Author: Cade Jobe

Boiling wort is considered a crucial step in the brewing process, as it serves multiple purposes including eliminating beer spoilage microbes, halting the enzymatic conversion of starch to fermentable sugar, driving off the DMS precursor, and promoting the Maillard reaction. It’s also during the boil that alpha acids from hops isomerize into iso-alpha acids, which contribute bitterness while reducing proteins that lead to increased body and haze.

Despite the general benefits of boiling, there are those who view the process as having downsides as well, particularly those interested in Hazy IPA. Hops contain a number of aromatic terpenes that react differently to certain temperatures, and many of the most desirable fruity ones are known to volatilize at boiling temperature. For this reason, some brewers of Hazy IPA opt for a “raw” brewing approach where the boil step is eliminated altogether, which ostensibly leads to increased fruity hop character as well as fuller body and improved haze stability.

What I appreciate most about a good Hazy IPA is the combination of fruity hops and a slightly viscous mouthfeel, which creates an impression of fruit juice. Unfortunately, it seems many struggle to produce this quality, myself included, and I recently began to wonder if perhaps skipping the traditional boil step might be one way to achieve it. Inspired by a past xBmt showing tasters could reliably tell apart a Scottish Heavy that was not boiled from one that was, I decided to retest this one on a well hopped Hazy IPA.

| PURPOSE |

To evaluate the differences between a Hazy IPA where the wort was held at 185°F/85°C and one that was boiled for 60 minutes.

| METHODS |

For this xBmt, I went with a fairly simple recipe designed to emphasize fruity hop character.

Couch Lock

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 60 min | 18 | 3.7 SRM | 1.053 | 1.012 | 5.38 % |

| Actuals | 1.053 | 1.012 | 5.38 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 9 lbs | 70.59 |

| Oats, Flaked | 2 lbs | 15.69 |

| Wheat Malt, Pale (Weyermann) | 1.75 lbs | 13.73 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 7 g | 60 min | Boil | Pellet | 12 |

| Centennial | 8 g | 5 min | Boil | Pellet | 6.1 |

| Citra | 8 g | 5 min | Boil | Pellet | 13.3 |

| Idaho #7 | 8 g | 5 min | Boil | Pellet | 13 |

| LUPOMax Sabro | 5 g | 5 min | Boil | Pellet | 19.5 |

| Centennial | 8 g | 1 min | Boil | Pellet | 6.1 |

| Citra | 8 g | 1 min | Boil | Pellet | 13.3 |

| Idaho #7 | 8 g | 1 min | Boil | Pellet | 13 |

| LUPOMax Sabro | 5 g | 1 min | Boil | Pellet | 19.5 |

| Citra | 28 g | 5 days | Dry Hop | Pellet | 12 |

| Idaho #7 | 28 g | 5 days | Dry Hop | Pellet | 13 |

| LUPOMax Sabro | 22 g | 5 days | Dry Hop | Pellet | 19.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 74% | 32°F - 32°F |

Notes

| Water Profile: Ca 142 | Mg 10 | Na 6 | SO4 104 | Cl 186 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water for each batch, adjusting both to my desired mineral profile, then setting the electric controllers to heat them up.

I then weighed out and milled the grain for each batch.

With the water properly heated, I added the grains, turned the pumps on to recirculate, and set the controllers to maintain my intended mash temperature of 148°F/64°C.

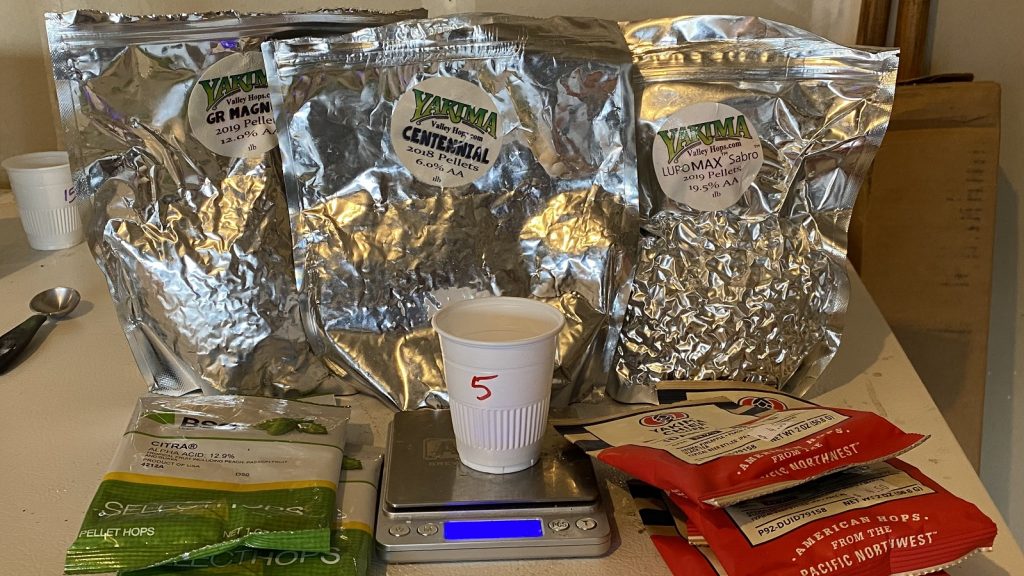

While the mashes were resting, I weighed out the kettle hop additions.

Following each 60 minute mash rest, I removed the grains then heated one batch to 185°F/85°C while the other was brought to a boil, adding hops at the same points listed in the recipe.

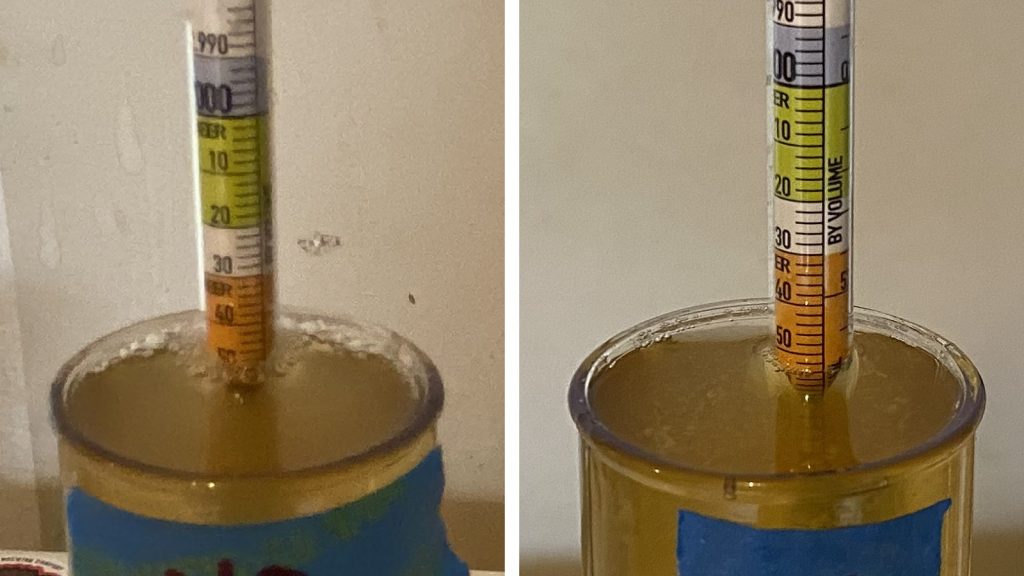

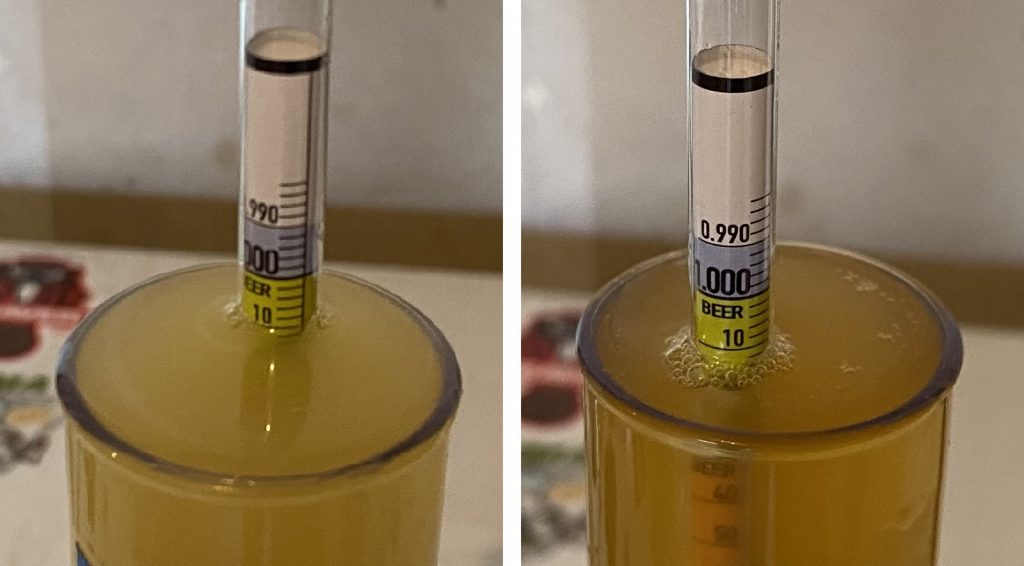

Once complete, I chilled the worts and racked each into separate Brew Buckets before taking hydrometer measurements showing a 0.004 difference in OG.

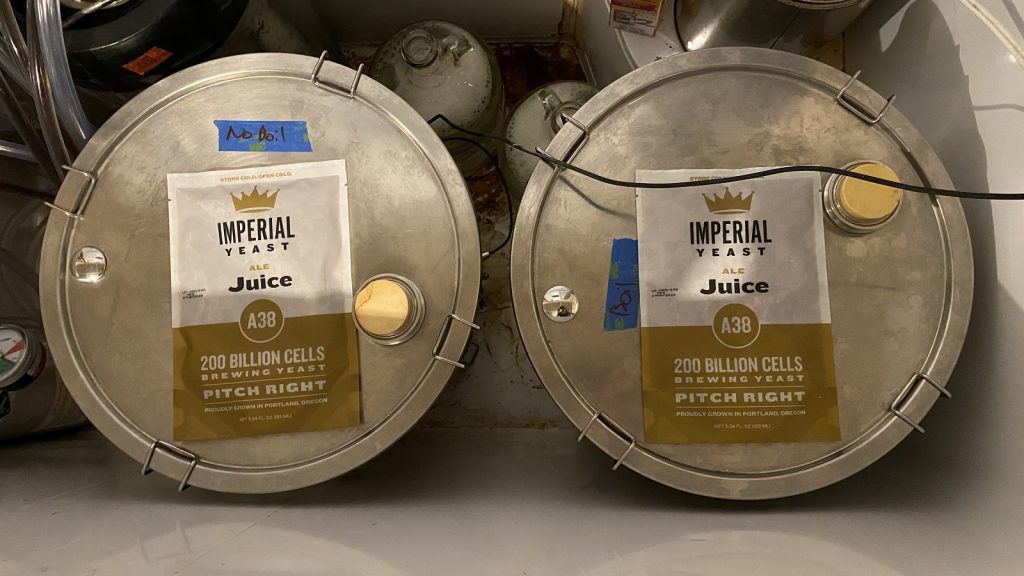

The worts were left in my chamber for a few hours to finish chilling to my target fermentation temperature of 66°F/19°C, at which point I pitched a pouch of Imperial Yeast A38 Juice into each batch.

After 5 days of fermentation, I raised the temperature to 72°F/22°C and added the dry hop additions then let the beers sit an additional 10 days before taking hydrometer measurements showing a slight FG difference.

At this point, I cold crashed to 30°F/-1°C overnight before proceeding with packaging.

The filled kegs were placed on gas in my keezer and allowed to condition for a week before they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the no-boil Hazy IPA while the other set was filled with the standard boil Hazy IPA. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample at least 7 times (p<0.05) in order to reach statistical significance. In the end, I correctly identified the unique sample just 5 times (p=0.21), indicating my inability to reliably distinguish a Hazy IPA that was boiled from one that was not boiled.

Other than the obvious color disparity between these beers, they were perceptibly identical to me. The aroma had plenty of juicy hop character with a supporting grainy malt backbone, and they had just enough bitterness to compliment the tangerine and mango characteristics.

| DISCUSSION |

Many reactions occur during the boiling of wort that affect various aspects of the finished beer including condensation of the wort, isomerization of alpha acids, and protein coagulation to reduce haze. Traditionally viewed as a standard part of the brewing process, some brewers of Hazy IPA have opted to forgo this step altogether, contending not only that hefty hop additions made later in the process render boiling unnecessary, but that beers made in such a manner retain more desirable hop character. My inability to reliably distinguish a Hazy IPA that was boiled from one that wasn’t suggests any differences were small enough as to be imperceptible.

Similar in terms of aroma, flavor, and mouthfeel, these beers were very clearly different based on appearance, with the boiled version being notably darker in color than the one that wasn’t boiled. I suspect this is a function of the wort condensing due to evaporation, though it’s also possible some of the darker color is from the Maillard reaction that can occur during the boil. Seeing as both beers were treated identically on the cold-side, where every effort was made to keep oxygen exposure to a minimum, I do believe the difference in color was a function of the variable.

While I’ve brewed batches with reduced boils over the years, this was the first time I completely skipped the step, and I admittedly expected doing so to have a noticeable effect. The fact I couldn’t tell the beers apart was certainly surprising and has caused me to reevaluate my own beliefs on the importance of boiling wort. I’ve no plans to start skipping the boil all the time, but I do look forward to experimenting more with this curious approach in a less characterful style like a pale lager, which is said to be especially susceptible to DMS due to the heavy use of pilsner malt.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

33 thoughts on “exBEERiment | No-Boil Effect: Evaluating The Impact On Hazy IPA”

Hey,

Really interesting experiment and to be honest, I was expecting more difference between the 2 beers, although the color difference would still be enough to motivate me.

Just to make sure I got it right: you kept the non-boil beer at 85 Celsius for 60 minutes? Was there a specific reason for keeping it 60 minutes (other then doing a good comparison)? If that was the only reason, then I guess it wouldn’t be really necessary to keep it for 60 minutes so it would also be a shorter time involved, right?

Thanks.

Yes, that’s correct. There were several reasons to keep it at 60 minutes, for example, keeping the hop additions similar. I added 60 minute, 5 minute, and whirlpool hops to the boil. You could reduce the time for the boil, but I don’t know how that would affect the hop additions. Just something to think about.

Indeed, it would affect the hop contribution, but that is something worth considering in exchange for a shorter brewing time.

Thanks.

That’s crazy, especially considering the fact that there was 9 IBU @ 60’ boil, plus 5 IBU @ 5’ boil. However, the no-boil beer was kept in 185ºF/85ºC on the hop additions, i.e., theoretically in the range that occurs isomerization. Maybe the bitterness difference was not significant because of that, so we could isolate the variable to the Maillard reaction itself.

Great job, guys!

I’m wondering whether the lack of a rolling boil affected the so-called “hot break”, which is supposed to coagulate and precipitate proteins from the wort. I guess NEIPA makers are not bothered about clarity in the final beer, so the hazier the better. Cutting out the boil would certainly save a lot of energy, as well as conserve hop aroma. Interesting that you chose to keep the non-boil wort at 85°C to allow some isomerization of the hops. I did make a beer once without any boiling or even heating of the wort. I included the hops in the mash at 65°C. I found a terrible lack of bitterness and flavor in the finished beer and had to add hop extract in the end. I never tried it again. Maybe your 85°C idea would work OK. Whether avoiding the boil would make for a hazy beer is another thing. I prefer a reasonably clear beer.

Yes, based on my understanding, I think the “hot break” would be reduced in the no-boil batch. I suspect the color difference in the beers was due to 1) more haze-causing compounds in the no-boil batch because of lower protein coagulation (causing it to look lighter), and 2) evaporation from boiling that concentrated the wort (darkening the boil batch). So I would think there would be a clarity difference between a beer at 85C vs at boil. Just a guess though.

Regarding bitterness, Scott Janish performed an experiment where he avoided adding a bittering addition in an NEIPAs. Similar to your experience, he preferred a bittering charge.

I once had a pro brewer who makes no boil New England IPA’s frequently that he shoots for 170 F/ 76.7C because above 180F DMS can become an issue. I don’t know how true that is but something by to think about.The no boil beers this brewery has made are among some of my favorites in the style.

Nice! I didn’t notice any DMS in the no-boil batch, but that sounds like a reasonable concern.

I find the boiled version very dark given the grain bill?

Whenever I brew similar recipe, (I boil)

I get a much lighter color.

I wonder if anything unexpected happened on top of the Boil/No Boil difference…

That’s always a possibility. Since I didn’t notice any flavor or aroma differences, it’s hard to say one way or the other.

Any reference for that Maillard reaction thing you mention a couple times? Maillard reaction occurs at temperatures much higher than boiling, I see no way for it to occur in a rolling boil.

Maillard Reaction Products in Different Types of Brewing Malt: https://pubs.acs.org/doi/10.1021/acs.jafc.0c06193

Free and Protein-Bound Maillard Reaction Products in Beer: Method Development and a Survey of Different Beer Types: https://pubs.acs.org/doi/10.1021/acs.jafc.6b02649

Browning and pigmentation in food through the Maillard reaction: https://link.springer.com/article/10.1007/s10719-020-09943-x

Did you use less sparge water on the no boil method as you were not going to have as much, if any, evaporation? I loose 2 gallons of wort during a 75 minute boiler, if no boiling then I would have that much more beer to drink! It took me YEARS to make clear beer, now I am considering the no-boil method to make a cloudy beer 🙂

No. We discussed it, but opted to keep volume and grist the same up to the point of boil, where the variable is introduced. We consider volume loss due evaporation during the boil to be a result of the variable.

Cade:

When I first read that you did not “top up” the boiled batch I was certain it would be tasted as different. (Ones may disagree but I believe this would constitute a second variable to the experiment)

The fact that there was not a drastic discernible difference is surprising!

In fact, I am constantly amazed how often these brew experiments seem to “bust” many old brewers tales. So maybe you have the right idea, that of adding several factors at once to an experiment to find what actually “does make a difference”.

Thanks for the “sacrifice” in the name of home brewing!

Tom

Hi Cade,

To isolate possibile causes to the color discrepancy you could try to dilute the boil beer to obtain the Same FG for both. After this, if there Is still difference you can narrow the cause to haze, maillard, etc… Right?

Thanks, LucaG

Great experiment! I just brewed a NEIPA on Monday, considered skipping the boil, but chickened out.

What’s your method for cold crashing overnight in the brew buckets without exposing the beer to too much oxygen?

I added an aftermarket tri-clamp port to the top, so I hook it up to light CO2 pressure (1-2 psi) before crashing.

Ah, that title was a little misleading, but sure. Interesting result, however, it would be more interesting to test the actual “No boil”-method, where one skip the boiling step totally, not even holding a constant temperature of 85 degrees. That method is more interesting since that actually cuts like 60 or 90 minutes from your brewday.

I have been cold brewing with extract… take ro or distilled water add nutrients, add dme add hops add yeast… takes all of 15 minutes… great results done 10+ batches now and may never go back for the NEIPA style.

Ben, tell us more – you’re saying that you just make sure you dissolve the DME in the enough water and add the hops like a dry hop and the yeast at the same time? Now, that’s a short brew day!

So yeah… I ferment in kegs now and have a floating dip tube I got from more beer I think? Just a stainless ball on a hose basically. I sanitize the keg fully… pour in distilled water… add some salts or gypsum or whatever to build my water profile… pour in dme… usually golden light and wheat mixed or have done each separately as well… then add whatever hops add some dry yeast and close up… and ferment under maybe 2-5lbs of pressure…don’t fully carbonate at this stage as the hops will stay in solution too much and it’s a pain to get the beer through the tube… my garage walls know this was a bad idea… had to open a fully carbed batch once and went everywhere… I then place my keg in my ferm Freezer at 66 degrees or so and let it hang for a week and then transfer to a new keg and serve… the “brew” or mix portion takes all of 15 minutes… now being interested in testing it I did a blind test against a full boil standard New England I brewed vs a cold brew and then just for fun threw in som heavy hitting commercial beers I think it was an Ikarus and a treehouse vs my standard boil and my cold brew… everyone like the cold brew better than the all grain full boil myself included… and the cold brew was tied for 1st overall … not a full huge test but like 5-6 of is that really like beer… and the cold brew has been great pretty much every time… also the flavor and taste seem to last longer maybe it’s the smaller batches? Maybe it’s cause it’s all closed? Dme vs grain? But it does not seem to oxidize nearly as much as full boil?

Cold brew beer

4 gallons water

6lbs dme

1 lb sugar

1-1.5 ounces of hops per gallon of water

3 teaspoon cacl2 calcium chloride

S 04? Yeast?

Hey Ben,

I’m keen to know more about your cold brew NEIPA. I use FWKs and do the same thing with a big keg hop and works great. So there’s no need to boil the water or the DME to kill if any nasties?

Hey , my question is in regards to the IBU , yours say its IBU 18 but when I add this (no boil) recipe to brewfather it gives me a IBU of 7 … any idea how to bring that up a notch? and im guessing im pretty much just hop standing at 85C the whole time right?

IBU calculation is dependent on a bunch of factors, and in my experience, isn’t very reliable. I do a number of things like changing my last hop addition to 1 min (even if it’s being tossed in after heat is turned off), adjusting my extraction % from whirlpool hops, adjusting my equipment profile, but mostly totally ignoring the IBU. When designing, I use experience to get “enough” hop flavor or bitterness. For hazies like this one, I’ll just use 8-14 grams of magnum at 60 mins to get “enough” bitterness. I rarely go above 20 grams magnum, even when doing West coast IPAs.

Thanks for the Reply <3

When you say 8-14 g of magnum at 60mins to get enough Bitterness, Do you mean you leave the hops in for the full hour (60mins) at 85 degrees?

8-14 g at 100C for 60 minutes, since I don’t usually do a no-boil.

I really want to know if a 30min 85C reduced boil makes a difference to a regular 60min vigorous boil. The two xbmt experiments on their own didn’t produce significant results for pale ales I’m wondering if for the NEIPA style it would make a difference. I may try a 30min 85-95C “boil” in March for a Double NE IPA however it would be good to know if it does cause any problems and differences.

After various research I’ve decided to go raise the temp to 79C for a “boil” and let it drop to whatever but above 77C in the 30 mins to hopstand then cool. Hopefully that’ll remove the production of DMS.

I usually pasteurize for half an hour at 76°C (no chance for DMS) while boiling about one fifth of my wort with bittering hops. Works great, saves cooling time and energy.

I’ve actually decided to do something very similar now after a lot of research. I’m doing it on Saturday. Hitting 79C not anything over (to limit DMS whilst using low colour MO rather than pilsner malt and increase hop untilisation when compared to 76C). Adding all my Hopstand equivalent hops in at this point for 30 minutes allowing the wort to drop what ever it does in 30 minutes. Adding my sugar in at 15 minutes. Reading up with the amount of hops on using I should still get roughly 30 IBUs without any traditional bittering hops. We’ll see how it turns out.

How do your “raw” ales or raw ale Neipa turn out?

My process works just fine for me. No issues with shelf life, taste is great, nothing “raw” about it. At first I tried the whole batch with a max temp of 76°C but that didn’t get me enough bitterness, thus the “partial boil”. 79° could be the way to go. I actually first tried this to emulate what Beermkr is doing, ramping up temperature from 50°C to 76°C over the course of a couple of hours (at the moment I mainly do very small batches on the kitchen stove). Beermkr uses isomerized hops, so they don’t have to boil at all to get bitterness, Might be worth a try.

Next time do an no-chill IPA