Author: Will Lovell

Making up approximately 95% of a beer’s composition, water is inarguably the most prominent ingredient in brewing, hence brewers are right to focus on its quality. While ensuring the absence of disinfectants such as chlorine and chloramines will reduce the risk of developing undesirable off-flavors, adjusting the overall mineral profile of brewing water is widely viewed as a way to dial in specific characteristics in beer.

Mineral adjustments are typically made to the brewing liquor prior to mashing through the addition of salts, though as many brewers have experienced, there are times the final product just doesn’t quite hit the mark. One corrective measure recommended by some involves making further mineral adjustments to the finished beer, which purportedly has the same impact on perceived character as earlier mineral adjustments.

I recently made a simple American Pale Ale that, while good, I felt was lacking a bit of hop punch, and when I mentioned this to the crew, I was reminded of a past xBmt showing tasters could reliably tell apart Belgian Pale Ales adjusted to different mineral profiles post-fermentation. Since I’d adjusted the water to a specific mineral profile prior to mashing, I thought it’d be interesting to see how adding a dose of gypsum to up the sulfate level might affect this beer’s character, so I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between an American Pale Ale that received a post-fermentation gypsum addition and one that was not adjusted post-fermentation.

| METHODS |

I went with a single-hop American Pale Ale recipe for this xBmt.

Domino Effect

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 39.5 | 6.4 SRM | 1.059 | 1.009 | 6.56 % |

| Actuals | 1.059 | 1.009 | 6.56 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Wildfire Pale Malt | 10 lbs | 83.33 |

| Vienna Malt | 2 lbs | 16.67 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

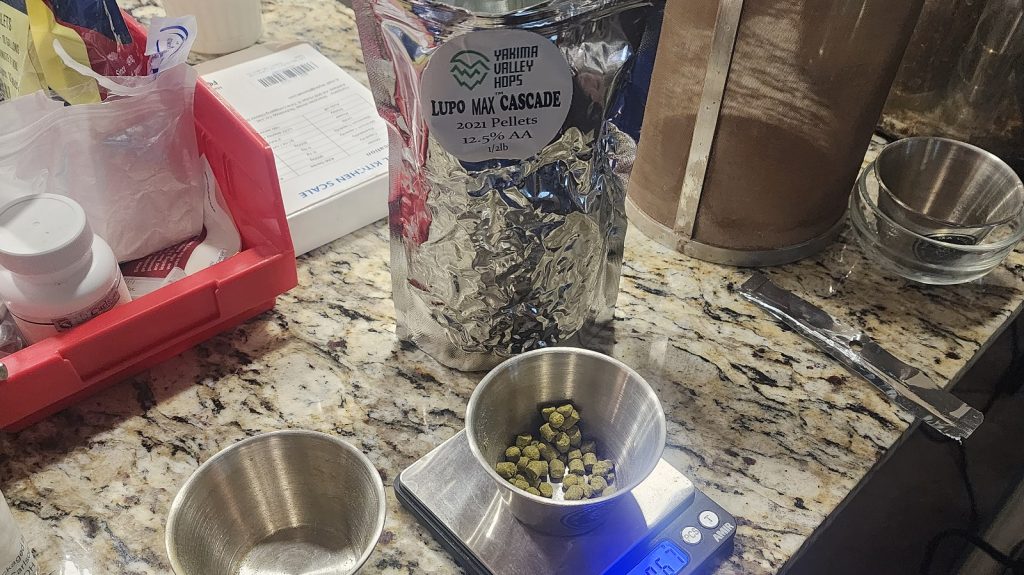

| Cascade LUPOMAX | 10 g | 60 min | Boil | Pellet | 12.5 |

| Cascade LUPOMAX | 15 g | 20 min | Boil | Pellet | 12.5 |

| Cascade LUPOMAX | 21 g | 5 min | Boil | Pellet | 12.5 |

| Cascade LUPOMAX | 56 g | 2 min | Boil | Pellet | 12.5 |

| Cascade LUPOMAX | 56 g | 4 days | Dry Hop | Pellet | 12.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Original Water Profile: Ca 92 | Mg 0 | Na 0 | SO4 152 | Cl 49 Profile After Gypsum Addition: Ca 155 | Mg 0 | Na 0 | So4 306 | Cl 49 |

Download

| Download this recipe's BeerXML file |

The night prior to brewing, I collected the full volume of RO water, which I adjusted to my desired profile before weighing out and milling the TexMalt Wildfire Pale malt.

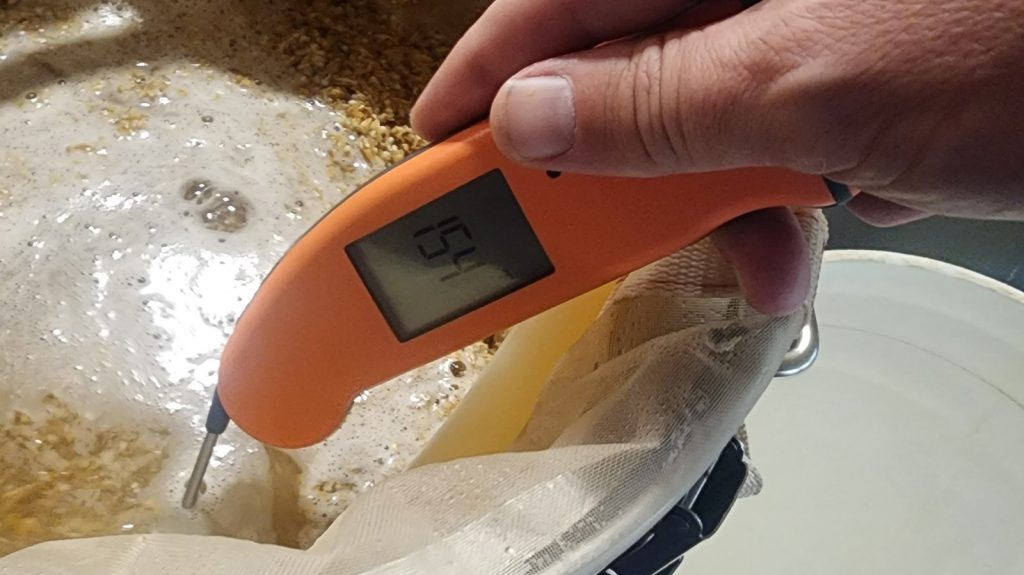

When the water was properly heated the next morning, I incorporated the grains then checked to ensure the mash was at my desired temperature.

During the mash rest, I prepared the kettle hop additions.

Once the 60 minute mash was complete, I removed the grains and proceeded to boil for 60 minutes, adding hops at the times stated in the recipe.

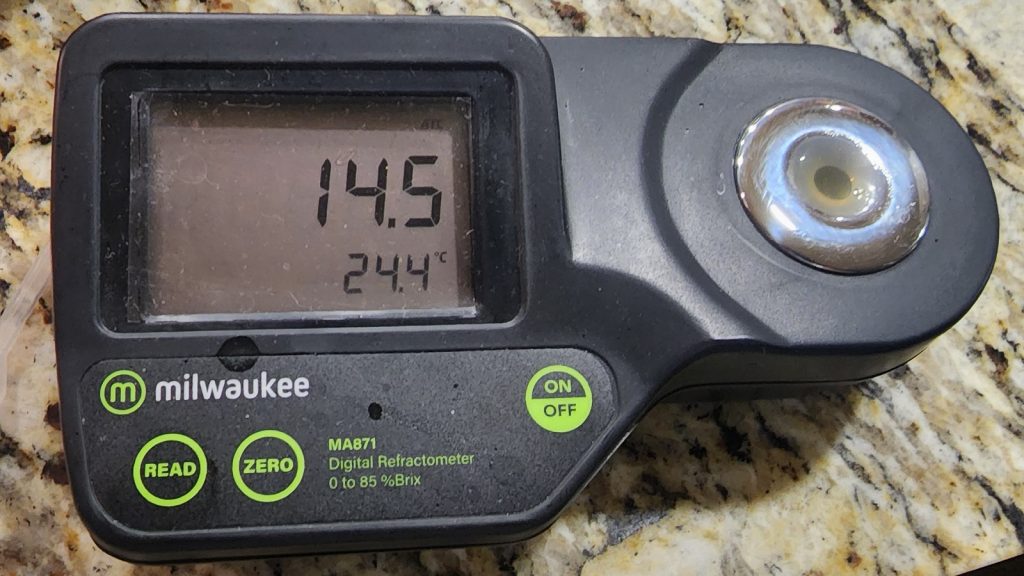

When the boil was complete, I quickly chilled the wort then transferred it to a sanitized Kegmenter before taking a refractometer reading showing it was at my target OG.

After transferring the wort to a sanitized fermented, I direct pitched a single pouch of Imperial Yeast A07 Flagship.

The beer was left to ferment at 66°F/19°C for a week before I took a hydrometer measurement confirming FG was reached.

With fermentation complete, I cold crashed the beer then pressure-transferred it to a CO2 purged keg, which was placed in my kegerator and burst carbonated overnight before the gas was reduced to serving pressure. After a couple weeks of conditioning, I began sampling the beer and felt it was lacking a bit in the hop department, which is when I got the recommendation to make a post-fermentation mineral adjustment. Seeing as the water was adjusted prior to mashing, I opted to add only gypsum in order to boost hop character. Prior to splitting 5 gallons/19 liters of finished beer, I added 3.5 gram gypsum to one CO2 purged Oxebar PET keg, while the other received nothing.

I then gently racked identical volumes of beer into both kegs and placed them next to each other in my kegerator on gas.

After another week of conditioning, the beers were ready to serve to tasters for evaluation.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer that did not receive a post-fermentation gypsum addition and 1 sample of the beer that did receive a post-fermentation gypsum addition in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 4 did (p=0.95), indicating participants in this xBmt were unable to reliably distinguish an American Pale that was dosed with gypsum in the keg from one that did not receive a post-fermentation gypsum addition.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just 2 times, indicating my inability to consistently tell these beer apart. To my palate, the gypsum addition had not qualitative impact on these beer, they were the same in terms of aroma, flavor, and mouthfeel.

| DISCUSSION |

The mineral makeup of brewing water can have an impact on certain objectively measurable things such as pH and conversion efficiency, though it has also been shown to influence the perceptible characteristics of beer. Given how readily common brewing salts dissolve in liquids, post-fermentation adjustments can purportedly be used as a means of dialing in a brewer’s preferred sensorial experience. Interestingly, tasters in this xBmt were unable to reliably distinguish an American Pale Ale that received a post-fermentation gypsum addition from one that was not dosed with gypsum once packaged.

Considering the significant results from a past xBmt on the same variable, these findings are a bit confounding. The difference in sulfate levels between the beers was was 154 ppm, which is unquestionably vast enough to have been perceptible, leading to the presumption that something else was at play. Initially, I wondered if perhaps the gypsum was at its saturation point in the beer, though cursory investigation revealed the 306 ppm was more than 3x lower than the maximum solubility of this salt. Another knee-jerk reaction was to blame the high hopping rate of the beer as covering up any differences, but then again, that’s exactly what sulfate is known to affect.

In the end, these findings admittedly left me stumped. Having experienced first-hand the impact different mineral profiles can have on beer, I fully expected the beer dosed with gypsum in the keg to be easily distinguishable from the unadjusted beer. The fact it wasn’t definitely has not caused me to change my views on water chemistry, in fact seeing how easy post-fermentation adjustments are, I’d be inclined to at least try it on beers I think might benefit from it. Still, I look forward exploring this variable more in the future on different styles with different starting and ending mineral profiles.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

8 thoughts on “exBEERiment | Water Chemistry: Impact Post-Fermentation Gypsum Addition Has On An American Pale Ale”

What are your thoughts on the oxebar kegs? I have one I purchased and haven’t used it yet. At the very least, I was going to use it as a bottling vessel if I don’t find it adequate for my needs

I like them so far. Nice when you need to split off some beer for travel or an xBmt. Also, they’re super lightweight, which is nice. Who knows how well they’ll hold up over time, but so far so good.

Maybe the sulfate level was already optimum, so adding more had no effect. Just a wild guess.

This matches my own experience: that it takes a lot more salts/adjustments post-fermentation to realize a significant flavor change than if the salts are added on the hot side. As to Why, I don’t know, but it probably has to do with pH and yeast performance.

That is good to know. Maybe its worthwhile to do this one again at some point and double the amount of gypsum.

One other factor that could be covering up the impact of the salts is the projected IBUs that are probably well under what was realized. If you are using the Tinseth model to determine IBUs, it can dramatically underestimate late hop additions especially when high alpha hops are used. To illustrate, it will predict 0 IBUs if hops are added at flameout (time 0). The two minute 2 oz addition per the Tinseth model only adds ~6 IBUs. If you extend the time to 8 mins to adjust the calculation it adds ~24 IBUs, I huge difference for just 6 extra boil minutes. Based on your recipe, the realized IBUs could be well over 70, which may overwhelm ones ability to perceive a difference.

The Tinseth under over estimation crossover point happens around 30 mins and anything below 15 mins can have a dramatic impact on projected vs realized if using high alpha late additions. Early hop additions projected vs realized differences are not as dramatic.

Here is a link to the mIBU model that goes in depth on this factor. https://alchemyoverlord.wordpress.com/2017/03/30/mibu-experiments-1-and-3/

I think Gypsum isn’t soluble in finised beer. Hence it makes no difference.

Food for thought. Reference 7 in this post seemed to find that higher sulfate levels result in lower perceived hop flavor. Definitely results in a dryer crisper flavor in my experience.