Author: Jake Huolihan

Fermentation is the seemingly magical, though scientifically understood, process whereby yeast metabolize sugar to produce both alcohol and CO2. While most brewers pay close attention to yeast pitch rate to ensure healthy fermentation, cell growth continues during the start of fermentation and requires the presence of oxygen, which is necessary for the production of sterols and unsaturated fatty acids.

A common method for many beginning brewers is to add oxygen to wort through agitation, either by racking from the kettle to the fermenter with vigor or shaking the fermenter, though a more advanced approach involves dosing wort with pure oxygen from a tank. Compared to the 8 ppm of oxygen that can result from simpler aeration methods, dosing wort with pure oxygen from a tank has been shown to leave the wort with upwards of 26 ppm of dissolved oxygen. However, it’s been claimed by some that a risk of dosing from a tank is over-oxygenation, which can purportedly lead to fusel alcohol development.

Despite numerous past xBmts showing oxygenation doesn’t seem to have much of an impact on beer, I’ve stuck to regularly dosing my wort with pure oxygen, typically for about 60 seconds at yeast pitch. Recently, I noticed a recommendation by Imperial Yeast to dose wort to 20-25 ppm oxygen when using A38 Juice, a popular strain among brewers of NEIPA. Curious to see what kind of impact this might have, I put it to the test.

| PURPOSE |

To evaluate the differences between a NEIPA dosed with no oxygen at yeast pitch and one dosed with pure oxygen over 4 minutes.

| METHODS |

The recipe for this xBmt was similar to other batches of NEIPA I’d made in the past– simple grist, lots of hops, and the Boddington’s yeast strain.

Astronaut

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 98.7 IBUs | 5.5 SRM | 1.058 | 1.014 | 5.8 % |

| Actuals | 1.058 | 1.014 | 5.8 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Genie Pale Malt (Root Shoot Malting) | 9.5 lbs | 66.96 |

| Wheat Malt | 3.75 lbs | 26.43 |

| Vienna Malt | 12 oz | 5.29 |

| Melanoidin | 3 oz | 1.32 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Experimental 04190 | 65 g | 60 min | Boil | Pellet | 3.4 |

| Nugget | 16 g | 60 min | Boil | Pellet | 13 |

| Bru-1 | 11 g | 30 min | Boil | Pellet | 13 |

| Citra | 11 g | 30 min | Boil | Pellet | 12 |

| Sabro | 11 g | 30 min | Boil | Pellet | 14 |

| Bru-1 | 21 g | 5 min | Boil | Pellet | 13 |

| Citra | 21 g | 5 min | Boil | Pellet | 12 |

| Sabro | 21 g | 5 min | Boil | Pellet | 14 |

| Bru-1 | 21 g | 3 days | Dry Hop | Pellet | 13 |

| Citra | 21 g | 3 days | Dry Hop | Pellet | 12 |

| Sabro | 21 g | 3 days | Dry Hop | Pellet | 14 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 74% | 64°F - 74°F |

Notes

| Water Profile: Ca 174 | Mg 0 | Na 8 | SO4 150 | Cl 200 |

Download

| Download this recipe's BeerXML file |

After collecting the water, adjusting it to my desired profile, and turning on the element to heat it up, I weighed out and milled the grains.

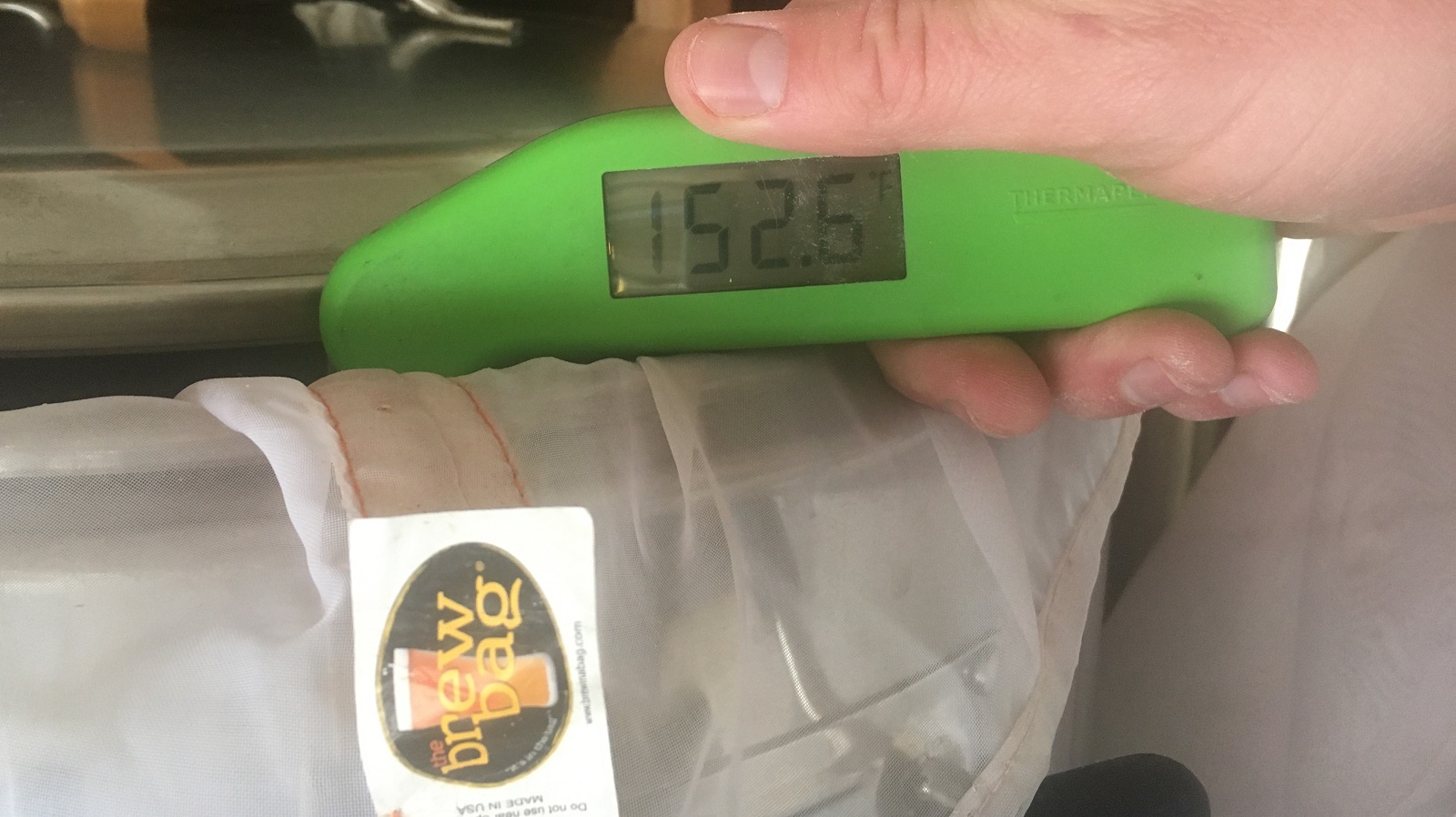

With the water adequately heated, I stirred in the grist then checked the mash temperature.

I let the mash rest for 60 minutes, stirring intermittently.

When the mash was completed, I lautered and collected the sweet wort in my kettle.

I then boiled the wort for 60 minutes, adding hops at the times stated in the recipe.

When the boil was complete, I quickly chilled the wort with my immersion chiller.

A refractometer reading showed the wort was right at the expected OG.

Identical volumes of wort were then racked to separate sanitized Ss Brewtech Brew Buckets, making sure to transfer over as little trub as possible given past xBmt results.

The fermenters were connected to my glycol system and left to finish chilling to my desired fermentation temperature of 66°F/19°C before I pitched a pouch of Imperial Yeast A38 Juice into each.

At this point, I hit one batch with 4 minutes of pure oxygen while the other was left alone.

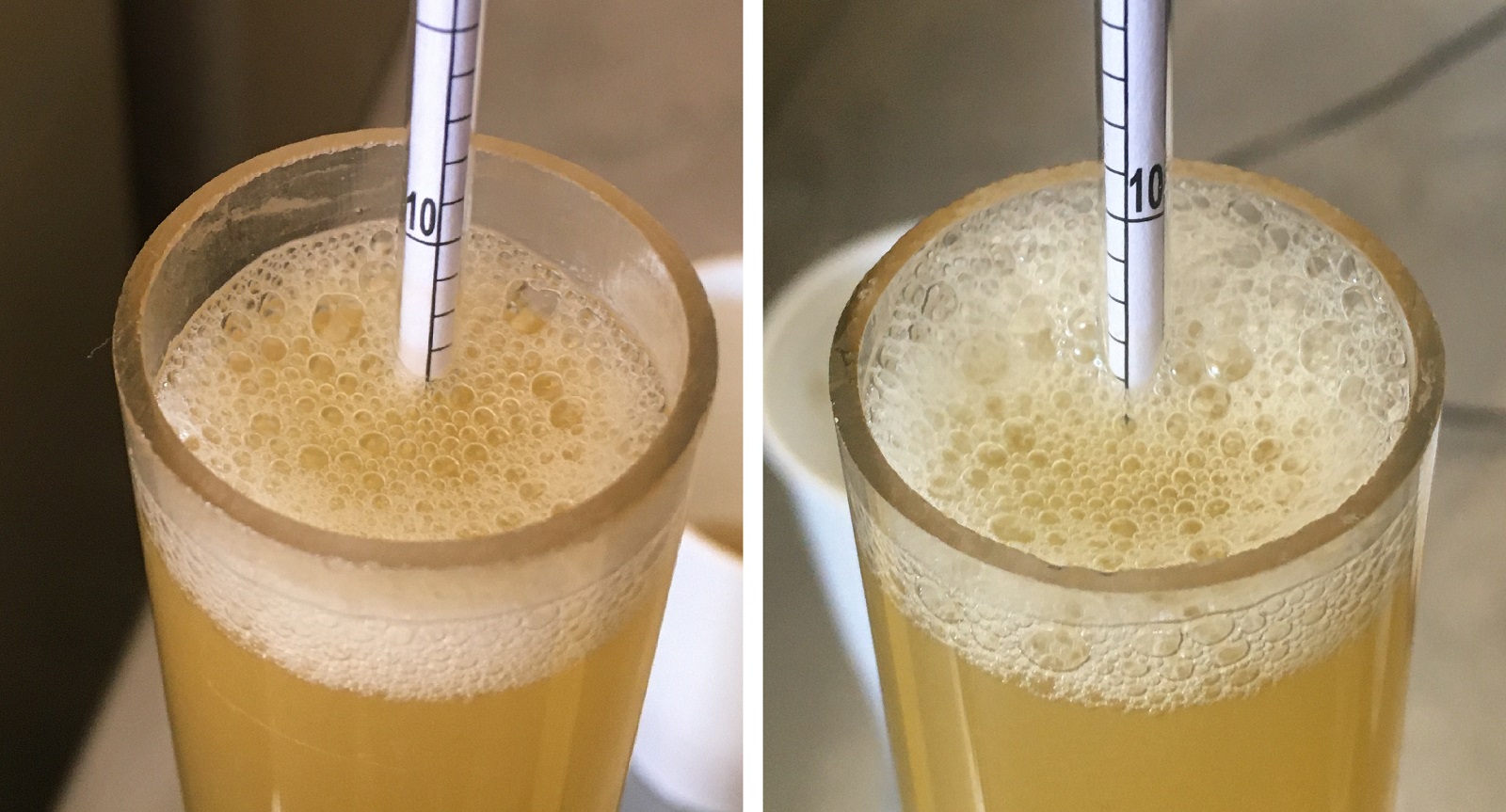

The following day, both batches were fermenting actively and continued similarly. I added the dry hop addition 4 days into fermentation and with signs of activity absent a 3 days later, I took hydrometer measurements indicating both beers were at the same FG.

I proceeded to pressure transfer the beers into sanitized and CO2 purged kegs.

The filled kegs were placed in my keezer and burst carbonated overnight before I reduced the gas to serving pressure. After a few more days of conditioning, the beers were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the non-oxygenated beer while the other set was filled with the beer dosed with pure oxygen for 4 minutes at yeast pitch. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I did so just 4 times (p=0.44), indicating my inability to reliably distinguish a NEIPA that was not oxygenated at yeast pitch from one that was hit with 4 minutes of pure oxygen at yeast pitch.

Outside of the fact these beers were perceptibly identical to me, they also tasted pretty great! I’ve brewed a few different IPA recipes of late in my attempt to get something close to Oskar Blues Can-O-Bliss, and this one really hit the mark for me.

| DISCUSSION |

The lag phase of fermentation lasts a few hours after pitch and is a time when the yeast uses oxygen to synthesize the sterols and unsaturated fatty acids necessary for growth. This lipid synthesis can be negatively impacted if the wort has too little oxygen, which can result in limited growth and consequent fermentation issues. However, it’s also been claimed too much oxygen can lead to undesirable fusel alcohols and other off-flavors. My inability to tell apart a NEIPA not dosed with oxygen from one dosed with 4 minutes of pure oxygen indicates the excess oxygenation had little if any perceptible impact, at least to my palate.

Given the statement by Imperial Yeast that A38 Juice benefits from higher levels of dissolved oxygen, I went into this xBmt fairly confident there’d be at least some differences. However, not only were the beers perceptibly identical to my palate, but the oxygenated and non-oxygenated batches fermented and attenuated similarly as well. There are a few potential explanations for this including yeast freshness (20 days old at time of pitch) and batch size, though it seems at least somewhat telling that these results corroborate a number of past xBmt on oxygenation.

Dosing beer with oxygen at yeast pitch is something I do as a matter of course, as I’ve engaged in this practice basically since I started brewing. While I find the results of this xBmt interesting, especially when viewed next to past xBmts on the same variable, I won’t be ditching my tank and wand anytime soon. Admittedly, this is most likely due to the difficulty I have breaking free from the jaws of dogma, though I tell myself it’s an easy way to reduce risk.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

19 thoughts on “exBEERiment | Wort Aeration: Impact Of Over-Oxygenation On A New England IPA”

Correct me if I’m wrong, but I believe the concern is leftover DO once the replication phase is over, causing premature staling.

However, I wonder if the CO2 produced from fermentation scrubs that leftover DO. If that’s true, I also wonder if over-oxygenation is still a concern to those that pressure ferment since that freed oxygen could then be reabsorbed.

Good stuff! Stale flavor takes time to develop. Try the forcing test and you will probably notice that overly oxygenated sample will taste less fresh. In the short run, there is no difference and your experience proved it!

The yeast takes up all the oxygen within minutes of pitching. If you run a DO test on fermenting beer it will be 0ppb.

As confirmed here, I’ve never seen oxidation ruin a beer because of O2 at yeast pitch. This is the golden window for O2 to be added bc yeast are about to enter the growth phase.

Where I HAVE seen O2 ruin a beer (neipa) is during whirlpool and after the growth phase. This leads me to conclude the two big factors besides presence of O2 is TIME and TEMP. Time for the oxidation reactions to occur and temp to accelerate those reaction. If you dosed the same O2 during the whirlpool and pitched yeast the next day… or after fermentation and have it a few weeks to stale, those beers will look and taste like SHT

At Bel Air Brewing, we never add O2 to the wort at pitching time. And all of our beers have been excellent (knock on wood!). But we do allow a good amount of agitation/aeration as the wort is racked into the fermenters.

+1 to this, confirmed at “My Basement Brewing” 😉

Interesting experiment but if the goal was to determine whether too much dissolved oxygen will have a negative effect then the appropriate approach would have been to compare overly oxygenated wort with normally oxygenated wort. As it stands, the lack of difference could be because both conditions (no oxygen/overly oxygenated) resulted in subpar beer or because oxygen makes no difference.

Just to clarify– goal was to see if an over-oxygenated NEIPA was distinguishable from a non-oxygenated version of the same NEIPA.

Well… I agree that is what you tested but why not design an experiment that will help people make better beer? If the goal is to identify those factors that lead to better beer then the control condition should be the standard approach, which is to provide normal oxygenation.

Because “better beer” is largely subjective. We figure people can use the info from our xBmts to make decisions for themselves.

But you may not have achieved the treatment of “too much oxygen” like you think you did. First, without measuring DO quantitatively, you have no idea what the levels were. Which is fine, I get that the intention is to manipulate the independent variable under “typical” homebrewer conditions. Very reasonable.

But more importantly, the levels may not have been as different as you think, because in this experiment, your O2 addition from the tank depends massively on how far you open that regulator (I use the exact same setup).

Contrary to popular belief, molecular oxygen doesn’t really like to dissolve much in aqueous solution. So, with this particular oxygenating setup, how much O2 gets dissolved is largely a function of how much the regulator was opened. And ironically (to non-scientists at least), the more you open that regulator, the less O2 gets dissolved. Any bubbles rising to the surface is oxygen that does NOT dissolve in solution. When you open the regulator a lot, it’s like an oxygen hottub—lots of bubbles. That’s bad. It’s all just off-gassing into the air. What you want is a very, very fine mist of bubbles coming out of that O2 stone, and you don’t want these bubbles reaching the surface, because that means the O2 is dissolving before it can gas off into the headspace.

Sounds pedantic, I know, but long story short, we don’t know how much O2 actually dissolved into the wort for use by the yeast.

Yeast companies deliver fresh pitches with the yeast in the most robust condition possible, i.e. full of the sterols and nutrients needed for growth. Its subsequent generations where lack of O2 becomes and issue. I’ve seen Juice start to crap out with just normal O2 (12ppm). If you wan’t to reuse that pitch a few times, definitely hit it with heavy oxygen.

Good stuff. I don’t want to worry about another piece of equipment to add oxygen so I’m glad this didn’t provide evidence that I should add one.

I’ll keep carrying my carboy to the fermentation chamber (down 4 flights of stairs) and let it agitate along the way. Only downside is it needs to come back up those 4 flights to get into the keg!

I’ve kind of wondered as well if there’s a limit to the amount of O2 you can actually dissolve into the wort. I know that I’ve read in the old literature that shaking creates some amount of DO in the wort. And I’ve also seen the old charts that show that about 1 minute of exposure to pure O2 generates something like 8 ppm of DO, which is supposedly some kind of sweet spot. I’d be curious to know if there is simply an upper limit to the amount of O2 a volume of liquid at a certain density can absorb. FWIW I used hit my lagers with 2 doses of O2. Once at pitch and then again 12-24 hours later to give the yeast additional O2 for growth in the cold environment.

It would be interesting to measure the DO with various techniques. Shaking, stone etc. A cursory search seems to show those meters are expensive though. Is that something Brulosophy has done? I currently use an immersion blender with the beater attachment (i.e. like making whipped cream). Seems to work fairly well in the sense that my beers seem ok and take off quickly and ferment heartily.

You say “making sure to transfer over as little trub as possible given past xBmt results.” but that links to an xBmt where the tasters did not find signficance, and Marshall had a (seemingly strong) preference for the high-trub beer.

Yeah, i read that too, some time ago, so why bother? Why even mention it?

This experiment indicates to me that there is little/no need to be oxygenating your wort to assist in fermentation. Find it odd you plan to continue the “dogma”, as there was no percieved improvment in time to ferment, your FGs were identical, and ultimately no difference in taste. The hobby to me is all about keeping it as simple as possible, so this is just another feather in the cap of those, like me, who sort of raise eyebrows at expansive systems providing little to no improved results, rather just prolonging brew day.

For this experiment, i would suggest however that it might be worth sanpling both beers after perhaps 6, 8 or10 weeks, and seeing how fresh that oxygenated NEIPA is over the standard.

I wish you would have kept a little bit of these around for a second round of tests after six weeks – not that I question the results, but because I wonder if a difference would have started to expose itself after that long (and six weeks is probably the longest you’d want a NEIPA in a keg).