Author: Marshall Schott

Back in September 2017, I published the results of an xBmt I performed comparing a New England IPA packaged in a manner to reduce cold-side oxygen exposure to one packaged with less rigorous methods. Up to that point, I’d been highly skeptical of the concerns many voiced about the perils of cold-side oxidation, in part because I’d racked hundreds of batches of beer to non-purged kegs that ended up being perfectly fine, at least in my anecdotal experience. However, as stubborn as my wife may say I am, both the results of that xBmt and my own evaluation of those beers had an impact.

Cold-side oxidation sucks.

I adopted the perspective that, even if past batches of beer were subjectively incredible, minimizing oxygen exposure on the cold-side was one way to reduce the risk of something potentially going wrong. After determining one of the main vectors of cold-side oxidation in my process was packaging, I began purging my kegs by using CO2 from a tank to push sanitizer out, a method used by many.

Based on my years of kegging, I reckoned I could purge about 15 kegs off of a single 10 lb/4.5 kg tank and accepted the cost of gas was worth the benefits of better beer. Then I blew through 30 lbs/13.5 kg of CO2, an amount that would usually last me half a year or longer, in just 2 months and spent $100 to fill those tanks up. A bit of simple math told me that my newfound zealotry would end up costing 3 times more than my previous ways.

Cold-side oxidation sucks, indeed, but so does spending $600 per year on CO2. I wasn’t prepared to kick keg purging to the curb, so I began brainstorming ideas for reducing the risk of oxidation without breaking the bank. I was very well aware of the fact fermentation produces a rather large amount of CO2, which typically flows through an airlock or blowoff tube and into the environment. I wondered if it might be possible to use that naturally produced gas instead of store-bought CO2 to purge kegs and discovered that, yes, it could be done very simply with various types of fermentation vessels.

USING CO2 FROM FERMENTATION TO PURGE SERVING KEGS

While I’d been curious about whether or not CO2 produced during fermentation could be used to push sanitizer out of a serving keg for a couple years, I only decided to try it out in May 2019 after I started using the Spike Brewing FLEX+ fermenter.

SPIKE BREWING FLEX+

When Spike Brewing announced their new FLEX line of fermentation vessels, I found immediately appealing the fact the higher end FLEX+ could hold up to 15 psi. Not because I’m interested in pressurized fermentation or carbonating in the fermenter, but rather it seemed more than enough to push 5 gallons/19 liters of liquid out of a serving keg (I’ve since learned it’s way more than enough… more on that in a bit). With my FLEX+, I received the optional gas manifold, which has a pressure gauge, a PRV, and a ball lock gas post. Useful for fermenting and transferring beer under pressure, it would also work great for my intended purposes

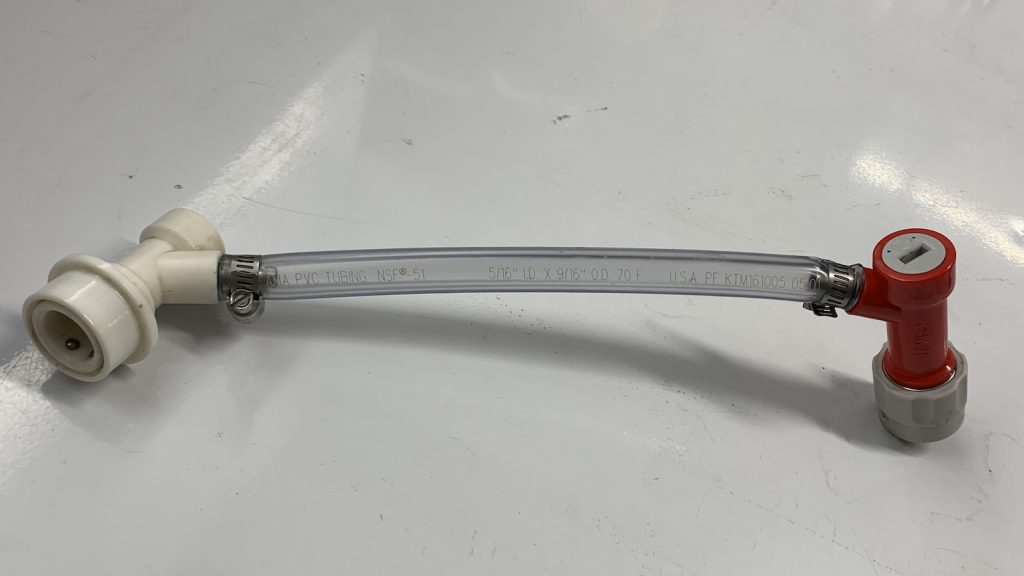

For the gas created during fermentation to leave the vessel, I fashioned a gas jumper hose out 5/16″ tubing, connecting a ball lock gas disconnect to one end and a pin lock gas disconnect to the other (because I use pin lock kegs).

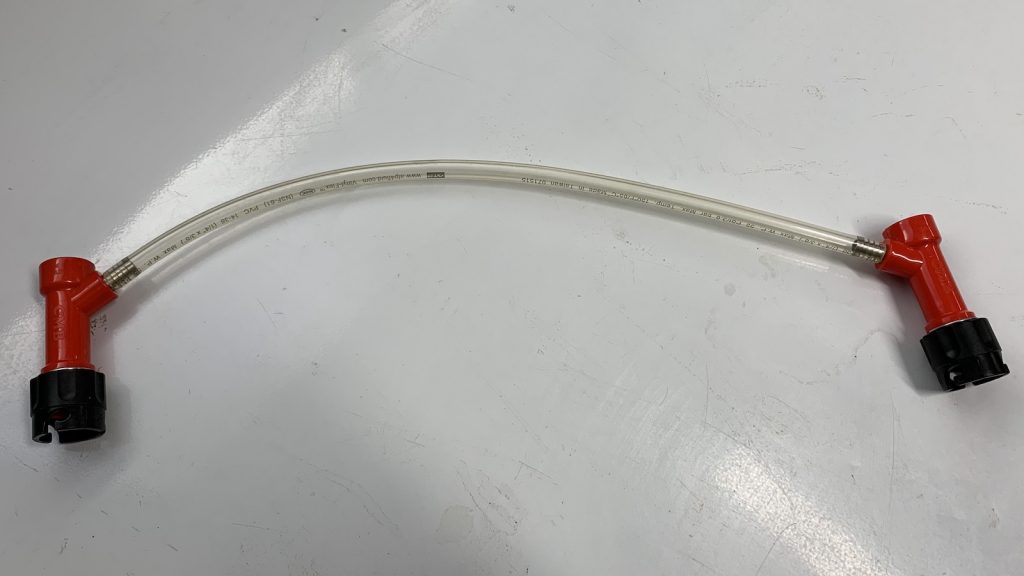

In order for the sanitizer in the serving keg to flow into the secondary keg, I use a liquid jumper hose made of 3/16″ beverage line and 2 liquid disconnects.

That’s it! After pitching the yeast, I make sure to seal every tri-clamp on the FLEX+ very well before connecting the gas jumper from the gas post on the fermenter to the gas post on the keg. Then, I connect the liquid jumper from the liquid post on the serving keg to the liquid post on the secondary keg. Finally, I connect a pin lock depressor (an extra gas disconnect works fine) to the gas post on the secondary keg to allow the air to escape– this part is very important!

I’ve used this setup many times to successfully purge a serving keg of oxygen and it works beautifully. Curious as to just how much pressure is needed to push liquid out of one keg and into another, I tested it out with a tank of CO2 and found it’s around 1.5 psi, which to me meant a similar rig would probably work with other fermenters that have lower pressure ratings. Moreover, while the Spike Brewing gas manifold provides some convenience, the standard barbed elbow would certainly work just as well so long as the gas tubing is secured to it tightly enough.

SS BREWTECH BREW BUCKET

I’ve been using Ss Brewtech Brew Buckets for over 4 years and love their combination of functionality, simplicity, and durability. With a pressure rating of just 2-3 psi, I was initially concerned I wouldn’t be able to use my Brew Buckets to naturally purge serving kegs, but after the previously mentioned test, I was confident enough to try it out. I started off by purchasing a weldless gas ball lock post that attaches to the hole in the Brew Bucket lid.

I noticed the bulkhead was quite a bit smaller than the hole on the lid, which led to some concern it wouldn’t seal tight enough, but it ended up not being an issue at all. With this piece in place, the process was exactly the same as for the FLEX+, simply connect the jumper hoses to the proper posts, make sure some form of pressure relief is attached to the gas post of the secondary keg, and purge away!

With just a few extra parts, it’s easy as pie to purge a serving keg with CO2 produced during fermentation in a Brew Bucket. I thought maybe the pressure would build up enough to where I’d notice some gas leaking out from under the lid, but nope, that hasn’t been the case over numerous batches.

With just a few extra parts, it’s easy as pie to purge a serving keg with CO2 produced during fermentation in a Brew Bucket. I thought maybe the pressure would build up enough to where I’d notice some gas leaking out from under the lid, but nope, that hasn’t been the case over numerous batches.

PET Carboy

Prior to moving to stainless fermenters, I was all-in on inexpensive 6 gallon/23 liter PET carboys that won’t sever a limb if dropped. For years, I used these vessels exclusively and continue to ferment fruited hard cider in them. Understanding how common such fermenters are, I thought it’d be good to see if I could figure out a way to use one to purge a serving keg of oxygen. Having experienced bunged airlocks popping off of carboys many times, I opted to use a cheap carboy cap because it seemed to form a better seal.

I left the white cap attached to the taller of the two openings, crossing my fingers any pressure build-up during fermentation wouldn’t force it off. In order to attach gas tubing to the carboy cap, I repurporsed the barb from an old keg disconnect, forcing it through the bottom of the cap and securing it with a worm clamp. Any number of sturdy hollow tubes (like the end of an old racking cane) would work fine.

Next, I attached one end of a 5/16″ hose to the barb in the carboy cap, while the other end of the hose was connected to a gas disconnect.

Once everything was put together, I shared the following image with the Brülosophy crew and asked for their thoughts as to how it might work. The overwhelming opinion was that…

…it wouldn’t. There was a lot concern that the pressure required to push sanitizer out of the serving keg was higher than that needed to pop the cap off of the carboy, and one contributor was convinced the little white cap would be the point of failure. I told them about my prior pressure test, I brought up the whole “path of least resistance” argument, I even placed the carboy cap around my mouth and blew as hard as I could without the white cap coming off. Ultimately, I knew nothing but actual evidence would suffice for this critical crew.

Thankfully, it works like a goddamn charm! Just as before, it’s imperative to relieve the pressure in the secondary keg during fermentation, otherwise the pressure will build-up enough in the carboy to push the cap off. I know because I forgot to do it once.

| The Verdict |

Over the last few months, I’ve published numerous articles that feature each of these natural CO2 purging rigs, and they consistently yield hundreds of requests to share how I do it. I was hesitant up-front because, frankly, it’s so incredibly simple that I felt like it wasn’t really worthy of an article. Once I was convinced otherwise, I wanted to make sure to cover a few common types of fermentation vessels, which is what ultimately motivated me to experiment with the Ss Brew Bucket and PET carboy. I’ve since used this method numerous times on all three fermenters and it works amazingly well, to the point I plan to purge serving kegs with naturally produced CO2 indefinitely.

Any issues I’ve had with using this method have been small and easy to fix, all due to user-error. For example, on more than one occasion I’ve failed to relieve the pressure from the secondary keg, which in addition to over-pressurizing the fermenter, will stop the flow of the sanitizer out of the serving keg. So, don’t forget! Other than that, the only problem has been crappy seals due to dry o-rings, which is why I make it a point to lube the keg post and lid o-rings every time.

One question I’ve received since I’ve been using this method has to do with whether or not the naturally produced CO2 impacts beer character differently than CO2 from a tank. Honestly, I don’t know, and while we do have an xBmt planned to test it out, I’m not convinced it matters at all. In fact, racking beer to a keg that was purged with the gas produced by said beer seems about as clean as it gets. I’m open to be proven wrong.

Note: it’s been brought to my attention others have been using a similar method as this, which while unaware of before this article published, was expected. I may have to come to this idea on my own, but I never claimed to invent it. Cheers to like-minded brewers!

If you have any thoughts about this DIY, please do not hesitate to share them in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

82 thoughts on “Using CO2 From Fermentation To Purge Serving Kegs | Do It Yourself”

Wait . . . was that a Miller Lite I saw in the lube pic ??

Gotta stay refreshed.

With the Flex+, do you ever have issues with krausen getting into the manifold? If you do, how do you resolve that when going to transfer to your keg? I’ve got the same setup and was hesitant for that reason. Cheers!

In many batches, I’ve not had this issue once. Not even close.

I have a flex+ and had the same concern, so I added a small valve between the manifold and gauge for “just in case”. I close the valve to the gauge during fermentation. Only do this to the gauge and not the safety valve. I also force carb in the flex+ and serve from it at first. Eventually it gets racked to a cold keg through a 3/16 20 ft line very slowly. The gas output of the receiving keg (which was liquid/CO2 purged) is fitted with a disconnect and hose that is in a bucket of starsan. I use the bubbles to gauge how fast the beer is moving through the line. As the receiving tank fills the back pressure will increase, so I gradually bump the psi up while watching the bubbles to manually regulate transfer velocity.

Deploy the recommended max batch size for the fermenter; i.e; 7 gallon fermenter- 5 gallons wort. Ample headspace will avoid yeast/trub in the blow off/purged keg.

Disregard…misread

Similar in method with one less keg I ferment in a keg (typically 3-4 gallons batches going into either a 3 or 5 gallon serving keg) and connect my gas in on the fermentation keg to the beer out on what becomes the serving keg and put a spunding valve set to 4-5psi on the gas in to the eventual serving keg. Assuming CO2 is denser than air (it is) I forgo the pushing of starsan and let the generated CO2 from fermentation push out any O2 from the eventual serving keg as well as giving it a head start on carbonating the beer (and typically close the spunding valve after 4-5 days and let it slog wly build to 1 atm/15psi at which time I’ve given the beer about half the carbonation it needs at serving temp (usually results in 7-8 psi at 38 degrees)…the I do a pressure transfer from the fermentation keg to the serving keg and haven’t had any issues using this method either. Great article….

Michael, I think the density difference between CO2 and O2 is completely insignificant. Your method would still work equally well even if O2 were the heavier gas because gases mix and you are diluting the concentration of one gas with another, not using a heavy gas to displace a light gas.

The point of starting with a keg filled with liquid is to begin with a very low quantity of O2. But as your experience indicates, even starting with a high quantity of O2 in the keg, the CO2 from fermentation will still displace (dilute) enough of that initial O2 to prevent cold-side oxidation from damaging the beer.

The gases in air do not stratify based on their densities; perhaps they might at cryogenic temperatures.

Life, I think you’re wrong. CO2 is absolutely heavier than the “O2” in air. There have even been suffocation deaths caused by volcanic emissions of CO2 many times in human history so CO2 does “sink.”

I think you’re referring to the fact (according to Boyle) that in an undisturbed, closed volume, gases will homogenize. But this process is adding CO2 continually, thus displacing/replacing the lighter O2.

Jim,

That is interesting about the eruptions, but don’t you think the asphyxiation was caused by the rapid increase in CO2 concentration relative to O2 concentration? In effect the volcanoes were purging the local air of O2 (by dilution, and not by pushing the O2 upwards).

The gas laws do explain this without requiring that gases have any difference in molecular weights! The O2 is replaced not because it is lighter, but because volume, temperature, and pressure are not increasing, while you are continually adding CO2. During the purging of the keg, the O2 and the CO2 exit together and the absolute quantity of O2 is reduced while the CO2 quantity is increased (because you are continually pushing it into the keg). The gases exit according to their relative concentrations, not according to their molecular weights. This is my understanding of the gas laws.

I’ve been doing this for a long time now, except I don’t push sanitizer out of the serving keg. I actually attach a spunding valve to the gas post to keep 2-3 psi of pressure on the fermenter, with the fermenter gas out connected to the liquid side of the keg. Towards the end of fermentation, I’ll raise the pressure by adjusting the spunding valve. I end up with somewhat carbonated beer, and a handy reservoir of pressurized CO2 for when I cold crash the fermenter.

This idea is genius! How did you ever think of such a clever idea? Wait .. wasn’t this posted like 3 years ago at HBT and discussed ever since on other forums as well?

Inspired by brulosophy I use this setup now also with my speidel fermenter. Only difference is toward the end of fermentation I’ll slap a spunding valve on the serving to hold a few psi so I can cold crash with it. The speidel also has a bottom spigot so I leave the fermenter to gas post jumper on during transfer with a hose from the spigot to the liquid post and have a gravity fed closed transfer. Works like a charm.

Awesome…This is the exact set up I am hoping to re-create… so just to confirm are you saying that once fermentation is complete and you start cold crashing the suck back that occurs simply pulls back some of the captured co2?

Silly question here. I like this idea but why not just sanitize the keg first, dump the sanitizer, seal it, and just have the CO2 push out the oxygen? CO2 is heavier so it should sit on the bottom and adding it to the dip tube seems like it would force the air on top out the gas tube.

Gases mix.

https://www.homebrewtalk.com/threads/keg-purging-with-active-fermentation.628658/

Gases mix, but this thread someone broke down the amount of co2 produced should be enough to dilute the oxygen and purge it down to very very small amounts. Very interesting read but very heavy on the math.

yeah, many of us just purge an empty keg throughout fermentation, and it seems to work very well. as has been said, it is best to connect the gas out post on the fermentation vessel to the beer out post on the serving keg if you are doing this so that the CO2 comes in through the bottom of the keg and purges the air up and out of the keg. i also, put on a blowoff tube the for first day or two to make sure there is no blowoff and then connect to the keg with the jumper.

Theoretically there is some level of turbulence and mixing. If you just assume that CO2 is heavier than air, there is a reasonable chance that ppm(ppb?) of O2 will remaining in the initial keg. By pushing out the star san you are only allowing the gas from fermentation to remain and it isnt just theoretical. If we are this concerned about cold side oxidation that we are purging lines and kegs to this degree, we should go the full mile and make sure there isnt any mixing as the author is doing

Mixing with what air/oxygen?

Marshall, I have seen pictures of beers and wine fermented in plastic buckets where the air lock clogged from krausen and cause a huge mess when the lid finally popped of the bucket. I am guessing this is far more pressure that 1.5 psi. Do you think a plastic bucket could be used in this method?

I think it could if the lid is sealed well and you’re able to figure out a way to keep the airlock bung secured— maybe a bung on either side of the lid?

I’ve adopted the method with both my plastic buckets and pet carboys with out any noticed leakage. I use an old air lock with a length of tubing stuck in a rubber stopper in both cases. My lastblast was fermented in a bucket and I purged 7 kegs on the one fermentation. The lid doesn’t have a rubber seal, so some co2 may have leaked but I don’t think it matters if sanitizer is being pushed.

I’ve read that silicone tubing is not recommended for this purpose because of o2 penetration. Before I learned this, I have been using this process since seeing it done on this website. I have a Spike conical with a Blichmann tri-clamp spunding valve and 1/2” silicone tubing blow off and keg jumper tubing. I haven’t noticed any signs of cold side oxidation over several batches. Is this something to be concerned about? If so, is there a particular tubing material you would suggest? It seems that “gas line” tubing is only offered in smaller ID and not large enough to fit over the 1/2” blowoff fitting.

I’m not concerned about it.

How does krausen impact the pressure manifold on the Flex+? I’ve thought about doing the same with mine, but was worried krausen might get into places it shouldn’t with that.

It’s large enough that I’ve never had an issue with kräusen.

Head pressure keeps the krausen down. I maintain about 6-8 psi in my conical during fermentation on my NEIPA’s using London Ale III which for me has always produced a fast and very active fermentation. While I cannot see the inside, during cleanout, the krausen line never gets close to the spunding valve attachment. This is based on 5.5 gallons in a Spike CF-5.

Using this method, I’ve found that all of the sanitizer doesn’t purge from the serving keg. Do you leave the sanitizer and If not how do you completely empty the serving keg before transfer?

It could be that my legs/dip tubes are different, but there’s nothing but a few drops left when I use this method. I don’t open keg at all after it’s been purged.

Cut off your gas in dip post so it is flush or above the keg top surface. Then u can invert the keg and drain sanitizer out of the gas in connector

Good idea. I already cut all my dip tubes like this so I could fill the serving kegs all the way with sanitizer. I just leave the tiny bit of sanitizer with no issue but damn this would be such an easy step to add

Thanks Aaron but all my serving kegs have Sankey couplers 🙁

I use “brewing liquor”-filtered water that I’ve dropped the alkalinity w H3 PO4 & add some K2 S2 O5, so a little bit left in the corny is fine by me.

Thanks, can you please be a little more detailed with your brewing liquor? I’m assuming this take the place of sanitizer, also doesn’t potassium metabisulfite have a nasty odor to it?

Cool idea! What’s your process for cold crashing? Could you leave the keg connected to prevent O2 suck back? I assume some sanitiser would dbe rawn back into the keg, but only a small amount of bottled CO2 would then be required to push it back out.

I unhook the whole thing and attach either a BrüLoonLock or CO2 tank to cold crash.

Could you let pressure build up in the co2 filled keg towards the end of fermentation and then cold crash, allowing the pressure to compensate for pressure loss due to temperature change?

Of course I have no idea how much pressure would be required for this…

You know, a balloon on an airlock is not the greatest idea in the world. Whatever fusels, etc. are expelled by the fermenting beer can react to the interior components that a balloon manufacturer uses to prevent the balloon from sticking together, decompose, then make it back into the beer, causing god knows what to affect your beer and potentially kill you. Good idea in theory, but not something anyone should promote.

Mylar balloons?

Any concerns that you’re pushing with partial oxygen at first (whatever was in the headspace to start with).

I’ve recently started using this method as well, but I wait until there’s been active fermentation for a bit to ensure that the headspace in the fermentation vessel has been mostly purged before I start purging the keg.

Nah, I haven’t worried about that and things have been working fine.

Sorry if I missed it, but how much sanitizer do you have in the serving keg? When fermentation is complete, how do you move beer from fermenter to keg? I’ve seen you talk about this closed process in earlier articles, just curious if anything has changed. I’m particularly interested in the Brew Bucket, as that’s what I’m using these days.

I make a 5 gallon batch of sanitizer, so the keg is full.

I use CO2 from a tank to push the beer out of the fermenter into the purged keg.

Brew Buckets are the bees knees.

Another awesome writeup. I realize the point of this is to remove the oxygen in an efficient and cost effective manner, but I’m wondering if there are any flavor-positive gains to this technique? I know that when my beer is bubbling away, there are definitely some great aromas coming out along with the odorless CO2. This technique could actually be adding to the flavors and aromas of your packaged beer – at least it’s “pre-seasoning” the keg. I would guess there is some mixing of the CO2(ish) gas in the keg with the beer as you’re packaging – as there is with the O2 in an unpurged keg. Just musing. (another exbeeriment? purged with fermentation gas, versus off-the-shelf gas? 🙂

Anyway, thanks for sharing. Stay hydrated! It’s hot out there!

I’m so happy you made this article Marshall. I had to kind of piece together how to do it from different forums a few months ago but eventually figured it out. My only difference is I ferment in a corny keg as well and have a Kegland blowtie spunding valve on my fermenter. Any pressure over 15psi exits the spunding valve into the second keg to push out the sanitizer and purge it with co2. I really feel like I’m saving a lot of co2 this way which fantastic. Pressure/closed transfers could be another future article

Oh I forgot to mention above, once the second keg is empty of sanitizer I move the spunding valve onto the second keg and keep a jumper between the fermenter and second keg so both hold a constant 15psi. Fermenting at 15psi is just a number Ive found that works best for me with pressure fermentation.

Do you wait until after fermentation has been active for a while or hook this up right away? It seems to me it you would have a lot of O2 in the headspace that would be pushed into the keg at the start of fermentation.

i would wait a day for the headspace to purge out O2 if it were me and i were using marshall’s method. If you just sanitize a keg and use the constant purge with CO2 method through the beer in post, you can just hook it all up right away.

A little extra air-O2 is a good thing at the start of Fermentation, unless maybe you aerated the wort with a good dose from an O2 tank.

I hook it up right after pitching the yeast.

Even this is not a proper scientific post, it should be common sense to give credit to those who have posted the idea before in other HB forums. (As mentioned by another reader in this thread.)

Cheers!

Oh please. I’ve also come up with “novel” ideas that turned out to be pretty common. For example, I am the original inventor of the “Use a paint stirrer attached to a drill with an immersion chiller to achieve chilling rates comparable to plate chillers.” At least I thought I was until I’ve seen it everywhere now.

Putting a paperback book under my kettle to drain every last drop of wort into the fermenter? Yep, my idea. Not worrying about trub? I thought of that first. Forgoing “secondary” for most all beers? YEP!

This method is nothing but common sense . . . But I hadn’t considered it and now can’t wait to do it with my Speidel.

We all have “original” ideas that turned out to be pretty common. But if we wish to publish these ideas, it’s common sense and etiquette to do a reasonable check on what others have done before us regarding this idea, and make a reference to it .

You’re a good dude, Ricardo, which is why I’ve decided to respond to you.

I had no intentions of hurting anyone’s feelings with this article, in fact I even mentioned I was hesitant to write it because of how stupid simple the idea is. But tons of people asked for it, so I shared what I’ve tried and never laid claim to inventing it. I understand certain people want credit for discussing it before me, and that some of those people aren’t big fans of Brülosophy, hence the shit slinging. Fine. But that doesn’t change the fact I came to this idea myself, despite the cynical arguments 4 people have posed. Either way, this article merely outlines what I’ve tried with various fermenters so that others might benefit. It wasn’t intended to pump up my ego or to prove I’m in any way more clever than anyone else. I promise. That’s not how I roll.

Now, more importantly– what do I have to do to have you send me some of your incredible Kölsch?!

Just need to come to Austin 🙂

With Cade there, it’s definitely on the list of things to do!

Thanks for posting this. A few months back I started doing this based on looking at pictures of your rig and realizing what you were doing. Wish I had started doing it years ago. Cheers!

For ‘comedy’ value I took this concept to the next logical point and wondered if you could force carb a keg with a ‘sugar engine’ which is basically a 2 litre pop bottle jumper cabled to a keg with enough sugar to prime the keg and account for the volume of the bottle.

Aaaaand it worked so much better than I imagined and force carbed the keg faster than set-and-forget on gas. I wrote an excel sheet to mimic online carb calculators that you put the volume of the keg and engine into, the temp of the beer to work out its residual co2 and it’ll tell you what ABV the sugar water will get to so you can judge if it’s a struggle.

Glad to see I’m not the only inmate in the “I’ve just gotta know!” asylum.

Cheers.

Get the hell outta here! That’s awesome. But how do you keep the keg cool enough to absorb CO2 while keeping the pop bottler warm enough to ferment?

That’s the great thing about it, you don’t have to keep the keg cool and the carbonation level is based purely on the amount of sugar used. Just let it stay at the same temp as the pop bottle and get it into the keezer after. I was sending the gas down the beer out so you could hear the gas going in just like a burst carb but on a very, very slow timescale. I did it purely to see if it could be done and was wowed by the results. I used bread yeast, sugar and nutrient.

The saving over gas is next to nothing. In fact I think it might have cost a little bit more but just knowing was enough.

What would be the best way to rack the beer in the keg when using PET fermenter ?

Just read an article (I think BYO) on aromatics, including hop aromatics released from airlock during fermentation. Wondering of the flushed keg smelled of hops? Nice that the beer you make will go into that keg

When a keg kicks it’ll be at whatever carb level your beer was at – you could use the gas post to sanitiser push a whole keg before you clean it. More savings!

Drunkula, good idea! I’m curious if there is a concern about contamination when the CO2 is passing through a “dirty” keg before filling the clean one? Have you done this often and without getting off-flavors from contamination?

I’ve done it twice so far, and no problems but I’m still at the stage where it make me a little bit wary. I hope that the residual star san will go to war in there. At the end of the day it’s not that different from doing it with the active fermentation. If anything goes wrong down the line I’ll reply back.

Damn sir, What an idea! I just thought about wasted hissing CO2 last weekend when I popped open a kicked keg to clean it. I’ve got another one coming up soon, and will give your trick a try. Cheers!

Marshall, thanks for writing this up, very clear! When it comes time to cold crash my brew bucket could I just disconnect the liquid jumper line and leave the keg with gas attached? Therefore CO2 and not O2 would get sucked back in. How much gas volume is needed for cold crashing?

I’ve ordered the parts to try this but I have to say I’m concerned about doing this with my Ss Brewtech buckets. Every so often I have a batch that ferments up to the lid and starts blowing trub and foam through my hose bib. I can’t have that happen with this setup. I suppose I should look into some fermcap or something but I’d like to not add to the process.

If you’re making a beer you’re pretty sure will blowoff (like a Hefeweizen or DIPA), wait until high krausen dies down then connect the kegs. It only takes an hour or so of active fermentation to push all of the liquid out of the first keg.

I ferment in glass carboy and it works great. I use a carboy cap with a stainless racking cane in the center hole connected to a liquid ball valve and a hose barb in the side hole that connects to a gas ball valve connected to the liquid post in the keg to be purged. (Usually push the star San into another carboy for storage)

For transfer: fermenter elevated above keg for gravity assisted transfer

1) I swap the gas valve to the gas post

2) lower the racking cane into the beer

3) start the flow with a suction bulb connected to the liquid ball valve with one of those stainless carb caps and some tubing

4) connect the liquid ball valve to the Keg

Beer then flows out of fermenter through racking cane into liquid post of keg which pushes CO2 from keg out the gas post back into fermenter for an oxygen free transfer

How much pressure should build up in the serving keg? Also after the star San has pushed into the 2nd keg, can I disconnect the serving keg and just leave the 2nd hooked up as an airlock? Thoughts on leaving everything connected thru fermentation, or what I explained above?

> How much pressure should build up in the serving keg?

You shouldn’t be building up much pressure at all in the serving keg if the secondary keg is vented (as it should be).

> Also after the star San has pushed into the 2nd keg, can I disconnect the serving keg and just leave the 2nd hooked up as an airlock?

Sure, just don’t forget to swap the gas disconnect from the fermenter with a liquid one, otherwise you’ll be squirting sanitizer everywhere.

Just to double check the process:

I also have a new Flex+ that is 3 days into its first fermentation – bubble rate has peaked and has started to slow, but still active. Is it too late to start this purge idea?

Also, for my next batch if I set up this system right at yeast pitch time, will I be able to purge a serving keg, plus end up with fully pressurized beer in the Flex+?

Thanks!

It may be too late to start now, but yeah, you should be good next batch.

Thanks – looking forward to trying it out!

Thanks for writing this up Marshall, and for all the follow up discussion. I have been using BrüLoonLocks for cold crashing and will try this method for purging to save some CO2. My question is about taking gravity readings. I am fermenting in PET carboys so I have to unhook everything and open it up to pull a sample. Any thoughts on how to get around this? Further, I like to take another sample at kegging but this is a real pain when transferring through a quick disconnect into the beer out post. Thoughts? Maybe I need to get away from so many readings??

Marshall, thank you for sharing this. I love the website. I’ve been thinking about how I would do this in a glass carboy since I am not into making glass bombs. A link from another poster shows that a 5 gallon ferment makes roughly 100 gallons of CO2 which is more that enough to purge an empty, air-filled serving keg of any appreciable amount of oxygen, even if the gases perfectly mix. In the second keg, just have an inch or two of water to cover the liquid dip tube: a low-pressure purge with an air lock.

Marshall, recently started doing this. Have you seen that the CO2 is released in spurts, especially when clearing the initial keg of sanitizer? Its almost as if the fermenter has to build up excess pressure to move the head presser of the sanitizer in the keg.

For anyone who uses this method, what do you find that happens when you cold crash? Do you get sanitizer getting sucked back into the serving keg?

If so, do you then use CO2 to push the sanitizer back out of the serving keg?

Is the top flange nut with orange o-ring installed upside down in the photo of the weldless gas ball lock post installed in the lid? Seems to me the o-ring should be against the top side of lid. And looks that way in the linked store image.