Author: Andy Carter

Sulfites are chemical compounds containing a sulfite ion that are widely used as a preservative in the food and beverage industry. While most commonly used in wine as a means of inhibiting unwanted microbial activity, there’s been increased interest in the positive impact sulfites can have on beer, particularly as it relates to reducing the risk of cold-side oxidation.

When using sulfites for the purpose of prolonging beer freshness, all a brewer has to do is, at packaging, dose the beer with one of two similar salts—sodium metabisulfite (SMB) or potassium metabisulfite (PMB), also known as Campden tablets. While both are equally effective microbe inhibitors and antioxidants, some opt for one over the other due to the belief the cation can have a perceptible impact, namely that the sodium from SMB will contribute undesirable characteristics.

I’ve had success avoiding cold-side oxidation in my beers using non-chemical methods, so my use of sulfites has largely been to stabilize wine, mead, and cider, though I certainly see the utility of using them in beer. Curious of the claims regarding a flavor impact caused by the different types of sulfite, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between a German Helles Exportbier dosed with either sodium metabisulfite or potassium metabisulfite at packaging.

| METHODS |

I went with a simple German Helles Exportbier recipe for this xBmt in hopes any impact of the variable would be easily noticed.

Cationatonic

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 30.8 | 3.7 SRM | 1.055 | 1.008 | 6.17 % |

| Actuals | 1.055 | 1.008 | 6.17 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsen MD | 5.5 lbs | 48.89 |

| Pilsner | 5.5 lbs | 48.89 |

| Biscuit | 4 oz | 2.22 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Centennial | 23 g | 60 min | Boil | Pellet | 10 |

| Tettnang | 28 g | 15 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 58 | Mg 5 | Na 0 | SO4 102 | Cl 42 |

Download

| Download this recipe's BeerXML file |

I made a single large starter with 2 pouches of Imperial Yeast L17 Harvest a day prior to brewing.

I started my brew day by adding identical volumes of RO water to separate BrewZilla units then setting the controller to heat it up.

After adding the same amount of minerals to each kettle, I milled the grains into separate buckets.

Once the water for each batch was adequately heated, I incorporated the grains then checked to make sure both were at the same 150°F/66°C mash temperature before preparing the kettle hop additions.

Once each 60 minute mash was complete, I sparged to collect the same pre-boil volume then boiled the worts for 60 minutes before running them through a plate chiller.

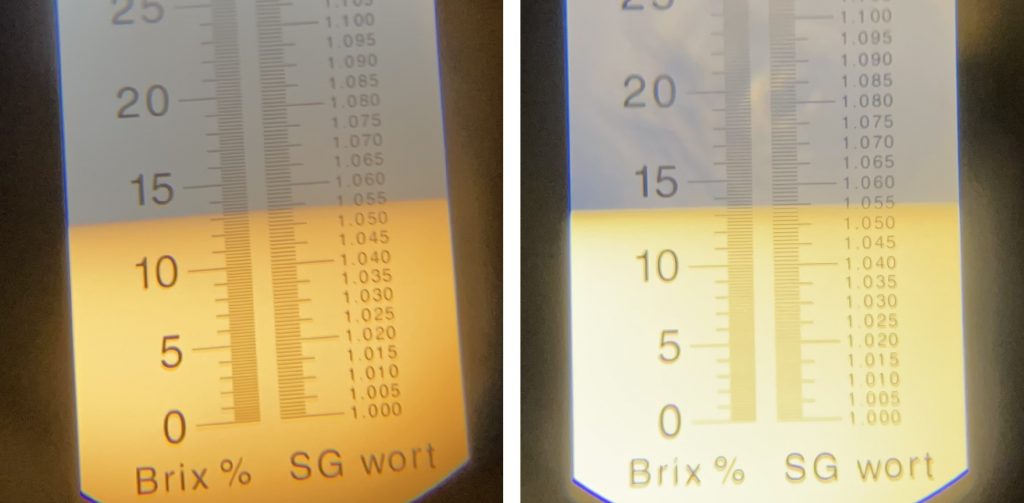

Refractometer readings showed both worts achieved the same target OG

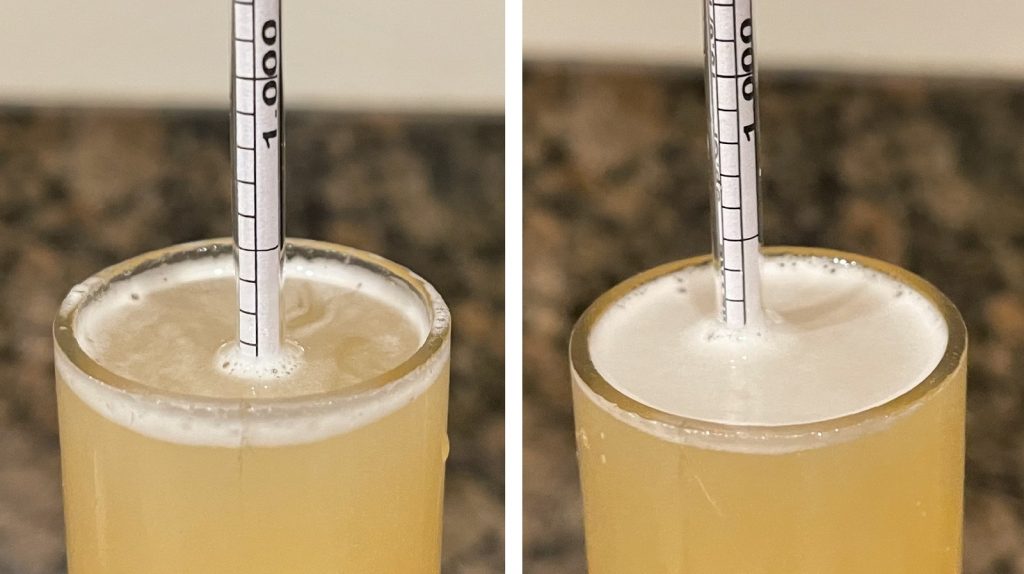

The filled fermenters were placed in my chamber and left to finish chilling to my desired fermentation temperature of 50°F/10°C for a few hours before I evenly split the yeast starter between them. After a week, I raised the temperature in the chamber to 55°F/13°C and let it sit for an additional 2 weeks before taking hydrometer measurements showing the beers reached the same FG.

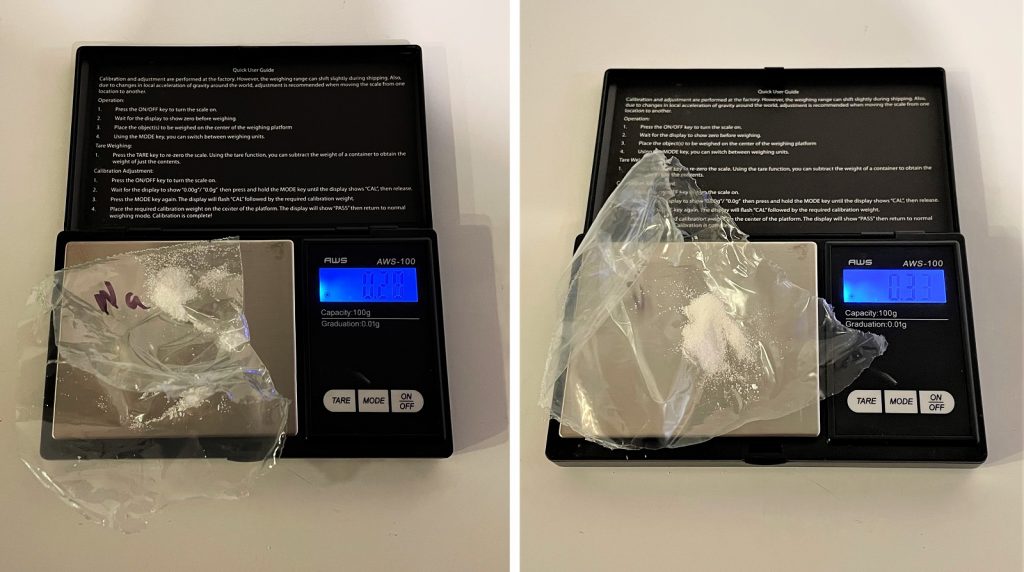

At this point, I prepared for packaging by first using CO2 to purge 2 kegs then measuring out the amounts of SMB and PMB it would take to achieve 10 ppm sulfite in both beers; given the molar concentration of active sulfite in each salt, this required 0.28 grams of SMB and 0.33 grams of PMB.

The beers were then pressure-transferred to CO2 purged kegs.

The filled kegs were placed in my keezer and left on gas for 3 weeks before they were ready to serve to participants.

| RESULTS |

Data for this xBmt was collected at the annual VIBEtoberfest event put on by the Ventura Independent Beer Enthusiasts (VIBE) homebrew club.

A total of 23 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dosed with SMB at packaging and 2 samples of the beer dosed with PMB at packaging in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 6 did (p=0.83), indicating participants in this xBmt were unable to reliably distinguish a German Helles Exportbier dosed with sodium metabisulfite at packaging from one dosed with potassium metabisulfite at packaging.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly chose the odd-beer-out just once, and even that was a complete guess. These beers were perceptibly identical to me, no differences in aroma, flavor, mouthfeel, or appearance. I really enjoyed this beer, which had a firm bitterness that led to a pleasant interplay between the crackery malt and floral hop flavor.

| DISCUSSION |

While presently uncommon, dosing beer with sulfites at packaging has been shown to reduce the myriad negative effects of cold-side oxygen exposure, thus prolonging the life of beer. Sodium metabisulfite (SMB) and potassium metabisulfite (PMB) are two commonly available salts, both equally effective at impeding microbial activity and reducing oxidation, though some believe the different cations influence beer character. That fact tasters in this xBmt were unable to reliably distinguish a German Helles Exportbier dosed with SMB at packaging from one dosed with PMB to the same sulfite level indicates any impact was minimal enough as to be imperceptible.

The most plausible explanation for these results would seem to be that the total cation amount remaining in the beer following the redox reaction is simply too little to have an impact on the various characteristics of beer. While higher dosage rates would likely lead to a more noticeable difference, the amount of SMB or PMB required to achieve the intended goal is remarkably small, less than 0.5 gram/0.02 oz, leaving little to be concerned about.

Prior to this xBmt, I tended to keep PMB on-hand for use in wine and cider, my choice being one of convenience—SMB was a bit more difficult to find. The results of this xBmt confirmed my suspicion that the cation likely doesn’t matter, so I’ll continue picking up whatever is available. Given the results of prior xBmts showing sulfites do reduce the risk of cold-side oxidation, I view it as an incredibly cheap way to reduce the risk of cold-side oxidation, and all it requires is an inexpensive scale.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

12 thoughts on “exBEERiment | Sodium Metabisulfite vs. Potassium Metabifulfite When Used At Packaging In A German Helles Exportbier”

Interesting experiment. Just wondering how you introduced the SMB and PMB into the beers?

Thanks Cade. A quick question about your dosing technique: your write-up doesn’t specify *how* you get the SMB/PMB into the keg? With a closed system where I’m trying to avoid opening either the purged keg or the FV, I’m still not sure how to get such a fidly amount of fine powder into the packaged beer without letting O2 in at the same time. Cheers!

For each keg, I opened the lid, put the salt in, closed the lid, and re-purged the keg. Not optimal, but the way I could be consistent. I am looking into adding the salt to a liquid and pushing it down the dip tube; that works for Biofine Clear, but I do not know if the PMB/SMB will react too quickly after being liquified.

Thanks Andy (not Cade!), that’s helpful. I’ve tended to throw it into the FV just before packaging, at the point where I switch the tri clamp fitting from my blow-off attachment to my gas line attachment. It’s the only point where the system is exposed to air (if only for a few seconds), but it’s fidly to do quickly.

I’d love to see a how-to on how you do the biofine.

I’ve read that ascorbic acid (vitamin C) can also be used to prevent oxidation without having the issue with people sensitive to sulfates. Any chance of an exbeeriment with that?

I’m also very eager to read such a followup experiment.

While I am not picking up any PMB flavour in my beer when i use it, I consistenly get morning-after headaches after consuming just one 500ml bottle 🙁

I use SMB all the time, works for me! I like to mix it in with the gelatin and pour into each keg at packaging. On another note, may I suggest you remove the tabs on the outside of the grain hopper and install them INSIDE the hopper. They are designed to help grain feed into the middle of the rollers.

Being someone with a sensitivity to sulfites, it sucks to see someone promoting the use of these poisons in beer.

Looks like somebody needs to man up to sulphites.

Bottles of wine need to warn that they contain sulfites; in the UK at least. Does this apply to beer with sulfites too?

I just listened to the podcast episode featuring this experiment. At the beginning you mention that sulfur dioxide (SO2) smells of rotten eggs. It actually smells more like burnt matches and it’s quite irritating in the nose and can trigger allergic reactions.

Rotten eggs is the smell usually associated with hydrogen sulfide (H2S), which can be produced during fermentation by some lager strains. It’s also toxic and can kill.