This xBmt was completed by a member of The Brü Club in collaboration with Brülosophy as a part of The Brü Club xBmt Series. While members who choose to participate in this series generally take inspiration from Brülosophy, the bulk of design, writing, and editing is handled by members unless otherwise specified. Articles featured on Brulosophy.com are selected by The Brü Club leadership prior to being submitted for publication. Visit The Brü Club Facebook Group for more information on this series.

Author: Matt Skillstad

Pitching yeast at or just below fermentation temperature is said to result in the formation of fewer esters and other fermentation byproducts, leading to a cleaner overall profile. This is a reasonable proposition for ales where fermentation occurs around room temperature, but it can be more difficult to accomplish when brewing lagers that are traditionally fermented at cooler temperatures.

Professional brewers often rely on two-stage heat exchangers with a glycol booster to very efficiently chill wort to whatever their target pitching temperature might be. However, homebrewers typically rely on groundwater alone to chill prior to pitching yeast, which makes it difficult to achieve such results. While some resort to letting the wort sit in a cool chamber for a few hours to finish chilling, others opt to pitch yeast into the warm wort before reducing the temperature, which has been claimed to reduce the lag phase of fermentation while having minimal impact on flavor.

When brewing lagers, I prefer to pitch the yeast as soon after chilling as possible, typically when the wort is still around 68°F/20°C, knowing my temperature controlled chest freezer will chill it down before the majority of fermentation occurs. In the times I’ve mustered the patience to pitch cool, I didn’t notice any differences in the finished, but having never done a side-by-side, I decided to put it to the test.

| PURPOSE |

To evaluate the differences between a Märzen where the yeast was pitched at 58°F/14°C and one where the yeast was pitched at 68°F/20°C when both were fermented at 52°F/11°C.

| METHODS |

With fall close at hand, I felt a Märzen presented the perfect opportunity to put this variable to the test.

The Other Side Of The Pillow

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 6 gal | 30 min | 23.4 IBUs | 8.0577297 | 1.057 | 1.014 | 5.7 % |

| Actuals | 1.057 | 1.01 | 6.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Munich I (Weyermann) | 6 lbs | 46.15 |

| Pilsen Synergy Select (Briess) | 6 lbs | 46.15 |

| Aromatic Malt | 8 oz | 3.85 |

| Victory Malt | 8 oz | 3.85 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Northern Brewer | 35 g | 30 min | First Wort | Pellet | 6.8 |

| Northern Brewer | 15 g | 10 min | Boil | Pellet | 6.8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Saflager Lager (W-34/70) | DCL/Fermentis | 75% | 48°F - 59°F |

Notes

| Water Profile: Ca 100 | Mg 12 | Na 11 | SO4 75 | Cl 21 | HCO3 248 |

Download

| Download this recipe's BeerXML file |

I started my brew day by collecting the full volume of water and getting it over the burner to heat it up.

When the water was properly heated, I stirred in the grains and checked to make sure it was at my target mash temperature of 153°F/67°C.

At the end of the 40 minute mash, I removed the grains then boiled the wort for 30 minutes with hops added at the times listed in the recipe, after which I used my IC to quickly chill it.

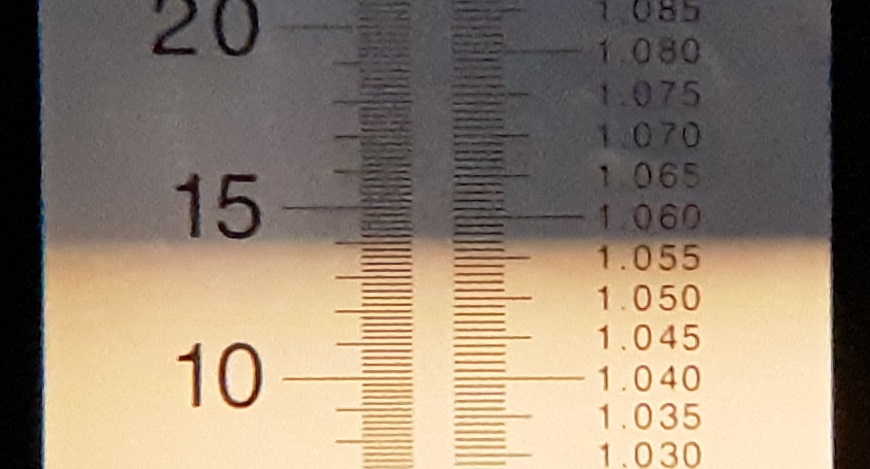

A refractometer reading showed the wort was right at my target OG.

After letting the wort settle for a few minutes, I racked identical volumes to two similar stainless fermentation vessels.

With both worts sitting at 68°F/20°C, I placed them next to each other in my chamber controlled to 52°F/11°C then pitched 2 packs of Saflager W-34/70 into one batch, leaving the other alone to further chill.

When I returned 12 hours later, the temperature of the unpitched wort had dropped to 58°F/14°C, slightly warmer than my target fermentation temperature. Having exhausted my patience, I pitched 2 packs of the same yeast. Observations made 4 hours later, 16 since the yeast was pitched into the warm wort, showed the temperature had dropped to 55°F/13°C and the warm-pitch beer was actively fermenting. I noticed the first signs of fermentation activity in the cool-pitch beer approximately 24 hours after pitching the yeast, at which point both beers were at 52°F/11°C. A week later, fermentation had subsided in both beers, so I placed them on my counter and let them gradually warm up to 66°F/19°C. After another week, I took hydrometer measurements showing both beers reached the same FG.

At this point, the beers were pressure transferred to separate CO2 purged kegs.

The filled kegs were burst carbonated at 30psi for 24 hours before the gas was reduced to serving pressure. After a month of lagering in my kegerator, the beers were carbonated and ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the cool-pitch beer while the other set was filled with the warm- pitch beer. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I only did so 5 times (p=0.213), indicating my inability to distinguish a Märzen where the yeast was pitched cool at 58°F/14°C from one where the yeast was pitched warm at 68°F/20°C, despite being fermented at the same temperature of 52°F/11°C.

These beers were identical to me. At times, I thought I might have detected the warm-pitch version as being slightly more fruity and sharp, though after doing my triangle tests, it seemed more likely bias was at play. I found these beers to have a lightly toasty and beady malt character with some light brown sugar accents and a clean finish that wasn’t too sweet. Very enjoyable.

| DISCUSSION |

With my cool Midwest groundwater and kickass immersion chiller, I can easily chill sweet wort from boil to an adequate ale pitching temperature without much trouble, but chilling to lager pitching temperatures requires more extreme measures. While pitching yeast into cool wort is believed by many to be imperative to producing clean lager character, my inability to reliably distinguish a Märzen pitched cool from one pitched warm indicates pitching temperature had minimal perceptible impact.

It’s possible these results would have been different had I waited for the cool-pitch wort to chill to my target fermentation temperature of 52°F/11°C before pitching the yeast, but I wasn’t comfortable leaving alone any longer than 12 hours, as despite my best sanitation efforts, I was still anxious about a potential contaminant taking hold. In fact, tasters from a past xBmt were able to tell apart lagers pitched either cool or warm with Saflager S-23 yeast. It’s also possible these results can be explained by the heartiness of Saflager W-34/70, which has been shown to be less sensitive to temperature than other yeast strains. The main objective difference that I noticed was that the warm-pitch beer showed signs of fermentation sooner than the batch pitched cool, which is to be expected.

I scored my chest freezer for free because it won’t freeze but still chills, which after connecting a temperature controller, makes for a fine fermentation chamber that does a decent job of maintaining set temperatures. However, it can take quite a while chill wort more than a few degrees, which is part of the reason for my preference to pitch warm when making lagers, and based on my experience with this xBmt, I’ll likely continue to do just that.

Matt Skillstad is a happy husband to a wonderful wife (who likes his beer!) and proud father of 5 young children from Pierce, Nebraska. He has been brewing since 2011 and, in addition to The Brü Club, is a member of the Elkhorn Valley Society of Brewers. He enjoys experimenting with his brewing in an effort to make better beer in less time with less effort. When not brewing or hanging with his family, Matt enjoys bike riding and golfing (poorly).

Matt Skillstad is a happy husband to a wonderful wife (who likes his beer!) and proud father of 5 young children from Pierce, Nebraska. He has been brewing since 2011 and, in addition to The Brü Club, is a member of the Elkhorn Valley Society of Brewers. He enjoys experimenting with his brewing in an effort to make better beer in less time with less effort. When not brewing or hanging with his family, Matt enjoys bike riding and golfing (poorly).

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

9 thoughts on “The Brü Club xBmt Series | Yeast Pitch Temperature: Cool Vs. Warm In A Märzen”

We have pitched the yeast at the ferment temp of 56 degrees, and we had to wait over 12 hours for the wort to reach that temp in the freezer. During summer, we cannot cool wort below 74 degrees.

Waiting the 12+ hours has never been a problem as the wort is in a sterile fermenter, inside a freezer.

You may have had more appropriate results if you pitched at ferment temp.

The recipe looks pretty simple and straightforward and I will try it soon. Except for the Hops. Why would you use Northern Brewer instead of a german noble hop such as Hallertauer in this Marzen?

I agree that the hop choice is a little odd. I would probably use something more traditional next time. I was just going with what I had on hand so I had to make some compromises. It ended up tasting pretty decent though.

Thank you for running this exbeeriment. Being a lager brewer I have always been concerned with pitching and fermenting warm. I can counter flow chill at 1.5 gpm to 10F over my water temp. So in the winter about 55F and summer 70. Most of the time I slow the chilling down for lagers but still cannot acheive my desired pitch temp of 46 to 52F. One easy thing to do is just buy ice and get a large bucket or garbage can and drop your fermenter in there. In 4 to 6 hrs if you keep an eye on how much ice there I have chilled to as low as 44F. With carboys this is easy. For my Spike CF -15 I have to wait overnight in a freezer set at 32F, (note keep the probe out of the fermenter or unless your controller has a timed shut off you WILL over heat your freezer). So if a follow up exbeeriment is done maybe chill one beer to at least 4 F below ferment, and the other 68F. A third opion is just get to ferment temp and pitch and hold.

I suspect the similarity has a lot to do with the pitch rate. 2 packs of 34/70 is about 460B cells. Generally the liquid yeast labs recommend warm pitching their single packs of yeast due to the required growth rate when pitching a paltry 100B cells (if the pack is a day old). What I’m saying is the real world comparison is something like pitching 400-500B cells cold vs pitching 100B cells warm, then cooling. That’s the difference between a yeast lab’s recommendation to a lazy homebrewer vs pro brewer’s empirically driven instinct.

I don’t think this was a correct experiment. The lower temp should have been at 8°C (couple of degrees lower than the ferm temp) like german brewers do. That’s the correct cold pitch.

Here you just test two “warm pitchings” at two different warm temperatures. Not much of a difference.

I can’t argue that the “cold” pitch temp definitely “should” have been alot colder. Based on what is typically recommended I didn’t end up comparing against a perfect control, but given my equipment limitations I got what I got & thought it would still be interesting to some. I’m not really saying that a difference wouldn’t have been evident if I had pitched at 48 or something. All I really learned is that with this beer it’s not really worth it to wait to pitch at 58 rather than 68. I’d have to look at alternatives to get colder faster if I want to test it again. Thanks for reading.

No no dont get me wrong, the test was interesting and as always I read it in one breath. Just a thought it would be better to test it with a “german way” cold pitch. Thats it. All good to you and more good testings in Brulosophy! 🙂

put a computer fan in your fermentation chamber. A little air circulation will significantly increase the heat transfer rate, cooling things a lot faster.