Author: Mike Neville

The cold crashing method involves reducing the temperature of beer that’s done fermenting, which encourages the rapid precipitation of suspended particulates, thus leading to improved clarity. Due to thermal contraction, as the beer chills, its volume is slightly reduced, creating a vacuum in the fermenter. As many brewers have undoubtedly experienced, when using a blow-off tube, this vacuum can suck a decent amount of liquid up the tube and ultimately into the beer.

A very common liquid used in a blow-off vessel is sanitizer solution, and one of the more popular sanitizers is Iodohor, an iodine based disinfectant that includes a surfactant. Even when blended with water at the recommended rate, an Iodophor solution is quite odorous, hence some opt to rinse it off their gear before use. In addition to potentially affecting beer flavor, sanitize suck-back caused by cold crashing will dilute the beer, and should the blow-off vessel be emptied, the beer could be exposed to oxygen and microbial contaminants.

Before I was able to pressurize my fermentation vessels, I would simply place them in the refrigerator with a blow-off tube submerged in a little bit of sanitizer to cold crash. There were certainly times I’d check on my chilling beer to discover less sanitizer solution in the blow-off vessel than before, though I never noticed any adverse effects from this. While I rely on external CO2 when cold crashing these days, I recently began to wonder if the suck-back of Iodophor solution has a perceptible impact on beer and put it to the test.

| PURPOSE |

To evaluate the differences between an American Pale Ale cold crashed under pressure and one cold crashed with blow-off tube that results in sanitizer being sucked into the fermentation vessel.

| METHODS |

Given how sensitive hoppier styles can be to oxygen, I went with an American Pale Ale recipe for this xBmt.

It Certainly Does Suck!

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 44.2 | 7.5 SRM | 1.056 | 1.007 | 6.43 % |

| Actuals | 1.056 | 1.007 | 6.43 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Ale Malt 2-Row | 10 lbs | 83.33 |

| Munich I | 1 lbs | 8.33 |

| Vienna Malt | 12 oz | 6.25 |

| Special Roast | 4 oz | 2.08 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Columbus/Tomahawk/Zeus (CTZ) | 7 g | 60 min | Boil | Pellet | 15.5 |

| Caliente | 27 g | 5 min | Boil | Pellet | 17.7 |

| Columbus/Tomahawk/Zeus (CTZ) | 20 g | 5 min | Boil | Pellet | 15.5 |

| Galaxy | 20 g | 5 min | Boil | Pellet | 13.6 |

| Galaxy | 27 g | 4 days | Dry Hop | Pellet | 13.6 |

| Caliente | 20 g | 4 days | Dry Hop | Pellet | 17.7 |

| Columbus/Tomahawk/Zeus (CTZ) | 20 g | 4 days | Dry Hop | Pellet | 15.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| House (A01) | Imperial Yeast | 75% | 32°F - 32°F |

Notes

| Water Profile: Ca 70 | Mg 8 | Na 8 | SO4 147 | Cl 43 |

Download

| Download this recipe's BeerXML file |

After collecting the water for a single 10 gallon batch, I weighed out and milled the grain.

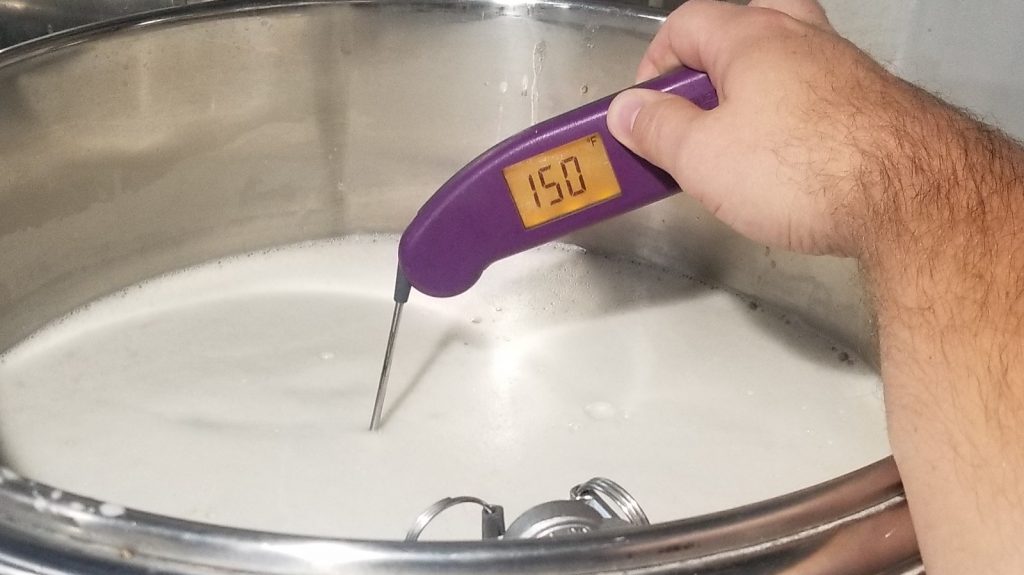

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

The mash was left alone for 60 minutes.

During the mash rest, I prepared the kettle hop additions.

Once the mash was finished, I batch sparged to collect my target pre-boil volume then proceeded to boil the wort 60 minutes, adding hops at the times listed in the recipe.

When the boil was complete, I quickly chilled the wort.

Next, I transferred identical volumes of wort to separate fermenters.

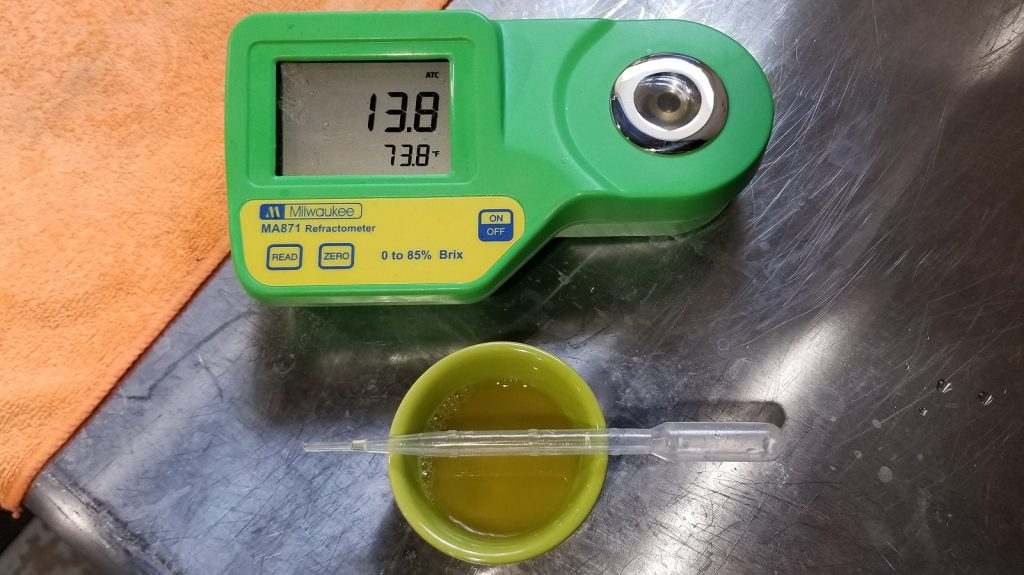

Refractometer readings showed both beers achieved the same FG.

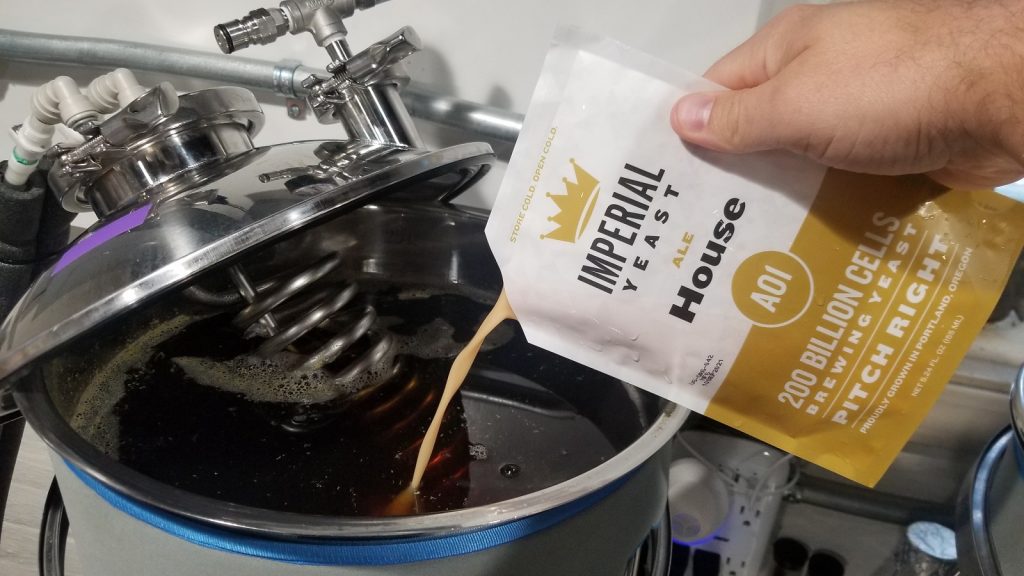

The fermenters were connected to my glycol unit and allowed to finish chilling to my desired fermentation temperature of 68°F/20°C, at which point I pitched a single pouch of Imperial Yeast A01 House into each batch.

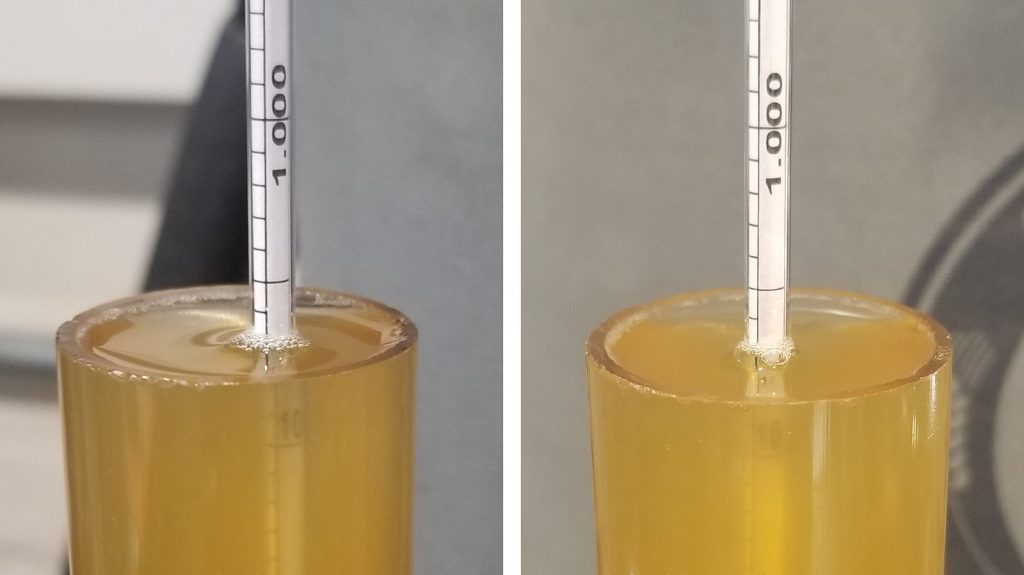

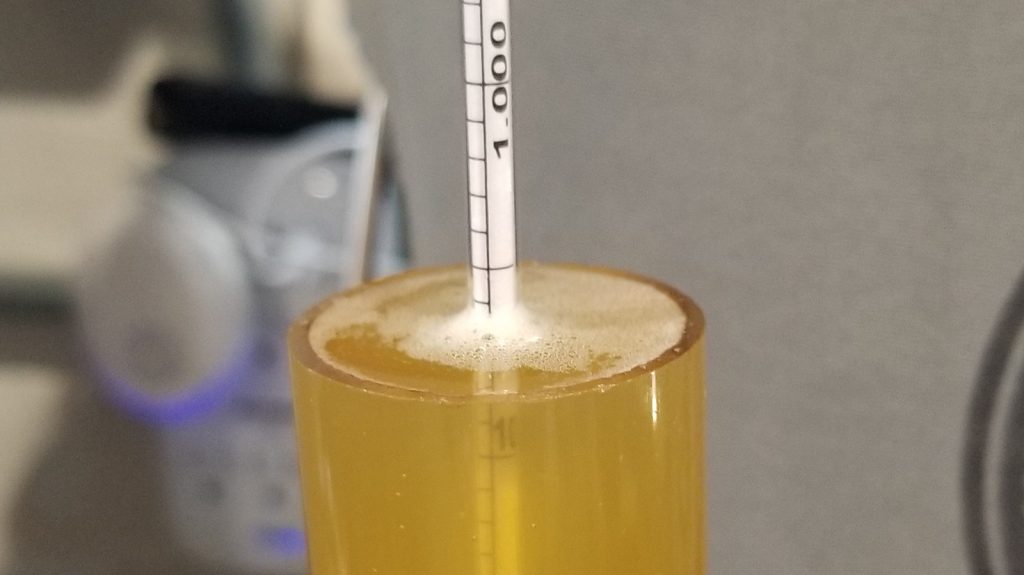

The beers were left to ferment for 10 days before I took hydrometer measurements showing both had reached the same FG.

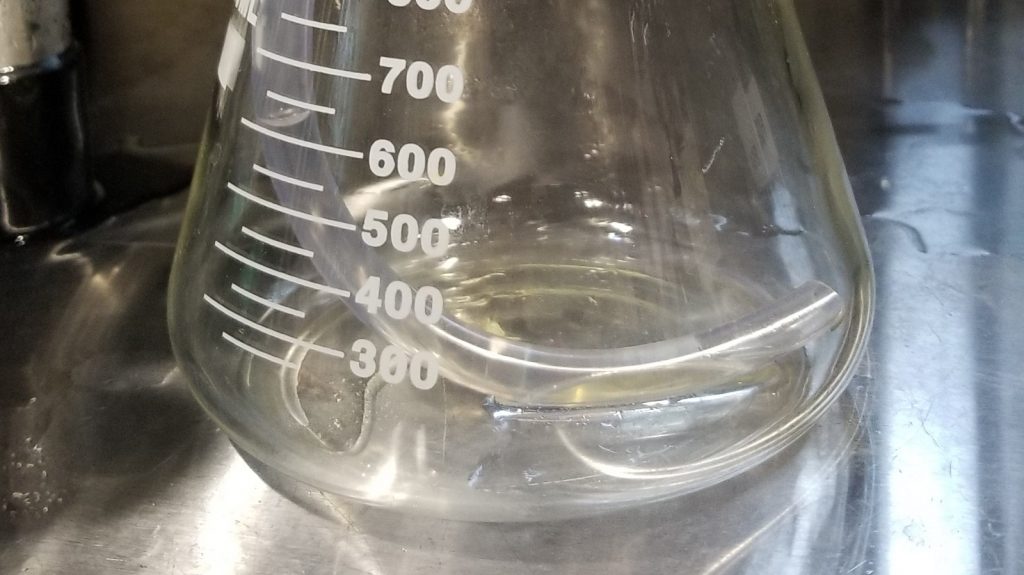

In preparation for cold crashing, I detached the blow-off tube on one batch and pressurized the fermenter with a small amount of CO2 to maintain positive pressure. For the other batch, I placed the end of the blow-off tube in a flask that contained 1 liter of Iodaphor sanitizer solution (12.5 ppm concentration). At this point, I set my glycol controllers to 38°F/3°C for cold crashing. After just 6 hours, I noticed nearly all of the sanitizer solution had already been sucked out of the flask.

By the following morning, the flask was completely empty, meaning the beer not only possessed an entire liter of sanitizer solution, but however much oxygen happened to enter the fermenter as well.

Out of curiosity, I took a hydrometer measurement of the beer containing the sanitizer solution and found it was approximately 0.0005 SG points lower.

After a full 24 hours of cold crashing, I proceeded to pressure transfer the beers to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a week of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Big thanks to the guys at Cadillac Straits Brewing Company in Madison Heights, MI, for letting me collect data at their monthly Homebrew Meetup. A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer cold crashed under positive CO2 pressure and 2 samples of the beer where 1 liter of Iodophor sanitizer solution was sucked into it during the cold crash. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 did (p=0.40), indicating participants in this xBmt were unable to reliably distinguish an American Pale Ale cold crashed under pressure from one that was cold crashed with a blow-off tube in Iodophor sanitizer solution, 1 liter of which was sucked into the beer.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice. Despite my bias from having brewed these beers, I perceived them as being characteristically identical. Both had a subtle malt backbone that supported the pungent grapefruit, pine, and peach hop characteristics.

| DISCUSSION |

Brewers employ the cold crashing method as a way to accelerate the precipitation of suspended particulates in beer, which not only expedites the clarification process, but makes transferring from fermenter to package easier. For those who don’t have a means of pressurizing their fermenter during this process, the contraction of beer as it chills can lead to sanitizer solution, oxygen, and microbial contaminants being sucked into the fermenter. The fact tasters in this xBmt were unable to reliably distinguish an American Pale Ale cold crashed under pressure from one that was cold crashed with a blow-off tube in Iodophor sanitizer solution, all of which was sucked into the beer, suggests any impact was minimal enough to be imperceptible.

One possible explanation for these results is that the volume of sanitizer solution sucked into the fermenter during cold crash wasn’t enough to noticeably change the beer’s character. However, the beer also showed no signs of oxidation or contamination, indicating whatever else was sucked in had minimal, if any, impact as well.

I employ various tactics to ensure my beer has minimal contact with oxygen, which include cold crashing under CO2 pressure. However, in my earlier days, I wasn’t so careful and often found air locks and blow-off vessels empty of their sanitizer hours after reducing the temperature of my beer. Anxious as this would make me, it never seemed to ruin a batch, and the results of this xBmt confirm it may not have had much of a perceptible impact. I’ve no plans to stop cold crashing under pressure, but for those who may not have such means, perhaps the worry is just a bit misplaced.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

18 thoughts on “exBEERiment | Impact Sanitizer Suck-Back During Cold Crash Has On American Pale Ale”

I’ve also found that the 1 or 2 ozs of star san sucked back from an airlock did not negatively influence any brew it happened to, although I didn’t have a another to compare it to. What was more concerning was the exposure to air for that time. I know there’s some multi-jar gadget you can buy or make that prevents that. These days I ferment in corny kegs which solves that problem anyway.

Great Experiment. I recently started a closed transfer method. I ferment in 7 Gallon Fermonsters and the Anvil Brew Bucket, so I can use only one or two psi. My kegs are all torpedo kegs, and can retain up to 4 or 5 ounces of StarSan after purging with CO2. I had been wondering if that could affect my 5 gallon batch. Thanks!

Mike – am assuming use of corny kegs for fermentation reduces your total volume of beer from 5 gallons (using a fermenter) to approximately 4 gallons (which accounts for some head space along with the needed grub space in the keg). So you lose a gallon in the beer using this process. Correct ?

I had iodophor solution suck back a couple of times and was more scared about the potential health impact of ingesting iodine than what could happen to the beer.

I was even afraid of sharing those beers with (good) friends and family. Was this a concern for you guys (the potential health damage)?

One thing that made me less concerning was the fact that the iodophor solution I poured in the blow off flask becomes almost as clear as water by the end of fermentation, so there’s probably some reactions that take place and probably make the iodine become something lesse dangerous for the living organisms (I guess).

Iodine is a necessary trace nutrient, with a recommended daily allowance (RDA) of 150 micrograms for most adults (higher for women who are pregnant or lactating). Upper limit on consumption is unclear, but checking multiple sources it appears to routinely be above 1 mg/day.

The 5 gallon batch of beer sucked back 1 L of the iodophor solution at 12.5 ppm (side note, that appears to be half the recommended concentration according Five Star?). If I’m doing my math right and there’s been no biological or chemical processes to decrease the iodine content, that works out to roughly 300 micrograms per pint. That is 1) above the RDA, even for lactating women, and 2) well below even the conservative estimate for hazardous daily intake. Conclusion: beer with iodophor suckback is health food!

I feel better now. Thanks for doing the math!

There are so many ways to prevent idophor solution suck back; Use star san solution, use a co2 balloon, use a basic air lock that allows air in but no suck back, put under co2 pressure, etc., etc. fascinating that people couldn’t detect a ~5% idophor solution in the beer. well done on the experiment.

I’ve heard about grandparents using balloons as improvised airlocks for home brewing wine decades ago, so it certainly has a long lineage.

“the beer also showed no signs of oxidation”

After one week of conditioning? Of course not.

I bet the result would be different after 4-8 weeks. I had several beers ruined by oxidation and I blame it on oxidation due to air sucked in during cold crash.

Agreed. The focus of this article was the impact the sanitizer suck-back had on a finished beer after a week or so. Results could have very well been different after 4-8 weeks and would make for another good xBmt.

Giving people Iodaphor mixed with beer seems like a very strange experiment. You should avoid Iodaphor being sucked back into the fermenter, so testing whether the effect is noticeable it’s pointless, as it should always be avoided (just replace the blow off with a bung in the worst case).

If it happens, and you think the beer is fine to drink, that’s OK, but I wouldn’t let Iodaphor being mixed with beer just because I can’t tell the a difference in flavour, which seems to be what the

experiment encourages people to do.

The intent of the article is not to encourage people to mix Iodaphor sanitizer with their beer. The idea is all brewers experience the vacuum created by cold crashing and if the fermenter is left as is with a blow off or airlock, for whatever reason, you’ll experience this suck-back. I agree the suck-back should be avoided but this may not always be possible or what actually happens.

In the future – when someone asks you why you are cold crashing under pressure – what will you tell them?

To prevent the suck back that’s created by the vacuum.

Irrelevant to your exbeeriment but I have 2 questions. When did CSB restart their homebrewers meet ups and wanna be friends in real life? I live over in Ferndale…

Believe they started back up over the summer. I don’t make all the homebrew meetups but if you want to come out to a Motor City Masher meeting I’ll be there, just look us up.

What is the cause of the vacum effect? Is it the contraction of airspace/Co2 in the fermenter? Or is it the contraction of liquid in the fermenter? If it is the liquid, is it the same amount as it is with water? If it is, I’m going to do some testing of the suckback volumes.

It’s the contraction of the liquid in the fermenter. I guess I don’t know for sure if it’s the same volume it’d be with water, but I can’t imagine there’d be much difference