Author: Mike Neville

Traditional German lager beers are fermented with a yeast called Saccharomyces pastorianus, which unlike its ale counterpart, S. cerevisiae, performs well at temperatures as low as 48°F/9°C. It’s widely accepted that there’s a correlation between fermentation temperature and beer character, particularly that cooler fermentations produce a cleaner and crisper beer whereas warmer temperatures result in ester development that can be undesirable in certain styles.

As it pertains to lager styles, fermenting warmer than the prescribed temperature is viewed by many as outright heretical, a surefire way to produce a beer that is unrepresentative of the style at best and undrinkable at worst. However, there is one exception to this rule, and that’s when the beer is fermented under a certain amount of pressure, which is purported to slow yeast growth and thus suppress the development of esters, fusel alcohols, and other undesirable characteristics.

Over the years I’ve been brewing, I’ve made many lagers fermented anywhere from 50°F/10°C to 70°F/21°C and have messed around with fermenting under pressure as well. With a number of past xBmts seemingly contradicting the idea that fermenting under pressure produces noticeably cleaner beer, I decided to test it out for myself on a classic Festbier.

| PURPOSE |

To evaluate the differences between Festbiers fermented at 68°F/20°C under either 12 psi of pressure or no pressure.

| METHODS |

In hopes of emphasizing any differences caused by the variable, and because of the season, I designed a straightforward Festbier recipe for this xBmt.

The Greatest Beer In All Ze Vuld

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 19.9 | 4.9 SRM | 1.059 | 1.004 | 7.22 % |

| Actuals | 1.059 | 1.004 | 7.22 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner | 10 lbs | 80 |

| Munich Malt | 1.25 lbs | 10 |

| Vienna Malt | 1.25 lbs | 10 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Triumph | 14 g | 60 min | Boil | Pellet | 11.2 |

| Triumph | 14 g | 5 min | Boil | Pellet | 11.2 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | Fermentis | 83% | 32°F - 32°F |

Notes

| Water Profile: Ca 74 | Mg 7 | Na 5 | SO4 55 | Cl 71 |

Download

| Download this recipe's BeerXML file |

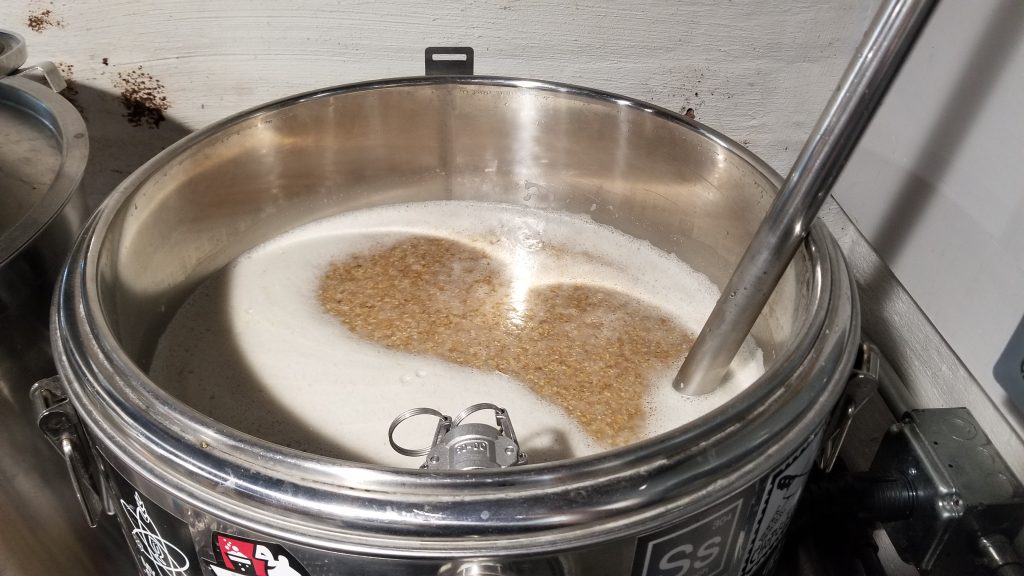

After collecting the water for a single 10 gallon batch, I weighed out and milled the grain.

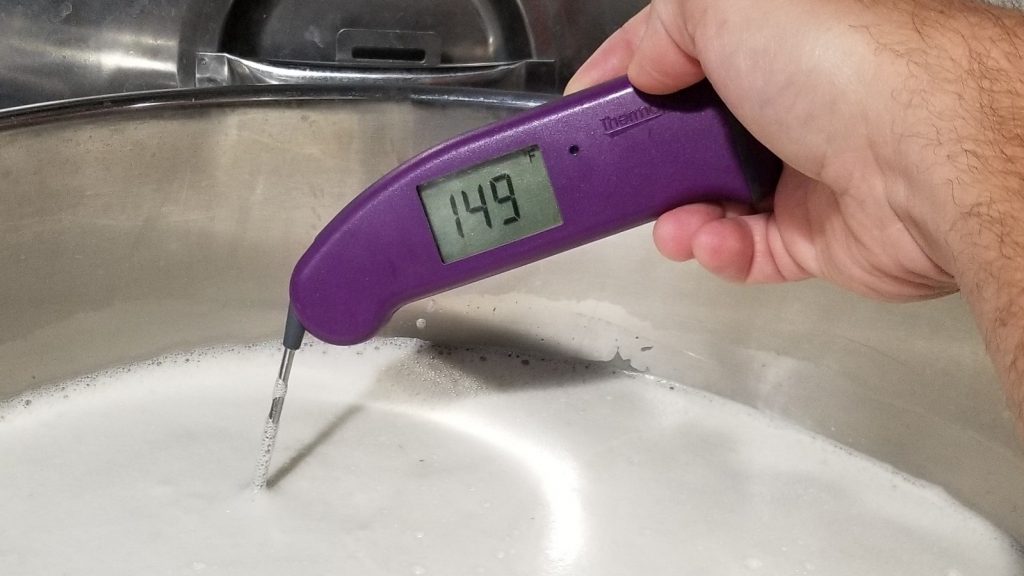

With the water properly heated, I incorporated the grains then checked to make sure the mash was at my target temperature.

The mash was left alone for 60 minutes.

When the mash rest was complete, I collected the wort in my kettle and set the controller to heat it up, at which point I prepared the kettle hop additions.

The wort was boiled for 60 minutes with hops added at the times listed in the recipe.

When the boil was finished, I quickly chilled the wort.

Next, I transferred identical amounts of wort to separate fermenters.

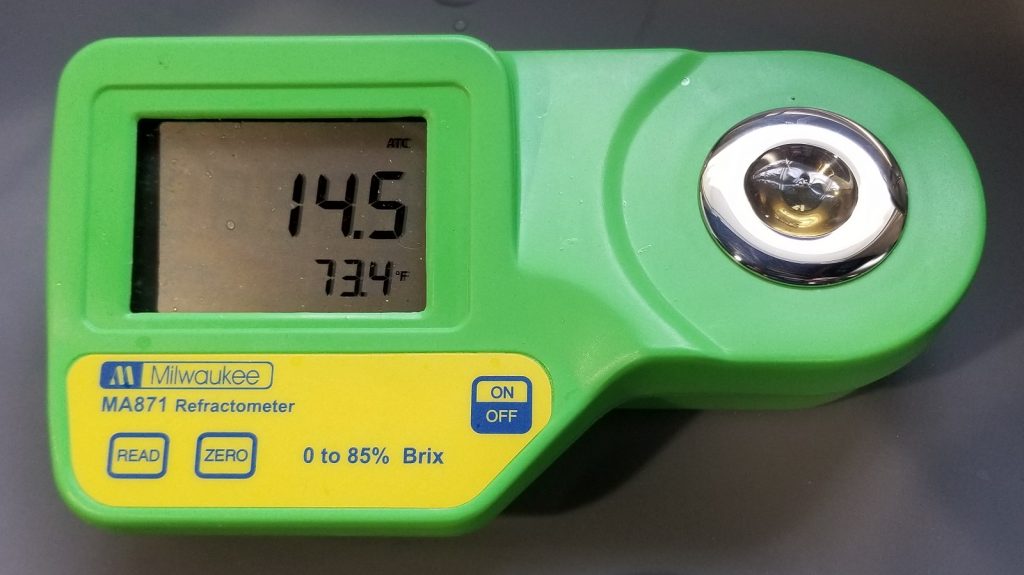

A refractometer reading showed the wort was right at my intended OG.

I attached the filled fermenters to my glycol system and let the worts finish chilling to my desired fermentation temperature of 68°F/20°C before pitching equal amounts of rehydrated Saflager W-34/70 into each batch.

Next, I attached a blowoff tube to one fermenter and placed a spunding valve set to 12 psi on the other fermenter.

After 10 days of fermentation, I raised the temperature of each beer to 70°F/21°C for a 2 day diacetyl rest before taking hydrometer measurements that indicated both beers had reached the same FG.

At this point, I detached the blowoff tube from the no-pressure batch and attached a spunding valve so pressure could be kept on both beers while cold crashing. After spending the night at 38°F/3°C, I pressure transferred both beers to CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After 3 weeks of conditioning, they were carbonated and ready for evaluation.

| RESULTS |

Thanks to the Kuhnhenn Guild of Brewers (KGB) out of Warren, MI for letting me crash their meeting to take part in this xBmt. A total of 20 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer fermented under no pressure and 1 sample of the beer fermented under 12 psi in different colored opaque cups then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 8 did (p=0.34), indicating participants in this xBmt were unable to reliably distinguish a Festbier fermented at 68°F/20°C under no pressure from one fermented at the same temperature under 12 psi of pressure.

My Impressions: Out of the 5 semi-blind triangle tests I attempted, I correctly identified the odd-beer-out just twice. Despite my bias from having brewed these beers, I perceived them as being characteristically identical. Both had a pleasant bready malt note with minimal hops and surprisingly clean fermentation character.

| DISCUSSION |

Many brewers avoid making lagers because of the extra effort and time it takes to ferment them cool, so any technique that promises to expedite the process while having minimal qualitative impact is sure to be viewed positively. Fermenting under pressure is one such method, as it’s said to suppress the development of stylistically inappropriate ester and fusel alcohols that many claim are produced by warmer fermentation temperatures. The fact tasters in this xBmt were unable to reliably distinguish a Festbier fermented at 68°F/20°C under no pressure from one fermented at the same temperature under 12 psi of pressure indicates any differences were small enough as to be imperceptible.

There’s nothing new about fermenting beer under pressure, though the idea of doing so as a means to produce lager faster by being able to ferment them warm seems to be getting more attention lately. There are a number of potential explanations for these findings, for example, it could be that another yeast strain might react differently, or perhaps a higher amount of pressure would produce different results. Given the number of past xBmts where tasters couldn’t tell apart lagers fermented at disparate temperatures, it’s also possible these yeasts are more robust than than people believe, or that the negative characteristics associated with fermenting warm are a function of batch size.

My setup makes fermenting under pressure just as easy as not, so I’ll likely continue doing it for some of my beers, though my primary motivation is to mitigate cold-side oxidation. I remain interested in the impact pressurized fermentation has on warm fermented lagers and look forward to exploring both higher pressures as well as higher temperatures in the future.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

17 thoughts on “exBEERiment | Impact Of Pressurized Warm Fermentation On A Festbier”

This is interesting. I haven’t been brewing for too long (under a year, about 6 brews) but the only time I produced fusely/estery results was when I brewed a kolsch and pitched at 82F. I wonder how far above 68F you would’ve had to go to see if pressure fermentation made a noticeable impact, if any.

Sounds like a good xBmt!

Seems like 68°F is still in the cool range since lager strains typically ferment at 60°-75°F. A higher temp, at say 80°F, will more likely produce the unwanted esters and make more of a difference in the unpressurized batch.

We’ve done an xBmt on that: https://brulosophy.com/2016/06/13/under-pressure-pt-3-the-impact-of-pressurized-fermentation-on-lager-exbeeriment-results/

Curious, how many packets of yeast did you use in total for both batches?

Each batch got 20g of yeast

Mike, your transfer of cooled wort to the ferm chambers with a pump seems like there would be little agitation and oxygenation before pitching. I use a ‘splash’ technique to get some O2 into the wort in the transfer from boil kettle to carboy, and then usually use an airstone for 15 minutes. I see no mention of oxygenation in your writeup. Do you skip it?

I also use the ‘splash’ method. I open the pump to full blast and fill from the top of the fermenter to get the most splash possible. The result is very foamy wort. I no longer use pure O2 or an oxygen stone

I like that hose barb tee setup to fill the two flex fermenters. Does it work as well as I imagine and evenly split the batch, or are there any downsides?

It works well as long as the two pieces of tubing that split off the tee are equal length. You do have to keep an eye on it to make sure one isn’t filling faster than the other. When that’s happened in the past, I just pinch the tube that’s filling faster so the other can catch up

Process question: “Next, I attached a blowoff tube to one fermenter and placed a spunding valve set to 12 psi on the other fermenter.” Just to be clear, did the pressure batch get 12psi immediately or was the spunding valve set and pressure was allowed to build to 12psi?

The spunding valve was set and allowed to build to 12psi

34/70 is pretty clean at ale temps. I’d be curious to see the results with something like S-189 or a liquid yeast strain that isn’t quite as forgiving.

Yeah, certainly something we should test out

Interesting approach. I enjoy this blog because I see interesting methods that are new to me. Thanks. I have brewed many lagers using the quick approach, also found on the Brulosophy website. I bottle condition. It takes about a week longer than this pressure method and also produces clean beers with no off flavors consistently. It seems that a couple of extra weeks in the bottle makes a huge improvement tho. As one pro brewer told me, “you just can’t rush a lager”.

34/70 is notoriously good at warm temperatures and continually performs, for me, aggressively in just about any lager I’ve used it in (even used regularly in tropical stouts!) I ferment all my lagers under pressure but I don’t have any temperature control on the fermenters and I have never had a problem with any off flavours. Every single lager finishes clean and crisp.

I would have liked to have seen a comparison between a similar lager fermented under pressure and no pressure with no temperature control but using something other than 34/70. I would hazard a guess that there would be a perceptible difference.

I’d be curious to see how a beer fermented with lager yeast under pressure at room temperature would do against the same beer/yeast using a proper lager process