Author: Cade Jobe

There’s nothing worse than having to dump a batch of beer due to contamination, hence the importance brewers place on sanitation. Concerns about sanitation on the hot-side tend to be low because the boiling wort eliminates most contaminants; it’s on the cold-side, once the wort has been chilled, that problems are most likely to arise. While various methods of sanitation exist, the most common involves soaking gear that comes into contact with the cool wort or beer in a chemical solution known to eliminate wild yeast and bacteria, with one of the more popular options being Five Star’s Star San.

Star San consists of two active ingredients—15% Dodecylbenzenesulfonic acid and 50% Phosphoric acid, which make for an effective and easy to use sanitizer. As anyone who has used this particular product is well aware, it foams quite heavily, which is intentional, as the foam is an active sanitizer that can make contact with more difficult-to-reach areas of equipment. As a no-rinse sanitizer, any residual foam stuck to a vessel’s surface can remain and, according to the manufacturer, will have no impact on the finished character of the beer.

Star San has been my sanitizer of choice for years, particularly when it comes to ensuring my kegs are free of any unwanted microbes that might spoil my beer. When sanitizing my kegs with Star San, there’s always a good amount of foam left behind, and while I can’t say I’ve noticed this as causing problems in my beer, it doesn’t seem far-fetched to think it might have some impact. Curious to see for myself, I designed an xBmt to test it out!

| PURPOSE |

To evaluate the differences between a beer packaged in a keg with a high amount of Star San foam and one packaged in a keg with a minimal amount of foam.

| METHODS |

I went with a simple lager for this xBmt in hopes of emphasizing any impact the Star San foam might have on beer character.

Fizzy Lifting

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 22.0 IBUs | 5.6 SRM | 1.048 | 1.015 | 4.4 % |

| Actuals | 1.048 | 1.011 | 4.9 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Munich I (Weyermann) | 4.375 lbs | 45.45 |

| Pilsner (2 Row) Ger | 4.375 lbs | 45.45 |

| Vienna Malt (Weyermann) | 14 oz | 9.09 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 14 g | 60 min | Boil | Pellet | 12.2 |

| Tettnang | 14 g | 5 min | Boil | Pellet | 4.5 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 65 | Mg 18 | Na 38 | SO4 65 | Cl 64 |

Download

| Download this recipe's BeerXML file |

I started off my brew day by collecting the proper volume of water for a 10 gallon/38 liter batch, adjusting it to my desired profile, then lighting the flame under the kettle.

While waiting on the water to warm, I weighed out and milled the grain.

Once the water was appropriately heated, I incorporated the grains before checking the mash temperature– a bit higher than expected, but nothing too worrisome.

The mash was left alone for 60 minutes.

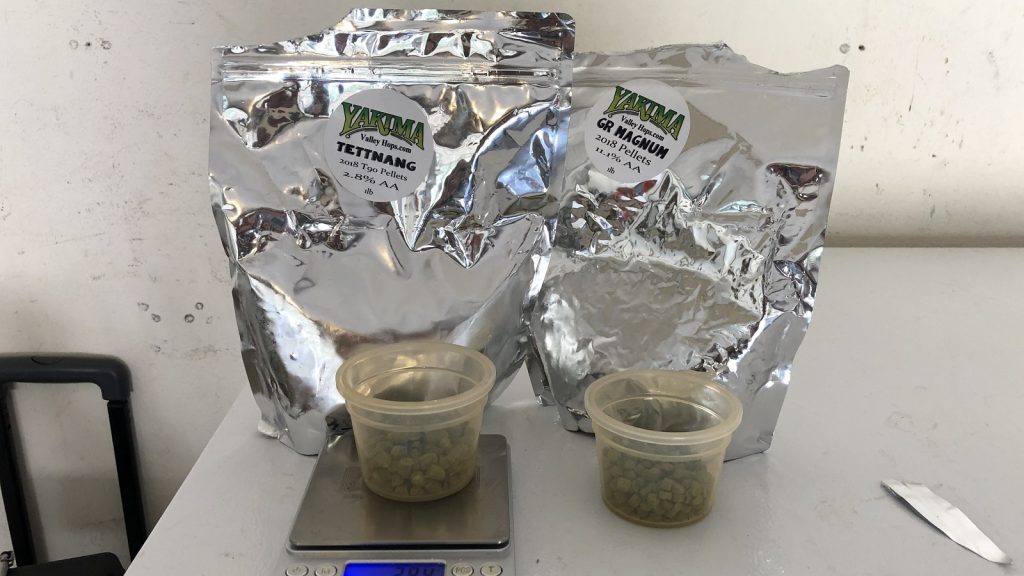

During the mash rest, I measured out the kettle hop additions.

When the 60 minute mash was complete, I sparged to collect the target pre-boil volume then boiled the wort for another 60 minutes before chilling it with my IC. After taking a hydrometer measurement that showed the wort was right at the expected 1.048 OG, it was racked to a 14 gallon Ss Brewtech Brew Bucket that got placed in my chamber. At this point, I pitched two pouches of Imperial Yeast L17 Harvest.

The beer was left to ferment at 54°F/12°C for a week before I raised the temperature to 66°F/19°C, where it sat for an additional 10 days before I took a hydrometer measurement confirming FG had been reached.

The night prior to packaging the beers, I thoroughly cleaned and sanitized two kegs using my standard procedure, emptying both, then left both alone to dry overnight. The next day, after racking 5 gallons/19 liters of beer to a foam-free keg, I whipped up a fresh batch of Star San, making sure to agitate to increase foam production. I then carefully transferred approximately 12 cups/3 liters of foam to the empty keg before racking the beer into it.

The filled kegs were placed in my keezer, burst carbonated, then left to condition for three weeks before I began serving them to participants.

| RESULTS |

A total of 27 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the beer packaged with Star San foam and 2 samples of the beer packaged without Star San foam in different colored opaque cups then asked to identify the unique sample. A total of 14 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, but only 6 did (p=0.928), indicating participants in this xBmt were unable to reliably distinguish a pale lager racked to a keg with approximately 12 cups/3 liters of Star San foam one packaged in a foam-free keg.

My Impressions: I attempted 4 semi-blind triangle tests and guessed correctly just once, the beers were identical to my nose and palate. I was happy to have made 11 gallons/38 liters of this beer, as it was delicious!

| DISCUSSION |

“Don’t Fear the Foam!” Every brewer has heard this catchy saying Five Star came up with to ease concerns about racking beer into a foam-laden vessel sanitized with Star San. As anyone who has ever sucked a bit too hard on tubing submerged in Star San solution knows, it definitely has flavor to it, and thus it’s not crazy to think large amounts of foam might affect beer character. However, the fact tasters in this xBmt were unable to distinguish a lager racked into a keg with a large amount of Star San foam from one with no foam provides confirmation of Five Star’s claim that it has no impact on flavor.

Star San foam is made of bubbles, and seeing as bubbles are mostly air, the actual volume of Star San solution in 12 cups/3 liters really isn’t that much, which may explain these results. It’s entirely possible that higher volumes of Star San solution blended with beer would have a perceptible impact, and while no brewer would intentionally do such a thing, it may be a worthy xBmt based on the number of stories that exist about folks who accidentally forgot to empty their keg or bottling bucket of Star San before racking beer to it.

Having racked many a beer to kegs containing fairly large amounts of Star San foam, I admittedly had some preconceived ideas as to how this xBmt might turn out. Indeed, the results confirmed my personal hunch, and while I look forward to looking more into the flavor impact Star San in higher volumes has on beer, I’ll continue using it without worry as my no rinse sanitizer of choice.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

27 thoughts on “exBEERiment | Impact Star San Foam Has On An International Pale Lager”

Don’t Fear The Foam indeed. It’s kind of funny if you have someone watching you brew, and they don’t realize what Star San is. To them, it looks like soap suds. I had the fear early on, it just seems so non-intuitive.

But after brewing, bottling and kegging with Star San for years, I embrace the foam.

Thanks for doing this one. Curious about it for a number of years.

Thanks for this experiment. I’ve never really worried about the foam until recently. For me, it isn’t the actual foam I’m worried about but rather the air trapped within it. Therefore I wonder if you would see a different result with a NEIPA or similar beer which is very oxygen sensitive.

When I have checked my kegs before filling there looks like there could be several liters of foam which equates to several liters of air. I don’t think purging would make a difference as the CO2 would just compress the air bubbles which would expand again when you vent the keg. I may be worrying about nothing as my hoppy beers don’t seem to be affected but I do now try to minimise foam in the keg.

You raise an interesting thought. I wonder if purging doesn’t just compress the bubbles, but pop them instead, releasing air which then gets purged. Seems like if we were introducing several liters of air into a corney keg, we would see more bad beer from oxidation. What IS going on in that invisible keg??

I found this video on youtube which is not terribly clear but seems to show some bubbles popping and some shrinking and then expanding again when the pressure is released. I guess it probably depends on how stable the foam is as to whether it pops and the gases mix, or contracts and expands, in which case the air would remain in the keg. https://www.youtube.com/watch?v=KGmKeBNMD64

Wow! There must be a video for everything these days.

☝🏼This is the thing I worry about at packaging on NE IPA’s. A lager in the experiment may not show signs of oxidation while fresh like a very hoppy beer would.

Great experiment. I’ve been waiting for you guys to tackle this one for a while and think you did a great job. Effectively this experiment compared a little (dried, I think) starsan with a fair amount of starsan. Perhaps another chapter in this series could be comparing the impact of different sanitizers. Maybe starsan and iodiphor ?

The problem with Star San is that it’s generally not effective in killing wild yeasts/fungi/molds, all of which are quite acid-tolerant. It’s mainly effective only against bacteria. Iodophor, on the other hand, kills everything and so is a better choice in a homebrewery, especially if you do mixed fermentations.

A friend of mine accidentally dumped his wort into a carboy that had like 1-2 gallons of star san in the bottom one time. he said it fermented out fine and tasted fine, if a bit tart!!!

The exact same thing happened to a friend of mine with a double IPA (a sort of Sixpoint Resin clone). He wasn’t sure how much, but safe to say between 3 and 6L on a 21L batch. Aside from lowering the strength, there was no perceivable off taste and ended up being good beer

I brewed a NEIPA last summer and forgot that there was about a pint of Star San solution (not just foam) that I’d meant to empty out at the bottom of the keg. Realized it about halfway through racking and at that point, stressed about it but had nothing to do but press on. After the keg was carbed, I tried to convince myself that I tasted some hint of the Star San when I started sampling, but quickly forgot about it, as the beer was delicious. The people I served it to didn’t notice anything either.

I stopped worrying about Star San at all at that point, though I do always remember to flip kegs/carboys upside down to drain out excess before racking now.

Good to know. I guess I can stop rinsing those bubbles out of the keg before filling it, now.

yeah, don’t rinse. several years ago the owner of the company was on the Brewing Network and said that he drank a glass of diluted Star San at a homebrew meeting to show that it is safe!! ha ha

That’s a pretty beer. Also no darkening I can see between the beer in the glass and the beer in the hydrometer sample at packaging. Did you use any kettle or fermentor finings on this beer?

I’m scratching my head as it sounds like you went with open transfer in order to be able to do this experiment. I re-read your background and see your standard process is closed transfer. I’d have expected an open transfer to show some darkening even at 3 weeks. Am I missing something about the process?

Thanks! No finings, just time lagering. This was a closed transfer. I put the foam in the keg and then purged with CO2 before transferring.

I tried to brew a Alpine Nelson twice. Both times the beer, after less then a week in the keg turned a brownish red and had an odd metallic taste to it. I do use techniques to prevent oxidation. So I don’t think it would be oxidation, not twice. I clean my kegs and fill them with Star San to store. When needed I dump the keg, let drain for a few and fill with the beer. I always noticed a “coating” on the side of the keg thinking it was the Star San but didn’t think to much about this. After the Nelson failures I was thinking it could be the coating the Star San left on the keg and was doing something to the beer. I had to take a break from brewing for a few months and never figured out what was causing the odd tasting brown beer. I should be up and brewing again soon. Ill try to get to the bottom of this. Any one else ever see this happen?

I suppose it is at least plausible that the acid solution will deteriorate the oxidized protective layer on the aluminum resulting in this? I don’t really see the point in “storing” Starsan in a keg. I store mine dry. When ready to keg, I drop a few drops of Starsan, shake the keg to coat (and create a lot of foam) then drain/keg beer.

“There’s nothing worse than having to dump a batch of beer due to contamination …”

Thx for avoiding the ‘infection’ misnomer.

I’ve had issues with an unexpected bitterness in a few of my hoppy beers. I’ve always pushed starsan out with CO2 leaving a bit of very fine foam in the bottom.

After listening to some comments on an episode of experimental brewing I’ve tried rinsing this last bit of foam out for my last couple of beers, and haven’t had the issue.

I certainly haven’t done enough to be conclusive, or done a side by side, but I had 2 “bad” hoppy beers in a row with foam, then 2 “not bad” ones in a row with a rinse.

This does seem to go against what everyone else has said, so it may be another random variable I haven’t accounted for.

I’ve had the same issue. Maybe it’s the chlorine or sodium in your water supply used to mix the starsan ?

I’ve since changed my mind on this, as I had the same bitterness come back on a couple of beers where I’d flushed the keg.

I now think it was due to oxidation of hops through my plastic fermenter (fastferment), as it only ever happened in hoppy beers, and I’ve not had the issue since I switched to an SS brewtech bucket

You can also cut the gas in dip tube flush or above the keg ceiling height. Then you can get about every drop of sanitizer out the gas in post after an upside down rest. Easier to get ALL of the air out when filling with starsan too

I don’t use kegs, only clean and well (well well well) washed mechanical cap bottles, used only for my beers.

Four successive batches of different beers (pilsner, porter, APA and blond ale), using bottles rinsed with Starsan, did not carbonate as expected. So I used the old oxy to rinse the bottles: well carbonated beer.

It’s anedoctal, not scientific maybe, but never used Starsan for bottling and I had not anymore unexepected problems with carbonation.

I have accidentally taken a slug of starsan that was in a pint glass next to my beer… tastes tangy, doesn’t hurt a bit, but not what I was expecting!

So 15+50=65, what are the rest 35 per cent made of?

May be isopropanol and Water?!