Author: Mike Neville

It’s widely accepted that the rate of staling is positively correlated with the temperature beer is stored at, which is why commercial brewers prefer their packaged product stay as cool as possible until the point of purchase. Arguably, the most prominent cause of staling is oxidation, which leads to reduced hop character and other unpleasant flavors.

While cans have long been the preferred container for large commercial beer, its use in the smaller craft and homebrewing sectors is relatively new, but it has become a popular option for many reasons including its impermeability to oxygen. This is a very good thing for styles known to be sensitive to oxygen exposure, the most notable being Hazy IPA, which not only develops the aforementioned off-flavors, but tends to take on an odd purplish color as well.

I recently bought an Oktober BenchMK Can Seamer and have been using it exclusively when packaging beers from my kegs for transport. My process involves flushing the cans with CO2 prior to filling and storing them in my refrigerator until I’m ready to hit the road. Considering the care I take to reduce oxygen exposure during the canning process, I’ve often wondered how a canned Hazy IPA would fare when stored at a warmer temperature and designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between a canned Hazy IPA stored cool and one stored warm.

| METHODS |

For this xBmt, I designed a Hazy IPA recipe based off of past batches I’ve brewed that turned out well.

Extra Gloves

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 15 min | 47 | 4.5 SRM | 1.057 | 1.011 | 6.04 % |

| Actuals | 1.057 | 1.011 | 6.04 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pelton: Pilsner-style Barley Malt | 8.75 lbs | 60.87 |

| Lamonta: Pale American Barley Malt | 1.75 lbs | 12.17 |

| Oats, Flaked | 1.75 lbs | 12.17 |

| Wheat | 1.75 lbs | 12.17 |

| Rimrock: Vienna-style Rye Malt | 6 oz | 2.61 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Dr. Rudi | 25 g | 5 min | Boil | Pellet | 10.7 |

| El Dorado | 55 g | 20 min | Aroma | Pellet | 13.8 |

| Southern Star | 48 g | 20 min | Aroma | Pellet | 13.3 |

| Talus LUPOMAX | 26 g | 20 min | Aroma | Pellet | 9.5 |

| El Dorado Lupomax | 50 g | 4 days | Dry Hop | Pellet | 17 |

| Southern Star | 26 g | 4 days | Dry Hop | Pellet | 13.3 |

| Talus Lupomax | 26 g | 4 days | Dry Hop | Pellet | 9.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 76% | 32°F - 32°F |

Notes

| Water Profile: Ca 120 | Mg 24 | Na 5 | Cl 173 | SO4 92 |

Download

| Download this recipe's BeerXML file |

Note: Additions listed as “Aroma” are hop stand additions made at 185°F/85°C and held for 20 minutes.

After collecting the water for a single 5 gallon/19 liter batch, I weighed out and milled the grain.

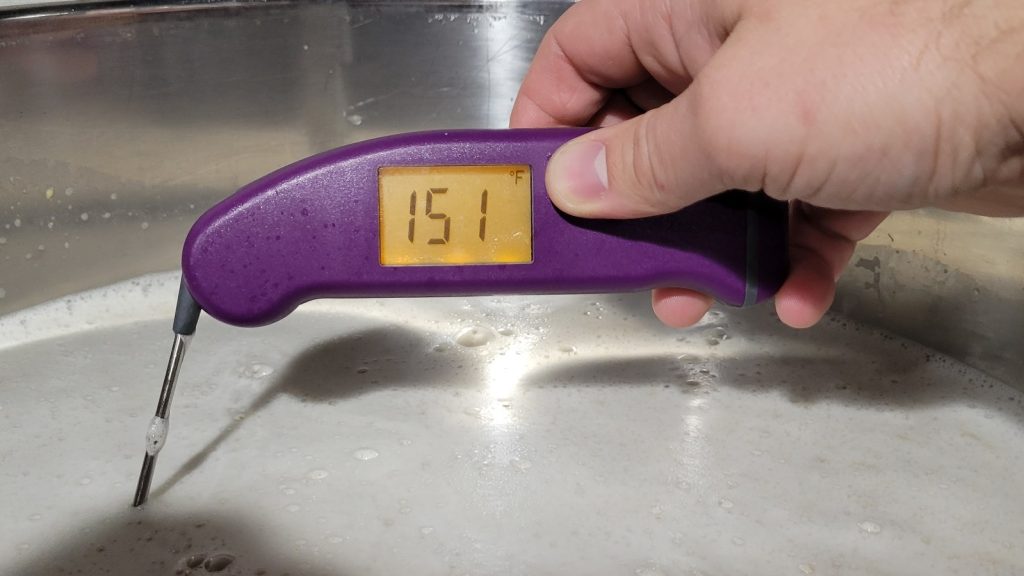

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

During the mash rest, I prepared the kettle hop additions.

Once the 60 minute mash was finished, I removed the grains then proceeded to boil the wort for 15 minutes, adding hops at the times listed in the recipe.

When the boil was complete, I used my JaDeD Brewing King Cobra IC to quickly chill the wort to 185°F/85°C, which is when the hop stand additions were made and held for 20 minutes before I finished chilling the wort.

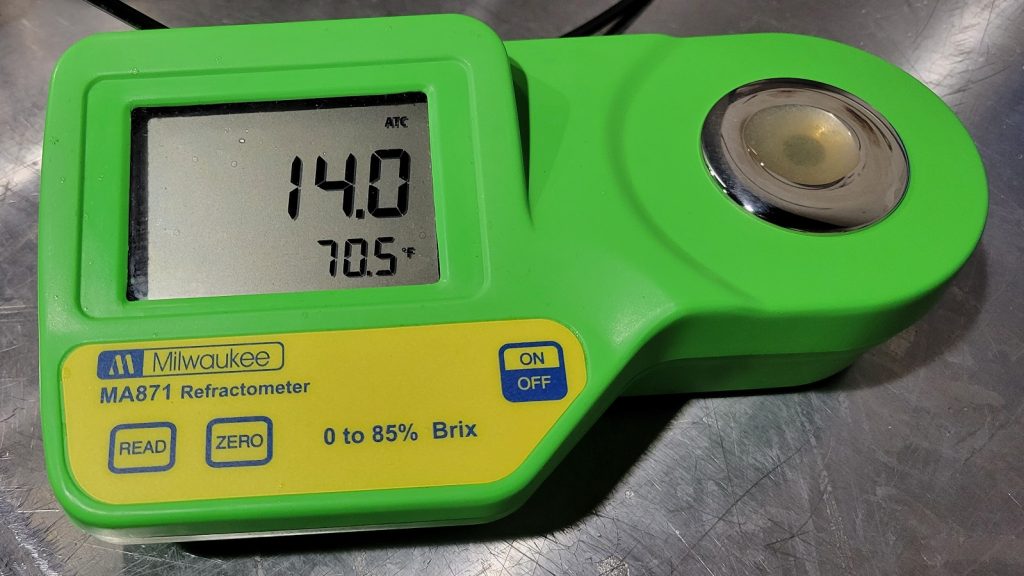

A refractometer reading showed the wort was at the expected OG.

Next, I racked the wort to my Spike Brewing CF10 conical fermenter.

The filled fermented was connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 68°F/20°C, at which point I pitched a pouch of Imperial Yeast A38 Juice.

The beer was left to ferment for a week before I took a hydrometer measurement indicating it had reached the target FG.

At this point, I cold-crashed the beer overnight at 38°F/3°C then pressure transferred it to a CO2 purged keg.

The filled keg was placed in my keezer where it was left to carbonate and condition for 10 days before I proceeded with the canning process, making sure to sanitize and flush each can prior to filling and sealing.

I then placed half of the cans in my 38°F/3°C refrigerator while the rest of the cans were placed in a room in my house that maintains a steady 68°F/20°C. The beers were left alone for 8 weeks before I began serving them to tasters for evaluation.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer stored cold and 1 sample of the beer stored warm in different colored opaque cups then asked to identify the unique sample. In order to reach statistical significance, 12 tasters (p<0.05) would have had to accurately identify the unique sample, which is exactly how many did (p=0.021), indicating participants in this xBmt were able to reliably distinguish a canned Hazy IPA stored at 38°F/3°C for 8 weeks from one stored at 68°F/20°C for the same amount of time.

The 12 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 4 tasters reported preferring the beer that was stored cold, 6 said they liked the beer that was stored warm more, 1 had no preference despite noticing a difference, and 1 reported perceiving no difference.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out every time. In addition to perceiving the beer that was stored warm as having slightly different carbonation, it also had a cleaner berry and floral character compared to the more dank berry and pineapple notes in the cold-stored version. While subtly different, I enjoyed drinking both of these beers.

| DISCUSSION |

Cans are an ideal package for beer due to their ability to block exposure to light as well as oxygen, which ostensibly prolongs shelf-life. However, given the well-established fact that the rate of chemical reactions is a function of temperature, brewers prefer their canned beers to be stored in cool environments in order to retard the development of certain off-flavors, particularly when it comes to styles known to be more sensitive to oxidation. Corroborating this notion, tasters in this xBmt were indeed able to reliably distinguish a canned Hazy IPA stored at 38°F/3°C for 8 weeks from one stored at 68°F/20°C for the same amount of time.

In considering explanations for these results, it’s entirely possible the perceptible differences between these beers was caused by oxygen exposure, as despite the efforts taken to flush the cans with CO2, the beer still came into contact with some amount of air. Interestingly, this didn’t seem to have much of a detrimental effect, as a good number of participants reported preferring the Hazy IPA stored warm, which may indicate oxidation wasn’t at play. As far as the difference in appearance, it seems plausible the cold environment caused more precipitates to fall out of solution, which may also have impacted sensory characteristics.

I went into this xBmt expecting the beer stored warm to have obvious signs of oxidation, namely an unpleasant sickly sweet flavor with muted hops, but that wasn’t the case. While perceptibly different, I felt both beers were quite good, which I believe is due to the care I took to reduce oxygen exposure during the canning process. Despite this perspective, I have no plans to start storing cans of Hazy IPA at room temperature as a matter of course, though I’ll rest a little easier if I run out of fridge space and need to keep a few cans in my house for a few days.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

10 thoughts on “exBEERiment | Impact Storage Temperature Has On A Canned Hazy IPA”

Your discussion revolves around oxidation, but I was left wondering whether the results were due simply to particulate settling out faster at refrigeration temperatures versus room temperature as the warm beer was noticeably more hazy. I don’t brew IPAs, but when I buy hazy IPAs there’s always sediment at the bottom of the can so obviously crap does settle out of these beers.

Could hop creep have come into play beer causing higher carbonation and a slight change in flavor? Drier with more fruitiness?

Obviously mean to say “come into play here”, guess I had “beer” on the brain. 🙂

Refermentation in the can does seem to be a factor here. It seems that the warm stored has higher carbonation suggesting refermentation to some degree, whether that’s hop creep, or the beer not being completely stable prior to Packaging. Different levels of carbonation are cited, but not which is higher so I am making an assumption.

Imo, carbonation variation is a very significant variable and one in which someone would be able to perceive, but perhaps that is an exbeeriment for another time?

Hey guys, your merch links don’t seem to be working.

Learning about processes and variables is a major purpose I think for these amazing Brulosophy experiments and articles. I’ve learned a ton over the years from you guys. In this article, it would be nice to see your process for flushing the cans with CO2, not as a variable but as a process step. By now, I have a pretty good idea how a pouch of yeast is poured. But flushing a can? Any photos and descriptions of your flushing process? Thanks.

One brewery assistant brewer pointed the finger to “Temperature Fluctuations” as a major problem in brewing. He was talking about fermentation and not having temperature control, but how many of us have purchased a bottle of European lager that is not good… UV could be a culprit but I’ve thought frequent temperature fluctuations (with temp going much higher than 20 deg C / 68 deg F) could be a big one too. temperature fluctuation is likely a factor. And yeah, you’re right, Hazy IPA should show it even more.

Good experiment. It would be interesting to try and mimic what beer coming from overseas and to a bottle store might go through but it would be an interesting additional test. Much wider temperature differences, with temp fluctuating frequently.

Stored at 20° C, definitely further conditioning. Cold crashing might clear beer, but there will still be remains of yeast in it.

You take care to remove oxygen by using CO2. I transfer from a DJ to a bottling bucket, then transfer to bottles, and store them in my garage, in the coolest place possible, which is close to the concrete floor. My beers survive every summer we had in the last years (many heatwaves, definitely > 20° in the garage), and are still nice after six to twelve months of storage (and I don’t care for NEIPA).

I sometimes have the impression, compared to how I make homebrew beer with simple things (two stock pots and a self built filter bucket), where I always get the question “Can we have some of that nice beer from you?”, that most of you guys do overthink things too much.

Overthinking is part of the fun! 😉

Despite their respective differences in clarity, I wouldn’t say there’s much difference in colour, which I perhaps would have expected there to be. Unless 8 weeks was a sufficent duration, regardless of storage temperature, to produce an equal level of oxidation/darkening in both beers.

As you said in the article, certainly both beers were exposed to some level of o2 during canning, though neither has the tell-tale look of an oxidised NEIPA. Very interesting. What would have been really great is a photo of a freshly poured beer from the keg next to the two canned beers. That would have given an indication as to whether the difference in clarity was indeed as a result of cold-storage or… and whether there was any deviation/darkening in colour from the beer stored under ‘ideal’ conditions (i.e. closed transfer kegged beer, stored cold, not having undergone any additional o2 exposure past the normal rigorous kegging procedure).

As an aside, an in-depth look at canning, especially as it pertains to home-canning with detail on best practice would make for an interesting podcast episode. I’d listen. But then again, I always do.

Would you consider replying with your canning process in the meantime?

If you were able to find access to a DO meter for measuring o2 in the minutes after completing your packaging process Mike, that objective data would be fascinating as the lack of any perceived traditional oxidative character in either beer, for what is the most o2 sensitive style going, certainly peaks my interest.

Thanks for the cool experiment