the nice bitter twang).

OTOH, I’ve been making fantastic Kolsch’s with essentially equal amounts of gypsum and CaCl — but both on the very, very low end.

If Kimmich is going 750ppm sulfate for HT — that’s pretty amazing. (Never had it — so I can’t comment on the taste.) But I’m guessing there’s no way a hoppy beer can be made with 750ppm CaCl, though (because, based on my own experience at least, the sulfate addition would be very nearly non-existent.)

This is great stuff, though! I’ve sort of come around — after years of brewing — that water and mineral additions are the keys to great homebrew (and beer, in general). I only wish I’d learned this stuff years ago when I was reading Papazian and suffering through batch after batch of really, really bad beer. It wasn’t ingredients or even process that was failing me — it was my tap water.

Whoever said — and continues to say, “If your water is drinkable, your beer will be fine” — is completely, completely wrong. Some beers might be fine, but most won’t — and you’ll go through a lot of crappy batches without knowing why you can’t get the right flavor profile for the style.

I actually agree with that statement, though there’s a difference between “fine” and “fantastic.”

Besides quantity of beer, is there a reason you didn’t have a 3-way or two part test with a “no addition” beer as a control? I wonder if it is akin to an exaggerated example of “can you tell the difference in salted coffee vs sugared coffee” rather than can you pick out salt from regular coffee AND/OR pick out sugar from regular coffee.

I’m sure a future xBmt will be pre adjusted water vs post adjusted beer.

Keep up the great work!

Because it won’t work with the triangle test, which compares only 2 beers. It’s just the approach we’ve settled on.

We could, perhaps in the future, do more than one set of triangles but we would need to keep the nature of the experiment a secret until after the second run. It makes for more of a control and logistical nightmare. We’ve opted for a more simple method for a variety of reasons.

I recently did a very similar “experiment” with my brewing buddies. We added a pinch of CaCl to one glass, a pinch of Gypsum to another, and poured a baseline of our IPA. Albeit a pinch isn’t scientific the results were exactly as you described and shockingly pronounced. I was motivated to do the test based on the video floating around and lab reports that showed Heady Topper has a total hardness of 750 ppm. An insane number if you’re getting there with just gypsum. Our IPA was already up at 300 ppm of sulfate and I can confirm more gypsum was not a good thing and there is definitely a limit as the beer became harsh and mineral-y. For now I’ll be sticking with the 300-350 limit for IPAs. Great Exbeeriment and you helped me further confirm small mineral tweaks post fermentation are yet another tool to perfect my beers! Cheers!

Maybe I missed it, but did you do any pre-fermentation (mash) water adjustments? I’m confused on how you got your amounts to add if you didn’t start with a Mash profile baseline?

Yeah, I mention in the Methods section that “due to the blank-slate nature of my water, I added a small amount of minerals to my brewing liquor at this time.”

Made this beer last night and all went well and it is bubbling away nice but there is zero kräusen on top. I cant say I have ever had an ale ferment that way before is that typical for that yeast? My starter was the same except when I swirled it then it foamed up but then fell back. Mine also does not have the egg fart smell and smells pretty clean.

Interesting. Obviously, if it’s just kräusen you’re concerned about, I’d say let it ride and see how it turns out! My hunch is it will be really tasty. Did you use Wakatu as well?

Yes, I kept everything the same except I did BIAB and adjusted my water profile before mash to match the 1:2 and PH=5.33

Awesome!

I’ve been adding all mineral additions (calcium chloride and gypsum) to the strike water (RO water) to correct mash pH. The mineral ppm in the mash are very high, 100-130 ppm, but the overall ppm are in line with the mineral profiles from bru’n water when both first and second runnings are combined. Would it be better to divide mineral additions between strike and sparge waters? I could use lactic acid if need be to further adjust pH if a smaller dose of minerals fails to do so. Also, I’m using the advanced water calculator on Brewers Friend. Heres the link for a recipe; http://www.brewersfriend.com/mash-chemistry-and-brewing-water-calculator/?id=QJZXTCT

Thanks

This is an easy fix for some problems. A gypsum addition is truly a remarkable option for beers that have turned out too malty or cloying in their finish. A gypsum addition can help dry that finish and provide better balance. Just a thin pinch of gypsum between your finger and thumb added to a pint of beer is an addition of about 100 ppm SO4. Give it a try the next time you have a beer that leaves too much on your palate.

Started a hard cider several months ago with a starting gravity of 1.048. It took off great for about a week, but stalled out at 1.032. I left it sitting for longer than I probably should have (two months?) while I debated throwing it out or trying to get it going again. I added some yeast nutrient and re-pitched which got fermentation going again. Apparently, I was not careful enough and got some other kind of bug in which created an odd floating white film. It appears I got lucky and there’s no off flavors or odors other than acidification. It has again stalled out at 1.023, and I’m feeling like the acidity level is what has stalled it. I added 1 oz of baking soda dissolved in boiling water, and had immediate reaction and foaming. I will monitor fermentation check pH in a couple days. If I need to raise pH again, I’m concerned about adding more baking soda and ending up with a salty end product because of all the Na. Will calcium carbonate be a better option? Is there anything else anyone can recommend? Since I’ve carried on this far, I’m too stubborn to just give up!