Author: Jake Huolihan

Oxidation of beer is something commercial brewers have been concerned with since distribution became a thing, as any exposure to oxygen on the cold-side is known to rapidly deteriorate quality and thus reduce shelf-life. Recently, it seems homebrewers have grown increasingly concerned about cold-side oxidation as well, which has led to the development of certain practices to keep this bogeyman at bay.

The point at which beer is most likely to come into contact with oxygen is during the packaging process, when it’s moved from one vessel to another. While the use of chemicals to mitigate oxidation seems to be gaining popularity, a more common approach involves transferring beer to kegs purged of oxygen with CO2.

I started kegging a few years and initially worried little about cold-side oxidation, usually placing the end of some tubing at the bottom of an open and non-purged keg before starting the flow of beer. My experience was positive enough that I kept brewing, but the mounting evidence against oxygen eventually motivated me to change my ways. I was recently reminded of one of our first xBmts on cold-side oxidation where a Pale Ale racked to a closed keg was indistinguishable from one racked vigorously to an open keg, and it occurred to me this lack of a difference may have been due to the fact neither had been purged with CO2. Curious to see if this simple practice might have a noticeable impact on a pale lager, I tested it out again.

| PURPOSE |

To evaluate the differences between a pale lager transferred to a keg purged with CO2 and one transferred vigorously to a non-purged and open keg.

| METHODS |

Pale lagers are often described as delicate and offering little for off-flavors to hind behind, making it the perfect style for this xBmt

Splish, Splash

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 62.6 IBUs | 5.3 SRM | 1.055 | 1.010 | 5.9 % |

| Actuals | 1.055 | 1.008 | 6.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Odyssey Pilsner | 12.625 lbs | 95.28 |

| Melanoidin (Weyermann) | 7 oz | 3.3 |

| Carahell (Weyermann) | 3 oz | 1.42 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 28 g | 60 min | Boil | Pellet | 14 |

| Tettnang | 33 g | 30 min | Boil | Pellet | 4.5 |

| Tettnang | 41 g | 10 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 61 | Mg 0 | Na 8 | SO4 75 | Cl 55 |

Download

| Download this recipe's BeerXML file |

After collecting the water, adjusting it to my desired profile, and turning on the element to heat it up, I weighed out and milled the grains.

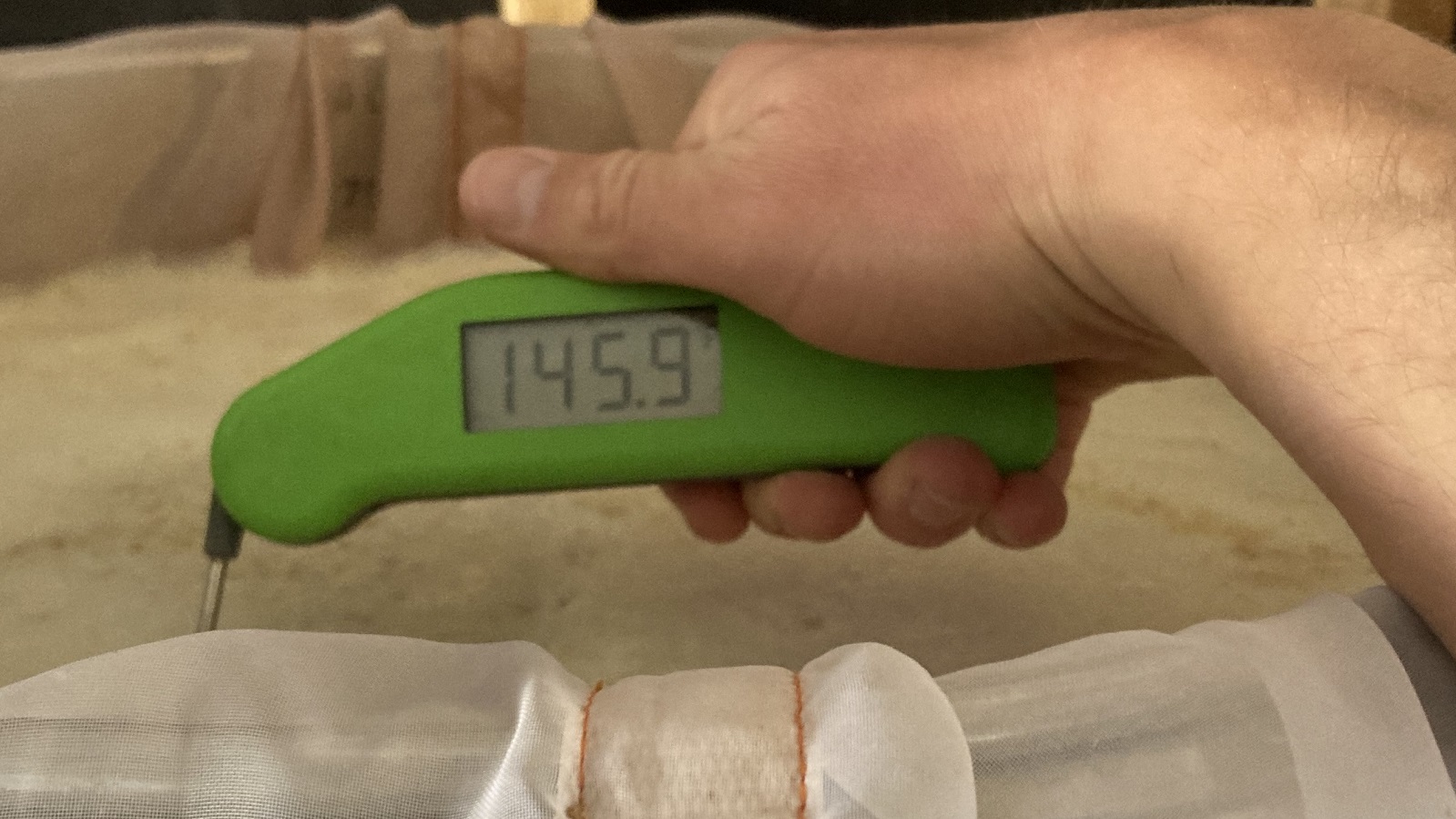

With the water adequately heated, I stirred in the grist then checked the mash temperature, which ended up being a bit lower than expected. Meh.

I let the mash rest for 60 minutes, stirring intermittently.

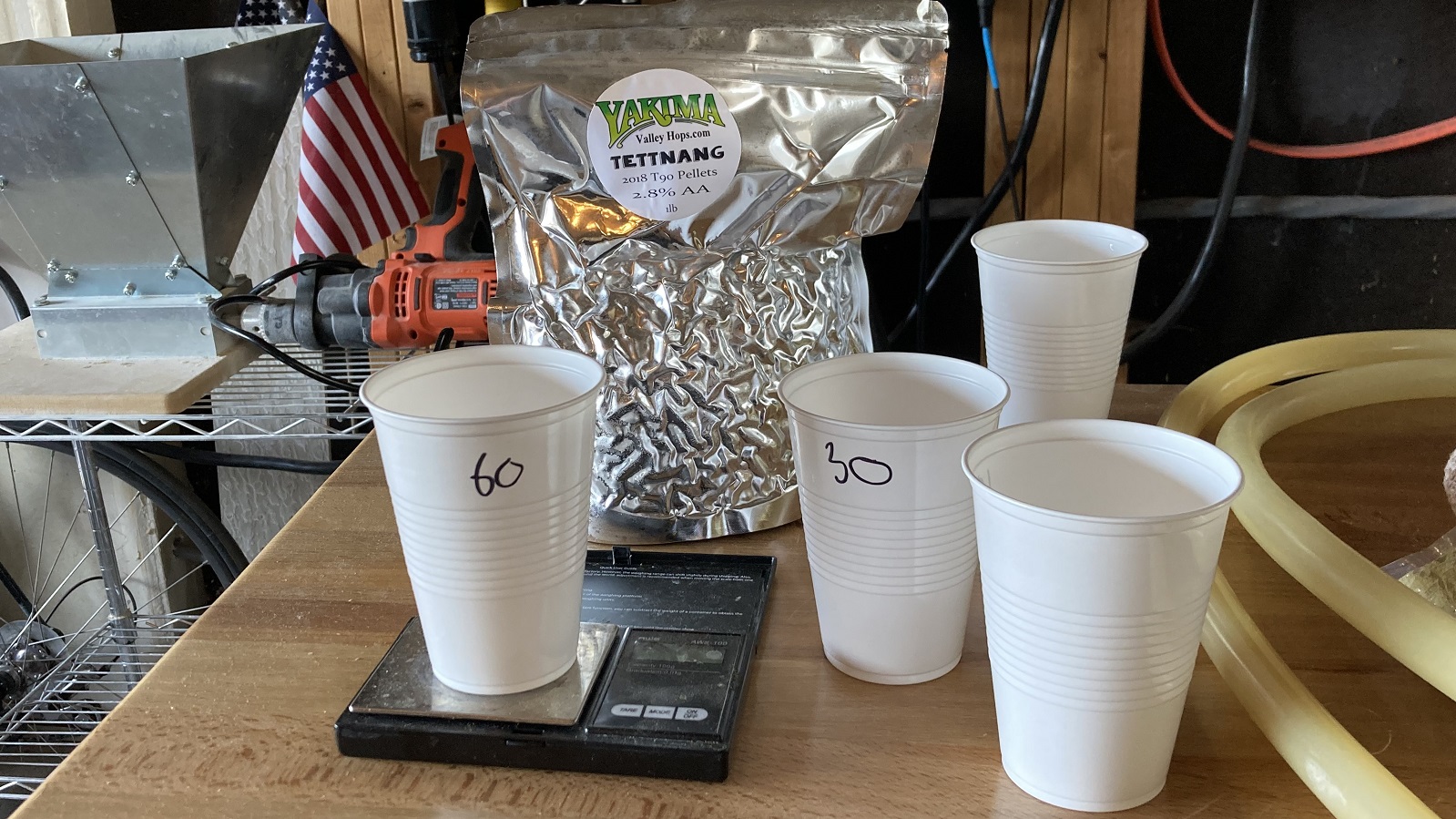

While lautering, I weighed out the kettle hop additions.

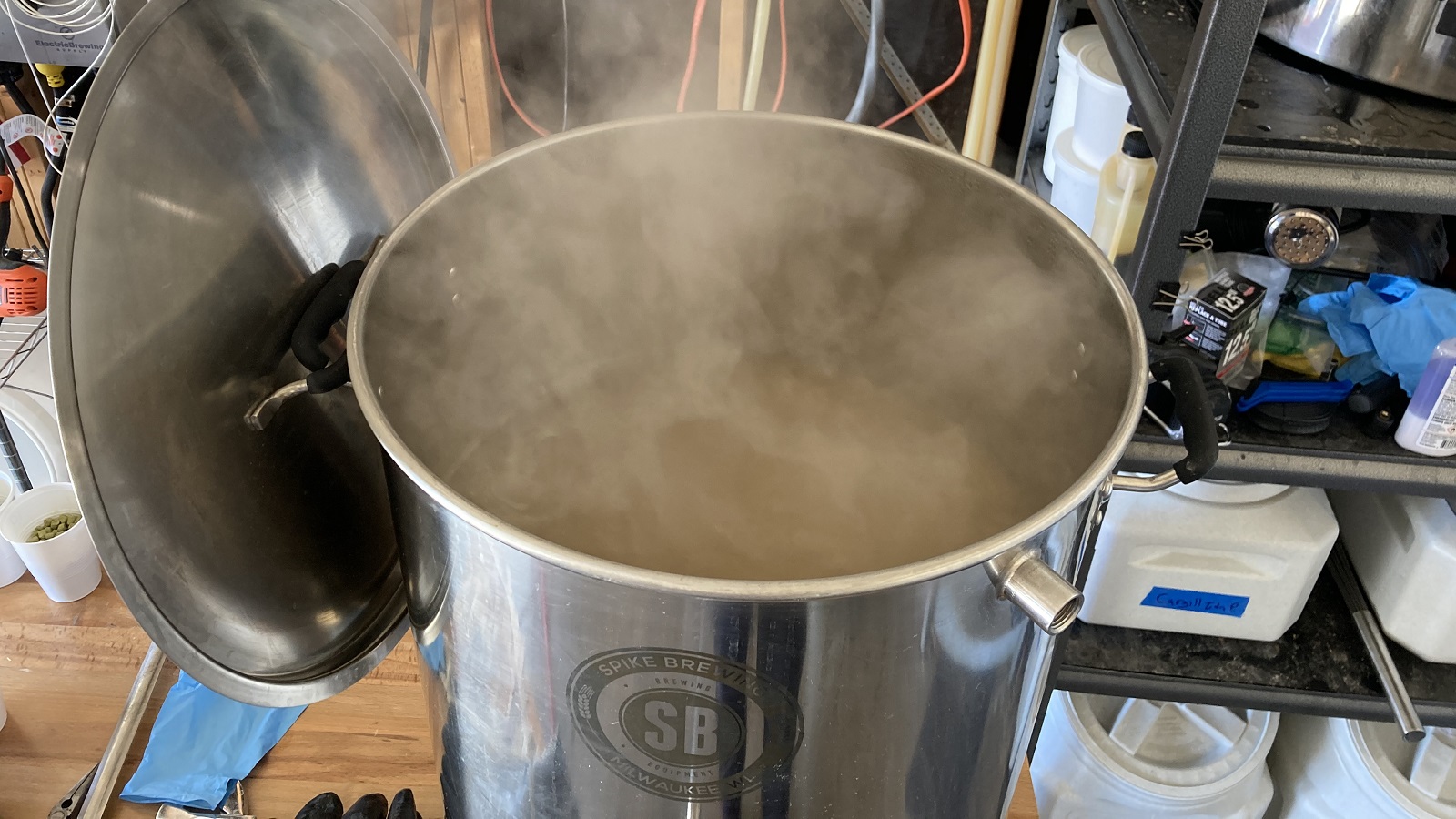

I then boiled the wort for 60 minutes, adding hops at the times stated in the recipe.

When the boil was complete, I quickly chilled the wort with my immersion chiller.

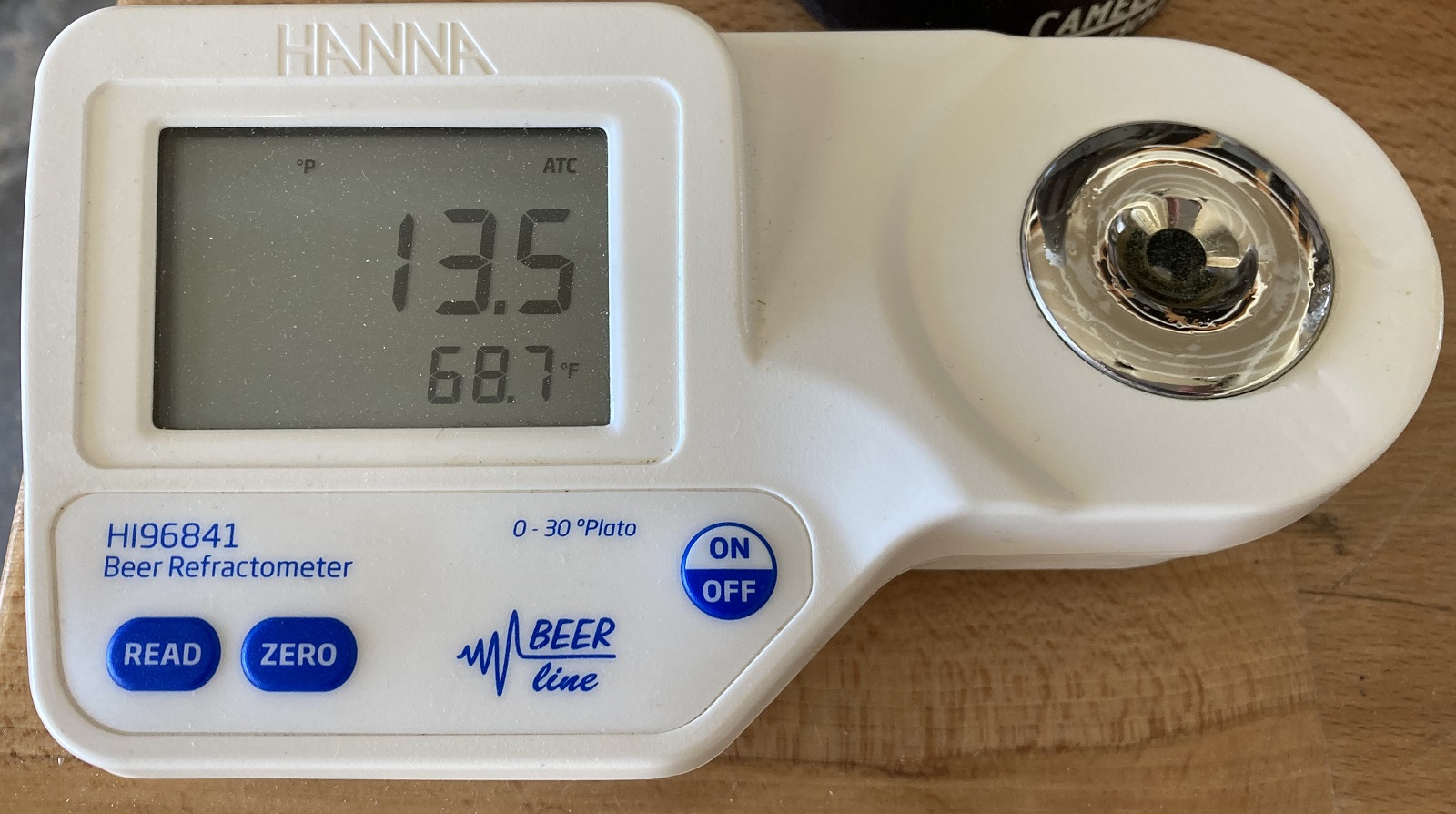

A refractometer reading showed the wort was right at the expected OG.

Identical volumes of wort were racked to separate sanitized Ss Brewtech Brew Buckets.

The fermenters were connected to my glycol system and left to finish chilling to my desired fermentation temperature of 50°F/10°C before I pitched a pouch of Imperial Yeast L17 Harvest into each.

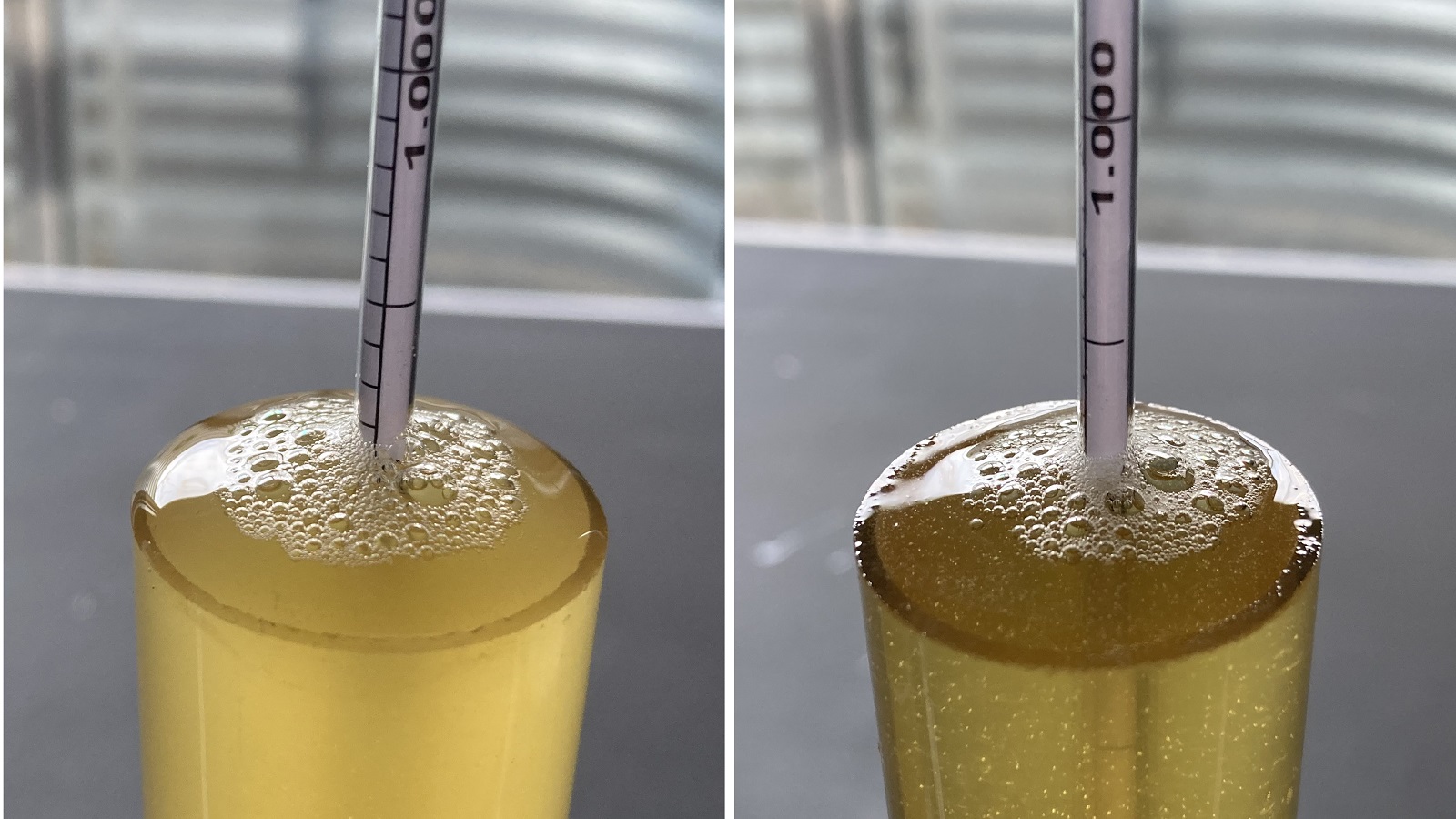

After 2 weeks, I raised the temperature of beers to 58°F/14°C and left them alone for another 2 weeks before taking hydrometer measurements confirming both reached the same FG.

After sanitizing two kegs, I purged one of oxygen by pushing sanitizer solution out with CO2 before transferring the beer in; the other keg was not purged, the lid remained open, and the racking tube was short enough to allow for a decent amount of splashing while being filled.

The filled kegs were placed next to each other in my keezer where they were burst carbonated overnight before I reduced the gas to serving pressure. After a couple weeks of lagering, the beers were ready for evaluation.

| RESULTS |

Due to social distancing practices as a result of the COVID-19 pandemic, data for this xBmt was unable to be collected in our typical manner. As such, temporary adaptations were made involving the author completing multiple semi-blind triangle tests in as unbiased a way as possible.

Utilizing 4 opaque cups of the same color where 2 were inconspicuously marked, one set was filled with the beer racked to a purged keg while the other set was filled with the beer racked to an open and non-purged keg. For each triangle test, 3 of the 4 cups were indiscriminately selected, thus randomizing which beer was the unique sample for each trial. Following each attempt, I noted whether I was correct in identifying the unique sample. Out of the 10 semi-blind triangle tests I completed, I needed to identify the unique sample 7 times (p<0.05) in order to reach statistical significance, though I did so just 5 times (p=0.21), indicating my inability to reliably distinguish a pale lager transferred to a closed keg purged of oxygen from one racked to an open and non-purged keg.

These beers were identical in every way to me, I honestly just guessed in each triangle test I attempted. I definitely expected the batch transferred vigorously to a non-purged keg to have the telltale signs of oxidative staling, but I was quite pleased that wasn’t the case, as both beers were wonderful. Light bready notes with a subtle hint of sulfur and a well rounded spicy bite from the Tettnanger hops. This is a beer I know well and love, I’ll definitely be brewing it many more times in the future.

| DISCUSSION |

It’s well known that beer stales and that cold-side oxygen exposure expedites the staling process, hence the effort many brewers invest in keeping oxidation at bay, whether through chemical or mechanical means. While closed transfers to kegs purged of oxygen with CO2 is a common method for reducing the risk of oxidation, I was unable to tell apart a pale lager kegged in such a manner from one that was vigorously transferred to an open and non-purged.

There’s ample evidence that certain styles, particularly hazy NEIPA, are especially sensitive to oxygen, which has led to speculation that higher hopping rates and the use of flaked adjunct contribute to this sensitivity. It’s possible the lack of either in my pale lager recipe explains my failure to distinguish between these pale lagers, though concerns of oxidation have been around a lot longer than NEIPA. The negative signs of oxidation are believed by many to occur quite rapidly, but perhaps this isn’t so for simpler styles and they would have been more noticeably different if I’d waited longer to evaluate them.

I couldn’t care less that the beers in the xBmt tasted identical to me, I have zero plans to start splashing my beer into open kegs that haven’t been purged of oxygen. Maybe certain styles are more sensitive to oxidation, it certainly seems that way, but I care enough about the quality of my beer to invest the few minutes it takes to purge a keg.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

12 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Of Transferring A Pale Lager To A Non-Purged Keg”

I think using a malty beer like this will show less cold side oxidation effects as the malt oxidation occurs at milling or mash in unless 1ppm DO can be achieved.

I think only most fermentation flavours such as dry hop are effected by oxidation in this setup.

Look up the low oxygen brewing website.

Interested to know how long “a couple weeks of lagering” is. I would think aging would show the effects more. But glad to see these results as I have been cutting back on CO2 use during pandemic. Also, natural carbonating a keg could scrub O2.

I’ve experienced oxidation damage after a month or more of storage, so I wonder if it takes some time to occur. I’d be interested in the results of repeating this test a month after brewing.

Were shelf-life and storage temperature factors? Commercial kegs get stored at room temp and are consumed ‘older’ while homebrewers keep their kegs cold and consume them fresher. This xbmt might show that oxidation of non-hoppy styles is not relevant for homebrewers (who do not have to worry about extended warm storage)?

interesting. looks like your actual OG was the same as your predicted with the 147F mash. So your extraction efficiency was the same in the mash at that lower temp?

Curious how long you lagered because you only said ‘a couple of weeks’. I would assume as others have mentioned that a lager won’t stale as fast as an IPA (aroma goes first). I’ve done both methods in my 10 years of brewing and never had issues. My belief is the DO was low enough that it never had enough time to stale because the keg was kicked within 2 months of kegging. The only issue I’ve had is when submitting beers to a competition and the handling of the entries by the drop-off location caused oxidation to accelerate (heat acts as an accelerant). I had this issue with a NEIPA that was judged (said it was purple upon pouring), but I filled another bottle and gave to the judge a week later and it was not purple).

I rarely purge my kegs unless it’s a hoppy style, but I do fill through the liquid out and release pressure via the prv. For my own personal consumption this seems to be good enough with no detriments that I can tell. It gets put into the kegerator and purged/ on gas right after being kegged.

As a side note, the pic of the closed transfer has a gas disconnect that appears to be engaged and open. If you run a hose from that back to the fermenter (either to a weldless post or just sticking a tube onto the airlock), that will completely close the loop and the pressure from the keg will aid in pushing out the beer from the fermenter. Just a thought.

Genius. I used this in my set and it worked perfectly. Thanks.

Great experiment with interesting results. The cold-side oxygen exposure experiments seem to yield conflicting answers, so I’m still curious to nail down what exactly is going on. One thing I was curious about was whether the dissolved co2 level inside the beer during transfer might actually have an effect. I use a pressurizable conical, and usually use the fermentation process to purge one keg. I brew 10 – 14 gallon batches, though, so usually I will purge one keg and not purge the other, and will give the second keg to my dad. Since the conical is pressurizable, I will actually carbonate the beer in the conical before transfer. I would be really curious to know if the carbonated beer is protected from oxygenation since the co2 is knocked out of solution and purges the keg as it is filling. In other words, is transferring carbonated beer different from transferring uncarbonated beer?

I would be curious if an experiment was able to be conducted under similar conditions but the beers were left to sit for 6 months and a second tasting conducted.

I think cold crashing is when beer is most likely to get oxidized, if you don’t have it perfectly sealed and suck back is not handled very well. I was using a mylar balloon for a while and could never be completely sure everything was air tight and I was having oxygen issues. I changed my process to eliminate cold crashing except to get it down in the 30s to carbonate after kegging (attaching CO2 at 2psi until it reached the 30s and then cranking it up to 30psi for 36 hours). Oxygen problems went away and the beers have been the best I’ve ever made.