Author: Jordan Folks

Back in 2016, a group of enthusiastic homebrewers from the German Brewing Forum, which was launched just months prior, published a paper called On Brewing Bavarian Helles: Adapting to Low Oxygen Brewing, in which they laid out the method for achieving what they termed “an elusive flavor quality” found in classic German lager. While most brewers at the time understood the perils of oxidation, concern laid largely on the cold-side, whereas the primary focus of the paper’s authors was on reducing oxygen exposure at every step in the brewing process, from milling to serving.

Strict adherents of the Low Oxygen Brewing (LOB) approach, also known as Low Dissolved Oxygen (LODO), claim that every step must be taken to achieve the desired “it” factor. However, given its arguably convoluted nature, some brewers have opted to adopt certain aspects of the recommended process, with reports that it improved the quality of their beer. One such process involves deaerating the brewing liquor by adding small amounts of yeast and dextrose, the idea being that the consequent fermentation will scrub the dissolved oxygen from the water.

I’ve sampled a few beers made using the full LOB technique, and in my experience, it really seems to create an incredibly pure and potent malt character. I’ve employed a less dogmatic approach due to certain gear limitations, though I have been consistently treating my water in the way mentioned above, and I’ve struggled to achieve the same elusive character in my lagers. Curious to learn more about the impact of yeast oxygen scavenging (YOS), I designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between a Märzen where the mash liquor was deaerated with baker’s yeast and dextrose and one where the mash liquor was not deaerated.

| METHODS |

Seeing as LOB is particularly touted for application in malty German lagers, I brewed my annual Märzen recipe for this xBmt, opting to add the Carafa Speciall III at mashout. Big thanks to F.H. Steinbart for hooking me up with the malt for this batch!

Fourth Stone From The Sun

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 90 min | 20.5 | 13.3 SRM | 1.051 | 1.012 | 5.12 % |

| Actuals | 1.051 | 1.012 | 5.12 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Barke Munich Malt | 5 lbs | 44.94 |

| Barke Vienna Malt | 3.5 lbs | 31.46 |

| Barke Pilsner | 2 lbs | 17.98 |

| Carahell | 8 oz | 4.49 |

| Carafa Special III | 2 oz | 1.12 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Tettnang (Tettnang Tettnager) | 23 g | 90 min | First Wort | Pellet | 1.8 |

| Hallertauer Mittelfrueh | 43 g | 60 min | Boil | Pellet | 2.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 77% | 46°F - 55.9°F |

Notes

| Water Profile: Ca 43 | Mg 4 | Na 10 | SO4 59 | Cl 29 |

Download

| Download this recipe's BeerXML file |

I started by collecting two identical volumes of filtered water in separate 240v Clawhammer Supply electric kettles then adding 15.5 grams/0.5 oz each of baker’s yeast and dextrose to one of them, which is based on the 2 g/gallon recommendation.

The waters were left alone for an hour to allow for yeast oxygen scavenging, after which I adjusted both to my desired mineral profile, which included adding 1.5 g/0.05 oz of sodium metabisulfite (SMB) and 4 g/0.14 oz of BrewTan B to each batch for further oxidation mitigation. Next, I flipped the switches on the controllers to heat the waters before mashing in, and since this was a classic German lager, I opted for a step mash with rests at 144°F/62°C, 160°F/71°C, and 170°F/77°C.

During the mash rests, I weighed out the kettle hop additions.

At the completion of each mash, I removed the grains and boiled the worts for 90 minutes, adding hops at the times listed in the recipe. When the boils were finished, the worts were chilled during transfer to cold break settling vessels that were placed in my chamber to finish chilling. Once the worts were at my desired pitching temperature of 47°F/8°C, I transferred identical volumes of clear wort to separate fermentation kegs.

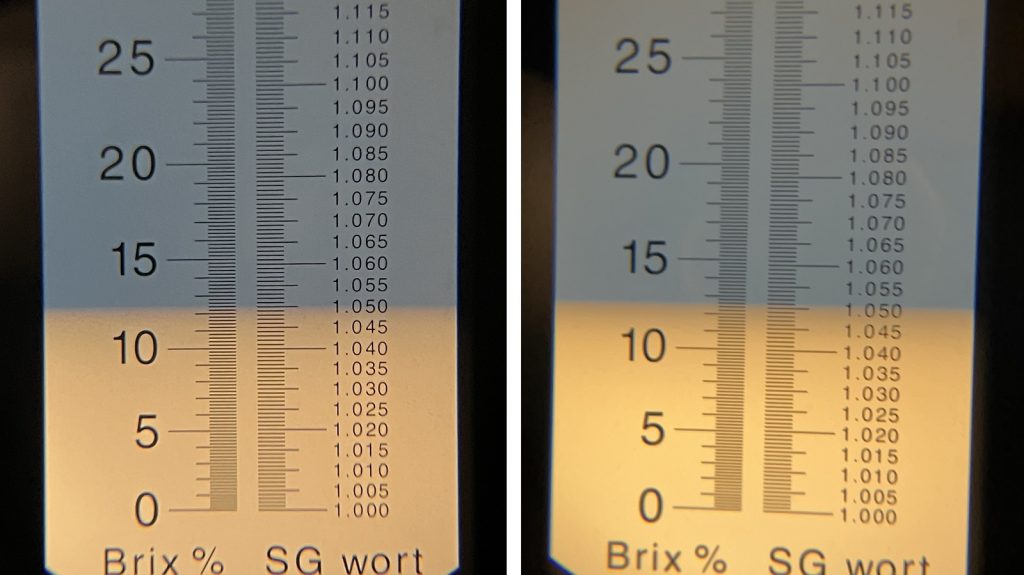

Refractometer readings indicated the YOS batch was 0.001 SG higher than the control batch.

At this point, I pitched two pouches of Imperial Yeast L13 Global into each batch.

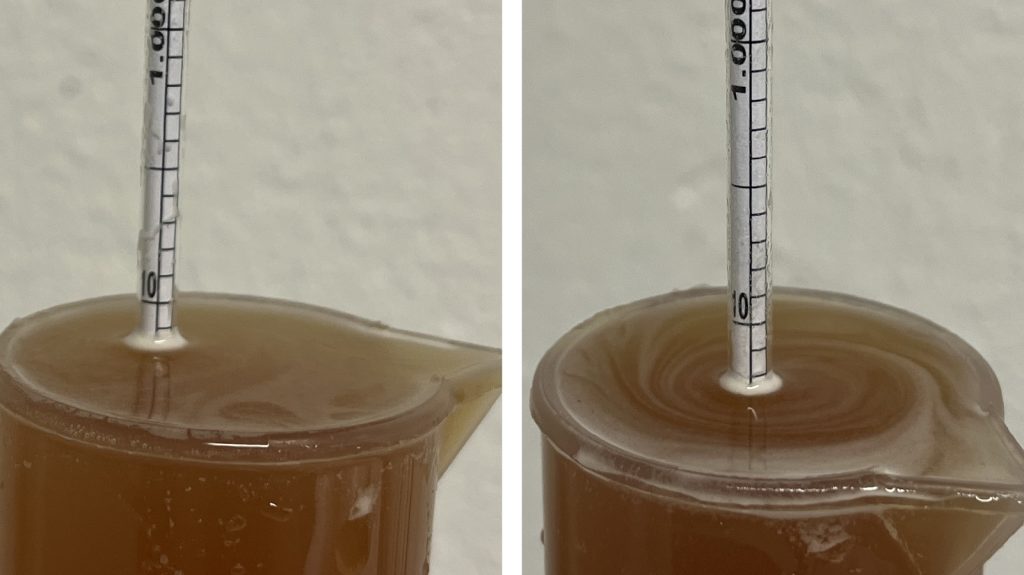

The beers were left to ferment at 48°F/9°C for a week before I added spunding valves to the fermenters and gradually began raising the temperature to 60°F/16°C. Hydrometer measurmenets taken at this point I took hydrometer measurements showing the beers were at slightly different FGs.

I gradually reduced the temperature of the beers to 32°F/0°C over the course of a few days, at which point they were pressure-transferred to CO2 purged serving kegs that were placed in my keezer. After a month of lagering, the beers were carbonated and ready for evaluation.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer where the mash liquor was not deaerated and 1 sample of the beer where the mash liquor was deaerated using the yeast oxygen scavenging method in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.52), indicating participants in this xBmt were unable to reliably distinguish a Märzen where the mash liquor was deaerated using the YOS method from one where the liquor was not deaerated.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out 3 times. Although I initially thought I detected a difference in aroma, I struggled to tell them apart with subsequent attempts. To my palate, both beers had similar sweet malt notes with supporting hop bitterness and clean fermentation character. I detected no off-flavors in either of these beers, both were equally delicious.

| DISCUSSION |

Märzen is a German lager style known for its uniquely rich malt character, which adherents of the low oxygen brewing (LOB) approach claim is hindered by oxygen exposure at nearly every step in the brewing process. Considering how difficult employing the total LOB approach can be, many brewers adopted those parts of the process they view as being most important including scrubbing oxygen from the brewing water prior to the mash. Interestingly, tasters in this xBmt were unable to reliably distinguish a Märzen where the mash liquor was deaerated using the yeast oxygen scavenging (YOS) method from one where the liquor was not deaerated.

Those who dogmatically adhere to the LOB approach often claim that, in order to achieve the “elusive” flavor found in classic German lager, one must employ every method they lay out, otherwise oxidation will occur that eliminates the so-called “it.” It’s possible these results are due to the fact certain LOB methods were not used for these beers, such as wet milling and underletting, which led to both beers being equally oxidized. However, the general consensus of those who completed the evaluation was that both versions of this Märzen were quite enjoyable and possessed no notable off-flavors. Another potential explanation for these results is that the LOB approach isn’t possible with all-in-one systems that rely on a mash basket being removed from the sweet wort, as it exposes the dripping wort to oxygen.

I’ve used the YOS method for years as a cheap and easy means to potentially maximize malt character in my German lagers. While these results aren’t enough to convince me that the claims made by LOB enthusiasts are false, I am left questioning the value of the YOS method, at least when it comes to my system, process, and unwillingness to employ the entire convoluted approach. Seeing as my bulk stash of baker’s yeast is dwindling, I’m not sure I’ll be acquiring a replacement brick once it’s gone.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

16 thoughts on “exBEERiment | Impact Yeast Oxygen Scavenging Of Brewing Liquor Has On A Märzen”

Could the YOS water have been tested for oxygen levels before mashing?

Only if I had a DO meter!

Would the sprayer on the Clawhammer system reintroduce oxygen to the wort?

The sprayer was submerged during mashing (maxing out the system with this batch size) – so I’m guessing/hoping that helps suppress oxygen introduction

Jordan, thanks for taking on this test. I too am struggling with portions of the LOB process. On my no sparge Brewzilla batches, I am convinced it is more the removing of grains and massive dripping taking place that introduces all the oxygen I have scrubbed from the brewing water and eliminated from the mash cycle. Pumping the wort into a separate vessel, letting the grains drain a while longer, removing them and pumping the wort back to boil is possible but a pain in the ass. I continue to employ the yeast, dextrose and brewtan on all batches but I have not been able to avoid the “teig” that Scott says you shouldn’t see pre boil.

Has there ever been a significant triangle test on LOB? Every experiment I have seen has been not significant. Impression I get from LOB crowd is that they are doing all kinds of PITA steps in brewing, so it must be better.

Also, why wouldn’t you want higher chloride to sulfate ratio to enhance the malt character?

Actually, a prior experiment testing a thorough LOB process yielded a significant result: https://brulosophy.com/2017/04/10/the-lodo-effect-evaluating-the-low-oxygen-brewing-method-exbeeriment-results/

I really like this water profile for my Marzen. I think it strikes a good balance that invites gulp after gulp.

Thank you for pointing out the significant result from the previous experiment on LOB. However, the results were 3 to 1 preferring regular process rather than LOB. So again, no evidence of LOB or LODO processes adding value. Thanks again for doing these experiments.

LOB lagers definitely have a unique flavor that I personally love – but I don’t think the average American craft beer drinker has a lot of experience with them, so I’m not surprised if lay preference would tilt towards familiarity. I’m not ready to throw the baby out with the bathwater on LOB just yet!

Doesn’t the campden tablet added to the mash water already reduce the DO?

I used ‘powdered campden’ (SMB) – and this fights oxygen pickup during the mash, but I don’t think SMB alone will scrub all O2 like YOS or pre-boiling can.

Hey Jordan! Great idea for an experiment.

I know you’re trying to test the effects of yeast scavenging oxygen, but it seems having two chemical oxygen scavengers added to both batches is like a textbook confounding variable. Assuming SMB and BrewTan B do what they’re supposed to do by scavenging oxygen, any effects of yeast doing that same thing could potentially be masked.

I mean just for the sake of argument, if you didn’t expect SMB and BrewTan B to scrub oxygen, then why would you have you used them? But if you did expect SMB and BrewTan B to scrub oxygen, then why did you intentionally confound the variable?

I’m trying to think of an analogous example to illustrate what I mean. It would be kind of like if you were attempting to see whether UV can cause light-struck off-flavors in beer that is fermented in glass carboy. So you put one carboy under a UV light for a few hours while keeping the other in the dark. But then the next day before kegging, you leave both carboys outside in the sun for a few hours. Maybe the UV light had an effect, but there’s no way to distinguish it from the likely effect of the sun because both batches would be expected to be light-struck. Maybe it’s a silly hypothetical, but I can’t shake the feeling that the chemicals you added to scrub the oxygen actually did so.

Either way, cheers! This was a really interesting idea for an experiment!

I have always wondered if the added character that LODO brewing supposedly has stems from the addition of SMB at various steps in the process. Wouldn’t this change the water profile to a significant enough degree, that it’s simply the difference in water rather than undamaged malt character?

LODO beers can definitely have more sulphur – so that might be part of it for sure. But both of the beers in this xbmt had SMB added to the mash, so this test nets that out of the equation (note: neither version was particularly sulphury when served – but I’m not using SMB at packaging and I used a fairly restrained amount in the mash).

Would mashing under positive CO2 pressure mitigate nearly all of the oxygen exposure? Just a few psi of CO2 in, say, a repurposed brite tank would likely reduce oxygen exposure during the mash to very low levels (nil?). That, coupled with YOS (or pre-boil), underletting, and a no-sparge approach could preclude the need for the meta-bisulfites.

The hard core LODO methods appear to use a “mash cap” as a tool to stop oxygen exposure during mashing. I just assumed “pressurized mashing” was the logical next step…

Stout Tanks actually has some products for this exact purpose! https://conical-fermenter.com/low-oxygen-brewing/