Author: Cade Jobe

Cold-side oxidation is a leading cause of shelf stability issues for brewers, with even small amounts of exposure quickly deteriorating otherwise delectable beers, especially modern hoppy styles. It’s for this reason many brewers go to such great lengths to minimize oxygen exposure on the cold-side by employing methods such as pressurized transfers and purging kegs with CO2 prior to filling.

The rapidity of oxidation reactions are positively correlated with temperature– as the temperature increases, so too does the rate of oxidation. As such, brewers aim to keep their beer stored in cool environments for as long as possible prior to being served in order to prolong shelf-life.

While numerous past xBmts have demonstrated the negative impact cold-side oxidation can have on IPA, they’ve tended to focus on beers packaged under different conditions then stored similarly. I recently began to wonder about the role storage temperature plays in cold-side oxidation, namely if a Hazy IPA packaged under non-optimal conditions but stored cold might maintain its freshness longer than the same beer stored warm.

| PURPOSE |

To evaluate the differences between an oxygen-exposed Hazy IPA stored in a warm environment and one stored cool.

| METHODS |

For this xBmt, I went with a tweaked version of my base Hazy IPA recipe where I swapped the usual hops for a more tropical blend of Citra, Mosaic, and Sabro.

Sweaty Lobbies

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 47.1 | 6.2 SRM | 1.054 | 1.007 | 6.17 % |

| Actuals | 1.054 | 1.007 | 6.17 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta: Pale American Barley Malt | 10.5 lbs | 73.68 |

| Wheat Malt | 2.25 lbs | 15.79 |

| Oat Malt | 1.5 lbs | 10.53 |

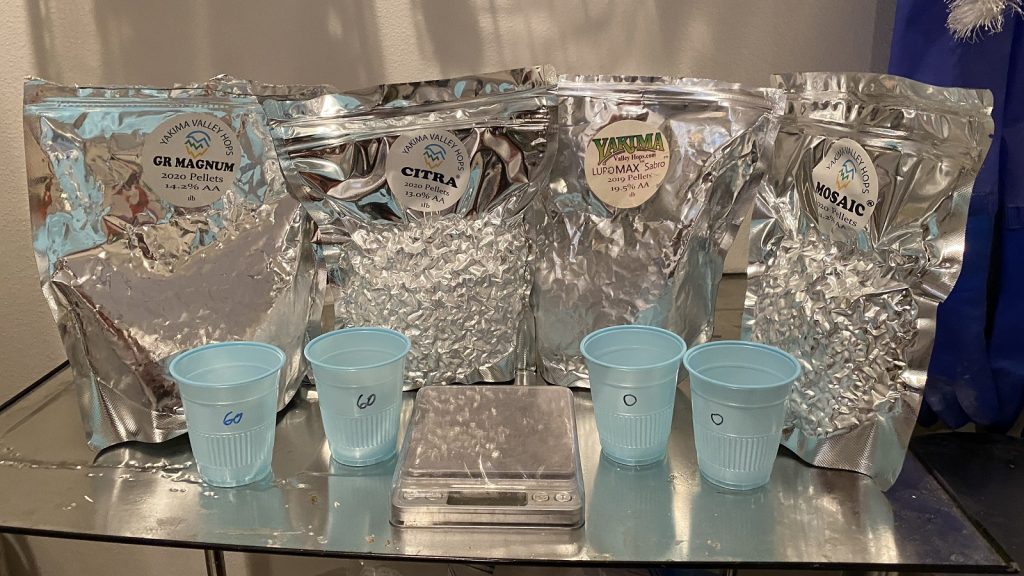

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 20 g | 60 min | Boil | Pellet | 14.2 |

| Citra | 30 g | 5 min | Aroma | Pellet | 13.2 |

| Mosaic | 30 g | 5 min | Aroma | Pellet | 11.2 |

| LUPOMax Sabro | 20 g | 5 min | Aroma | Pellet | 19.5 |

| Citra | 45 g | 3 days | Dry Hop | Pellet | 13.2 |

| Mosaic | 45 g | 3 days | Dry Hop | Pellet | 11.2 |

| LUPOMax Sabro | 30 g | 3 days | Dry Hop | Pellet | 19.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

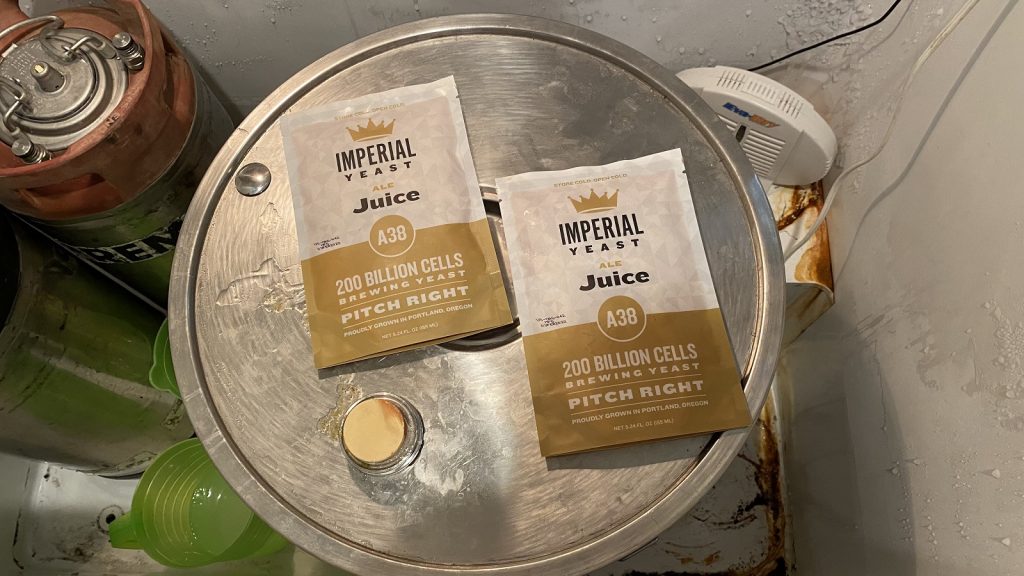

| Juice (A38) | Imperial Yeast | 76% | 32°F - 32°F |

Notes

| Water Profile: Ca 67 | Mg 2 | Na 8 | SO4 82 | Cl 67 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch, adjusting both to my desired mineral profile, then setting the electric controllers to heat them up.

I then weighed out and milled the grains for each batch.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 152°F/67°C.

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I raised the grain baskets out of the kettles and let them drain. The worts were then boiled for 60 minutes with hops added at the times listed in the recipe.

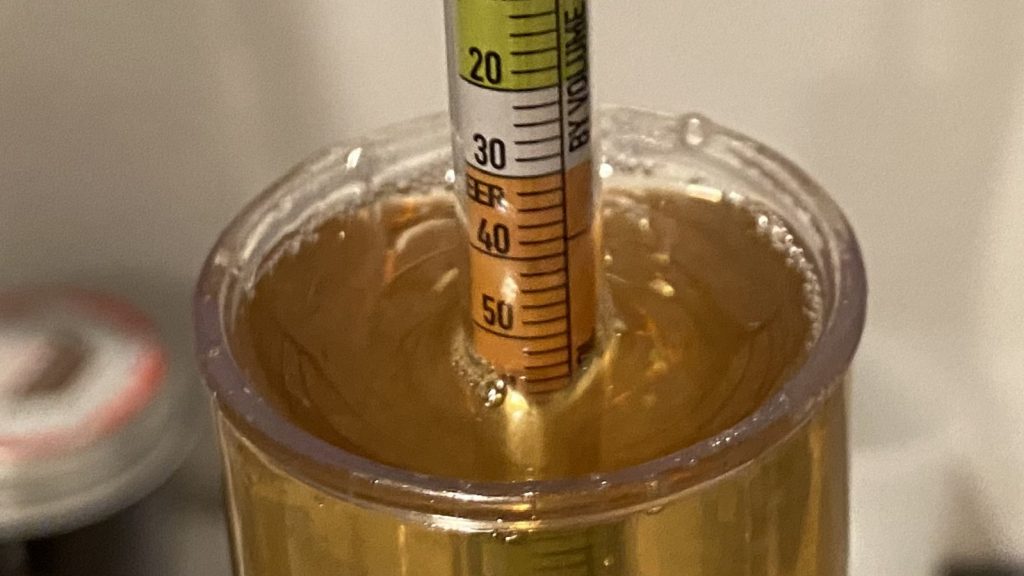

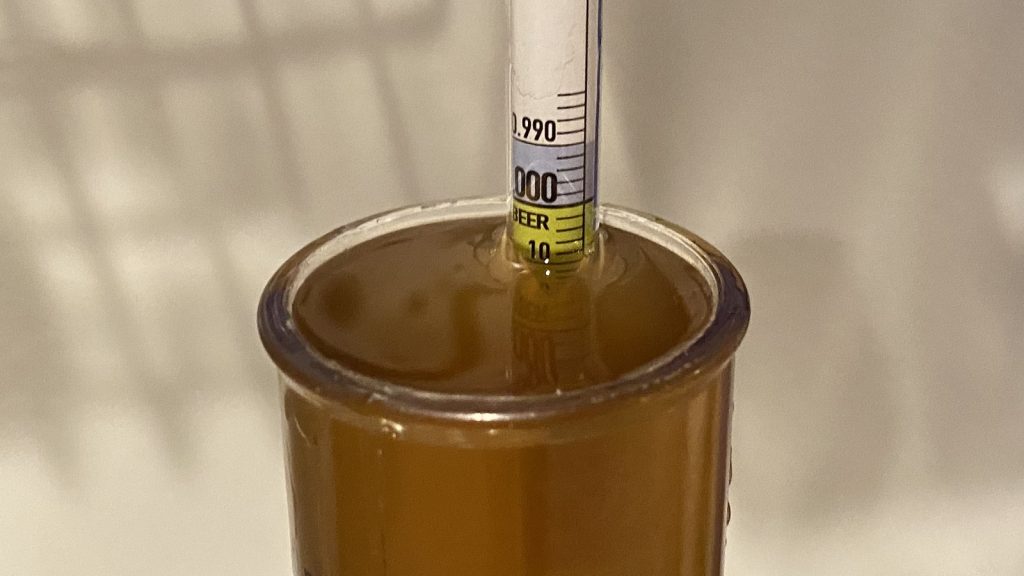

When the boils were complete, I quickly chilled the worts before racking both to a single 14 gallon/53 liter fermenter, at which point I took a hydrometer measurement showing it was at my target OG.

Next, I placed the filled fermenter in my fermentation chamber and pitched 2 pouches of Imperial Yeast A38 Juice into it.

The beers were left to ferment at 68°F/20°C for 4 days before I returned to add the dry hops.

After another 2 weeks, signs of activity had dwindled, so I took a hydrometer measurement indicating the beer had reached my target FG.

At this point, the beers were transferred via gravity to kegs that were not previously purged of oxygen with CO2; the tubing did run to the bottom of the keg to avoid excessive splashing.

As soon as the kegs were filled, I put one in my 38°F/3°C kegerator while the other was placed next to my kegerator in a spot that is consistently around 70°F/21°C.

After 10 days, I moved the warm stored beer to the kegerator and let it chill overnight. With both beers at the same temperature, they were burst carbonated for 15 hours then left to condition at serving pressure for 1 week before they were ready to serve to tasters.

| RESULTS |

A total of 24 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer stored warm and 2 samples of the beer stored cool in different colored opaque cups then asked to identify the unique sample. While 13 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, 18 did (p=0.000007), indicating participants in this xBmt were able to reliably distinguish an oxygen-exposed Hazy IPA stored warm from one stored cool.

The 18 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 2 tasters reported preferring the warm stored beer, 11 said they liked the beer stored cool more, and 5 had no preference despite noticing a difference.

My Impressions: Out of the 4 semi-blind triangle tests I attempted, I identified the odd beer out every time. While both had the tell-tale signs of oxidation, the papery, wet cardboard, and muted hop characteristics were noticeably stronger in the version stored warm. For the first time since I started brewing Brülosophy xBmts over 3 years ago, I felt guilty serving these to tasters, they were that gross.

| DISCUSSION |

Given the well established connection between chemical reactions and temperature, it’s no surprise brewers want their packaged beer stored in a cool environment for as long as possible, the goal being to prolong shelf-life. Of particular concern is cold-side oxidation, which is known to have an especially detrimental impact on hoppy styles. The fact tasters in this xBmt were able to reliably distinguish a Hazy IPA that was intentionally exposed to oxygen before being stored warm from one that was stored cool suggests temperature plays a role in the rate at which cold-side oxidation occurs.

While we did not send these beers to a lab for analysis, considering both were treated identically with the exception of the variable in focus, it’s probably safe to assume both possessed similar levels of dissolved oxygen, which would mean the perceived differences were most likely a function of storage temperature. Based on my own experiences over the years, I’m certain both of these beers possessed the gross characteristics associated with oxidation, though the one stored warm was noticeably grosser.

I’ve been employing numerous methods to reduce cold-side oxidation for years including pressurized transfers to purged kegs and storing my packaged beer cold, though I’ve often wondered the extent to which each of those processes matters. The results of this xBmt seem to indicate that while temperature may slow the oxidation reaction, it isn’t enough to mitigate the negative impact in a Hazy IPA. While I was bummed to have destroyed 10 gallons/38 liters of an otherwise spectacular beer, I was somewhat consoled by the fact I learned something from it.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

16 thoughts on “exBEERiment | Impact Storage Temperature Has On An Oxygen-Exposed Hazy IPA”

Typo:

> The 13 participants who made

Should be 18.

Cool exbeeriment though!

so, did you dump the beer or drink it?

I dumped it. /cry

So the international oxygen exposure here was only racking to an un-purged keg? Wow.

And, not purging the headspace once the lid was seated.

International Oxygen? Oooh, I see another experiment coming up. Difference using American air vs Mexican air in an Export Stout.

“For the first time since I started brewing Brülosophy xBmts over 3 years ago, I felt guilty serving these to tasters, they were that gross.”

Did the tasters feel that way? It would be interesting on a repeat to verify this. I think there is considerable evidence that a lot of beer drinkers don’t have the same aversion to diacetyl that is drilled into the heads of some brewers, so it would be interesting to capture whether tasters thought both beers were flawed, one was flawed but one was fine, or both were fine.

My club was one of the tasting panels. Both samples were atrociously bad and universally hated. Thanks for doing the lord’s work Cade!

Good to know!

I completely respect the interest in getting the raw numbers out, but sometimes it’s useful to get the subjective judgments out too.

You saying the un-oxidized beer was bad, not your liking? I see they used Sabro hops. I made 3 beers with them and didn’t like any of them. Actually threw out the rest of the pound…

Great content! Truly love what you are doing.

I’m slightly confused here. Do you normally rack to a secondary fermenter that’s sealed, so any leftover yeast can’t go to work and start pushing excess oxygen out an airlock? Or was this to create as much oxygen in the beer as possible?

When/If I secondary, it’s always to a vessel with some method of an airlock.

When you burst carbonate and drop to the lower pressure do you relieve the keg pressure first? I’m concerned about flushing out good aroma?

A few suggestions to significantly improve your hazy NEIPA recipe;

Put a few ounces of hops in a sub 180 degree F whirlpool for 20 minutes instead of adding during the boil.

Up your dry hop to more like an ounce per gallon.

Finally, change the water chemistry to 3 to 1 chloride to sulfate.

And venting a few times after filling the keg will take care of oxygen.

Otherwise, nice experiment

For what you did, you have a theorectical side of it.

There was a Swedish scientist, Svante Arrhenius, that stablished the Arrhenius equation.

– 20 ⁰C as standard temperature

You storage your beer at 20 ⁰C and expires 90 days later.

If you storage at 30 ⁰C, +10 ⁰C, the expire date will reduce to a 1/3 of the standard date, to 30 days.

If you storage at 40 ⁰C it will be 10 days. And so on.

The other hand, if you storage -10 ⁰C, at 10 ⁰C, it will be 3 times longer the standard date, to 270 days. From 3 to 9 months.

If you storage at 0 ⁰C, it will extend to 27 months.

This is a theory and maybe can be different in some beers, maybe don’t. That’s why this exBEEriments are so important !

Cheers

@Valter Pinto, that’s very interesting, thanks!

I’ll have to agree the hopping schedule could be back loaded more for a good Hazy. Also, the grain bill has essentially no adjuncts and uses all malted grains. (though different types) I find I need about 30-35% non-malted adjuncts for proper haze, mouthfeel, and ‘glowing’ color.

I’d be curious to see what the result would be with a closed transfer instead, Are variances in storage temp still perceptible? The Arrhenius equation would suggest so, but maybe equally aged beers are still close together right at first till the warm batch starts dying off.