Author: Will Lovell

More similar to wine than beer, hard cider is fermented apple juice, which when left alone, is perceptibly dry with a touch of tartness. As preferable as these characteristic are to some, many desire a bit more balance, which is often achieved through back-sweetening, a process that involves adding some type of sweetener to the fermented cider prior to serving.

A major concern when it comes to back-sweetening hard cider is re-fermentation, which has led to the development of a number of methods including the use of non-fermentable sweeteners, like xylitol and Stevia, and heat pasteurization. However, a growing trend involves stabilizing the fermented cider with chemical agents, namely sulfites and sorbates, prior to adding any fermentable sweeteners.

While recently planning a batch of hard cider, I recalled a conversation I had with a friend about back-sweetening, particularly his thought that cold storage might render yeast incapable of re-fermentation. Curious to see for myself, I designed an xBmt comparing cold storage alone to chemical stabilization with sulfites and sorbates prior to back-sweetening a hard cider.

| PURPOSE |

To evaluate the differences between a cider that was stored cold prior to back-sweetening and one that was treated with chemical stabilizers (potassium metabisulfite and potassium sorbate) prior to back-sweetening.

| METHODS |

For this xBmt, I went with a super simple mixed berry hard cider recipe that has never failed me.

What A Great Value!

5 gallons/19 liters store-bought apple juice

15 mL Lactic Acid

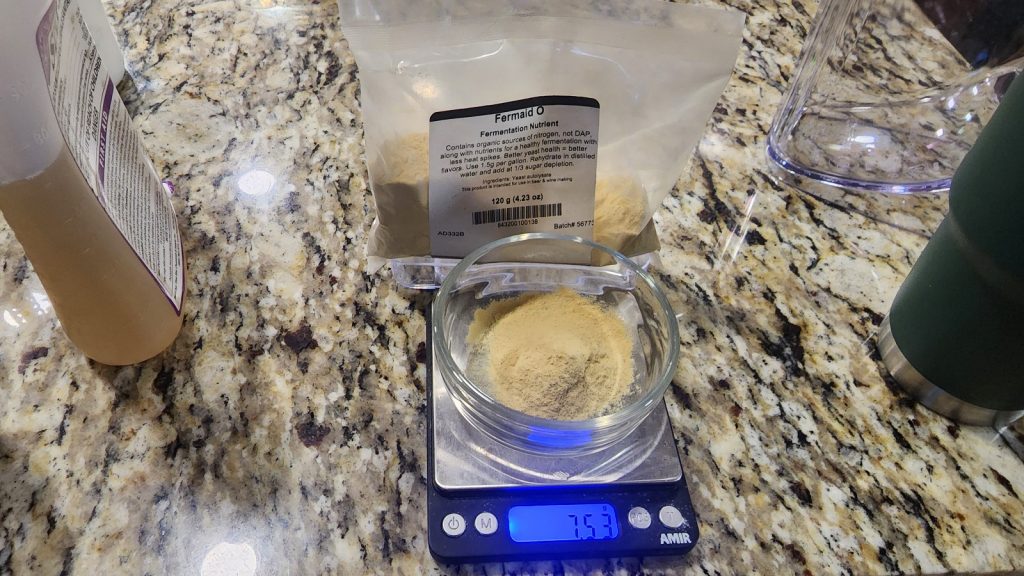

7.5 g Fermaid O

3 lbs/0.45 kg frozen mixed berries

24 oz/0.68 kg apple juice concentrate

½ tsp Potassium Metabisulfite

2.5 tsp Potassium Sorbate

I started off this cider brew day by purchasing ten 1 gallon jugs of inexpensive and minimally treated apple juice.

Next, I split the juice between 2 sanitized Kegmenters.

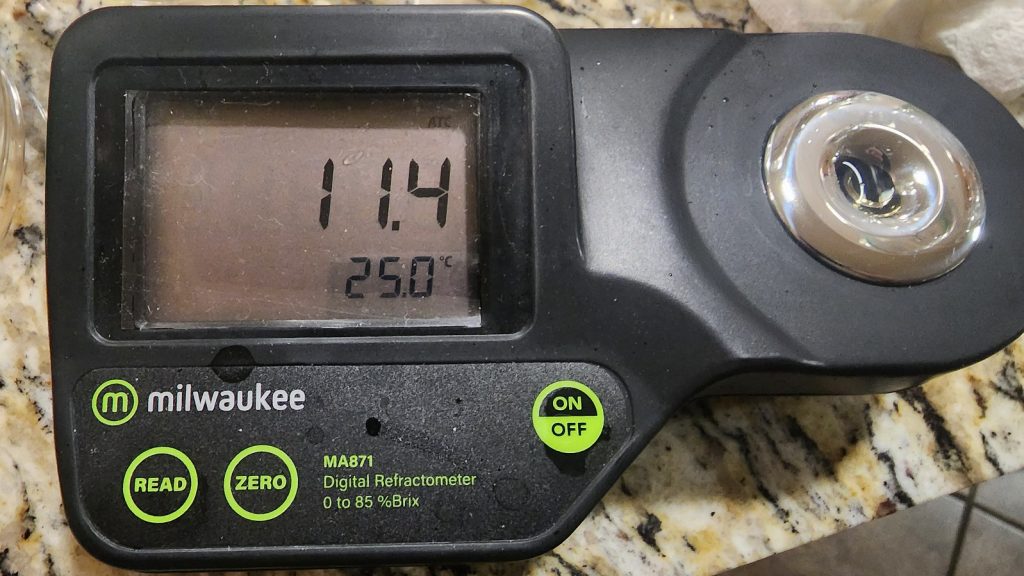

A refractometer reading confirmed the juice was right around where I’ve come to expect it.

At this point, I added identical amounts of yeast nutrient to each batch.

Finally, I pitched a single pouch of Imperial Yeast A40 Bubbles into each fermenter.

After 7 days, I noticed fermentation starting to slow and determined it was time to add the mixed berries, which allowed to thaw first.

I left the ciders alone for another week before taking hydrometer measurements showing both were at the same 1.003 FG, at which point I reduced the temperature of my chamber to 37°F/3°C. Following a 3 day cold-crash, I treated one batch with potassium metabisulfite and potassium sorbate.

After letting the ciders rest for 48 hours, I prepared for packaging by adding two 12 oz cans of apple juice concentrate to separate CO2 purged kegs.

After pressure-transferring the ciders to their respective kegs, I placed them in my kegerator and burst carbonated each at 30 psi for 24 hours before reducing the gas to serving pressure. The ciders were allowed to condition for 10 days before they were ready for evaluation.

| RESULTS |

A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the cider that was stored cold prior to back-sweetening and 2 samples of the cider treated with chemical stabilizers prior to back-sweetening in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 9 did (p=0.19), indicating participants in this xBmt were unable to reliably distinguish a berry hard cider that was chilled prior to being back-sweetened from one that was treated with chemical stabilizers before back-sweetening.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the unique sample just 2 times, and even those were wild guesses. To me, these ciders were identical in aroma, flavor, and mouthfeel, and they were delicious!

| DISCUSSION |

Apple juice consists primarily of fructose, a monosaccharide that is highly fermentable by yeast, which explains the dryness of unadulterated hard cider. Many cider makers prefer to add sweetness back to balance this dryness, though given the presence of live yeast, resort to stabilizing the cider with chemicals first to prevent re-fermentation. Interestingly, tasters in this xBmt were unable to reliably distinguish a berry hard cider that was chilled before back-sweetening from one that was treated with chemical stabilizers prior to being back-sweetened.

These results not only support the idea that chilling cider prior adding back-sweeteners results in a perceptibly similar product as using chemical stabilizers, but it also seems cold storage retards yeast activity enough to prevent re-fermentation. The one glaring difference between these ciders was appearance, though it should be noted this was observed immediately after adding the mixed berries and prior to introducing the variable. It’s my belief the ratio of berries in each bag contributed to the color difference, though based off of these findings, it didn’t seem to have a perceptible impact.

Despite my own inability to tell these ciders apart, I will continue treating the ones I make with sulfites and sorbates, as it’s a cheap and easy way to ensure re-fermentation doesn’t occur. If I were out of chemical stabilizers, I wouldn’t flinch at chilling the cider prior to back-sweetening, at those I plan to keg.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

6 thoughts on “exBEERiment | Impact Chemical Stabilization Has On A Back-Sweetened Berry Hard Cider”

In addition to inhibiting fermentation activity, cold crashing likely caused much of the yeast to floccuate out of solution. Couple with a closed transfer system, the yeast weren’t re-oxygenized (thus preventing propagation). Bottle conditioning usually take a minimum of 3 weeks to complete. Under the conditions described, its possible that the 10d conditioning time just wasn’t sufficient to observe additional fermentation.I’d be interested to see what happened after another 4-6 weeks in the keg (including a final gravity measurement).

That is fair, but and if I repeated this xBmt the one thing I would change is conditioning time. That said, when you are designing a new xBmt, you have to start somewhere, and 10 days seemed like a fair starting off spot.

If you do ever do it again, consider taking a gravity reading after adding the sweetener, and again following cold conditioning, to be sure that fermentation was actually arrested. Of course taste is the most important thing, I’m just curious (and as a bottler not going to do this experiment myself).

I don’t add anything to stop fermentation when adding apple juice concentrate to back sweeten. The cider is kegged and put into the fridge. After MONTHS of being on tap, the cider will slowly become less sweet/more acidic. Now, I don’t take readings at this point, but I am pretty sure that even at cold, fridge temps, over time the yeast will continue to consume the added sugar. I would not expect any noticeable difference in 10 days. Granted this is anecdotal and not scientific, but if a person really wants to be a sure as possible to stop further fermentation they would probably want to add something.

I typically backsweeten my ciders using fresh juice, then keg them and keep them cold. I don’t use any stabilizers. The cold storage does slow the refermentation process, but over the course of a couple of months the cider does evolve a bit to become drier. Yeast choice may affect this (I use Cote des Blancs), but I think that over time almost any yeast will slowly ferment the residual sugar.

I hope that no one reads this xBmt and thinks that cold crashing makes it safe to then backsweeten and bottle their cider. It may take some time, but without proper stabilization or pasteurization you will end up with bottle bombs. THIS IS ONLY SAFE FOR KEGGING!

Just a heads up for anyone trying to follow this recipe outside of the U.S.: the author used 3lbs of frozen fruit, which is 1.36 kg, not the stated o.45kg.

I followed the recipe as stated (.45kg) and was disappointed in the lack of berry flavour.