Author: Martin Keen

Wort is the sweet liquid that results from the mash, a process where malted grains are steeped in warm water, during which enzymes convert starches into sugars that can be fermented by yeast. In order for this to occur, the malt has to be crushed to allow the water to access those starches. A fairly commonly talked about factor when it comes the mash has to do with how fine to crush the grain, and modern opinions on the matter are rather mixed.

Favored by those who use the Brew In A Bag (or Basket) method, a finer crush is associated with higher and more consistent conversion efficiency, but can cause problems with lautering, and some claim the shredded husks increase the risk of tannin extraction. While a coarser crush has the benefit of creating a more effective filtration bed, hence the reason it’s recommended for those who fly/continuous sparge, this comes at the expense of a few specific gravity points.

I brew on an electric all-in-one system where the grains are mashed in a mesh basket that gets removed from the sweet wort, so I don’t worry about the grain acting as a filtration bed. Moreover, the mesh on the grain basket is such that even the finest grain particulate is easily retained. Curious of claims that too fine of a crush can lead to an astringent beer, I designed an xBmt to test it out for myself!

| PURPOSE |

To evaluate the differences between a Munch Helles where the grains were crushed coarsely and the same beer with a fine grain crush.

| METHODS |

For this xBmt, I came up with a simple Helles Bock recipe that I hoped would allow any impact of the variable to shine through.

I’ve Got My Spine

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 60 min | 28.5 | 6.3 SRM | 1.061 | 1.008 | 6.96 % |

| Actuals | 1.061 | 1.008 | 6.96 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Modern Pilsner | 9.625 lbs | 71.96 |

| Vienna | 2.5 lbs | 18.69 |

| Munich Malt | 1.25 lbs | 9.35 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 15 g | 60 min | Boil | Pellet | 12.2 |

| Saaz | 25 g | 15 min | Boil | Pellet | 2.4 |

| Saaz | 25 g | 5 min | Boil | Pellet | 2.4 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Global (L13) | Imperial Yeast | 75% | 32°F - 32°F |

Notes

| Water Profile: Ca 62 | Mg 5 | Na 8 | SO4 50 | Cl 90 |

Download

| Download this recipe's BeerXML file |

I started my brew day by adding the same volume of RO water to separate Clawhammer Supply 240v electric systems and adjusting them to my desired mineral profile. While the waters were heating up, I weighed out 2 identical sets of grain then ran both through my mill with the rollers set to a coarse crush of 0.055 in/1.4 mm.

I then changed the setting on my mill to reduce the roller gap, leading to a finer crush, and ran just one of the sets of already crushed grain through it again.

There was a very obvious difference in how the crushed grain looked at this point.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure they were at the same target mash temperature.

While the mashes were resting, I prepared the kettle hop additions.

When each 60 minute mash was complete, I removed the grains then boiled the worts for 60 minutes before chilling them with my CFC.

Refractometer readings showed the wort made from coarse crushed grains had a notably lower OG than the wort made from fine crushed grains.

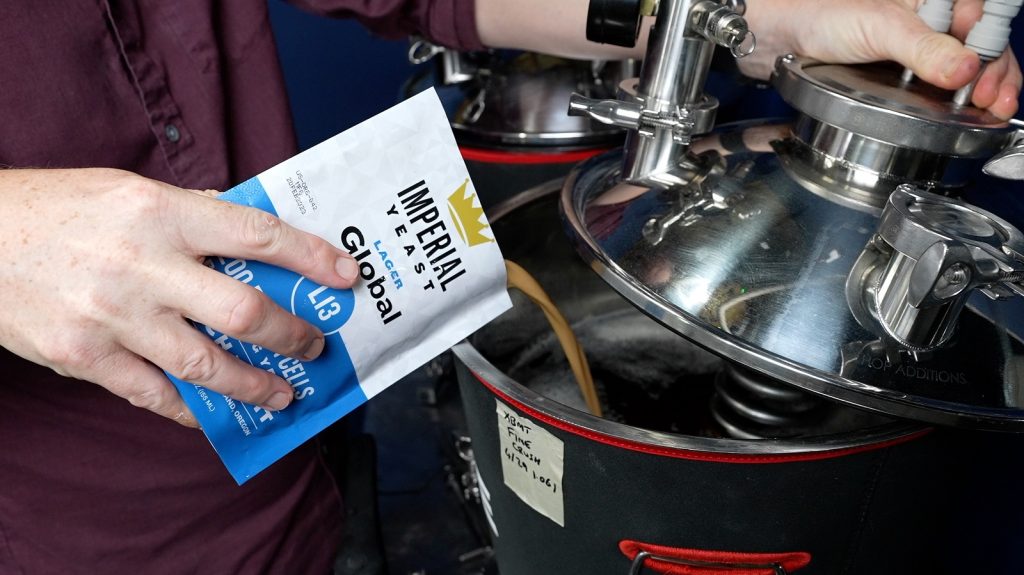

Identical volumes of wort from each batch were transferred to separate fermenters that were connected to my glycol chiller. When the worts stabilized at my desired fermentation temperature of 54°F/12°C, I pitched a pouch of Imperial Yeast L13 Global into each.

After a few days, I raised the temperature of the beers to 68°F/20°C and let it sit for a week before taking hydrometer measurements showing they finished at the same FG.

At this point, I pressure-transferred the beers to CO2 purged kegs that were placed in my keezer and left on gas for 2 weeks before they were ready for evaluation.

| RESULTS |

Major thanks to the White Street Brewers Guild in Wake Forest, NC for allowing me to collect data for this xBmt at a recent monthly meeting!

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer made with coarse crushed grains and 1 sample of the beer made with fine crushed grains in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 13 did (p=0.007), indicating participants in this xBmt were able to reliably distinguish a Helles Bock made with coarse crushed grains from one made with fine crushed grains.

The 13 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 5 tasters reported preferring the beer made with coarse crushed grains, 7 said they liked the beer made with fine crushed grains more, and 1 had no preference despite perceiving a difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I was unable to correctly identify the odd-beer-out, choosing the wrong sample every time. Obviously, I felt these beers were identical in every way, and thoroughly enjoyed drinking them.

| DISCUSSION |

When it comes to milling grain prior to the mash, brewers are often encouraged to refrain from crushing too fine, as the consequent shredding of the husks can lead to astringency causing tannin extraction. While coarser crushes are preferred by those who fly sparge since it creates a more effective filtration bed, full volume BIAB brewers tend to crush finer as a way to increase conversion. The fact tasters in this xBmt were able to reliably distinguish a Helles Bock made with coarse crushed grains from one made with fine crushed grains suggests crush size may have a perceptible impact on beer.

It’d be easy, perhaps even understandable, to presume these results were a function of the beer made with fine crushed grains being more astringent the coarse crushed grain version, but in follow-up conversations, this never came up. While numerous past xBmts have shown that people struggle to distinguish beer based on differences in alcohol, that may very well have played a role here, or it could be something else entirely. What can be said with confidence is that a finer grain crush led to notably better conversion efficiency, which confirms the anecdotal reports of many.

Based on past experiences, I expected the coarser grain crush to result in a lower OG, so that didn’t surprise me much. However, after failing to get a single triangle test attempt correct despite knowing the variable, I was sure tasters wouldn’t be able to tell a difference either, but clearly I was wrong. Given my own inability to distinguish these beers, as well as the fact more than half of the tasters who were accurate on the triangle test preferred the one made with fine crushed grains, I’ll be milling my grains finer from now on.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

7 thoughts on “exBEERiment | Impact Grain Crush Size Has On A Helles Bock”

Thanks for doing and sharing this experiment, Martin! I’m a weirdo in that I fly sparge through a brew bag in my old-school, 3-vessel RIMS. Mostly, the brew bag makes it easier to dough in (I mill straight into the brew bag in a Homer bucket, underlet that whole bag of milled grain into the preheated strike water, then stir) and to clean up the mash tun & false bottom at the end of the brew day. But the brew bag also gave me the confidence to sleep after I tightened the rollers from 0.040” to 0.035” (which I know is not very tight). I get an extraction efficiency around 80-82% and no stuck mashes, so based on my previous good results, I am prone to stay at 0.035”. But based on your experiment, I may try a brew with a 0.030” gap.

Question: Do you have the ability to compare slow crush to fast crush? I would love to know whether the too-fast shredding of the grain husks will really lead to more tannins and a perceptively different beer!

Nice experiment idea. Too many variables unfortunately.

One beer is a Maibock; the other is a Fest/Export.

Maybe a step mash or a decoction could have equalized the OG.

Next time pilot your efficiency with a given crush to ensure OG will end up the same.

Seems like the difference in OG was a function of the exact variable Martin was testing.

But the conclusion was something we already knew. Of course a fine crush will have better efficiency, as long as it is still lauterable, therefore will have a higher OG. Any effect in flavour would only be testable if the OG were the same. Of course a longer boil time to reach the same OG could also affect flavour….

I’d love to see the same exbeeriment done at 145-147F (63-64 C). The reason for that is that you would then have active beta-amylase for a much longer time, and I suspect that the difference in fementability that you got here may be due to most of the beta-amylase being denatured before a fair bit of the starch in the coarse crush had been gelatinized. You would probably also have gotten a smaller difference i OG with a longer mash time.

But the interesting result is of course that you got fairly similar beers with such a big difference in yield and fermentability. That’s actually not very surprising, as I would think the ammount of malt is what matters most.

Nice job:)!

Supposedly tannin extraction from the husks is not a problem as long as the temperature and pH are within reazonable limits. I´ve read that large breweries use hammermills to crush the malt to a fine powder, to maximize yield.

Hi

Would like to know in future comparison what was the actual “ perceptible impact on beer” ?

That would really help to kind of take decisions on how to brew the beer apart from the OG perspective.

Thanks