Author: Brian Hall

The experience of stepping off the airplane in Yakima, WA during hop harvest is like no other– the intense hop aroma in the air is similar to opening a fresh can of Heady Topper. Capturing this aroma is precisely what brewers of heavily hopped IPA, whether of the crisp West Coast or soft New England variety, aim to achieve when making dry hop additions.

Hops come in two main forms, whole cone or pellets, and opinions abound as to which is capable of imparting the most desirable characteristics to beer, particularly when it comes to use in the dry hop. Despite the fact some of the most notable commercial breweries dry hop with pellets, some maintain whole cone hops are superior because they don’t go through as much processing, which is believed to increase oxygen exposure and degrade oils. Countering this claim, a prior xBmt comparing beers dry hopped with either whole cone or pellets hops returned non-significant results, suggesting both hop types imparted similar aroma and flavor characteristics.

I’ve relied almost entirely on pellet hops in my brewing because they’re readily available in all varieties, cheap to ship, and much easier to weigh out and store. Having occasionally heard others voice their opinions as to which hop type is better, I decided to replicate the aforementioned xBmt to see for myself if a beer dry hopped with whole cone hops is perceptibly different than one dry hopped with pellets.

| PURPOSE |

To evaluate the differences between a Pale Ale dry hopped with either whole cone or pellet hops of the same variety and crop year.

| METHODS |

For this xBmt, I went with a simple Pale Ale loosely inspired by Tiny Bottom Pale Ale with a solid Centennial dry hop.

Beldar’s Plight

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 36.6 IBUs | 9.1 SRM | 1.054 | 1.012 | 5.4 % |

| Actuals | 1.054 | 1.008 | 6.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Lamonta American-style Pale Malt (Mecca Grade) | 8.5 lbs | 77.27 |

| Caramel/Crystal Malt - 15L | 12 oz | 6.82 |

| Vanora Vienna-style Malt (Mecca Grade) | 12 oz | 6.82 |

| Victory Malt | 10 oz | 5.68 |

| Caramel/Crystal Malt - 60L | 6 oz | 3.41 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 16 g | 60 min | Boil | Pellet | 11.6 |

| Perle | 14 g | 25 min | Boil | Pellet | 8.6 |

| Fuggles | 14 g | 10 min | Boil | Pellet | 4.4 |

| Fuggles | 15 g | 2 min | Boil | Pellet | 4.4 |

| Centennial - Whole Cone OR Pellets | 113 g | 5 days | Dry Hop | Pellet | 8.9 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 126 | Mg 0 | Na 0 | SO4 118 | Cl 135 |

Download

| Download this recipe's BeerXML file |

After collecting the brewing water and adjusting it to my desired profile, I lit the flame under the kettle then milled the grain.

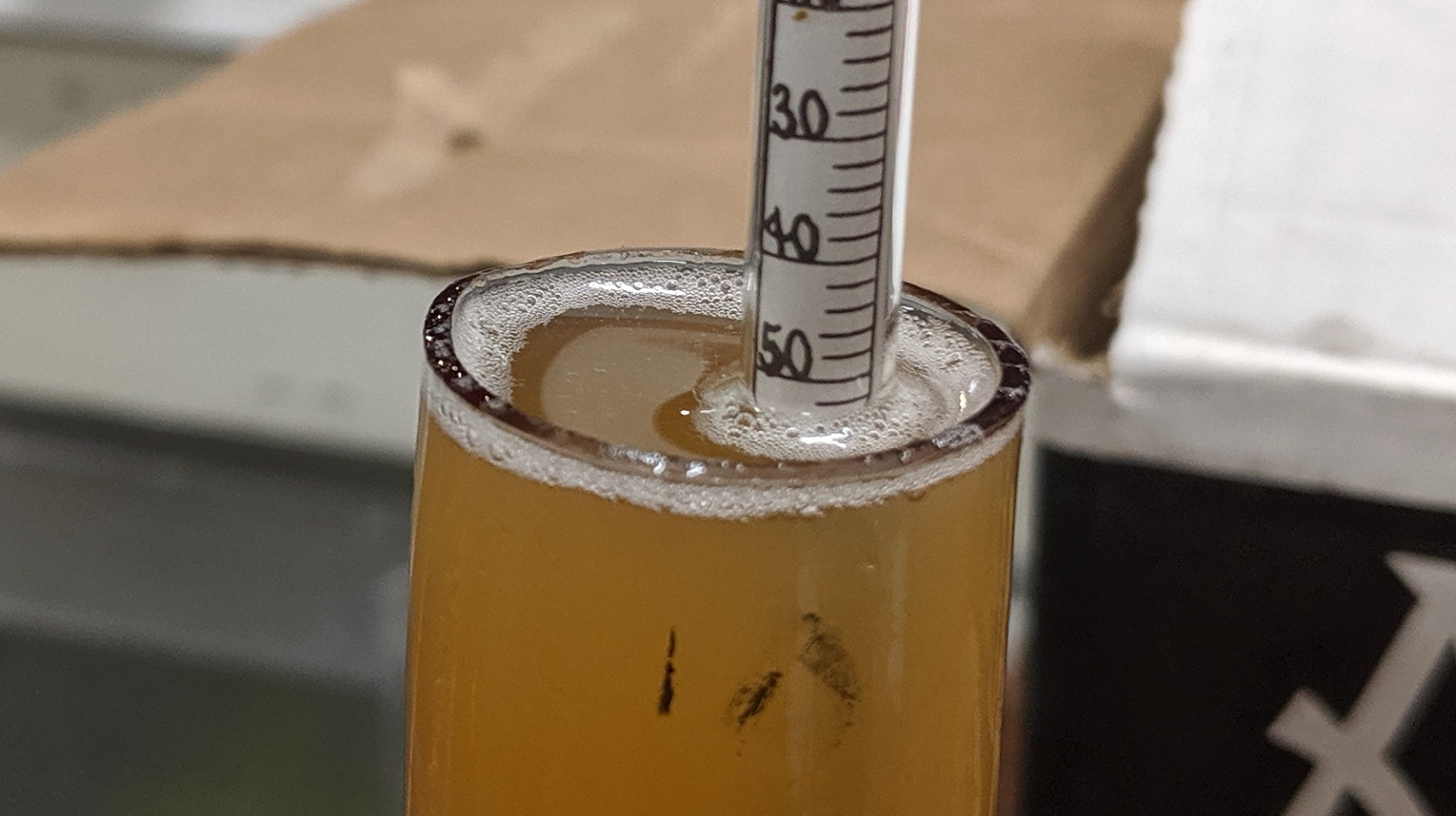

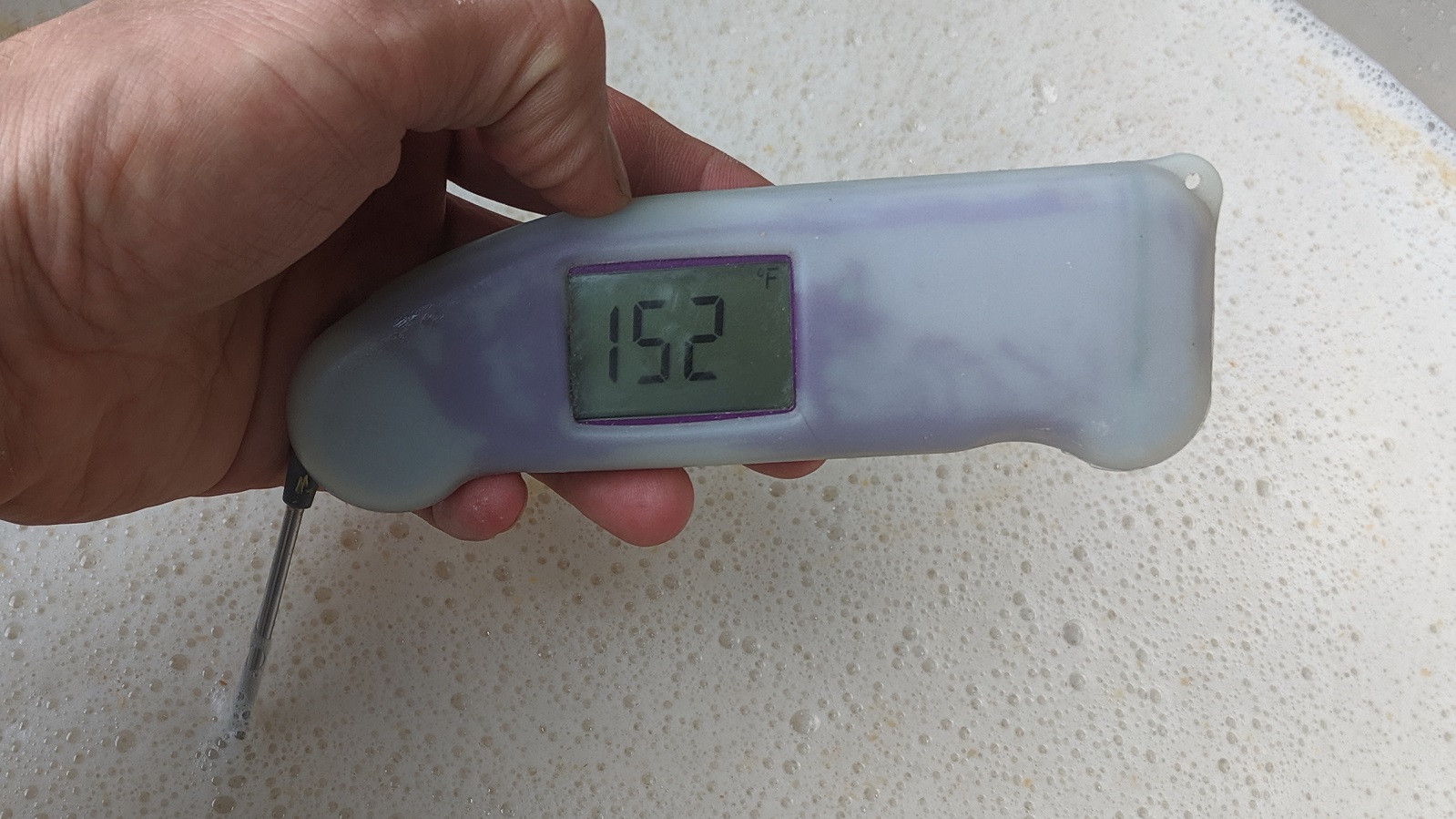

With the water adequately heated, I stirred in the grist and checked to make sure it hit my target mash temperature.

After a 60 minute mash rest, I sparged to collect the expected pre-boil volume of sweet wort then brought it to a rolling boil.

Following the 60 minute boil, I quickly chilled the wort before taking a hydrometer measurement showing it was at the target OG.

The wort was evenly split between two sanitized Brew Buckets that were placed next to each other in my garage that maintains 64-66°F/18-19°C, at which point I pitched a single pouch of Imperial Yeast A07 Flagship into each batch.

I let the beers ferment for 10 days before returning to add the same amount of 2018 Centennial to each batch, one receiving whole cone and the other pellets. For each batch, the hops were divided evenly between two stainless steel mesh canisters.

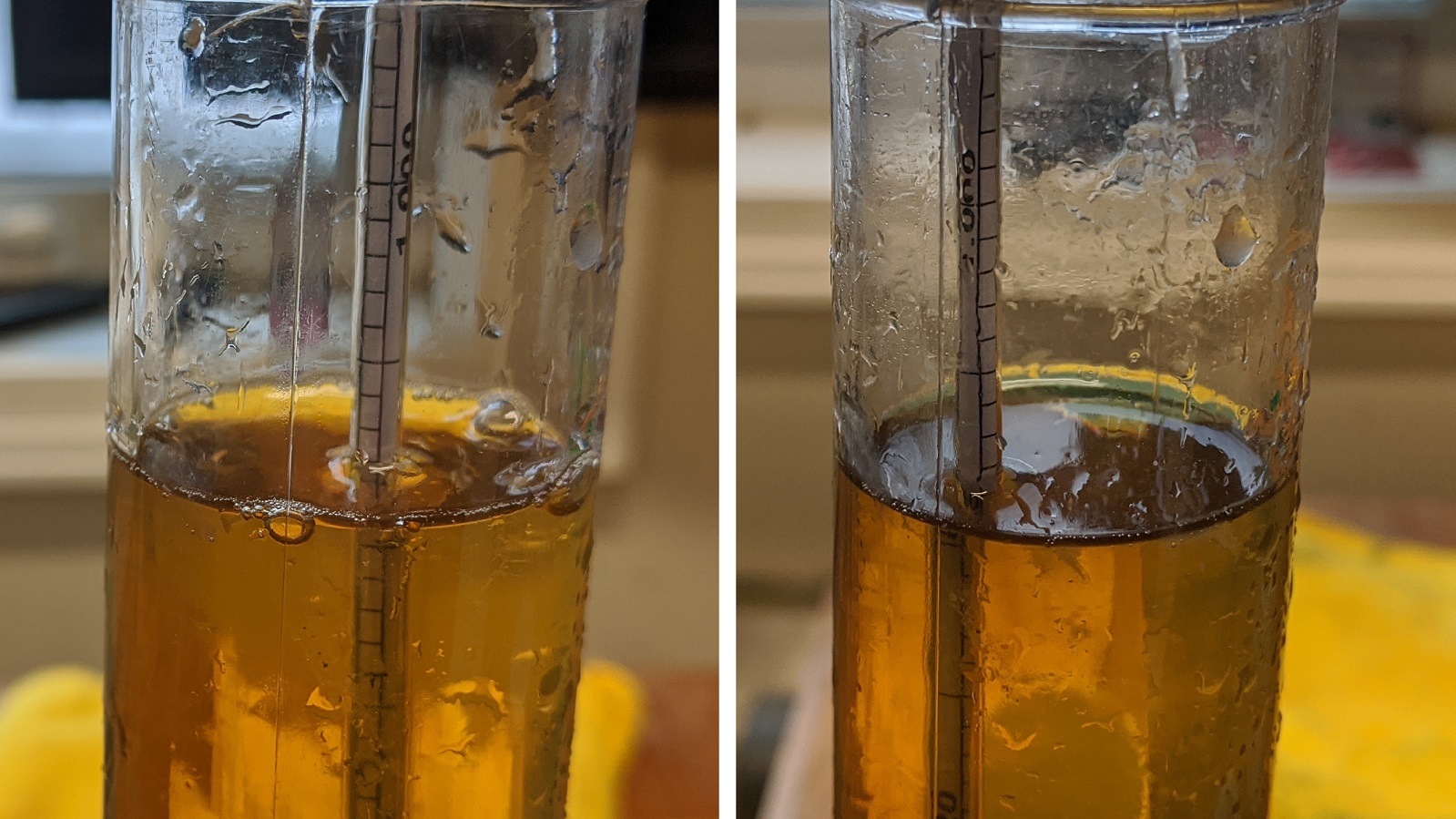

Hydrometer measurements taken 5 days later showed both beers had reached the same FG.

The beers were racked to sanitized kegs that were placed in my keezer, burst carbonated, and left to condition for a week before I began serving them to tasters.

| RESULTS |

Prior to the COVID-19 quarantine, 19 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dry hopped with whole cone hops and 2 samples of the beer dry hopped with pellets then asked to identify the unique sample. While 11 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 7 (p=0.46) did, indicating participants in this xBmt were unable to reliably distinguish a Pale Ale dry hopped with whole cone hops from one dry hopped with pellets.

My Impressions: Even knowing everything about how these beers were brewed and what was different about them, I simply could not tell them apart, which showed in my poor performance on multiple triangle tests.

| DISCUSSION |

After hop bines are cut and harvested from the field, they’re run through large plants where the individual cones are stripped then fed by conveyor to drying beds. At this point, some are packaged and sold as whole cone hops, while others move on to be pulverized into a fine powder before being compressed under high pressure into pellets. Some hold that the additional steps required to produce pellet hops reduces their pungency, though tasters in this xBmt were unable to tell apart beers dry hopped with either whole cone or pellet hops of the same variety and crop year.

The fact these results align with those of a previous xBmt on the same variable lends even more credence to the idea that dry hopping with pellets produces the same perceptible outcome as whole cones. This being the case, it seems brewers can feel confident using whatever form of hop best suits their needs without negatively impacting their beer.

I’ve always used pellet hops in my own brewing because they’re easier to store and use, and while I admittedly never worried much about whether whole cones might be better, these results do confirm my choice. If whole cones are all that’s available, I’d have no problem using them to dry hop a beer with, but I’ll definitely be sticking with pellets as my go-to for future batches.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

7 thoughts on “exBEERiment | Whole Cone vs. Pellet Hops When Used To Dry Hop American Pale Ale”

This is about dry hopping, what are the results when wet hopping?

Wet hopping uses fresh whole cones, so you wouldn’t be able to compare anything there.

Well depends on how you interpret his question; obviously there is no pellet wet hop equivalent, but you certainly could compare whole cone dry hops vs whole cone wet hops.

Was there any difference in final yield between the two batches? I’ve always heard whole cone suck up more beer and therefore less final yield in the keg.

interested here as well

Do you never have problems with hop creep? I have dry hopped twice where my fermentation was restarted, out of 4 dry hopped brews.

Tests have found that dry hopping cool and short (hours at serving temp) with agitation leaves more terpenes — flavor — in the beer than long and warm (days at ferm temp) (http://scottjanish.com/what-we-know-about-dry-hopping/). If you’ve ever made bubblehash you could see how this might be the case.

Any chance you might do an experiment to see if this is another difference found in the lab but not when tasting?