Author: Jake Huolihan

Dry hopping is a technique that’s said to have originated in Britain as a means of beer preservation—prior to shipping full casks of beer overseas, brewers would load them up with hops, which possess acids that have natural antibacterial and antifungal properties. With the advancements in brewing over the years, such usage is no longer necessary, though modern brewers continue to rely heavily on dry hopping to add a pungent punch of character to a range of styles, most notably IPA.

In the earlier days of craft brewing, the process of dry hopping involved adding a charge of hops toward the end of fermentation then letting it sit for up to a week or more before packaging. More recently, the idea of adding hops to beer at high kräusen became popular with the rise of New England IPA because it not only reduces the risk of cold-side oxidation, but it can also lead to biotransformation. Despite this drift toward earlier dry hopping, brewing authorities have never recommended tossing dry hops in at the time of yeast pitch, as doing so is believed by many to result in decreased hop aromatics and increased undesirable vegetal characteristics.

While designing an IPA recipe recently, I was reminded of a past xBmt on this very topic that showed tasters couldn’t tell apart a beer dry hopped at yeast pitch from one dry hopped toward the end of fermentation. With COVID in the air and hence no access to participants, this seemed like a good variable to readdress.

| PURPOSE |

To evaluate the differences between an IPA dry hopped at yeast pitch and one dry hopped toward the end of fermentation.

| METHODS |

With the xBmt variable in mind, I designed a recipe with a dry hop amount I felt would emphasize any differences between the beers.

Jump The Gun

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 30 min | 66.8 IBUs | 5.7 SRM | 1.066 | 1.016 | 6.6 % |

| Actuals | 1.066 | 1.015 | 6.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Genie Pale Malt | 14 lbs | 91.8 |

| Vienna Malt (Weyermann) | 1.25 lbs | 8.2 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 17 g | 30 min | Boil | Pellet | 12.9 |

| Bru-1 | 17 g | 15 min | Boil | Pellet | 13 |

| Citra | 17 g | 15 min | Boil | Pellet | 12 |

| Mosaic (HBC 369) | 17 g | 15 min | Boil | Pellet | 12.3 |

| Bru-1 | 28 g | 5 min | Boil | Pellet | 13 |

| Citra | 28 g | 5 min | Boil | Pellet | 12 |

| Mosaic (HBC 369) | 28 g | 5 min | Boil | Pellet | 12.3 |

| Bru-1 | 32 g | 0 min | Dry Hop | Pellet | 13 |

| Citra | 32 g | 0 min | Dry Hop | Pellet | 12 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| House (A01) | Imperial Yeast | 74% | 62°F - 70°F |

Notes

| Water Profile: Ca 50 | Mg 0 | Na 8 | SO4 75 | Cl 36 |

Download

| Download this recipe's BeerXML file |

After collecting the water, adjusting it to my desired profile, and turning on the element to heat it up, I weighed out and milled the grains.

With the water adequately heated, I stirred in the grist then checked the mash temperature.

I let the mash rest for 60 minutes, stirring intermittently.

During the mash rest, I weighed out the kettle hop additions.

When the mash was complete, I lautered and collected the sweet wort in my kettle.

I then boiled the wort for 60 minutes, adding hops at the times stated in the recipe.

When the boil was complete, I quickly chilled the wort with my immersion chiller.

A refractometer reading showed the wort was right at the expected OG.

The wort was than equally split between two sanitized Ss Brewtech Brew Buckets.

The fermenters were connected to my glycol system and left to finish chilling to my desired fermentation temperature of 66°F/19°C before I pitched a pouch of Imperial Yeast A01 House into each.

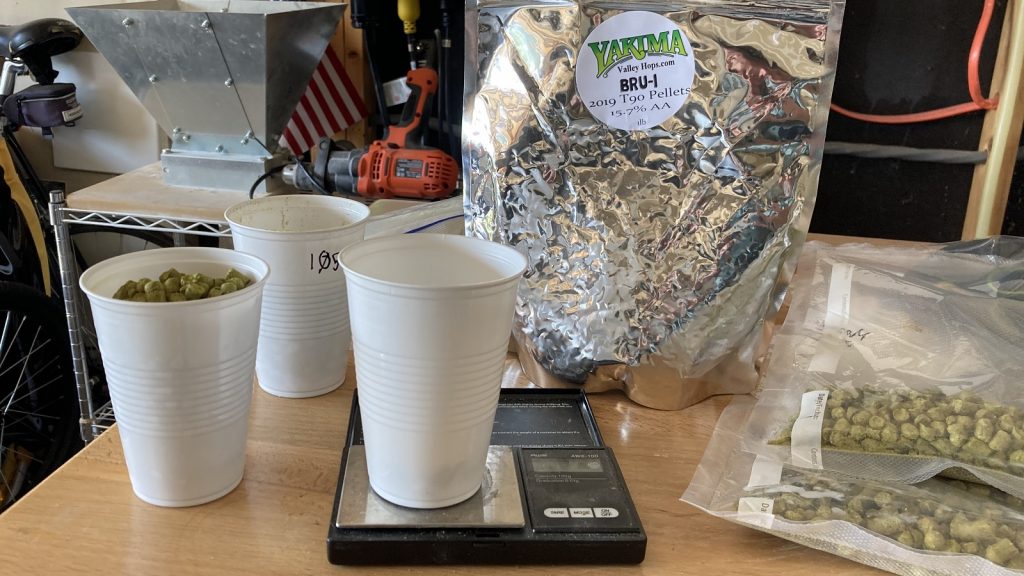

At this point, I weighed out a dry hop charge and tossed it into one of the batches.

The following day, both batches were fermenting actively and continued similarly. With signs of activity slowing 4 days into fermentation, I added the dry hops to the other batch of beer. After another 3 days, I took hydrometer measurements showing the beer dry hopped at yeast pitch finished 0.001 SG points lower than the beer dry hopped toward the end of fermentation.

I proceeded to pressure transfer the beers into sanitized and CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a few more days of conditioning, the beers were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer dry hopped at yeast pitch while the other set was filled with the beer dry hopped toward the end of fermentation. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I did so just 5 times (p=0.21), indicating my inability to reliably distinguish an IPA dry hopped at yeast pitch from one dry hopped toward the end of fermentation.

Prior to doing my series of triangle tests, I thought I perceived a slight difference between these beers, though once I was blind to what I was drinking, it became clear bias was at play. They tasted identical, which isn’t a bad thing, as I really enjoyed these beers. I’ve come to love the combination of Citra and Mosaic, and the addition of BRU-1 just further kicked up the fruitiness.

| DISCUSSION |

Without dry hopping, there would be no IPA, and while the method for adding hops to beer on the cold-side have adapted over the years, it’s generally advised to do so sometime after peak fermentation has been reached. In doing it this way, brewers avoid longer than necessary contact time between the hops and beer, which is said to impart undesirable vegetal or grassy characteristics, while ensuring optimal extraction of hop oils. Interestingly, I was unable to reliably distinguish an IPA dry hopped at yeast pitch from one dry hopped toward the end of fermentation.

The fact these results corroborate those of a prior xBmt on this topic further suggests that the point at which dry hop additions are made may not have as much of a perceptible impact as is often believed. What’s fascinating to me is that this was secondarily a test of dry hop duration, as the batch dry hopped at yeast pitch was in contact with the hops for 3 days longer than one dry hopped toward the end of fermentation. While arguably minimal, the beer dry hopped at yeast pitch did finish 0.001 SG point lower than the standard dry hop beer, which made me wonder if hop creep may have been at play.

Despite these results, I’ll continue dry hopping toward the end of fermentation, or at high kräusen when making NEIPA, as this conventional approach has always worked fine for me. And honestly, tossing hops in at yeast pitch just feels weird. That said, for the brewer struggling with cold-side oxidation, this might be a good method to try as a way to eliminate a vector of oxygen exposure.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

14 thoughts on “exBEERiment | Dry Hop At Yeast Pitch vs. Standard Dry Hop In American IPA”

Of course you didn’t get it…. damned. it’s just 64 grams in 5,5 gallons!! It’s like not even dry hopping the beer!!! Come on!!

I heard somewhere that some yeast strains are able to ‘biotransform’ hop compounds to give flavour compounds typical of NEIPAs while other yeast strains are not. Not sure if that is true? I can’t find much to support it…

However, if it is true; is this a strain known for biotransformation?

Yes, this is true, but the yeasts with measurable effects are all wine yeasts. Scott Janish had played around with this but the small quantity of wine yeast you need would be hard to measure out at the homebrew scale, it’s like 5% of your yeast pitch.

With the contributors that have the ability to dump yeast/trub, has anyone played around with dry hopping on the yeast cake vs dumping yeast/trub before dry hopping? I’m curious about exploring the relationship between dry hopping and hop creep.

From the pic, the color looks quite different. Can you speak to that?

One is clearly in the shadow of the other…

I’ve just started to do this on my last two IPAs and I find it a great time saver.

I really appreciate these exbeeriments that debunk the homebrewing dogma… Keep up the good work.

Did you just toss the hops in or were they in a bag or hop spider?

I have been dry hopping at (or close to) yeast pitch for the last dozen IPA’s. I find it way easier to, as the infomercial says, “set it and forget it”. I actually find less grassiness on these over traditional dry hopping, even if I don’t get around to transferring to the secondary/keg until as much as 2 weeks! (Admittedly tho I don’t dry hop more than 2 or 3oz for 5 gal)

I believe that there is a dry hop quantity threshold where grassy notes are imperceptible or at least work well with some hop profiles.

There was a relative small amount of dry hops comparing to the hops added during the boil. I think this made the variable in test do not receive the brightness it deserves. Any way, good experiment. Thanks!

Since studies on dry hopping have shown that hop oils are completely extracted in under 24 hours, after which some aroma compounds actually start to get reabsorbed back into the hop detritus, it’s not surprising you didn’t see a difference between the two beers. At most, you might expect the aroma of the earlier dry hop to be slightly weaker.

Curious if these lasted long enough to notice any effects of oxidation? Wondering if the one hopped at yeast pitch would hold on any longer than the one that was popped open to dry hop later.

Any problems with this method if you’re bagging your dry hops? Would the bag get in the way of the yeast being able to do its work?

I ferment warm (~25-30C) and under pressure (proper pressure around 25-30PSI not just 15PSI, look up Dr Hans’ YT) which means my ales are often ready for cold crash after 2-3 days.

Hopping at yeast pitch is defs the easiest option for me and I have no complaints!