The first beers I made were fermented with liquid yeast, my process looking something like this:

1. Take yeast out of fridge a few hours before brewing

2. Once wort was chilled to about 75°F, open vial and pitch

3. Place fermentor in closet and hope the airlock is bubbling the next day

While those first few beers were nothing spectacular, they still came out pretty damn good, at least to the point I never dumped a batch. It wasn’t until I really got serious about brewing at home that I even heard of yeast starters, which I initially viewed as being more work than it was worth. After a couple batches that just didn’t come out the way I planned, I figured one of the more simple things I could try was making a starter.

I’ve never looked back.

I fairly regularly field questions about whether making a starter is really all that necessary. My honest response is always the same: no. The truth is, you can make a perfectly good beer by pitching a single vial or pack of liquid yeast into wort. In fact, I recently heard from a dude who said he took 1st place in category with a beer he didn’t use a starter on, which is fucking great! And I’m certain he’s not the only one with a similar story. So what’s the point? Why invest the time and money making yeast starters when it is obviously possible to make a delicious beer without one?

Now, I’m no microbiologist. Not even close. I could pretend to know more than I do about budding and conjugation (thanks Wikipedia), but the simple fact of the matter is I’m hugely ignorant when it comes to these issues. What I do know is that I love, in an almost lustful sort of way, what yeast does for beer. I’m fascinated by the amazing plethora of flavors different types of yeast can create and how it acts differently depending on the environment. After hundreds of batches, fermentation still seems like magic to me. I abide by the doctrine that brewers make wort, yeast make beer.

While starters may not be necessary, they absolutely serve a function. I’m not sure new brewers ought to stress too much about this part of the process, at least in the beginning, though the investment is fairly minimal for what I believe to be a good payoff. Some of my main reasons for making yeast starters:

– Visibly observing yeast activity in a starter provides me with assurance the yeast is viable and ready to go to work turning wort into beer.

– While in the starter, yeast go through a growth phase, meaning there are significantly more cells being pitched into my wort, leading to decreased lag and a quicker fermentation with less chance of off-flavor development.

– Pitching a starter has significantly increased the consistency of my brewing, making it much easier for me to replicate a batch.

– Free yeast for future use! How would I harvest clean yeast if I didn’t have a starter to steal it from?

I’m sure with very little searching, numerous other reasons for making a starter can be found, along with much more scientific sounding explanations why one should make them. My point is this: in my brewing, making starters seems to have had one of the biggest impacts on the quality and consistency of the beer I make.

How I Make Yeast Starters

I see a lot of starter how-tos that differ from my process in various ways. With my penchant for simplification, I’ve settled on a method that seems to require a little less effort and has worked well over the years. The first step is determining the proper starter size, which is a function of the OG of your wort, batch size, and yeast age. Yeast Calculator is my calculator of choice. All you have to do is plug in the aforementioned data, select a “method of aeration,” and it’ll spit out the details. Easy-peezy. Just remember to a make a larger starter if you plan to harvest yeast for future use!

Yeast starters require little in the way of equipment, of which there are many options. I personally prefer using 5 liter Erlenmeyer flasks for myriad reasons, such as the ability to make larger starters for lager beers and larger batch sizes. I also have a 2 L flask I occasionally use for smaller batches of beer. I’m a huge fan of StirStarter stir plates due to their very affordable price-point, durability, and lifetime warranty (they make a new larger model now as well). While not really a piece of equipment, FermCap-S (anti-boilover agent) is an absolutely necessary part of my yeast starter kit that has saved me from more volcanic eruptions (and clean-ups) than I can count. That’s about it. For those who aren’t ready to invest in a fancy flask and stir plate, a clean and sanitized growler shaken every time you walk by will get you by. If you’re good with electronics and have the desire, you might also consider building your own stir plate.

Step 1: Weigh out DME and add it to your clean flask (a funnel helps)

Step 2: Add hot tap water from the faucet (if good quality, otherwise use cold), swirling the flask at first to fully incorporate the DME

Step 3: Once proper amount of water is added (I usually go a hair over my target to account for boiloff), swirl a bit more to make sure there is no DME stuck to the bottom of the flask, then add a couple drops of FermCap-S

Step 4: Place flask on stove, turn burner to high

Step 5: Watch the flask and turn burner down to low-med once bubbles start rising from the bottom of the flask.

Step 6: Once wort is boiling, set timer for 10 minutes, and watch for potential eruptions! A quick blow down the shaft of the flask will kill any large bubbles that may form.

Step 7: While wort is boiling, make a small bowl of sanitizer solution for the foil and stir bar

Step 8: When the timer goes off, carefully move the flask (OveGloves are a godsend) to a sink with the drain plug in place, drop sanitized stir bar in, cover top with sanitized foil, then surround it with ice and cold water.

Step 9: Once wort is chilled to about 70°F, pitch room temperature yeast, set the flask on the stir plate, and get things spinning.

Step 10: About 36 hours later, after stealing some yeast for future use, I usually move the flask to the fridge to crash overnight so I can decant the beer off before pitching. Don’t forget to attach the stir bar to the side of the flask with a strong magnet before crashing.

In the end, starters may not be totally necessary for beer production, though I think most experienced homebrewers would agree that it is one of the easiest ways to improve beer quality and consistency. If you’re looking to step up your game, I strongly encourage you to consider making a starter for your next brew.

Cheers!

***I’ve been asked a couple times about how I decant the starter prior to using them. Basically, just gently pour off all but maybe 500mL of starter beer, swirl up the rest to ensure homogeneity, then pitch as usual. If you have any other questions, don’t hesitate to ask!***

ATTENTION: There is some concern Erlenmeyer flasks run the risk of shattering if placed directly on stove-top burners, particularly electric coils. If you share this concern or have small children around, you might consider boiling your wort in a pot before adding it to your sanitized flask.

If you enjoy reading this stuff and feel compelled to support Brulosophy.com, please check out the Support Us page for details on how you can very easily do so. Thanks!

84 thoughts on “Yeast Starter Method”

Great write up. Could you just add a few more steps describing how you decant the beer off and actually pitch the cold crashed yeast? Thanks.

Good point, Kevin, I’ll get to that soon. Thanks!

Hey! Have you ever created a starter with a dried yeast? I want to make a big beer with some US 05.

Cheers,

Callum

Hey Callum, since DME costs more than than US-05, I’m much more likely to pitch 2-3 sachets rather than make a starter. Also, dry yeast are packaged to be pitched from the packet, not built up in a starter. That said, I know people who have made dry yeast starters and it works fine.

Ah ok, I’m in New Zealand and US 05 is not so cheap. I’ll give it a crack anyway!

Cheers!

I think rehydrating dry yeast is definitely the way to go rather than just pitching out of the packet. It gives the yeast a good start in life!

Hey Marshall,

How are you harvesting yeast from the starter, just pouring it off with some wort into a jar?

Thanks!

That’s basically it, yeah. Here’s my how-to write-up on harvesting from starters: https://brulosophy.com/methods/yeast-harvesting/

I usually boil my wort in a small pot then transfer to my flask. I’ve always wanted to boil in the flask so I don’t have to transfer but I never knew how people take a temperature reading of the wort in the flask. Just wondering how you know you’ve hit the ideal pitch temperature?

I usually boil my wort in a small pot then transfer to my flask. I’ve always wanted to boil in the flask so I don’t have to transfer but I never knew how people take a temperature reading of the wort in the flask. Just wondering how you know you’ve hit the ideal pitch temperature?

Usually, if the flask is cool to the touch, I’ll pitch the yeast. I do occasionally use my infrared thermometer to get a more accurate reading.

Word…I might have to pick up that thermometer. Price ain’t too bad either.I just made a starter and did the ol funnel trick from pot to flask. Thanks man.

I use a weber thermometer, which is very fast. I just hold it against the flask on the outside and isolate with a piece of paper towel. I feel get a fair accurate reading.

Hey! Have you ever tried making a big ole batch of wort and sealing it in a food grade container in the fridge, then boiling it every time you need to make a yeast starter? DME is relatively expensive where I am so I’m looking for alternatives….

Cheers,

Callum

I’ve never done that, I guess there is some concern wort is a breeding ground for botulinum.

you could try pressure canning wort. It will likely keep better. You could make higher OG wort, pressure can it, then water it down for a starter. Just a thought.

Sounds pretty much the same as my process. Luckily I have a gas stove, so boiling the flask is easy as. I normally put the stir bar in and boil it too, given they are coated in Teflon which can deal with temps much greater than 100C. I also don’t sanitize the foil (maybe not ideal), but once I turn the stove off to put the foil over the flask, I turn it back on again for maybe a minute or two and boil it with the foil on. Then I turn it off and let it cool down naturally, similar to a no-chill batch of wort. I figure this extended time with exposure to very high temps will sanitize it well enough. Once it feels lukewarm I put it in a water bath to speed up the cooling to be able to pitch yeast. Haven’t had a failure doing this so far so happy enough to continue with it. 🙂

Hey there – In step 8 you mention a ‘stopper’ – do you use a stopper in addition to the foil? Do you keep the stopper in place all throughout the remaining processes?

Ha! Sorry, I’m referring to the drain plug in your sink, not a rubber stopper for the flask. I just edited it for clarification 🙂

I use liquid malt extract in my starters. It is cheaper than dme and you can buy it in common grocery stores.

Do you have any issues using a 5l flask on the original Stirstarter plate? Would you recommend using the new larger Stirstarter for that size flask?

The 5L flask is a touch wobbly on the StirStarter, but it fits beautifully on the Yeastir.

Would you recommend using DAP as a nutrient to this process and if so what dosing schedule would you use?

Well, I wouldn’t not recommend it, but I can’t really recommend it either as I’ve never used yeast nutrient… and I’ve never had problematic fermentations.

Thanks for the quick response. I suppose then that I wont add anything additional to the procedure as not to complicate it.

Hi. I started to make my starters like you do, using the homebrew dad’s yeat calculator and overbuilding cell counts to 100 billions cells to save slury for the next batch. At fist time I made this ( two weeks ago) I collected slury in a graduated falcon tube. It was exact 12,5ml of compact slury. By the Jamil Z. yeast book calculations, assuming that 1ml of dense slury have 8 bi cells, I have the exact 100 Bi cells I was looking for. So last week I use this yeast and made a starter again overbuinding 100 Bi cells. I collected much more slury. Probably more than 100Bi. The falcon tube have 30ml of dense slury. Do you measure the volume of dense slury collected in your overbuild slury? Did you observed a variation like this?

I don’t regularly do it that way, but rather collect the amount of starter I overbuild by with the assumption the calculator is accurate. It probably is fairly close, but it always seems I end up with more yeast than expected… which I’ve never complained about 🙂

I’ve been reading about pasteurization, which apparently kills 99.999% of all pathogens at 150F for just a minute or two. Why do we need to boil the yeast starter for ten minutes, then? Seems like this would be worth an test….

I frequently boil for 2-3 minutes…

Which correlation do you use in YeastCalculator.com? Troester or Zainesheff?

Troester

I’m new to starters…first few went like clockwork. Current batch of Wyeast 1968 London ESB looked good at first, but after 24 hours suddenly looked like egg drop soup. I’m concerned that after crashing it, I’ll have jello rather than slurry. Any thoughts?

Totally normal! English yeasts are highly flocculant, those clumps are flocculated yeast.

So, ok to decant and pitch the clumps?

Indeed.

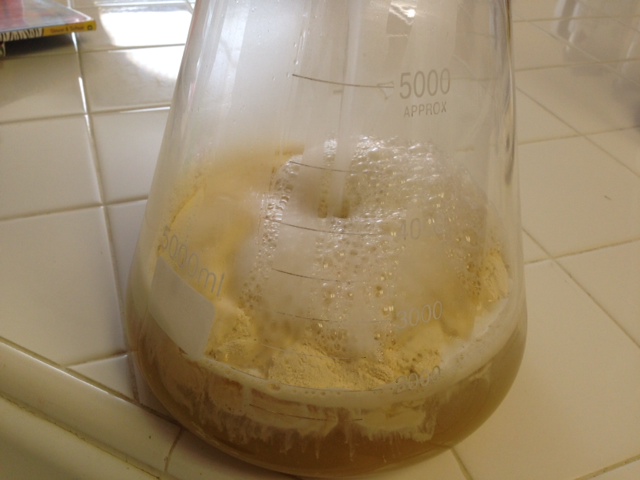

Thanks for the article. A coupe of questions for you, as my attempts at making a starter may not have been successful. I’ve never gotten foam like in your picture, and the wort I pitched into never went below 1.020. When using a “smack pack”, do you break the nutrient pack and let it swell before adding to the starter? Does that matter? Also, is ambient temperature crucial while the starter is on the stir plate? Thanks!

I break the nutrient pack, but it’s not totally necessary.

For good growth, temps between ~65°F and 75°F seem to work well for me. Anything cooler may slow the yeast down a bit.

Hey there. Great write-up. How long are your harvested yeast slurries good for? Do you use them up within 2 weeks? Or are they good for a few months? Thanks

I’ve gone as far as 6 months without issue.

Really. So when you want to use it again, you just make a starter again and have at it?

Yep.

How many times do you reuse a starter? Is the age of the yeast when it was last harvested or when it was originally produced?

I’ve gone as far out as 17 generations, took about 8 months.

Thanks for the great website guys. It’s great to see someone testing the many self perpetuating “theories” which grace typical homebrew forums.

I have a question about making yeast starters that, despite many hours spent in various forums, I have not been able to find a scientific and repeatable answer to.

When using a stir plate, how does one tell when the yeast have consumed all available sugars?

I put my first starter on a few days ago, which was Wyeast 1214. It got off to a really slow start, but eventually got going after about 48 hours (I tested with a refractometer after 48 hours and confirmed the OG was still at 1.040). After another 12 hours or so, the liquid got really milky looking, which I assume is a good sign of lots more yeast in suspension. I though to myself I’ll give it another 48 hours then take another reading to see where it’s at, but didn’t factor in the difficulty of getting a good clear reading with fermented wort with lots of yeast in the sample. So it’s a bit hard to tell with an SG sample. Obviously I’m not too keen on taking multiple large hydrometer samples in such a small total volume.

So I wonder how a logical brain like yours approaches this situation when thing don’t quite start well. Using the standard “just wait 24-36 hours” doesn’t work if it takes the starter 48 hours to get going. I feel like 48 hours after it visible kicks off might be a good thumb in the air, but I’m looking for something more reliable than that in case it’s just going slowly. Having the starter on a stir plate means the yeast is always in suspension, so I can’t tell when it’s going dormant and dropping out.

Sorry for the long post. Hopefully you or someone else has had these thought and can contribute. I’m probably just over thinking it, and it will all make more sense after I’ve done a few.

By the way, I’m following your yeast harvesting method, so I’m overbuilding this batch. Which brings me to another question… what size are those Mason jars you use for yeast storage?

Thanks again for the website. I don’t drink or make enough beer myself to be able to experiment as much as I’d like to. I brew vicariously through this site so that the brews I actually do are better 🙂

Steve

Just attempting to answer my own question… would the lack of rising CO2 bubbles be a good sign that the yeast have finished? My starter never got any krausen to speak of, but it did bubble like a good ferment does. When I stop the stir plate I see no sign of bubbles either looking through the side or on the surface.

Seem like an obvious answer, but I’m not 100% sure the lack of bubbles means fermentation has completed. I would get flamed by the old hands on most forums for suggesting such a concept. You know… “you can only tell fermentation is complete by 2-3 consecutive consistent hydro readings, don’t go by lack of air lock activity” etc etc…

I usually just wait until there aren’t bubbles crawling up the side of my flask… real exact ????

Thanks Marshall. Yeah it seemed pretty obvious to me after I posted my first comment and it got me thinking more. I actually went ahead and stopped the stir plate for a good half hour and saw a nice layer of yeast settling on the base of the flask – plenty more than went in that’s for sure.

Anyway thanks for the reply. Although it might not be an exact method, it makes sense, and obviously works well for you.

Great article, inspired me to decide to move from dry to liquid yeast.

I always brew 2 batches on brewday, and I may want different yeasts for each. I have decided to get the Maelstrom® Stir Plate. Question is: Should I get 2, or can I leave one starter in the fridge until the next is finished? How long before pitching is it OK make the first?

Really get a lot from this site.

Regards from Denmark

I’ve pitched starters that were made 2-3 days prior and stored in a fridge, they worked fine.

Just saw this article https://www.homebrewersassociation.org/how-to-brew/brooklyn-brewery-tips-yeast-health/

Do you make a new starter when you use your harvested yeast? The author says not to do that. Might be worth a XBMT

Haha. Yes, I always do, it works great.

Hey guys. I really appreciate all your info. On to my question, have you ever had an erlenmeyer flask break on you while heating on an electric cooktop? I have heard rumors of this and have feared trying it. What gives?

I have not experienced this… thankfully.

Thanks Marshall, while waiting on this response, and it was a short wait at that I tried out the electric cooktop and had zero problems. Thanks for the response.

I do not have an electric stove and typically do not associate with people who do….

With eyes lowered as to not make direct eye contact, I apologize for my assumption.

I have some of the little 50ml plastic tubes that i want to store some harvested yeast (from my starter) in for use next time. I’m not sure if I just fill them with the mixed wort/yeast solution or, let the yeast settle out in the starter over night in the fridge and just transfer slurry into the test tube before pitching the bulk of the yeast slurry into my main brew. And if it is the second option, how much slurry should I harvest into my test tube?

I believe this is what Olan from BrewUnited does, he may have a blog post about it.

Is temperature control important while making a starter. Should one follow the recommended temp range given for the yeast selected. I’m in Florida and it’s not unusual for ambient temps to hit 92 +. Is this to warm for a starter ?

Hi Susan,

I’m comfortable letting my starters get up to about 80F, though they tend to stay around 75F, and I’ve not noticed an issue with that. 92F seems really high, and since we haven’t tested it out yet, I’d be uncomfortable doing it myself.

I keep my starters in my laundry room where the temp hovers between 68-74F all year long.

to make a starter do you use wheat dme ? And can you use corn sugar instead ?

I use standard barley malt DME, but I’m sure wheat would work fine. I’d not recommend dextrose starters, personally, and here’s an xBmt we did on it: https://brulosophy.com/2015/06/05/real-wort-vs-dextrose-yeast-starter-exbeeriment-results/

If you are making a big starter for a high gravity lager, do you step it up or do it all at once? I need over a gallon but have no time to do multiple steps.

Just once. I know some will say that’s wrong, but it works for me.

Sounds like something interesting to test! Thanks for the quick feedback.

Thanks for the great info.

Prior to pitching the starter, do you bring it back up to fermenting temp or is it alright to pitch straight from the fridge?

I’ve done both, works fine either way.

Hi, Just a follow up on Jared’s question. I need 309 billion and I’m going to do a starter from a Wyeast 1214. Can I just make 4 litres of starter wort and it will then multiply to 400 so I can save some, or do I need to make a 1 litre and then another 2 litre from that? Time constraints would appreciate the first big batch technique. Cheers for your info. Sam

Some will claim growth/inoculation rate on that size starter with your pitch rate isn’t ideal. I’ve personally never made a step starter and always have great results.

Cheers Jake, I’m doing a Grand Cru clone set to be 1.074, don’t want it to get stuck!

Just curious as to why it wouldn’t make sense to boil the stir stick in the starter to sanitize it? I have done this in the past and it seems to work fine. One less thing to handle after boiling.

That’s exactly what I do.

Have you tried “reusing” yeast from previous batches of beer and “restarting” them?

If in a pinch for time do you think a 12hr starter not cold crashed and decanted would be enough time?

Hi there from Chios isl.-GREECE,

if i use zelatin can i harvest the yeast?

Regards to all B/team

TryfonEXBEERIMENTS

ps.if you want mastic recin for EXBEERIMENTS i can sent you..!

Yep, I’ve done it plenty of times and it works fine.

Thanks !!!!!

What are your ratios for DME to water in the starter?

1 gram DME per 10 mL water

I have an extra container of LME. Do you know how to figure out how much LME to use to make a 2 liter starter to achieve 1.040. The only info I’ve been able to find suggests using a brewing calculator, but the only one’s I’ve found all give quantities for DME.

Marshall,

When making a starter for lagers (i.e., 4-5 L starter for 10gal batch) do you recommend colder temps? And the same time for the cold crash/decant?

Thanks!

Nope, all starters get done at the same temp… which is whatever my laundry room happens to be at.

New to this. I have read not to reuse yeast after it has fermented a higher gravity beer in the 1.060 + range . Is this ok to do if your using the Brew Unite Calculator ? Or what am I missing here?

This is an old thread, but a good one. I agree with most the comments above and the process described by the author. I would add that there could be an advantage from making your own wort for the yeast starter from the ingredients that you plan to brew and NOT use commercially prepared DME/LME. John Palmer writes that yeast always need to “biochemically assess” their environment to optimize a genetically expressed enzyme profile and he is right (I have a degree in biochemistry). The closer you can target the actual wort conditions, the better. For reasons explained previously, this is obviously not a deal-breaker and we can all make great beer with commercially prepared yeast. But if you are going through the trouble to make a starter, might as well set up a perfect match of wort conditions for your brew starter. And it is the cheapest system as you only need one dry yeast packet and 2 cups of your specific grain bill.

48 hours ahead of brew day, make a mini-batch of wort from the grain bill intended for brewing. Using standard pots and strainers and the kitchen stove, add 2 cups of the crushed grain to 3 cups of water and adjust the temp up to maintain 155 F for 60-90 minutes (saccharification). Sparge at 170 F and then boil the wort down as needed to meet a target OG (like 1.060). Chill the sanitized wort to 70 F and then mix with the dry yeast prescribed for the batch in a 1L sterilized flask on a stir plate. Process for 24 – 36 hours, then pitch your beer with an active batch of perfectly conditioned yeast.