Author: Cade Jobe

One of the keys to making consistently good beer is to ensure consistently good fermentation practices, which for many brewers involves using various nutrients to encourage solid yeast performance. Viewed as being one of the most important nutrients, zinc is readily available for purchase and generally gets added to the wort just before pitching the yeast.

Zinc is a co-factor for certain enzymes that assist with yeast growth and metabolism. Even at relatively low concentrations (0.2-2.0 ppm), zinc is said to have a noticeable impact on fermentation by allowing the yeast to work more efficiently during the growth phase, resulting in a quicker start and healthier fermentation, which ultimately leads to a cleaner tasting beer. While too much zinc can inhibit yeast growth, usage rates at the higher end of the recommended range are also believed to contribute to beer foam stability.

I’ve used a few different types of yeast nutrients over the years, though I hadn’t really considered zinc until a recent episode of the Masters Brewers Podcast. Interested to see what kind of impact it might have on my beer, I designed an xBmt to test it out for myself.

| PURPOSE |

To evaluate the differences between beers fermented with and without a zinc addition.

| METHODS |

With the goal of maximizing any perceptible differences caused by the variable, I went with a relatively high OG Helles Bock for this xBmt.

No Good Keister

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.2 gal | 60 min | 25.0 IBUs | 6.7 SRM | 1.070 | 1.011 | 7.8 % |

| Actuals | 1.07 | 1.01 | 8.0 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pilsner (2 Row) Ger | 12.75 lbs | 91.89 |

| Honey Malt | 1.125 lbs | 8.11 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 14 g | 60 min | Boil | Pellet | 14 |

| Tettnang | 14 g | 5 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 56 | Mg 19 | Na 38 | SO4 47 | Cl 64 |

Download

| Download this recipe's BeerXML file |

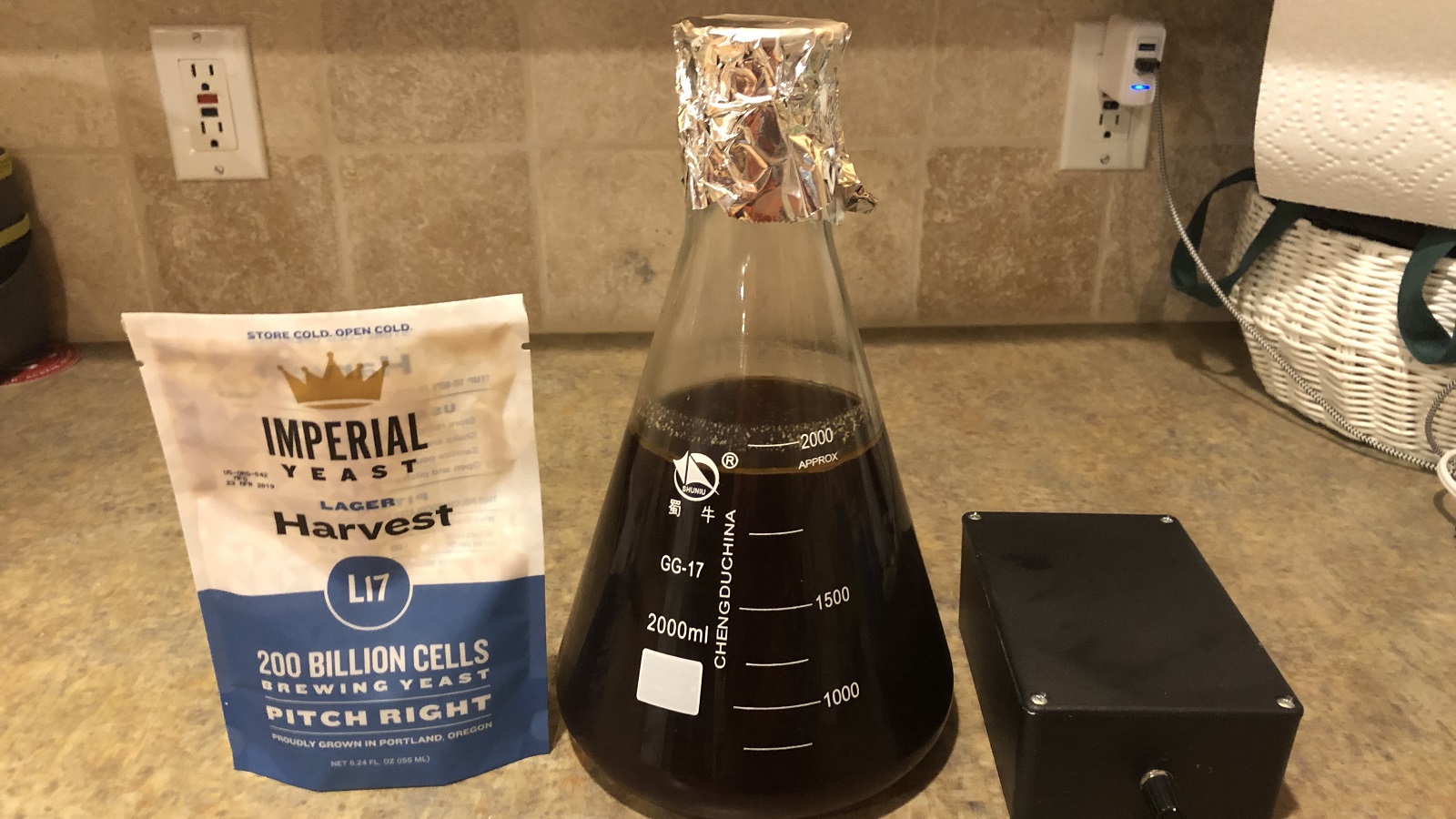

A couple of days prior to brewing, I made a large starter of Imperial Yeast L17 Harvest (using leftover dark malt extract) that would later be split.

I started off my brew day by collecting the proper volume of water for a 10 gallon/38 liter batch, adjusting it to my desired profile, then lighting the flame under the kettle.

While waiting on the water to warm, I weighed out and milled the grain.

Once the water was appropriately heated, I incorporated the grains before checking the mash temperature– slightly lower than expected, but nothing I was worried about.

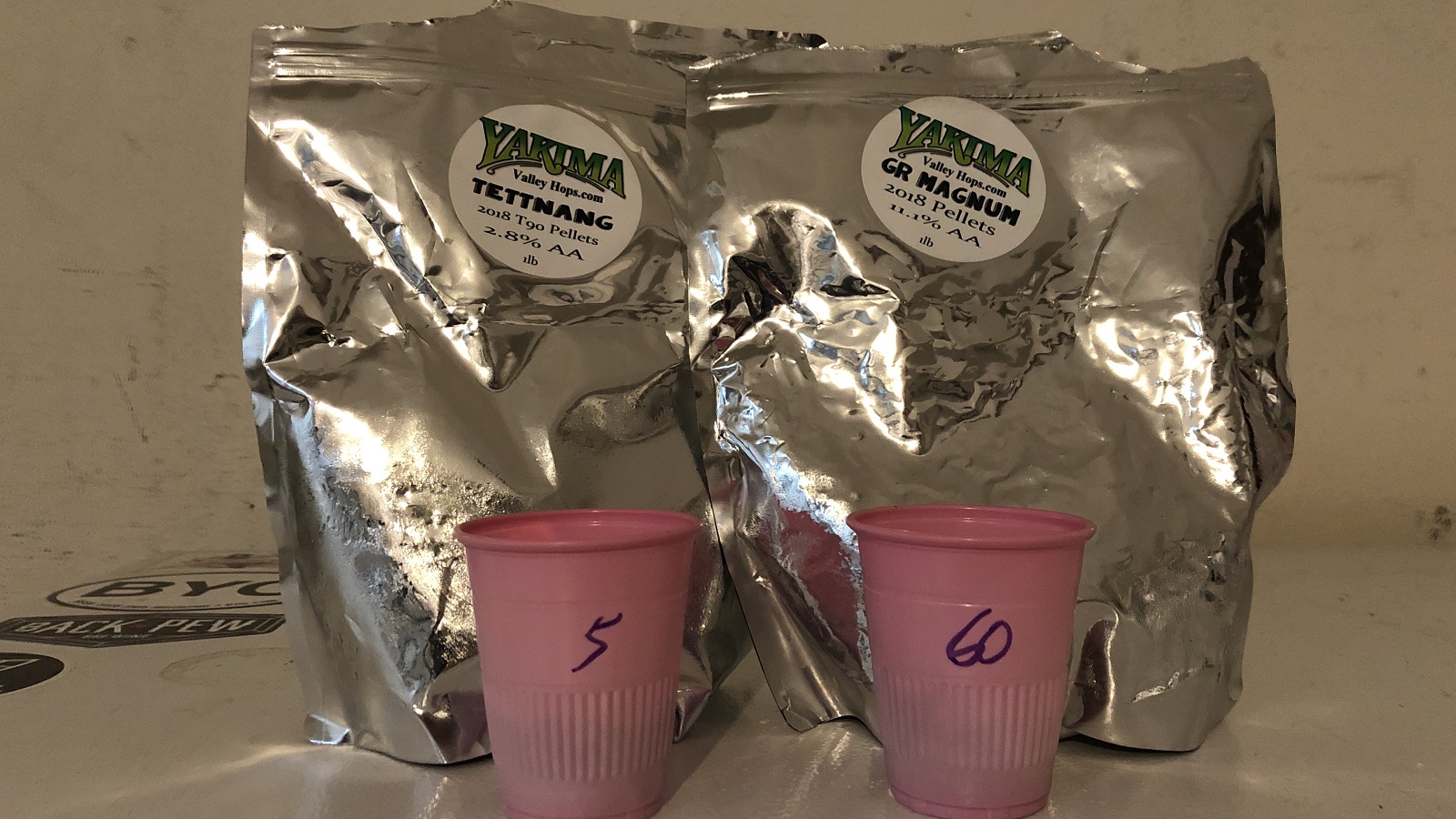

During the mash rest, I measured out the kettle hop additions.

When the 60 minute mash was complete, I sparged to collect the target pre-boil volume then brought the wort to a boil.

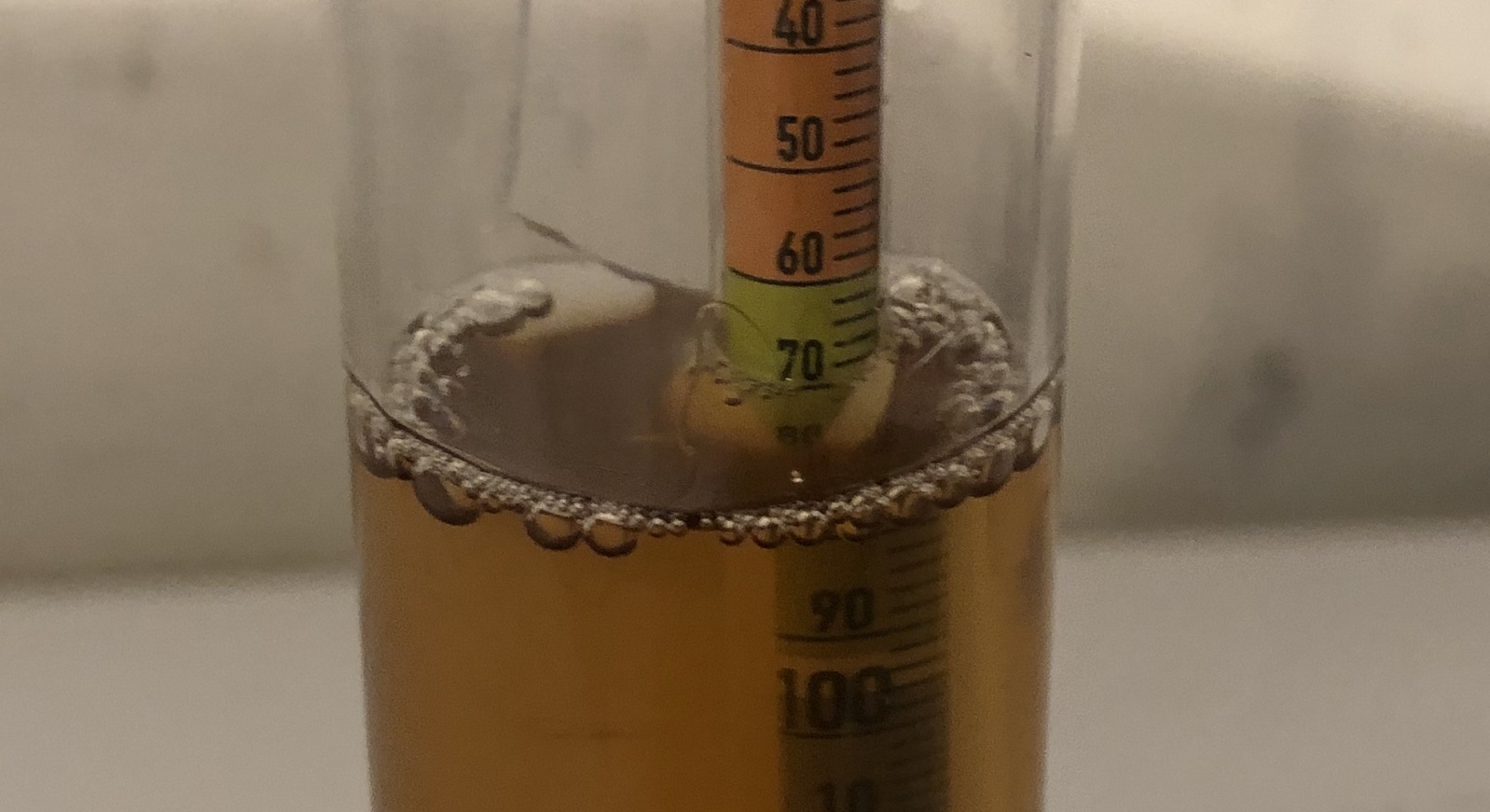

Following the 60 minute boil, I quickly chilled the wort with my IC before taking a hydrometer measurement it had hit my target OG.

Identical volumes of wort were racked to separate Brew Buckets that I placed next to each other in my fermentation chamber. After determining the amount of zinc required to achieve 2 ppm, I weighed it out and added it to one batch.

At this point, I evenly divided the yeast starter between two jars then pitched one into either batch.

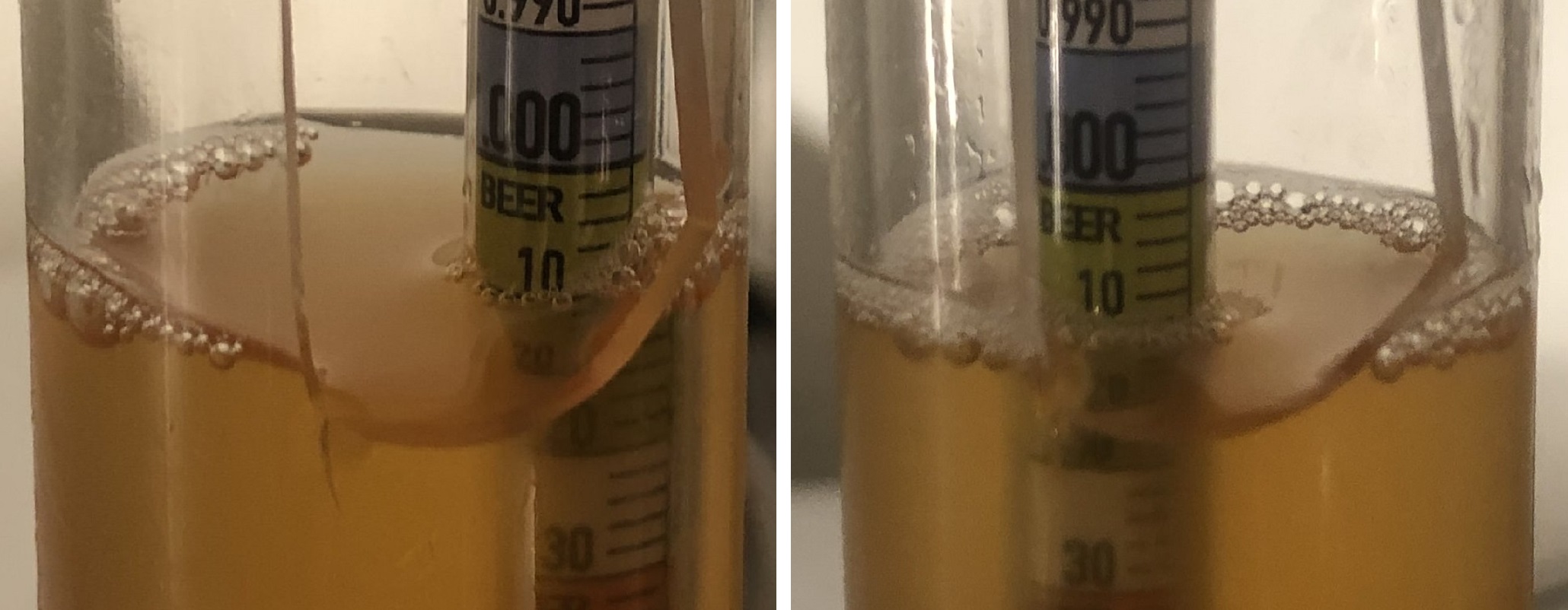

The beer was left to ferment at 54°F/12°C and I noticed the beer with zinc took slightly longer to show signs of activity than the non-zinc beer. After 7 days, I raised the temperature to 66°F/19°C and left them alone for another 10 days before taking hydrometer measurements confirming both beers had reached the same FG.

I reduced the temperature in the chamber to 38°F/3°C for an overnight cold crash, after which I pressure transferred each beer to separate sanitized kegs.

The filled kegs were placed in my keezer, burst carbonated, then left to condition for two weeks before I began serving them to participants.

| RESULTS |

A total of 15 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer fermented with zinc and 2 samples of the beer fermented without zinc in different colored opaque cups then asked to identify the unique sample. While 9 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 4 did (p=0.79), indicating participants in this xBmt were unable to reliably distinguish a pale lager fermented with zinc from one fermented without zinc.

My Impressions: Over the course of a couple weeks, I attempted multiple semi-blind triangle tests. Given what I’d read, I expected there to at least be a difference in mouthfeel between the two beers and even convinced myself that I could tell them apart prior to my own triangle tests. Nope, not even close. Out of 4 attempts, I picked the unique sample 0 times. The beers were indistinguishable to my palate, and thankfully, both tasted great, though a tad too boozy for my tastes.

| DISCUSSION |

Zinc is a nutrient for yeast that helps to facilitate growth and metabolism, but unfortunately it’s not abundantly present in malted barley. It’s for this reason many brewers have taken to adding zinc directly to wort prior to pitching yeast, the goal being to encourage the healthiest fermentation possible in order to ultimately produce the best beer possible. While there’s ample evidence yeast benefit from zinc, the fact tasters in this xBmt were unable to reliably distinguish a Helles Bock fermented with zinc from one fermented without it suggests it may not have much of an impact on perceptible characteristics.

It’s important to note that trace amounts of zinc are present in malted barley, and it’s possible even this small amount is enough to catalyze the enzymes used during yeast growth and metabolism, which would make any additional zinc unnecessary. Another possible explanation for these results is that the beers were in fact different, but the delta was too small for people to detect it. Indeed, my own experience with these beers was influenced heavily by what I’d read about the impact zinc can have on mouthfeel and foam, which unsurprisingly were the only areas I initially thought I was able to perceive a difference.

As a brewer who is interested in doing whatever I can to produce the best beer possible, I’m certainly open to using zinc if it has a positive impact. While I require more data before I’m willing to commit to a certain perspective, the results of this xBmt along with my own inability to distinguish the beers leaves me comfortable claiming that adding zinc at yeast pitch isn’t necessarily required to make good beer.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

26 thoughts on “exBEERiment | Impact Adding Zinc At Yeast Pitch Has On Helles Bock”

Great article on an interesting topic. I’ve tried adding Zinc to starters a couple of times but never to the actual wort for my brews. I wonder if the lack of a significant difference between the beers was down to the fresh Imperial yeast that you used? I imagine that yeast manufacturers are growing their yeast up in ideal conditions with pleanty of yeast. I had heard that additional zinc is really only necessary after multiple re-pitching when the lack of nutrient might be more apparent.

Great comment. I’ve read that as well.

Good article. One thing I’ve noted from a post on Pro Brewer is that the level of zinc in the final wort is much less than what you add. Some brewers performed some measurements and they had to end up adding 4-5ppm to achieve 2ppm in the FV, possibly due to zinc being bound up with trub. So theoretically it could be that both beers were the same as the level of zinc in the final beer wasn’t enough to be of any benefit.

In the end though I still don’t suspect it would have made a significant difference in brewer’s ability to taste beer here. But like the above poster mentioned, I think this may because fresh yeast vials has been pre-propagated with zinc already (it figures) compared to pro brewers who reuse yeast many times

Sorry I meant to say some brewers add 0.4-0.5ppm to achieve 0.2ppm in the FV

In addition to the above, I read alot of pro Brewers added zinc after finding out some of their yeast weren’t flocculating as well when they should. Again, this could be the nth generation of yeast were residual zinc has become depleted. I add zinc to every beer now as a matter of course, although I do harvest some of my yeast. Either way it’s cheap for the amount you use and has no negative benefits (unless you start to get near 10ppm and higher)

Sorry I meant to say near 1ppm or higher zinc can be inhibitory. I was thrown by the numbers you added – I just spotted you added 2ppm which is approximately 10x the recommended final concentration and definitely in the realms where it can do more harm than good. You did notice a longer lag period in the +zinc beer which suggests you were doing harm to the yeast by adding too much zinc. Do you think you maybe if you had added the recommended amount the beer may have shown a difference?

There seems to be abit of confusion/variability on the correct dose of zinc in brewing.

Some sites I’ve read say 0.6ppm and above and inhibitory, which aligns with recommendations on Pro Brewer (https://discussions.probrewer.com/archive/index.php/t-40562.html) and other places (http://brewlikeapro.net/tipsandtechniques.html)

However an older paper showing the effect of zinc on yeast (https://onlinelibrary.wiley.com/doi/abs/10.1002/j.2050-0416.1998.tb00996.x) shows only 600ppm and above have a negative effect (which is absurdly high). I initially assumed the author made a monumental mistake by quoting ppm instead of ppb, however in the material and methods it quotes values like 10mM which does correspond to 600ppm zinc. Very odd.

Another paper (https://rke.abertay.ac.uk/en/publications/zinc-interactions-with-brewing-yeast-impact-on-fermentation-perfo) shows the ideal zinc concentration is 0.48-1ppm (which makes more sense).

So it seems 0.5ppm is a good place to start?

Very thoughtful string of comments!

There’s also https://beerandbrewing.com/dictionary/kiIqhWg6y9/. Less formal source, but written by Bamforth.

Replying to your earlier comments, I added at 2 ppm to hit the high end of the range for the first test. Even if zinc at 2 ppm could hurt yeast metabolism, the xBmt still returned non-significant results, so at least in this sample, it didn’t have a noticeable impact positively or negatively. I do think we should do some more xBmts on this variable before I’d be willing to commit to a certain perspective about the use of zinc.

Your water profile appears to be from tap water. Tap water often contains sufficient zinc for yeast. Zinc additions are mainly considered to be of benefit to yeast when one is building water from quality RO or distilled, which are devoid of zinc. Do you know the zinc concentration of your source water?

Interesting. I just looked back at my water reports to check this. I don’t see zinc listed as a mineral in my utility district’s water report. It’s admittedly not something I test for regularly, since I use a BrewLab water testing kit. Still, I don’t see it listed as a trace mineral.

In pro brewing I noticed that it took a few generations of serial pitching to fully see the difference between adding and not adding it.

Curious why you didn’t add the the end of the boil as that’s how I’ve always done it and also how Wyeast has it in their instructions – does it matter?

To isolate the variable, I wanted to see if zinc had an impact on fermentation. Also, I’m not sure I see the point of adding it during the boil vs adding it to the fermenter. Zinc is supposed to help yeast grow and metabolize sugars during fermentation. I’m not sure what, if any, impact it would have during the boil itself.

I know Cloudwater brewery in the UK for a fact add at zinc at whirlpool as stated on one of their brewing spreadsheets they released some time ago for NEIPA V3.1, but as you stated it’s an element in tiny quantities that isn’t particularly reactive in the context of brewing (an assumption!), so it’s really not going to make a difference when you add it, hot side or cold.The only difference I can foresee is if it’s added on the cold side after trub has settled out more zinc *may* remain in suspension, but then yeast has been shown to metabolise zinc in trub.

I think a lot of practice, even in big breweries is that you should add things later if you want to leave it unchanged – a sort of subconscious notion that the more time/heat you give something the more likely it will react with something else. Other than sanitation precautions, in most cases it’s probably a form of brewing superstition.

I agree that the time of addition could affect concentration – zinc ions bind to protein and DNA so you are likely to get large losses due to the precipitation of denatured proteins when boiling. Adding zinc at the start of fermentation should give a much more consistent concentration. This might explain the large differences in the concentrations leading to negative effects on fermentation reported in papers mentioned above?

Can I ask, how many grams did 2ppm work out at? For 20L I work it out at 40mg of pure elemental zinc or 175.5mg if it’s zinc sulphate heptahydrate ….. Looking at that photo of you weighing it out, it sure does seem like a lot more than 175mg……

I used zinc gluconate, which is 14.3% elemental zinc. The tablets were 50 mg each, or 7.15 mg zinc per tablet, so I used 5.5 tablets to get 40 mg of pure elemental zinc.

Ah, that explains the large addition. Just make sure the 50mg is describing the zinc gluconate content and not the actual zinc content. I’ve found dietary pills are often a bit misleading about what they’re actually referencing/

Saying that they’re often biased in making the dose seem larger (as appears in your case) by stating 50mg zinc when in fact the elemental zinc content is far less, but it’s not a guarantee.

Good work though.

I’ve just tried to find the product your referring to and the closest I can come up with is this: https://www.heb.com/product-detail/now-zinc-50-mg-tablets/436298#product-description

Different colours in the label but same brand/dose etc.

It seems from a photo of the reverse that the 50mg per tablet is indeed referring to the elemental zinc content, not the zinc gluconate content. This kind of fits from the 333% RDA quote on the side (its probably nearer 400% RDA, but would be nearer 50%RDA if it was only 7.15mg zinc per tablet)

If this is true then you added nearly 14ppm elemental zinc….

I think you were looking for this one, https://www.heb.com/product-detail/h-e-b-zinc-50-mg-caplets/602764#product-description There’s no picture of the back of the bottle but the details are on the side of the page, 460% RDA of Zinc

I found it this morning but just noticed now you got there before me! Yes that’s the one. 460%RDA is approx. 50mg (male) 37mg(female) so safe to say 50mg is referring to elemental zinc and not zinc gluconate implying the author added 14ppm and not 2ppm

The picture makes it look like the zinc beer had better head formation/retention. Was that the case? Or is the head difference in the photo related to pour/photo timing?

Sorry to harp on about the same thing (I’m starting to wind myself up now!), but I think it’s profoundly relevant to the experiment. I’ve found the product you used here: https://www.heb.com/product-detail/h-e-b-zinc-50-mg-caplets/602764#product-description

On the product H.E.B product page it says each caplet contains 460% RDA zinc. The recommended RDA of zinc for men is 11mg, so this confirms each tablet you used contained 50mg of elemental zinc and not 7.15mg of elemental zinc. This means you supplemented zinc up to 14ppm not 2ppm (correct me if I’m wrong).

So, while the experiment might not show difference, it does show that adding nearly 50x the recommended concentration of zinc to a beer wont ruin it 🙂

That high of a concentration certainly could explain Cade’s observation of fermentation, which seemingly conflicted with the conventional wisdom about the effect of zinc on yeast health:

“The beer was left to ferment at 54°F/12°C and I noticed the beer with zinc took slightly longer to show signs of activity than the non-zinc beer.”

However, while it seems reasonable that 14ppm did have some inhibitory effect on the yeast being able to kick into gear, it certainly didn’t ruin (or even have a detectable effect on) the final product, which is encouraging for anybody who might be considering giving zinc a try but is holding back for fear of detrimental effects.

I’ve been using 0.17 gm from tablets that weigh 0.67 gm, and are claimed to contain 50 mg. of Zn, for 11 gal. batches. I didn’t see any change in my beers after starting this, but I will keep it up, as cheap insurance. My usual yeast is dry US-05, but I’ve used this level with Voss Kveik, same, no obvious effect with either of them. I make mainly West Coast IPA’s, and an occasional Porter. “your mileage may vary.”

Also, most of my yeast pitches are fresh 4x 11gm. US-05 packs for 11 gal., rehydrated. O.G. = 1.065 to 1.070, a bit of an over pitch. I occasionally repitch, and again, use about +50% of suggested amount of slurry. With Voss Kveik, I used 2x 100 ml. Omega OYL-061 pouches.