Author: Jordan Folks

Brewing a batch of beer involves various steps, one of which is the mash where, after blending the milled grain warm water, enzymes are activated that convert starches into fermentable sugar. Not to be confused with brewhouse efficiency, mash efficiency refers to the amount of conversion that occurs during the mash relative to what would be expected given the grains used, which typically ranges between 75 to 90%.

Arguably more important on the commercial scale, one method that brewers have adopted as a means of ensuring predictably good efficiency is continuous recirculation of the sweet wort throughout the mash rest. In addition to exposing more starches from the grains to enzymes, ostensibly improving overall conversion, recirculating the mash also helps to maintain a consistent temperature and some claim it can lead to a clearer beer.

My first all-grain batches were brewed using the batch sparge method with a converted cooler MLT, and while I was pleased with the beers I made, the limitations ultimately inspired my move to an electric all-in-one setup. These systems have come with pumps and ports designed specifically for mash recirculation, so I’ve been employing this method as a matter of course since upgrading a few years ago, and I’ve always presumed it’s been beneficial. However, after recently breaking (ahem… dropping) a recirculation pump, I wondered what impact recirculation actually has on my beer and designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between a Cream Ale where one was continuously recirculated during the mash and the other was left alone.

| METHODS |

For this xBmt, I went my house a Cream Ale recipe, a style I felt would allow any differences caused by the variable to shine through. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Endless Ruins Of The Past

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 60 min | 19.8 | 4.9 SRM | 1.048 | 1.016 | 4.2 % |

| Actuals | 1.048 | 1.016 | 4.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Barke Pilsner | 8 lbs | 59.26 |

| Pale 2-Row Malt | 3.5 lbs | 25.93 |

| Flaked Barley | 1.5 lbs | 11.11 |

| Carahell | 8 oz | 3.7 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Tettnang | 64 g | 60 min | Boil | Pellet | 1.8 |

| Saaz | 28 g | 10 min | Boil | Pellet | 1.9 |

| Saphir | 28 g | 5 min | Boil | Pellet | 1.6 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Pilgrimage (L26) | Imperial Yeast | 77% | 44.1°F - 55.9°F |

Notes

| Water Profile: Ca 50 | Mg 4 | Na 10 | SO4 25 | Cl 66 |

Download

| Download this recipe's BeerXML file |

I started this brew day collecting the full volume of filtered tap water for two 5.5 gallon/19 liter batches, adjusting each to my desired profile, and getting them heating up before preparing the grains.

When the waters were properly heating, I incorporated the grains and set the controllers to maintain the same 152°F/67°C mash temperature before turning on the recirculation pump for just one batch.

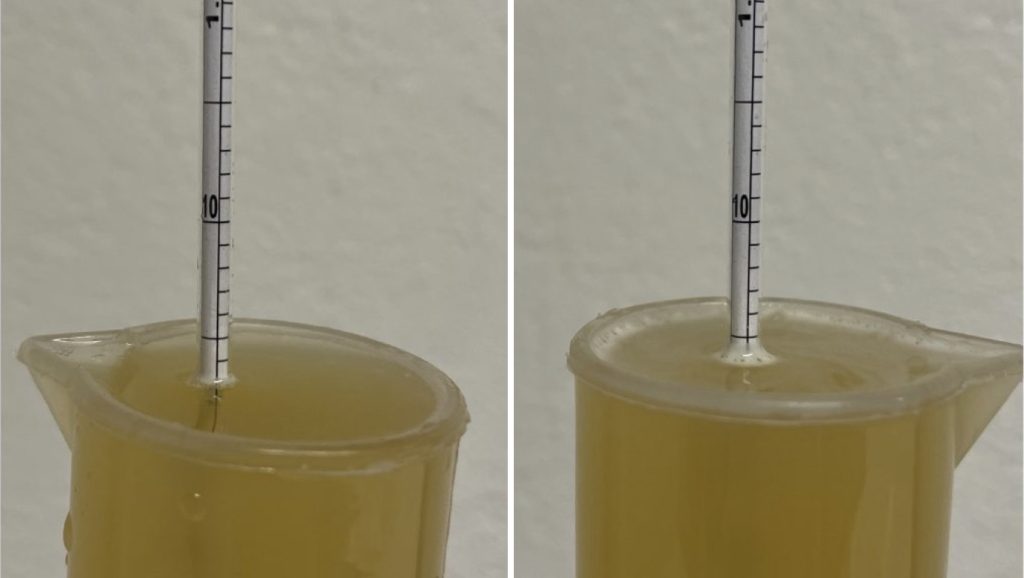

Once the mash rests were finished, I took samples from each batch and noticed the recirculated wort contained more particulates than the non-recirculated wort, which goes against claims that recirculation improves clarity.

I proceeded to boil the worts for 60 minutes, adding hops at the times listed in the recipe, after which both were run through a plate chiller during transfer to sanitized fermentation kegs.

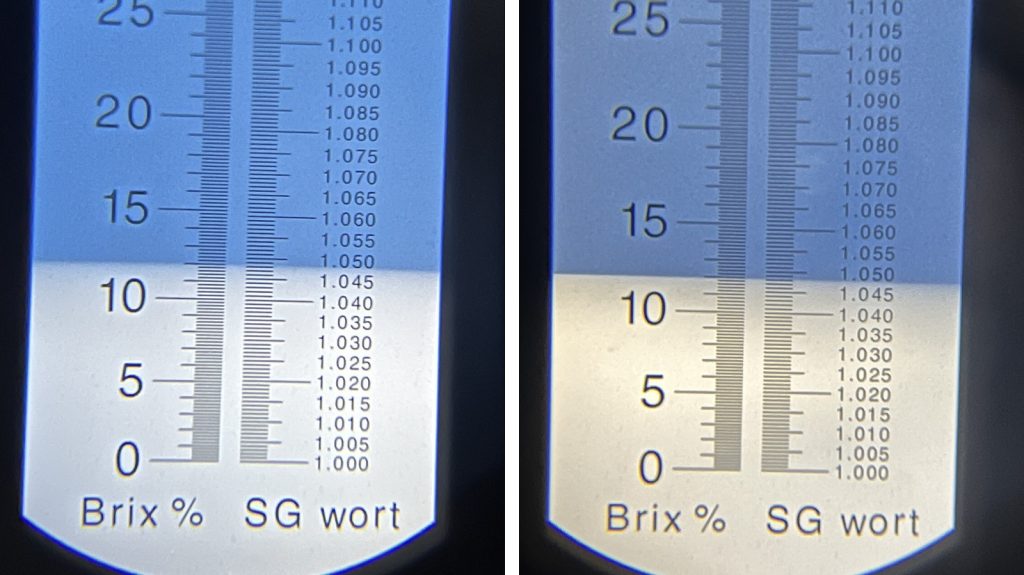

Refractometer readings indicated the worts were at the same OG.

I then pitched a pouch of Imperial Yeast L26 Pilgrimage into each batch.

The beers were left to ferment at 59°F/15°C for 10 days before taking hydrometer measurements showing a minimal difference in FG.

At this point, I gradually reduced the temperature of the beers to 32°F/0°C over the course of a few days then pressure-transferred each to CO2 purged serving kegs that were placed in my keezer. After a week of cold conditioning, the beers were carbonated and ready for evaluation.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of beer where the mash was not recirculated and 1 sample of the beer where the mash was continuously recirculated in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 10 did (p=0.12), indicating participants in this xBmt were unable to reliably distinguish a Cream Ale where the mash was left alone from one where the mash was continuously recirculated.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I was unable to correctly identify the odd-beer-out in any of the trials. To my palate, both beers had similar sweet malt notes with supporting hop bitterness and clean fermentation character. I detected no off-flavors in either of these beers and felt both were equally awesome!

| DISCUSSION |

Regardless of scale, recirculation of the mash is widely viewed as a best practice by brewers who claim it improves conversion efficiency, results in a more stable mash temperature, and leads to clearer beer. Interestingly, tasters in this xBmt were unable to reliably distinguish a Cream Ale where the mash was left alone from one where the mash was continuously recirculated.

This finding indicates that continuous recirculation of the mash not only had minimal impact on perceptible qualities of the resultant beer, but also on conversion efficiency and clarity. While essentially the same, the higher finishing gravities were a bit confounding, though considering how well received the beers were, I wasn’t too concerned.

I plan to continue using pumps to recirculate my mash simply because I can, and that’s how my systems are designed, even if it doesn’t have much of a meaningful impact on the final product. Moreover, should I run into a situation in the future where recirculation isn’t possible, I’ll be less prone to worrying about a potential negative impact.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

13 thoughts on “exBEERiment | Impact Continuous Recirculation Of The Mash Has On A Cream Ale”

Higher FG is probably because of higher mash temp. I guess the circulation maintain the correct mash temperature.

That was my thought as well. it’s easier to maintain the temp by having the wort recirculate over the heating elements.

I’m a couple years late to this xbmt. I found it wondering if it was worth the hassle of recirculating while I biab.

Very thought provoking exbeeriment here! My understanding as to why recirculating for clarity works in the first place is because you are using the mash bed as a kind of filter, similar to the curds in clarified milk punch. I suspect a system with a more traditional false bottom would have performed better since it’s forcing the wort to percolate through the whole mash bed. That said it’s surprising how the recirculated wort actually had more particulate in it. It really calls into question whether it’s worth doing for biab systems, be it bag or basket. Also, the lower fg on the non-recirculated is very interesting. I’ve often heard that all-in-1 systems struggle to hold consistent temps because the thermometer is so close to the heating element. I wonder if since the wort wasn’t constantly moving, if the element was switching off sooner resulting in a slightly lower avg temp throughout the mash.

Note the FGs got switched in the original publication (working on getting that fixed now) – the slightly lower FG was in fact the recirculated batch.

These days I recirculate the mash primarily to even out my temperatures and get the really hot wort from the bottom back to the top. I rely on manually agitating the mash a few times to achieve higher efficiency more than the pump.

Great one.

Probably with recirc you could do a shorter mash?

You’re doing something wrong on your re-circ. Your wort should look like this.

https://photos.app.goo.gl/nzAxzjVNcEMaDMuN9

Are you using Clawhammer 10 gal BIABasket too? Jealous of that clarity! (I’m not getting that level of mash wort clarity on my CH when using the factory pump and mash basket)

Nope, Spike kettle and basket. Everything else is custom though.

I have to agree. I have a RIMS system and all my wort comes out nice and clear (depending on the style of course).

Hi,

I have been pondering on the «to recirculate or not to bother” for quite som time now 😅

I must say, i was very surprised to see the result of this experiment.

Would you care to elaborate further on how the recirculation was done? 🤗

My Clawhammer has an external pump that pulls wort from the bottom of the mash tun and then sprays it over the top of the mash bed. Martin demonstrates this process in this video: https://www.youtube.com/watch?v=h0t4DvKY_3Y

I think the tall and narrow BIAB systems like a Grainfather has an advantage over the Claw Hammer system when it comes to recirculation clarity. The Claw Hammer system also has a much stronger pump, so would have a much stronger flow. The clarity gains are all about how the grain bed settles and ‘filters’ after all.