Author: Cade Jobe

Hops are a major contributor to the overall character of a beer, adding balancing bitterness as well as desirable aroma and flavors, which mainly come from the unique alpha acids and terpenes present in specific varieties. Over the last few years, another component of hops called thiols has received a bit more focus for their ability to impart potent fruity characteristics to beer, particularly as it relates to dry hopping.

The general understanding of thiols is still rapidly growing, but what’s known is that hops contain both free and bound thiols, the former of which have relatively low flavor thresholds while the latter are flavorless until activated by an enzyme that releases the free thiol from its precursor. While it’s believed certain yeast strains and process variables like fermentation temperature play a role in the freeing of bound thiols, there’s some evidence the use of exogenous enzymes added at the time of dry hopping can do the same with little effort.

As a lover of fruity IPA, I’m always open to new ways I can increase hop potency in my beers and was stoked when Federico Tondini from AEB offered to send me some ENDOZYM® Thiol to play with. As a “liquid carbon sulfur lyase” originally designed for use in wine, this product is ostensibly capable of increasing fruity aromatics in beer by favoring the hydrolysis of thiol precursors in hops. After receiving the ENDOZYM® Thiol from Federico, I designed an xBmt to test it out for myself!

| PURPOSE |

To evaluate the differences between an American Pale Ale dosed with ENDOZYM® Thiol at dry hopping and one that was not treated with the enzyme at dry hopping.

| METHODS |

Since Cascade is known to have relatively few free thiols with higher amounts of bound precursors, I designed a simple American Pale Ale recipe hopped mostly with this classic variety for this xBmt.

Baby In A Corner

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 60.6 | 6 SRM | 1.054 | 1.008 | 6.04 % |

| Actuals | 1.054 | 1.008 | 6.04 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta: Pale American Barley Malt | 10 lbs | 81.63 |

| ESB Pale Malt | 2.25 lbs | 18.37 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 28 g | 60 min | Boil | Pellet | 14.2 |

| Cascade | 20 g | 30 min | Boil | Pellet | 5.5 |

| Cascade | 28 g | 5 min | Boil | Pellet | 5.5 |

| Cascade | 28 g | 3 days | Dry Hop | Pellet | 5.5 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Endozyme Thiol | 1 ml | 0 min | Secondary | Other |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 140 | Mg 18 | Na 14 | SO4 183 | Cl 56 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch then set the electric controllers to heat them up.

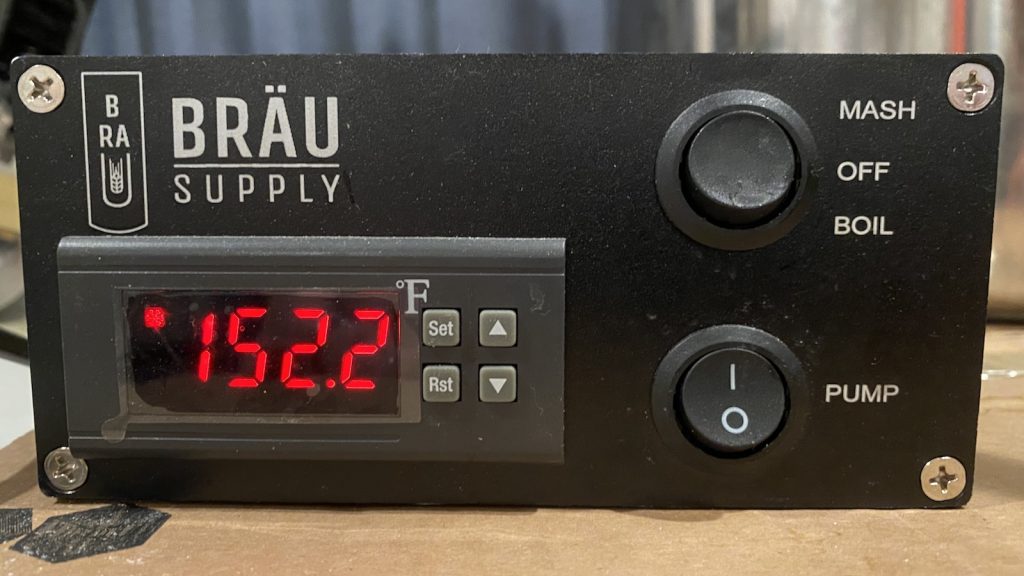

Once the waters were at the proper temperature, I added identical amounts of milled grain to each, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 152°F/67°C.

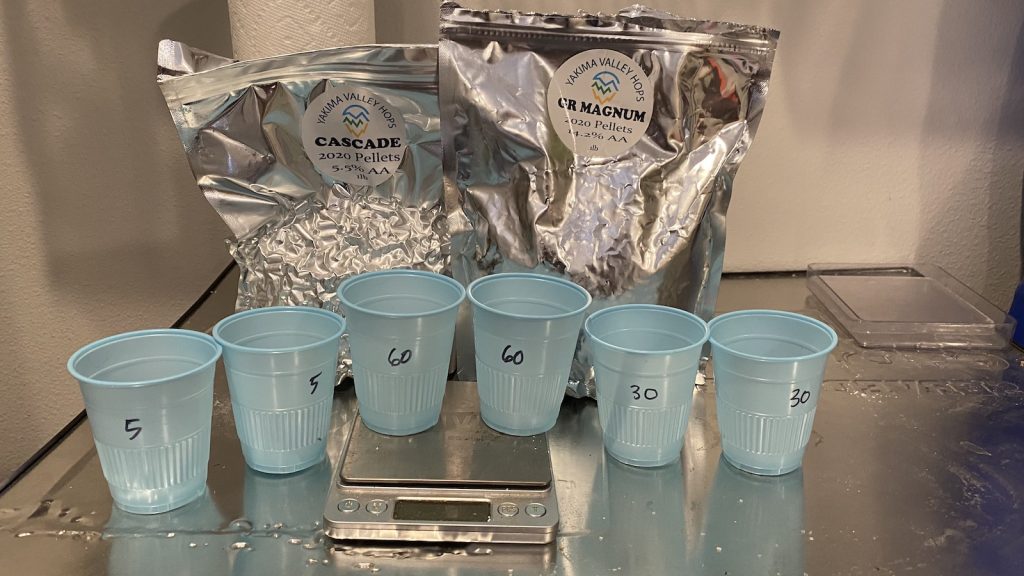

While the mashes were resting, I weighed out the kettle hop additions.

Once the mash rest was complete, I removed the grains then heated each batch to a boil, adding hops at the times stated in the recipe.

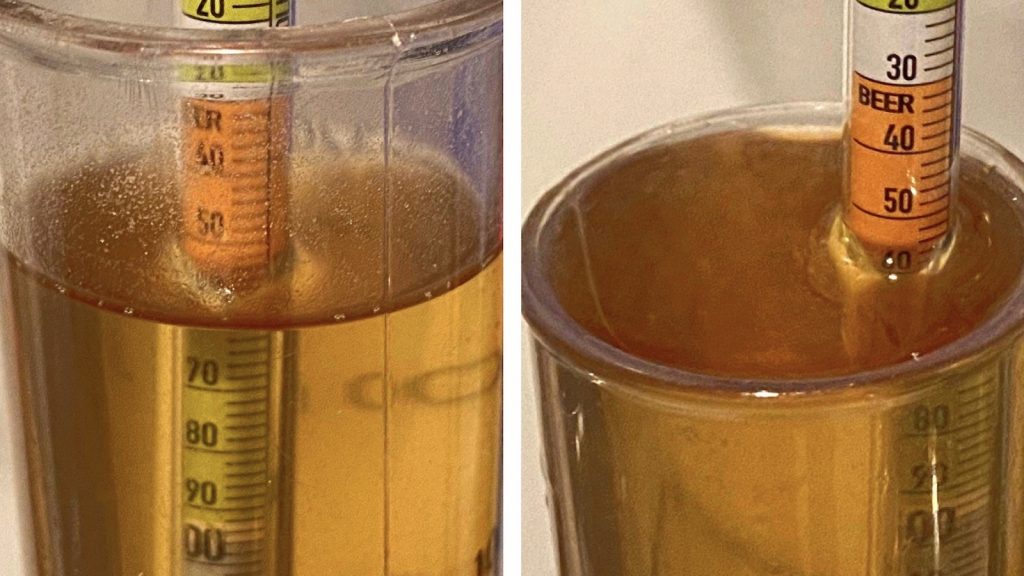

When the boils were complete, I racked identical volumes of wort from each batch to separate Brew Buckets before taking hydrometer measurements showing both were at the same OG.

The worts were left to finish chilling in my chamber for a few hours, and once stabilized at my target fermentation temperature of 66°F/19°C, I pitched a pouch of Imperial Yeast A07 Flagship into each.

After 3 days of fermentation, I added the dry hops to each beer with one receiving 1 mL of ENDOZYM® Thiol.

Hydrometer measurements taken 4 days later showed both beers reached the same FG.

At this point, I pressure transferred the beers to CO2 purged kegs.

The filled kegs were placed on gas in my keezer and allowed to condition for a week before they were ready for evaluation.

| RESULTS |

A total of 16 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dosed with ENDOZYM® Thiol at dry hop and 2 samples of the non-dosed beer in different colored opaque cups then asked to identify the unique sample. While 9 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 did (p=0.26), indicating participants in this xBmt were unable to reliably distinguish an American Pale Ale treated with ENDOZYM® Thiol at dry hop from one that was not treated with the thiol releasing enzyme.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the unique sample just one time, which aligns with my own perception of these beers as being identical in every way, including hop potency.

| DISCUSSION |

As the popularity of IPA continues to grow, so too do efforts by brewers to get the most desirable characteristics out of hops, and recently the focus has been on thiols. Hops contain varying levels of free thiols known to contribute fruity aromatics to beer, though many are bound and require an enzyme to be activated. While such enzymes can be present naturally, based on factors such as yeast strain and certain process variables, exogenous enzyme products such as AEB’s ENDOZYM® Thiol are said to efficiently free bound thiols when added at dry hop such that they increase perceived hop potency. Interestingly, tasters in this xBmt were unable to reliably distinguish an American Pale Ale dosed with ENDOZYM® Thiol at dry hop from one that was not treated with the enzyme.

Cascade hops are known to be higher in bound thiols, which is why they were selected for this xBmt, though it’s possible the lack of a perceptible difference is due to the total dry hop amount. Given the simple grist and use of the popular Chico yeast strain, it seems unlikely either of those would contribute to the freeing of bound thiols, which if that’s the case, suggests the exogenous enzyme did little to increase perceived fruitiness.

Our understanding of hop thiols is incredibly limited at the present time, and these findings certainly haven’t convinced me that they play no role in the way hops get expressed in beer. Similarly, I trust that ENDOZYM® Thiol is capable of doing what AEB says, so long as the conditions are right, and I’m willing to accept that may not have been the case here. I definitely look forward to exploring thiols and the impact of exogenous enzymes in the future!

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “exBEERiment | Impact Adding Thiol Releasing Enzyme At Dry Hop Has On An American Pale Ale”

Hey, Cade, nice experiment here.

Just a question, though. As I read on Endozym Instructions, they recommend using it on the second day of fermentation. Any particular reason you used it after three days? I don’t think there is such big difference, but still.

Thanks.

Hi Luca: I consulted with Dr. Tondini about the best time to add the enzyme, which he suggested would be at dry hop. Since I normally dry hop on day 3, it’s when I added the enzyme. Thanks! Cade

I see. On their website, on the instructions page, they state 2nd day of fermentation cause it needs to still have some sugars left. I guess it’s good info for brewers that dry hop later.

Thanks.

Hi Cade. Did you happen to make note what the SG was at the time of dry hopping?

Very interesting result! Glad you did this experiment!

The result is a little bit weird, in that, if a product is sold as being able to produce frutier beer, and in this case, well, it didn’t.

From your pictures, it appears that the enzyme has been repackaged. Could the enzyme itself have been degraded before use.

In the datasheet from AEB it says “Use promptly after opening”.

Over here (Scandinavia), things may freeze during transport this time of year. Could this be the case for you package as well, and have influenced the enzyme?

How did you decide on dosage?

I supposed it’s possible that the enzyme degraded before use. It was packaged by the supplier, mailed in an insulated ice-packed envelope, and stored in my refrigerator (4C/38F) until use. It was opened and used on the same day, though I would assume there’s not much degradation while it’s stored at refrigeration temperatures. It’s possible though.

Thanks for the detailed reply, Cade!

Given the care taken, I’d say it’s very unlikely that degradation of enzymes played a significant role 🙂

I am very curious about how dosage is determined, though. Maybe a topic for a podcast? 🙂

Very interesting xBmt! A question though: from my understanding, most bound thiol precursors in hops (and malts) are conjugated to the cysteine residue of glutathione, which most enzymes produced by yeast are not able to work on. Instead, the glutathione must be broken down so that the cysteine residues are free, which then enables the enzymes to work on it. Do you know if this is true for the Endozym as well, or should it work on any thiol regardless of conjugation? If not, maybe mash hopping and doing a protein rest might release the precursors better and hopefully give a more distinct difference?

All the best!

That’s an interesting point. Here’s the information from the technical datasheet: “Endozym Thiol is a liquid pectolitic enzymatic preparation with specific secondary activities, facilitating the hydrolysis of grape thiol aromatic precursors, such as 4MMP (4-mercapto-4-methylpentan-2one), A3MH (3-mercaptohexil-acetate), 3MH (3-mercaptohexan-1-ol), 4MMPOH (4-mercapto-4 methylpentan1ol), 3MMB (3-mercapto-3-methylbutan-1-ol).

These aromatic precursors are important components of aromatic and semi-aromatic varietals, however, these thiols come anchored to a Cysteine group, which makes them non-volatile. During alcoholic fermentation, these aromatic compounds are separated through the action of exogenous enzymes and enzymes produced by the yeast. Endozym Thiol is a liquid carbon sulfur lyase that favors the hydrolysis of these aromatic thiols precursors and enhances their expression in the wine.”

I was one of the tasters and one of only four in our group that got it right. This one was really hard to detect – my first whiff of the enzyme sample seemed to have a more potent dry hop aroma. I also *thought* it had a more intense dry hop flavor. After that first whiff and taste though, my ability to tell them apart waned. Ultimately I went with my initial gut reaction and ended up successfully choosing the odd beer out.

To me, these results suggest that most tasters won’t be able to pick the enzyme beer out of a lineup. Not to say that it didn’t serve its intended purpose; rather, that the impact is very delicate and our human ability to isolate it is difficult and possibly fleeting as you become desensitized to it over a tasting session.

Would the youth of the beer affect this experiment? 11 days seems like a very short time to evaluate nuances between beers. I am not a beer maker so I genuinely don’t know.

I was struck by the small size of the dose. From what *very* little I know about organic chem, I recall that enzymes are not consumed, so theoretically 1 ml could work an entire 5 gallon batch. But the mechanics of beer are different than wine. The enzyme can freely disseminate and circulate through a wine fermentation at a micro concentration, but it may not have reached much of the hop biomass or the compounds leached into the wort during dry hopping.

Any plans to perform a similar exbeeriment with a CRISPR modified yeast like Omega Cosmic Punch Ale?

Nice experiment design Cade. I think if this ever were to work, this recipe would give the best chance of success.

It would also be great to do a similar test of standalone enzymes for biotransformation of non-aromatic glycosides into aromatic terpenes, like Lallemand Aromazyme. I like the idea of getting part of the the London ale III effect with any type of yeast.