Author: Phil Rusher

Back in 2016, likely in response to the growing popularity of flavored sparkling water, a curious beverage began to pop-up on liquor store shelves that promised a refreshing and lower calorie way to catch a buzz. To the chagrin of some, White Claw quickly became a household name, which naturally led to other manufactures creating their own versions of hard seltzer including many macro and craft breweries.

While making a tasty batch of hard seltzer can be as easy as blending water with a neutral booze and flavoring, this approach not only poses various issues on the commercial scale, but many believe it results in a product with a less desirable flavor profile. The alternative involves using yeast to ferment a volume of sugary water, with the source of said sugar typically being either sucrose (table sugar) or dextrose (corn sugar). As it pertains to beer, many hold that sucrose imparts a cider-like flavor and hence prefer using the purportedly more neutral dextrose, though others claim they’re basically the same and use them interchangeably.

Considering sugar makes up 100% of the fermentables in hard seltzer, it stands that any differences in character imparted by sucrose and dextrose would be readily apparent. Given the newness of hard seltzer, there is a paucity of information regarding the impact either sugar has on flavor, so I figured I’d put it to the test myself.

| PURPOSE |

To evaluate the differences between a hard seltzer made with sucrose and one made with dextrose.

| METHODS |

Seeing as sucrose yields 46 points per pound per gallon (ppg) and dextrose yields 42 ppg, in order to achieve the same OG, I had to use slightly more dextrose than sucrose. For this xBmt, I designed a recipe using Imperial Yeast W04 Paramount, a strain of wine yeast specifically marketed for seltzer fermentation.

Devil In Disguise

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.7 gal | 10 min | 0 | 0 SRM | 1.025 | 0.997 | 3.67 % |

| Actuals | 1.025 | 0.997 | 3.67 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Sucrose (or 4 lbs Dextrose) | 3.312 lbs | 100 |

Miscs

| Name | Amount | min | Type | |

|---|---|---|---|---|

| Yeast Nutrients | 32 g | 0 min | Primary | Other |

| Activated Charcoal | 10 g | 0 min | Secondary | Fining |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Paramount (W04) | imperial yeast | 95% | 32°F - 32°F |

Notes

| Water Profiler: Ca 174 | Mg 0 | Na 30 | SO4 430 | Cl 52 |

Download

| Download this recipe's BeerXML file |

After collecting two identical volumes of RO water, I adjusted both to the profile of one of my favorite sparkling waters, San Pellegrino, before turning on the elements to get them heating up.

I then weighed out the sugars for each batch, 3.3 lbs/1.5 kg sucrose and 4 lbs/1.81 kg dextrose, then added them to either kettle of water.

The sugar solutions were boiled for 10 minutes to ensure any potential contaminants were taken care of.

When the boils were complete, I ran the sweet liquid through a plate chiller during transfer to separate Unitanks.

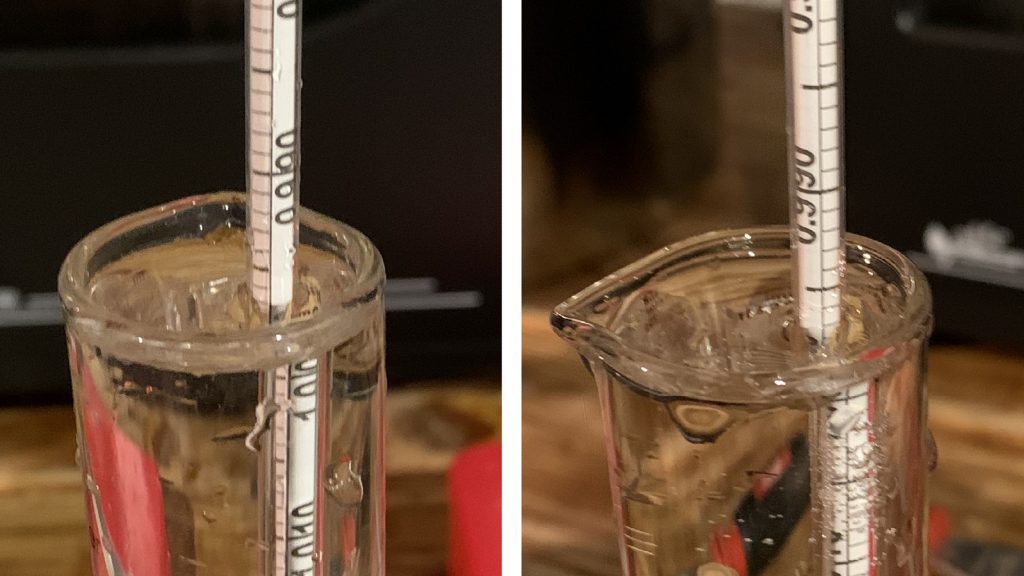

Refractometer readings showed both batches achieved the same 1.025 OG.

Each batch was then dosed with nutrient and pitched with a single pouch of Imperial Yeast W04 Paramount at 66°F/19°C.

I set the controllers to 75°F/24°C and let the seltzers ferment for a week before upping the temperature to 80°F/27°C. With signs of activity absent after another week, I cold-crashed to 38°F/3°C and added an activated charcoal solution as recommended by Briess.

The charcoal was left in contact with the seltzer for 18 hours before I applied a small amount of pressure to the fermenters and dumped the trub. Hydrometer measurements taken 2 weeks later showed both seltzers finished at the same FG.

At this point, I pressure transferred the seltzers to sanitized kegs.

The filled kegs were placed in my keezer, burst carbonated overnight, then left to condition for a few days before they were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the hard seltzer made with sucrose while the other set was filled with the hard seltzer made with dextrose. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I was only able to correctly identify the samples 2 times (p=0.90), indicating my inability to reliably distinguish a hard seltzer made with sucrose from one made with dextrose.

To my palate, there was absolutely nothing different about these seltzers, everything about them was identical. Admittedly, I’ve not been a big consumer of hard seltzer, but I’ve had enough to know what to expect, and despite these xBmt seltzers being unflavored, they were dry, crisp, and very refreshing. I trust this recipe would be a good place to start for flavored version.

| DISCUSSION |

In just a few short years, hard seltzer went from a novel beverage that self-proclaimed “connoisseurs” took delight in lambasting to a billion dollar industry that disrupted the craft beer market such that many breweries are now producing it themselves. Of the various approaches to making hard seltzer, the most common method involves fermenting sugar, which is typically either sucrose or dextrose. Countering claims that one produces a noticeable difference compared to the other, I was unable to reliably distinguish a hard seltzer made with sucrose from one made with dextrose.

While these results corroborate those from a recent xBmt comparing a Double IPA made with sucrose from one made with dextrose, another xBmt comparing the sugars in a Belgian Golden Strong did return a significant result, which leads me to wonder if perhaps there’s an interaction effect between sugar and yeast type. I intentionally chose not to add any flavoring to these xBmt seltzers, as I wanted to make sure there was nothing to mask any differences, yet they tasted identical to me.

To yield 5 gallons/19 liters of a tasty beverage that possesses the buzz-inducing powers of alcohol from a brew day that lasted maybe 30 minutes is pretty cool, I’ll certainly be making more hard seltzer soon. Since both versions tasted the same to me, I can’t say I had a flavor preference for either one, so my decision on what sugar to use is based largely on cost and convenience— table sugar is cheap and very easy to come by, so sucrose it is. As pleased as I was with this plain hard seltzer, I’m excited to play around with different flavors in future batches.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

30 thoughts on “exBEERiment | Hard Seltzer: Sucrose vs Dextrose”

What are the details regarding the charcoal addition? Could you please elaborate more regarding this part of the process and what effects of too little or too much are and why you chose your measurement of the addition and why you decided on that length of contact time?

I simply used the recommended dosage noted on Briess’s FAQ, which is 2-5 lbs/1000 gallons. Taking the average of 2-5, this converts to about 0.0035 lbs/1 gallon or 0.021 lbs/6 gallons. This gives us about 9.53 g of charcoal and I simply rounded up a bit for 10 g of charcoal.

The pot I used has graduations in it and all I did was take 400 mL of RO water, added 20g of charcoal, brought it to a boil (covered) and let it boil for 2 minutes. I then split the contents of the pot evenly between the two tanks, which was about 200 mL to each.

The contact time was something I heard Mitch Steele say when he was talking about their hard seltzer program. I believe the rule of thumb at New Realm is no more than a day.

Yeah, I’m fixated on the charcoal too. Did you do the easy/obvious thing of tasting both batches before the charcoal treatment? I’d be curious even if anecdotal.

See my reply to Clinton for the charcoal deets.

I did taste these prior to adding the charcoal. Neither seemed to stand out and they tasted as you might expect; a bit yeasty and dry.

3.3 pounds of sucrose is not the equivalent of 4 pounds of dextrose, gravity-wise. Not even close. Identical gravity readings would be impossible.

My gravity readings are in line with what both Beersmith and Brewfather predicted for me. Maybe you’re using a different setup and/or calculations.

4 pounds of dextrose ~= 3.64 pounds of sucrose, because dextrose contains ~9% H2O. 3.3 pounds of sucrose couldn’t have got you to the same place, in spite of what any software may have told you.

Using Beer Smith, the same amount of corn sugar or table sugar both yield the same estimated AVB.

You wrote, “in order to achieve the same OG, I had to use slightly more dextrose than sucrose.” But your recipe shows 3.312 lbs Dextrose (or 4 lbs Sucrose). I think perhaps you inadvertently switched amounts there.

Good catch! Fixed.

what yeast nutrient did you use and how did you use it?

I used Wyeast’s nutrient. I actually forgot to add it during the boil so I quickly mixed an RO water/nutrient solution and added it to the tanks after pitching.

Minor typo – the caption on the hydrometers reads 0.097 FG, but it should be 0.997. These things finish dry, but not THAT dry 🙂

Ha! That’d be quite dry, wouldn’t it. Fat fingers etc.

Nice work Phil! Did you try any different flavor addition after your evaluation? If so, what was your favorite and what did you use to flavor them?

Right, so for the purposes of the xbmt I made sure to do my evaluations without any other additives. However, after I completed my evaluations I did end up adding a citric acid solution to both kegs. It was on the order of 1g/L, or about 190g of citric acid. I just boiled a small amount of RO water and added in the acid before pouring it into the keg. This is a dosage recommended by Alaskan Brewing Company.

https://www.brewersassociation.org/wp-content/uploads/2020/05/CBC-Online-Seminar-Presentation-Hard-Seltzer-101-Development-Production-and-Troubleshooting.pdf

I’m very surprised with the use of carbon into the keg. It’s the first time that I saw. Is a process similar than gelatine? Or better?

It’s similar to using gelatin but carbon will remove more than gelatin. The FAQ I linked in the article from Briess was helpful. https://www.brewingwithbriess.com/wp-content/uploads/hard-seltzer/briess-brew_hard-seltzer_faq.pdf

This page is helpful too: https://www.brewersassociation.org/wp-content/uploads/2020/05/CBC-Online-Seminar-Presentation-Hard-Seltzer-101-Development-Production-and-Troubleshooting.pdf

“While making a tasty batch of hard seltzer can be as easy as blending water with a neutral booze and flavoring, this approach not only poses various issues on the commercial scale, but many believe it results in a product with a less desirable flavor profile.”

This sounds like it could be an interesting test. I assume you’d want to control for PH and mineral content between a fermented version and a soda water + alcohol version. Keeping carbonation levels the same too would be important, although it’s beyond my brewing knowledge to know how to test it with readily available equipment.

I was thinking this exact same thing. It would be interesting to see the results of a triangle test between fermented seltzer and mixed seltzer.

I thought the reason was that they are taxed differently–that it would actually be easier to blend, but then you’re handling hard liquor.

How did you get the charcoal out of suspension. I am on about 2 days now of cold crashing and there is a noticeable black tinge to the product. Do I just need to keep it crashing for a while and let it go, or transfer to a keg and let it condition in there?

You may want to do some mechanical filtration if you’re seeing a tinge.

I’m going to try fining some hard seltzer this week. How long did your charcoal tint take to settle? I am considering doing charcoal and then hitting it with gelatin.

Same issue with charcoal. Turned it black. No sign of it substantially settling out after 24 hours in cold and under slight pressure

Did it stay black after your post as well?

After post I did gelatin this again and now just tried it after 10 more days sitting cold. Poured off 16+ ounces from 5 gallon keg. First few ounces very very dark, small black pieces too, not just dust. A bit clearer after that but definitely still a noticeable black/gray tinge.

Please note that I added blackberry puree to the secondary with this batch. I made 10 gallons total and dosed one 5 gallon keg with 9gr activated charcoal powder. The non-charcoal batch that was only treated with gelatin is much clearer than the charcoal batch but still very fruit colored and not gray. Charcoal may work if you don’t have fruit in the mix but no way I would use it again if I was adding fruit. Maybe it does drop clear otherwise.

FYI – I also ran the batch dosed with charcoal through a 1 micron cartridge filter before the last addition of gelatin. Some, but relatively little charcoal residue noticed on the filter cartridge.

As you heated the sucrose (creating inverted sugar) you broke it down into simple sugars, glucose (dextrose) and fructose (levulose).

Just curious if you noticed a difference in fermentation time … Wondering if the sucrose batch took longer to ferment.

Thanks.

DJ