Author: Cade Jobe

Adorning the side of many a craft beer can is the brewer’s imploration to “store cold,” a solid piece of advice given the well understood concept that chemical reactions occur more rapidly in warmer environments. As it concerns beer, this means certain undesirable changes, such as oxidation effects, will occur more slowly when it’s kept cold, thus prolonging shelf-life and ostensibly increasing customer satisfaction.

Unfortunately, there’s simply not enough refrigerated space to store all beer, resulting in some being placed on warm shelves for weeks or even months at a time. While good brewers employ various practices to ensure adequate shelf-life, there’s little that can be done once the product leaves their facility, and it’s widely believed even relatively small amounts of time in warmer settings can have a noticeable impact on beer quality.

As a homebrewer, storage temperature isn’t something I have to worry too much about, but it’s certainly something we focused on during my time at Blue Owl Brewing in Austin, TX, where temperatures can get quite hot. Inspired by prior findings showing tasters could tell apart Bohemian Pilsners stored either cool or warm in kegs, I designed a similar xBmt with a few changes to see how those results would hold up.

| PURPOSE |

To evaluate the differences between a Cream Ale consistently stored cool and one stored in a warm environment for 3 days.

| METHODS |

For this Cream Ale recipe, I used malted barley provided to me by the Oregon State University Barley Project.

Unintentionally Intentional

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 22.3 | 2.9 SRM | 1.034 | 1.001 | 4.33 % |

| Actuals | 1.034 | 1.001 | 4.33 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (Wintmalt) | 6 lbs | 70.59 |

| Corn, Flaked | 2.5 lbs | 29.41 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

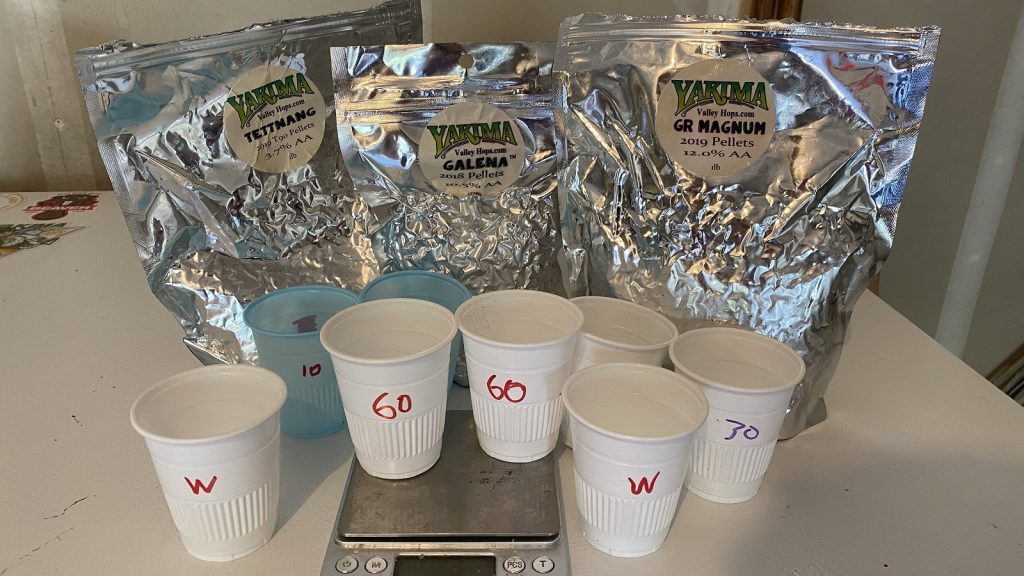

| Hallertau Magnum | 7 g | 60 min | Boil | Pellet | 12 |

| Galena | 7 g | 30 min | Boil | Pellet | 10.5 |

| Tettnang | 15 g | 10 min | Boil | Pellet | 3.7 |

| Tettnang | 15 g | 0 min | Boil | Pellet | 3.7 |

| Tettnang | 15 g | 5 days | Dry Hop | Pellet | 3.7 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 77% | 32°F - 32°F |

Notes

| Water Profile: Ca 50 | Mg 2 | Na 20 | SO4 62 | Cl 40 |

Download

| Download this recipe's BeerXML file |

After collecting the full volume of water, adjusting it to my desired mineral profile, and setting the electric controller to heat it up, I weighed out and milled the grain.

With the water properly heated, I added the grains, turned the pump on to recirculate, and set the controller to maintain my intended mash temperature of 149°F/65°C.

While the mashes were resting, I weighed out the kettle hop additions.

Following the 60 minute mash rest, I raised the grain basket out of the kettle and let them drain. The wort was then boiled for 60 minutes with hops added at the times listed in the recipe.

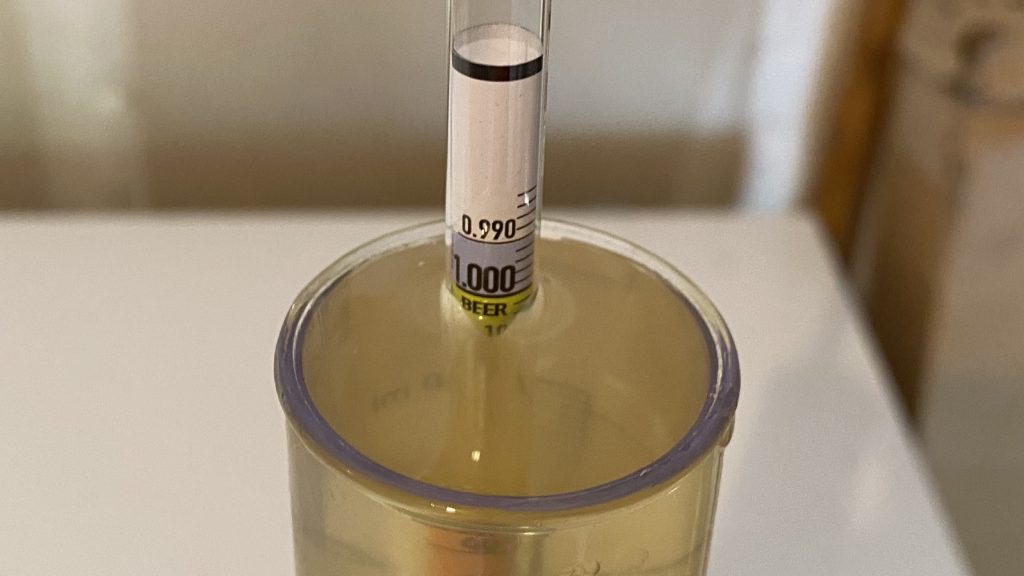

When the boil was complete, I quickly chilled the wort then took a hydrometer measurement showing it was at a slightly lower than expected OG, but nothing worrisome.

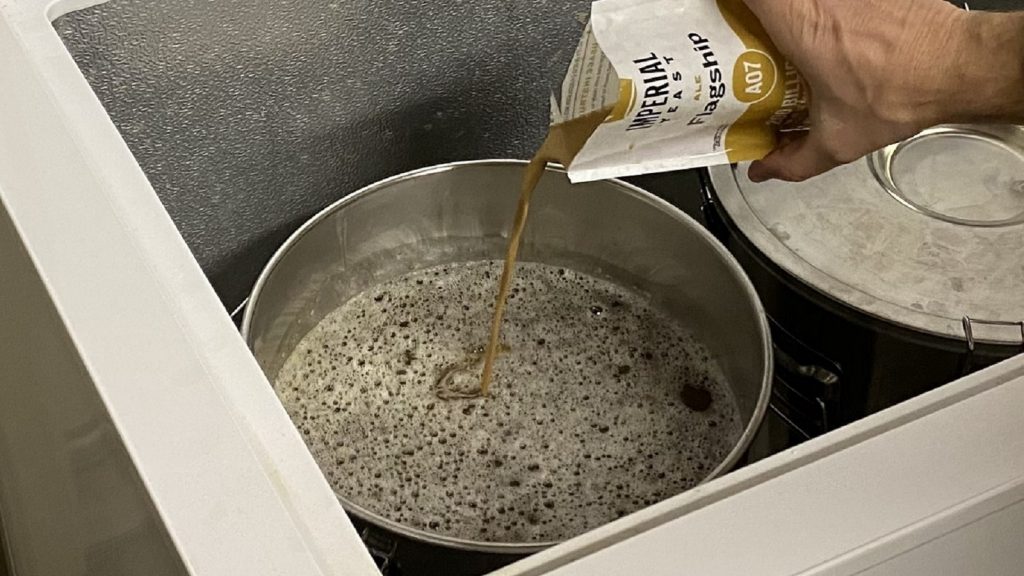

After transferring the wort to a sanitized Brew Bucket, I placed it in my fermentation chamber and pitched a single pouch of Imperial Yeast A07 Flagship.

The beers were left to ferment at 66°F/19°C for 2 weeks before I took a hydrometer measurement indicating the beer had reached 1.001 FG.

At this point, I pressure transferred to a CO2 purged keg that was placed on gas in my keezer and allowed to carbonate. After a month, I gently filled two 64 oz/1.9 L sanitized and purged Craft Master Growlers with the beer.

One of the growlers was placed in my 36°F/2°C refrigerator while the other was stored in my garage, which ranged between 70°F/21°C and 90°F/32°C.

After 3 days, I moved the warm stored beer to the fridge and let it chill overnight before proceeding with the evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer consistently stored cool while the other set was filled with the beer stored warm for 3 days. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 3 times (p=0.70), indicating my inability to reliably distinguish a Cream Ale consistently stored cool from one that spent 3 days in my warm garage.

Despite fully expecting these beers to taste different, I simply could not tell them apart, and what’s more, they both tasted the same as the beer direct from the keg.

| DISCUSSION |

Chemical reactions occur more rapidly in warmer environments, including those that are known to contribute to beer degradation and reduced shelf-life, hence the importance brewers place on ensuring their beer is stored cool. Interestingly, I was unable to reliably distinguish a Cream Ale that was stored in a warm environment for 3 days from one that was consistently stored cool.

In designing this xBmt, we opted to transfer beer from a keg to insulated stainless growlers that were first purged with CO2, a step that may very well have reduced both beers’ exposure to oxygen and thus mitigated the impact of storage temperature. Had the beers not been purged prior to packaging, it’s possible oxidation would have occurred more rapidly in the warm stored beer.

I was admittedly confident these beers would be easy to tell apart, and my surprise when attempting my series of triangle tests was palpable. Despite one beer sitting in my garage, which got up to 90°F/32°C during the middle of the day, these beers tasted identical to my palate. I certainly won’t be leaving beer in my warm garage in the future, but it’s nice to know that it may not be the death of a batch when it occurs, and I’m now more curious than ever to see how this pans out with a hoppier style.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

8 thoughts on “exBEERiment | Impact Storage Temperature Has On Cream Ale”

Would have been more interesting if you had consistently moved out some of the cold storage every week, so that you had consistently cool samples, 1 week warm, 2 weeks warm, etc…

Three days really is nothing.

FYI, I need to store my beers in my garage, at the floor, where during summer they also at least get stored sometimes between 20-25°C.So, some parts of my beer storage need to survive between 2 to 4 months there. I haven’t had any problems with taste after the summer (I even stored weizen).

It’s live beer. The results would probably have been different if it were pasteurized

3 days?? What are you trying to prove? 3 days is nothing! 3 months would have been interesting.

3 days is not nothing. this is a good first try. i bet this test would have mixed results depending on beer style as well. NEIPA vs cream ale vs stout could have very different times to stale flavor detection.

May also speak to the ability of those specialized growlers to keep the cool in for longer periods of time than standard glass growlers

Given the result it could be interesting to have two other candidates, on a non-purged growler both hot and cold stored to see if the oxidation would happen faster in one vs the other sample.

Interesting experiment none the less.

Cheers

Thanks for the interesting experiment. I agree with the others though, that the time needs to be longer, and possibly multiple lengths to see how it changes over time. I like Jürgen’s idea of 1 week, 2 weeks, 3 weeks…

I bottle condition all my beer and don’t have an extra fridge to keep it in so it stays in my office at around 20C for up to 3 months as it slowly disappears. I’ve noticed that the flavor slowly changes over time, but I haven’t noticed it getting worse. It usually just mellows a bit.

I have learned a lot from listening to the podcast and reading the articles on the website. Thanks and keep it up!

Great experiment, Thank you.

I think this experiment is very representative of my typical use case. As someone who often has growlers filled at breweries to bring home, they will often sit for a couple of days leading up to the weekend and unfortunately there’s not always ample fridge space.

It’s nice to have a little more confidence that a few days out of the fridge before chilling for the weekend isn’t having a huge negative impact.