Author: Matt Del Fiacco

Aeration of chilled wort with pure oxygen is commonly practiced by brewers as a means of optimizing the fermentation, as yeast use the oxygen for the synthesis of sterols and unsaturated fatty acids, which in turn facilitates cell memberane health and reproduction. Often contended as an important step for all beers, many brewers view wort aeration as critical to avoiding problematic fermentations and off-flavor development in the production of higher OG styles.

In their book Yeast: The Practical Guide To Beer Fermentation, White and Zainasheff note that for beers with a strength of 1.083 OG or higher, a second dose of oxygen after 12 to 18 hours may result not only in faster fermentation and higher attenuation, but reduced risk of diacetyl and acetaldehyde. Purportedly, the yeast cells undergo at least one cell division during the time between oxygen doses.

Considering the fact higher OG worts put more osmotic pressure on yeast and have lower oxygen solubility, the aforementioned concepts made enough sense for me to dogmatically embrace the practice of aerating such styles with pure oxygen at both yeast pitch and a day or so into fermentation. Curious if the second dose of oxygen was having any impact, I decided to put it to the test.

| PURPOSE |

To evaluate the differences between a high OG ale dosed only at yeast pitch and one dosed at both yeast pitch and a day into fermentation.

| METHODS |

I opted to go with an Imperial Stout for this xBmt, relying on a reiterated mash method to achieve the high OG using my smaller brewing system.

Altitude Sickness

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.2 gal | 60 min | 71.6 IBUs | 60.5 SRM | 1.123 | 1.050 | 10.0 % |

| Actuals | 1.123 | 1.017 | 14.5 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt, 2 row (Gambrinus) | 13.5 lbs | 59.02 |

| Oats, Flaked | 2.375 lbs | 10.38 |

| Chocolate Malt (Simpsons) | 1.562 lbs | 6.83 |

| Munich II (Weyermann) | 1.562 lbs | 6.83 |

| Rye, Flaked | 1.187 lbs | 5.19 |

| Roasted Barley (Muntons) | 1 lbs | 4.37 |

| Crystal, Medium (Simpsons) | 8 oz | 2.19 |

| Sugar, Table (Sucrose) | 1.187 lbs | 5.19 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Magnum | 60 g | 60 min | First Wort | Pellet | 12 |

| East Kent Goldings (EKG) | 67 g | 30 min | Boil | Pellet | 5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Flagship (A07) | Imperial Yeast | 75% | 60°F - 72°F |

Notes

| Water Profile: Ca 50 | Mg 5 | Na 8 | SO4 36 | Cl 80 |

Download

| Download this recipe's BeerXML file |

I made two starters of Imperial Yeast A07 Flagship a day ahead of time.

After collecting two sets of water on brew day, I turned on the elements to heat them up.

I then weighed out and milled the grain for each batch.

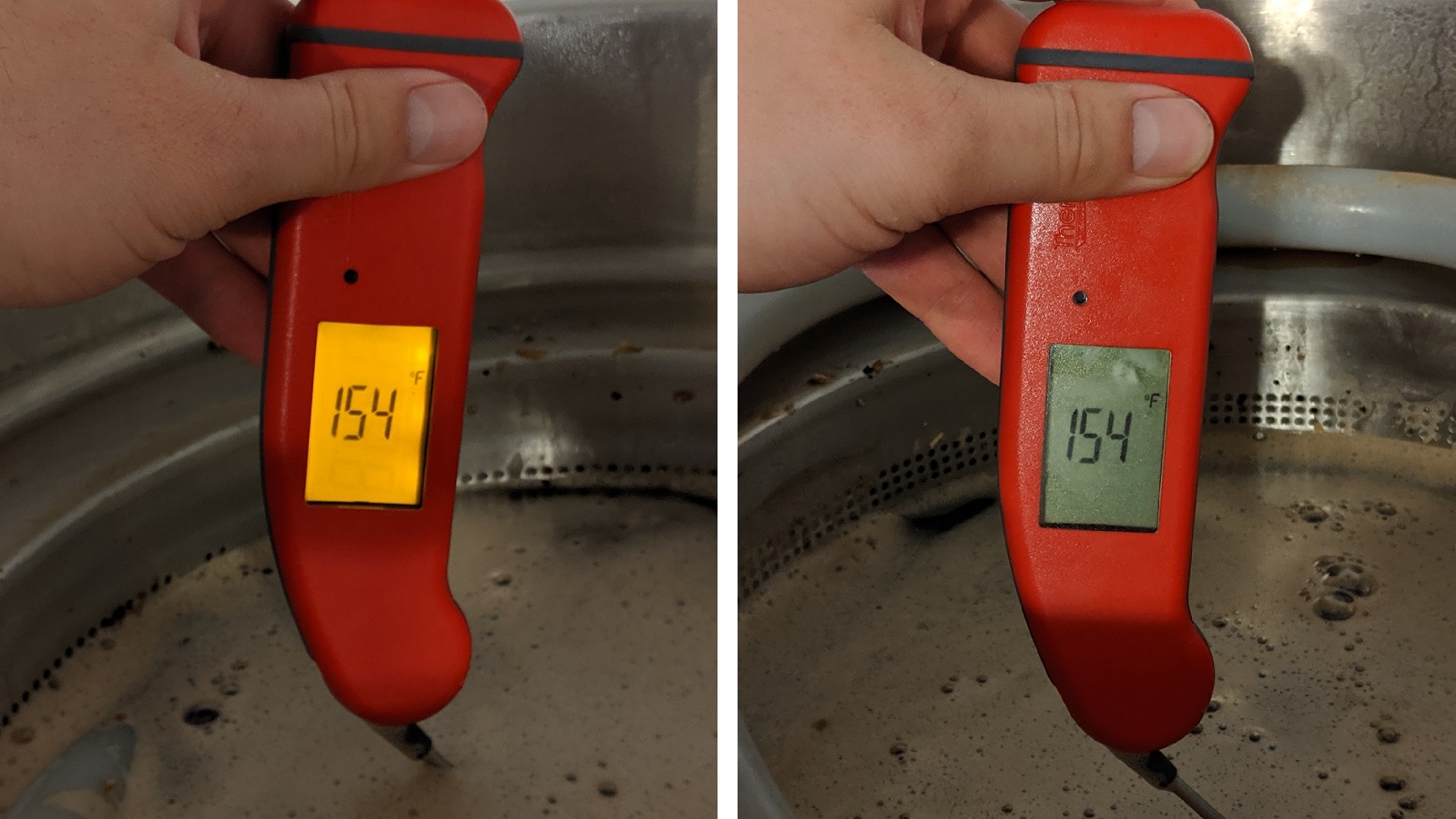

With the water adequately heated, I began the reiterated mash process by incorporating half of the grains for each batch into either kettle then checked to ensure both were at the same temperature.

After 60 minutes, I removed the grains from each batch then began heating the first “iteration” of wort to mash temperature. After cleaning the grain baskets, I added the second half of the grains to each batch of wort. When the second 60 minute mash rest was complete, I removed the grains and combined the worts in a single kettle to ensure homogeneity.

Next, I transferred half of the homogenized wort back to its own kettle and turn the elements on to heat them up, at which point I weighed out the kettle hop additions.

The worts were boiled for 60 minutes with hops added as stated in the recipe.

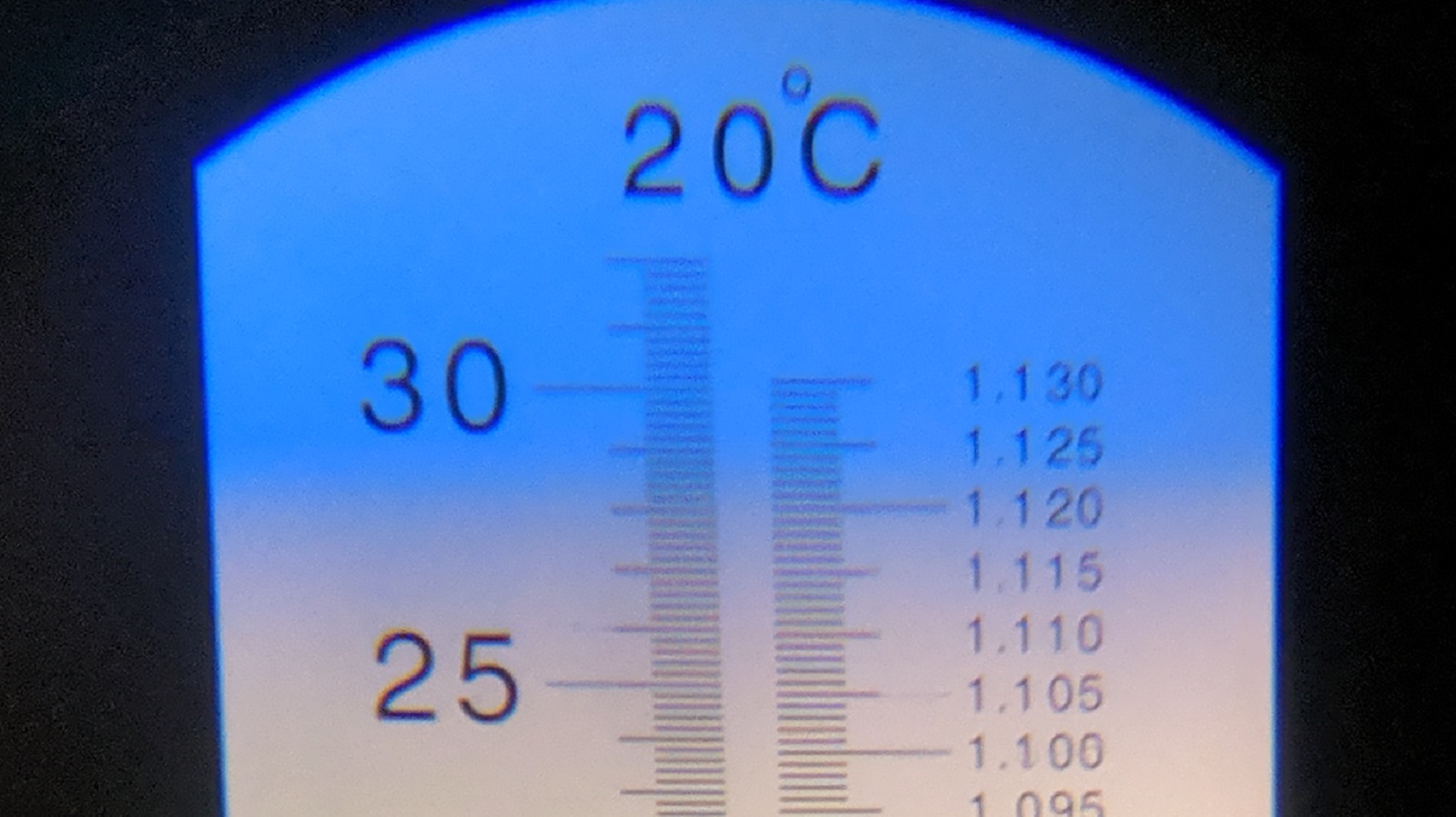

With each boil complete, I ran them through my plate chiller directly to fermentation kegs then took refractometer readings showing both hit the same 1.123 OG.

At this point, I hit both worts with 60 seconds of pure oxygen before pitching a yeast starter into each.

The fermentation kegs were placed next to each other in my chamaber controlled to 66°F/19°C.

With both beers actively fermenting 18 hours later, I gently removed the lid on one keg and proceeded to dose it with another 60 seconds of pure oxygen.

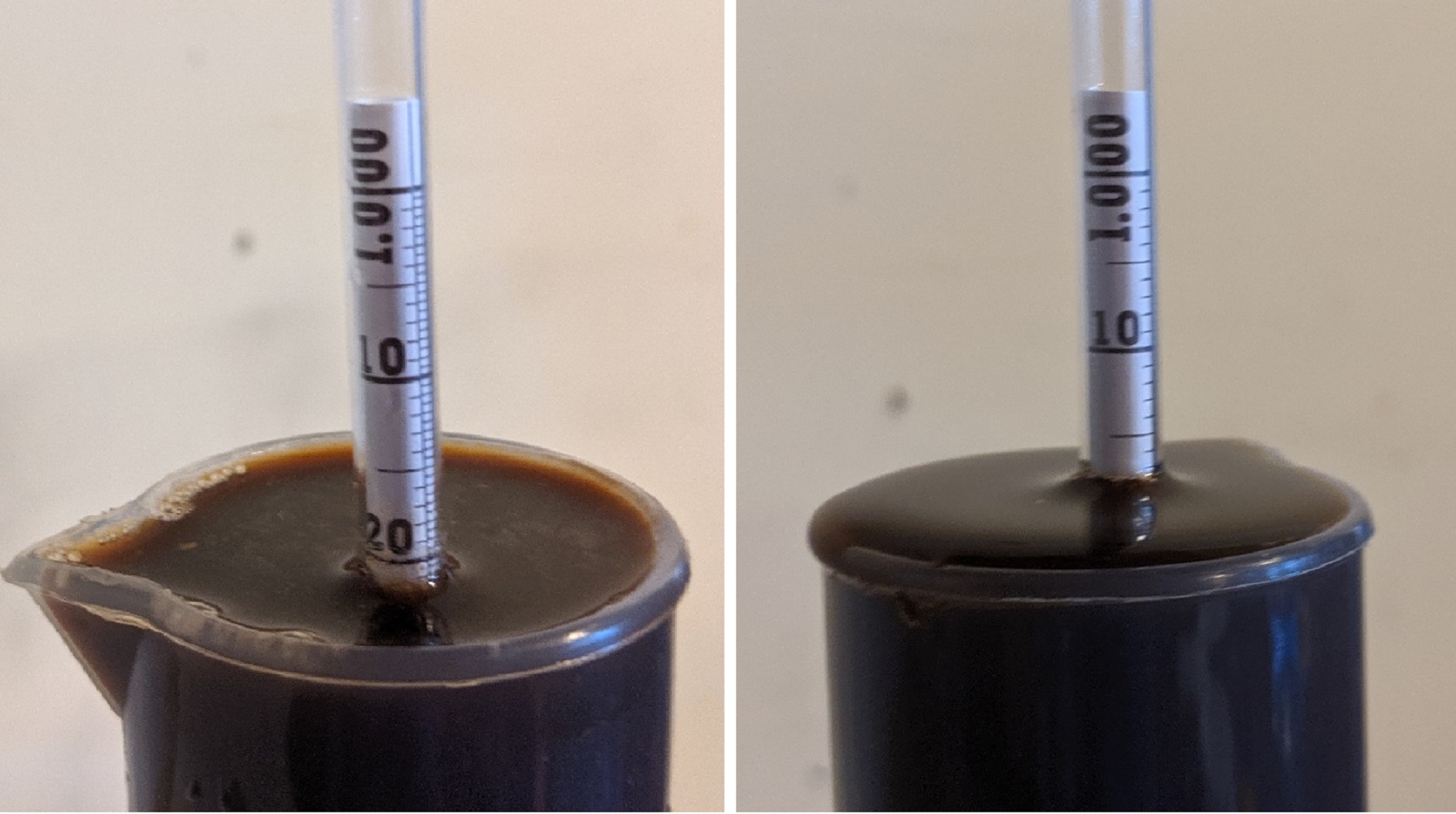

Following 2 more weeks of fermentation, neither beer was showing signs of activity, so I took hydrometer measurements showing a difference in FG.

I then pressure transferred the beers to sanitized serving kegs.

The filled kegs were placed in my cool keezer where they were burst carbonated and left to condition for several weeks before I served them to tasters.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer dosed once with oxygen and 2 samples of the beer dosed twice with oxygen in different colored opaque cups then asked to identify the unique sample. At this sample size, 12 tasters (p<0.05) would have had to identify the unique sample in order to reach statistical significance, though only 9 (p=0.29) did, indicating participants in this xBmt were unable to reliably distinguish a beer dosed with oxygen just at yeast pitch from one dosed with oxygen at yeast pitch and a day into fermentation.

My Impressions: Out of the 7 semi-blind triangle tests I attempted, I chose the unique sample just twice. To my palate, the beers were identical in every perceptible way. Both were clean with prominent bitter chocolate and roasted coffee character, and despite the high ABV, I didn’t detect any alcohol warmth from either.

| DISCUSSION |

Yeast require oxygen to grow effectively and ferment healthily, hence the the importance placed on wort aeration. Given positive relationship between osmotic pressure and specific gravity, many brewers opt to double dose their higher OG beers with oxygen, first at yeast pitch then again once fermentation has kicked off, the goal being to reduce stress on the yeast. The fact tasters in this xBmt were unable to tell apart a 1.123 OG Imperial Stout dosed just once at yeast pitch from one dosed at yeast pitch and the following day suggests both methods had a similar perceptible impact.

While the beers were indistinguishable on a sensory level, the one double dosed with oxygen finished 0.004 SG points, indicating slightly higher attenuation. It’s possible this relatively small difference in FG was caused by something else, but considering the the effort made to keep things between these beers as similar as possible, it seems marginally more likely the additional dose of oxygen played a role.

Based on both my personal experience and the blind taster results, I’ve no plans to start regularly double dosing my beers with oxygen, regardless of OG. In addition to being quiet messy, the difference in attenuation wasn’t enough to convince me the extra work is worth it. I would be interested to further explore the impact double dosing with oxygen has in less favorable conditions, for example, when pitch rates are low. Until then, I’ll stick to my normal routine of hitting wort with oxygen at yeast pitch.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

15 thoughts on “exBEERiment | Wort Aeration: Single vs. Double Dose Of Oxygen In An Imperial Stout”

You probably have the same kind of effect when moving the fermenting beer after five to seven days to a secondary fermenter. That seems to be my experience, I always get the attenuation expected from the yeast with just splattering my wort into my fermentation vessel, then racking after five to seven days in secondary with some wort or extra sugar to keep the fermentation going a bit longer.

I even got correct attenuation by just pitching my yeast on top of my wort, still in the boil pot with all the trub inside it, but I must also mention that in these cases I conducted an open fermentation.

My brewing set up is very low tech as concerns the mash and boiling, just a plastic bucket in bucket, and a 17 l stock pot. I do own a pH meter, a chiller and a malt crusher too, but all the rest is relatively low-tech.

You know what would be a nice series of experiments? Establishing the cost effectiveness of all these expensive things versus a low cost set up. Of course, a low cost set up is more difficult to scale, but testing for 5 gallon batches should be feasible.

I have to wonder if the style brewed would be hiding any difference. Such a malt-forward style with specialty grains dominating the flavor profile would seem to hide any difference that the yeast would impart. Yet at that OG, I’m not sure which style would let the yeast shine through.

Potentially! If we were to do this one again it may be worth trying something like an Imperial Helles, just all pils malt, high OG, and low IBU.

I would think a Belgian Golden Strong would be perfect for this type of experiment.

Definitely a contender! I think we would see some of the same comments, that potentially the Belgian yeast would be too expressive.

I agree with that the Belgian strain may be too expressive to determine benefit, though I would venture that this may lead to another avenue specific to Belgian strains!

I had the same thought, but I think an English Barleywine with a simple grain bill might be the appropriate choice. A lot of the complexity of that style comes from yeast phenolics, IMO, and something that really pushes the ABV envelope is going to make the phenolics pretty assertive. If testers still can’t tell the difference at that point, then I think the answer is conclusive.

I think you could make this argument about every variable. If you used a lighter malt bill, and a more characterful yeast, you could argue that the yeast character is outshining any subtleties making it hard to detect. I think it’s more interesting that the target FG was so far off the results, and I’d be curious to see the control be an undosed batch, and each oxygen dosing be variable 1 and variable 2. I realize that makes data collection more challenging though.

Any more info on the yeast starter? Did you aim for a certain # of cells, or just active yeast? I don’t brew many big beers, but I imagine it’s possible that the starter provided sufficient oxygen for the yeast. Some quick calculations show you could have easily pitched 488b cells with a stir plate.

Size and method of each starter?

Question for anyone: would open fermentation until high krausen is achieved (ex. 2-3 days depending on yeast) accomplish the same things as directly aerating with O2? I’ve done some open fermentation but never with a side by side tasting. Anyone have any knowledge to share?

Curious about your choice to cut off fermentation after just 2 weeks on such a big beer. I think it’s interesting (and consistent with an effect on yeast health) that the single-dose beer finished at a little higher gravity than the double-dose beer, but I wonder if the single-dose yeast were just given a bit more time if they might have caught up.

I think this is an excellent point. Usually all my Imperial stouts finish well within 2 week window, however my last imperial stout was deliberately fermented cold for the first 5 days (15.5C internal) with a 48hr cold crashed starter that was added to pre-chilled wort. The beer took 3 weeks to finish. The last 4 points crept along over a whole week when there appeared to be no CO2 being released and no temperature delta between my incubator (ambient) and internal beer temperature. It appeared done, even though it wasn’t. Maybe the single dosed beer was slower to finish, possibly even simply down to yeast being suspended more by the bubbling effect of O2. Other than residual sweetness there was no yeasty or diacetyl flavours to suggest it wasn’t done by week 2.

Another point worth noting is that even degassing a sample, simple pouring/shaking for a few minutes is never enough to get a true reading. I’ve done it many many times only to find that after leaving a sample chilling overnight, decanting liquid off yeast that had settled and rewarming to room temperature gave me an SG that was 3-4 points lower than the inital ‘degassed’ sample. The bigger the beer the more pronounced the difference for some reason.

Great job! Another well-done exBEERiment.

I would suggest that this is showing you the potential maximum possible attenuation for this situation as a brewery doing a forced fermentation test on a stir plate would. This test showed you that your standard oxygenation is inadequate to supply your yeast with what it needs to ferment the sugar in solution, hence it couldn’t hit terminal gravity before you wanted to package.

I would also suggest that their is another reason why brewers do secondary oxygenation. The presence of oxygen in the wort switches yeast from anaerobic to aerobic metabolism and therefore back into it’s reproduction phase. You’re increasing the cell count in the wort in the FV by oxygenating say 12-18 hours apart. Another solution would be to pitch the appropriate amount of yeast and oxygenate for maximum O2 in solution and compare your results to a forced fermentation test of the same wort. You can then start to dial in your O2 additions to match the needs of your yeast for different OGs and attenuation expectations.

If you’re bottling beer this could be a serious problem. This difference in attenuation as a percentage may look small when measured with the less than accurate SG hydrometer. A much more accurate way to measure gravity is with a temperature adjusted Plato hydrometer, both OG and FG. On the SG scale you’re range of OG (28.6P – 28.8P) to FG (a: 1.021 = 5.21 – 5.45P, b: 1.017 = 4.21 – 4.45P) in could be off by upwards of +/- 0.3P which translates to +/-0.15%abv and when added to the change in gravity from the under attenuated beer it could be upwards of 0.5%abv and the carbonation in the package that comes along with it. This low nutrient fermentation could cause the yeast to throw above threshold diacetyl concentrations depending upon which yeast you decided to use and the secondary fermentation conditions.

Just some thoughts, thanks and keep up the good work.