Author: Cade Jobe

It’s well-documented that oxidation, particularly that which occurs on the cold-side, leads to stale off-flavors and poor shelf stability in finished beers. This effect is especially apparent in heavily hopped beers like New England IPA (NEIPA), hence the reason many brewers of such styles take extensive measures to keep cold-oxidation at bay.

One method for reducing cold-side oxidation is to transfer the finished beer under CO2 pressure when packaging, an approach that has been shown to work rather well, though it requires gear that some may not have access to. Another option that’s been getting some attention lately involves adding a chemical antioxidant to the beer to stave off the effects of oxygen exposure. Available at most homebrew supply stores, both sodium metabisulfite (SMB) and potassium metabisulfite (Campden), when dissolved, allow free sulfite ions to bind with free oxygen in solution, leading to reduced oxidation reactions.

I was intrigued when blind tasters in a recent xBmt were able to distinguish a Kölsch dosed with SMB at packaging from one that didn’t receive SMB, as it supported the idea that a chemical option could be a viable way to avoid cold-side oxidation. However, in that xBmt, both beers went into kegs that were purged with CO2 prior to being filled. I was curious of the impact SMB might have on an arguably more sensitive NEIPA when transferred without any attempt to limit oxygen ingress at packaging, so I designed an xBmt to test it out.

| PURPOSE |

To evaluate the differences between beers packaged in non-purged kegs either with or without sodium metabisulfite (SMB).

| METHODS |

For this xBmt, I went with a NEIPA recipe that’s heavy on the late hop additions in order to keep the bitterness low and the juicy goodness high.

Seeker

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 40.3 IBUs | 3.9 SRM | 1.064 | 1.015 | 6.4 % |

| Actuals | 1.064 | 1.01 | 7.2 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 9 lbs | 64.86 |

| Oats, Flaked | 2.5 lbs | 18.02 |

| Wheat Malt, Pale (Weyermann) | 2.375 lbs | 17.12 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Hallertau Magnum | 7 g | 60 min | Boil | Pellet | 11.1 |

| Centennial | 7 g | 5 min | Boil | Pellet | 10 |

| Citra | 7 g | 5 min | Boil | Pellet | 12 |

| Loral | 7 g | 5 min | Boil | Pellet | 11.5 |

| Mosaic (HBC 369) | 7 g | 5 min | Boil | Pellet | 12.3 |

| Centennial | 7 g | 1 min | Boil | Pellet | 10 |

| Citra | 7 g | 1 min | Boil | Pellet | 12 |

| Loral | 7 g | 1 min | Boil | Pellet | 11.5 |

| Mosaic (HBC 369) | 7 g | 1 min | Boil | Pellet | 12.3 |

| Citra | 28 g | 5 days | Dry Hop | Pellet | 12 |

| Loral | 28 g | 5 days | Dry Hop | Pellet | 11.5 |

| Mosaic (HBC 369) | 28 g | 5 days | Dry Hop | Pellet | 12.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Juice (A38) | Imperial Yeast | 74% | 64°F - 74°F |

Notes

| Water Profile: Ca 51 | Mg 20 | Na 38 | SO4 51 | Cl 54 |

Download

| Download this recipe's BeerXML file |

I started off my brew day by collecting the proper volume of water for a 10 gallon/38 liter batch, adjusting it to my desired profile, then hitting the flame to heat it up.

While waiting on the water to warm, I weighed out and milled the grain.

Once the water was appropriately heated, I incorporated the grains then checked to make sure I hit my target mash temperature.

The mash was left to rest for 60 minutes.

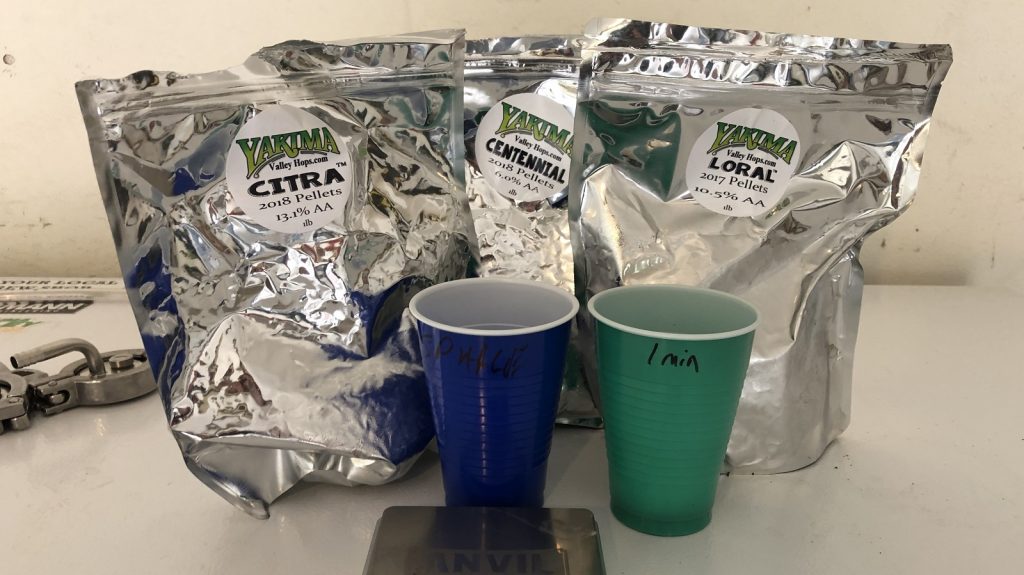

During the mash rest, I measured out the kettle hop additions.

When the 60 minute mash was complete, I sparged to collect the target pre-boil volume then boiled the wort for another 60 minutes before chilling it with my IC. A hydrometer measurement showed the wort was right at the expected 1.064 OG, after which it was racked to a 14 gallon Ss Brewtech Brew Bucket that got placed in my chamber before I pitched two pouches of Imperial Yeast A38 Juice.

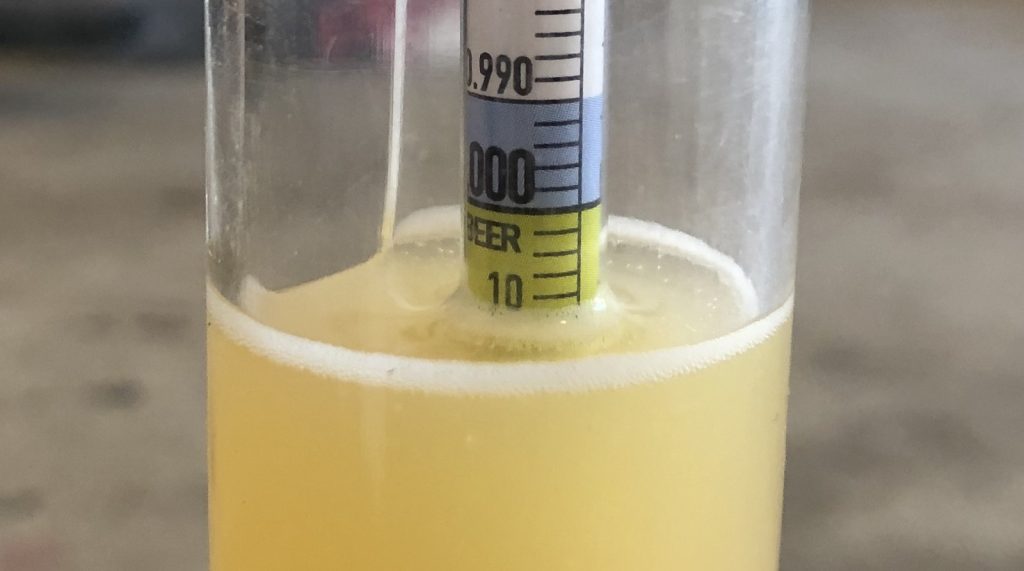

With signs of fermentation absent after 12 days, I took a hydrometer measurement indicating FG had been reached.

At this point, I measured out a 0.3 g of SMB and added it to one of two sanitized kegs.

In order to emphasize any impact of the SMB on oxidation, I forwent my typical CO2 purging process and racked the beer directly into open kegs, making sure each received the same volume.

The filled kegs were placed in my keezer and burst carbonated. I began taking samples a week later and noticed a fairly obvious difference in appearance.

Just 5 days later, the beer packaged without SMB was beginning to look much darker.

I began serving the beers to blind tasters around 3 weeks after packaging, a point at which both appeared to have changed color, though the non-SMB batch more noticeably so.

| RESULTS |

A total of 34 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer packaged with SMB and 1 sample of the beer packaged without SMB in different colored opaque cups then asked to identify the unique sample. A total of 17 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, which is exactly how many did (p=0.034), indicating participants in this xBmt were able to reliably distinguish a NEIPA packaged with SMB from one packaged without SMB.

The 17 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 9 tasters reported preferring the beer with SMB added at packaging, 5 liked the beer packaged without SMB, and 3 had no preference despite noticing a difference.

My Impressions: Out of 5 semi-blind triangle test attempts, I chose the odd-beer-out every time, regardless of time in the keg. While I initially preferred the non-SMB beer, which I felt like it had a more pronounced hop character, my preference switched after a week in the keg. To my palate, the SMB beer maintained its hop character while the non-SMB beer developed an undesirable harshness. Both beers were tasty until the effects of oxidation fully set in, which seemed to occur quicker in the beer packaged without SMB.

| DISCUSSION |

Brewers today are increasingly conscious of the negative effects oxygen can have on beer, especially on the cold-side once fermentation is complete. In concert with other preventative measures, dosing finished beer with an antioxidant like SMB seems like it could be a great way to further limit cold-side oxidation and produce better-tasting, longer-lasting beer. The fact tasters in this xBmt were able to distinguish a NEIPA racked to a non-purged keg with SMB from one that didn’t receive SMB suggests the chemical had a perceptible impact.

Equally as interesting as the triangle test data is the observed difference in appearance between the beers. NEIPA affected by cold-side oxidation tends to take on a brownish/purple hue, which is exactly what happened to the non-SMB sample in this xBmt. Indeed, the beer dosed with SMB maintained a lighter appearance in comparison to the non-dosed version, but it did start to turn over time, which I’m compelled to believe is a result of being racked to an open keg. This being the case, while adding SMB did seem to have some oxidation-buffering capability, it apparently wasn’t enough to overcome the careless packaging.

These results provide further evidence that metabisulfites work to reduce the negative impact of cold-side oxygen exposure, and as such, I look forward to further exploring ways to use them to my benefit. That said, these xBmt findings also made it abundantly clear to me the importance of limiting oxygen exposure during packaging, validating my current use of a closed-transfer process.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

57 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Adding Sodium Metabisulfite (SMB) At Packaging Has On A Hazy IPA”

This is really fascinating. I use SMB to treat my water prior to brewing to remove Chlorine, I wonder if it has an impact at the end of a brewday.

I also wonder what would happen if you added more than 0.3g (?) and would it stil be useful to use it even with a closed tranfert method in order to improve general shelf life (?)

After neuturalizing chlorine, any extra sulfite remaining will be converted to sulfate or off-gas as SO2 and it will provide no protection against oxygen.

I agree as I tried this over the weekend with a NE IPA. The gas dissipates into the keg making your beer smell like a fart. I wont do this again!

Any residual SMB will be consumed in the mash, its very unlikely it would survive to packaging.

Can you use SMB with bottle conditioned beers ?

I do. I use a stronger SMB solution (2%) as a no rinse antiseptic agent. If you leave too much in the bottle carbonation is slower but that’s all.

I used some campden when bottle conditioning and the beer reeked horribly of sulphur. Calculation was that one tablet = 0.44g so one tablet is enough for 29 litres.

I bottle condition all my beers including NEIPAs. Filling the bottle all the way to the top works perfectly. No air in bottle. Beer stays bright and fresh for at least 4 weeks. Maybe even longer.

I can’t tell as I always finish NEIPAs within this period.

I carbonate with tablets or drops so I can transfer from fermenter straight to the bottles.

You just need to make sure that your beer has reached its final gravity and don’t forget to include the effects of dry hop creep, which means an additional time in fermenter. It will prevent bottle bombs and hop burn too.

No SMB needed.

Please pardon me for erros, I’m not a native English speaker.

I do the same except I put a teaspoon of glucose into each bottle. If I’ve timed it right it just starts to fizz and would overflow the bottle but it’s capped at that point. So it purges all the air out of the bottle. Can be a bit scary if the beer is very fizzy.

Yes. I do it all the time. I dose each bottle with 5ml of a sugar solution I make to contain the exact amount of carbonation sugar I want and to have exactly 5ml x (number of bottles to package) total volume (to do this, just know that each gram of sugar adds about 0.64ml of volume to your solution). To this I add 0.01g SMB per liter of beer to package, so only about 0.2g total! (get a “drug dealer” milligram scale on ebay…), hence each 5ml will have about 3.3mg

of SMB dissolved in it.

How did you arrive at 0.3 grams as your measure of SMB? Was that based on a target ppm? Did you just pull it out of thin air as as a starting point?

A previous experiment on SMB and oxidation, linked below, indicates that 10ppm is the recommended dose which equates to 0.3g. I can’t recall where I read it, but I believe that this recommendation is based on an already low ppm of dissolved oxygen which is why 0.3g may not have been enough to over come the packaging process in this experiment… https://brulosophy.com/2019/02/11/post-fermentation-oxidation-the-impact-adding-sodium-metabisulfite-at-packaging-has-on-beer-exbeeriment-results/

I personally have added 1-2 whole tablets to my beers (5-6 gallons) either before transfer or in the bottling bucket and have had no issues at this high of dosing. It’s pretty common in winemaking to add a whole tablet per gallon. I too am curious if they increased their dosing if this would have had better buffering capacity than the small amount they’ve been using in their experiments. Obviously we can see the even that small of amount helps, but if the beer is continuing to oxidize that begs the question is it because oxidation occurs before the sulfite can bond to the oxygen or if that small amount they are using is insufficient in this style and the free sulfite quickly becomes used up.

Aaron – Tablets of what? Camden tablets? How do use those – do you crush them, mix them with hot water and then pour them in or just chuck them in? What is the best way to use Camden tablets for this purpose ?

It’s great to see the effect of SMB made so visual in this experiment.

Great experiment! Just curious, what was the calculation for the SMB?

I love how the non-SMB beer, after 1 week, looked liked 80% of the commercial and home brewed NEIPA’s I see on Instagram everyday. Packaging is important!

I’d be curious to see the effects of mash hopping on this style since I’ve heard Scott Janish talk about the effects of manganese on styles with heavy oat and wheat addition. This supposedly plays a large role in the oxidative effects as well. You could even tie SMB dosing in to identify the best way to package this style.

Nice work on the one! The pictures alone speak 1000 words.

Since one less taster would indicate the difference is insignificant, why not repeat the test two more times? Also what is the significant number of tasters that prefer one beer over the other? Have them rank the best of the three then ask the entire triangle tasters after the odd beer is identified to do so again. Having the exact number of tasters idenitify the odd beer once, is not statistically significant enough. Also having an O2 meter measure the finished beer could put a number on how much o2 is in each beer. Personally, I am concerned with adding SMB as people are allergic to sulphites. And it is ironic that when homebrewing and so called craft breweries started in the 80’s and 90’s, we as a group criticized the big breweries for using chemicals. If I loved NEIPA I might change my mind as I brew 15 gallons at a time and many styles last 1 year. Can I tell the difference, yes, but purged kegs and purging a carboy while syphoning and storing cold helps tremendously. I would predict that an unacceptable o2 level in a homebrew is less of a concern if always stored cold as opposed to having to deliver beer in a cooled environment and full kegs or bottles. I tend to bottle from kegs that run low as I need space and the CO2 has enough O2 to create staling when the keg is low.

Sulphite allergy is not a true allergy.

https://en.m.wikipedia.org/wiki/Sulfite

And most patients miss report / self diagnose this based on an unrelated antibiotic sensitivity.

Still even if not a true alergy many people react poorly. If there is a way to test for residual levels that would be a good idea. Is the reaction with O2 enough to reduce the amount?

Jim, interesting idea about kegs staling from trace o2 in the co2, hadn’t heard of that before.

Not sure I understand your comments about results being “statistically significant enough”. That term in brulosophy context simply means that there is less than a 5% chance that guessing could explain the tasting panel results. The choosing of 5% as the cut-off point is arbitrary (though conventional). This means that if in this experiment only 16 picked the odd beer, the probability of that result due to random guessing would be a little more than 5%. Which is to say people may really be tasting a difference despite the statistical nonsignificant result.

I have experienced oxidation in mostly empty kegs as compared to bottled filled after force carbonation in pilsners. THe best number I can find for O2 in CO2 is 30ppm max. Food grade CO2 is 99.9% and they do not provide a lot analysis..

As far as the triangle test. If one is trying to decide to change a process or material being one taster above or below the 95% confidence limit would not be adequate based on one test using attributes data. That is why it would be advisable to have the tasters do the test three times. For example if these were two lots of Bud light. I doubt the tasters would recommend dumping one or if there was a process or material change make that change based on this result. For this exbeeriment the smoking gun is the color (variables data) since we can put a number and color scale on it (srm or gold versus grey). If the O2 levels were measured the results would be even more convincing. In fact most of the time the author of these exbeeriments does the triangle test multiple times. So that is why I make the suggestion to repeat. maybe this has been done but to compare transferred to purged keg versus not purged keg and SMB versus no SMB could help determine whether a home brewer is better off getting to purged kegs or adding SMB. A 10 gallon batch in 4 2.5 gallon kegs could test both variable and their interaction. Is doing both much better than either? Cheers!

Confirmation of what I’ve known for years. And I can vouch for much more hop flavour for longer with just 1 SMBS tab crushed on kegging

Not sure whether it’s just a coincidence, but I did brew a couple of NEIPAs with Wyeast 1318 (same yeast strain as A38 AFAIK) and they would always oxidize quite fast when bottled. OTOH I’ve also brewed a couple of NEIPAs with WLP067 instead and those didn’t show any oxidation, even after two months of bottling.

As said before, maybe just a coincidence, not sure if anyone has experienced something similar.

067 has a diasticus strain. It probably keeps consuming O2 even after packaging by slow fermentation of long chain sugars

I’m very curious to hear whether this has any impact on bottle conditioning. I.e., does removing the excess oxygen with the sodium metabisulfate mean that the remaining yeast has too little oxygen to work with in the bottle? Is this even necessary when bottle conditioning since the yeast in theory would consume all the cold side oxygen in the bottle? Finally, does it matter if you use potassium metabisulfate instead of sodium metabisulfate?

As a bottler, I started using campden at bottling about 6 months ago, and have noticed no adverse effects on bottling- and very well preserved beer.

Fot the case of bottling, I would be afraid of the metabisulfite killing the yeast, whereby there would be no live yeast remaining to carbonate the bottles.

Sulfite will NOT kill the yeast.

(I’m no expert but) I presume the yeast consumes the oxygen over a period of several weeks, as it consumes the priming sugar. At bottle conditioning temperatures, this would be ample time for significant oxidation to occur (if judging by the results of this exp.) ie – the beer showed signs of oxidation after 1 week even at a relatively lower temperature in the keg

any reason to use sodium metabisulfite (SMB) vs. potassium metabisulfite (Campden)?

Interesting question. Both are sold as campden interchangeably depending on the store, and I’ve been using KMB. I’ve never heard of any difference, but it’d be interesting to know if others have.

I bottle condition all my beers including NEIPAs. Filling the bottle all the way to the top works perfectly. No air in bottle. Beer stays bright and fresh for at least 4 weeks. Maybe even longer.

I can’t tell as I always finish NEIPAs within this period.

I carbonate with tablets or drops so I can transfer from fermenter straight to the bottles.

You just need to make sure that your beer has reached its final gravity and don’t forget to include the effects of dry hop creep, which means an additional time in fermenter. It will prevent bottle bombs and hop burn too.

No need for SMB.

I’m not native English speaker so pardon me for any erros, please.

what would the equivalent dose of KMB be compared to SMB?

Thinking K has less of a flavor impact than Na

You need to use 1.2x potassium metabisulfite. You are correct potassium does not affect flavor, unlike sodium. Cheers.

I bottle condition all my beers including NEIPAs. Filling the bottle all the way to the top works perfectly. No air in bottle. Beer stays bright and fresh for at least 4 weeks. Maybe even longer.

I can’t tell as I always finish NEIPAs within this period.

I carbonate with tablets or drops so I can transfer from fermenter straight to the bottles.

You just need to make sure that your beer has reached its final gravity and don’t forget to include the effects of dry hop creep, which means an additional time in fermenter. It will prevent bottle bombs and hop burn too.

No SMB needed.

Please pardon me for erros, I’m not a native English speaker.

I apologize for multiple post of the same text. I just could not see my post showing up anywhere, so kept trying, Sorry.

I have had some slight troubles adding Campden powder. I always add the powder 24 h prior bottling in the fermenter. I try to aim at the same concentration stated in this experiment. However, even after 1 month I can still detect sulphur in the taste of for example IPAs. I could be because I also add Antioxin SBT in the mash but I’m not sure.

You should do a third experiment with three different samples of beer. A) One with SMB (albeit more then you used here), B) one without, and C) one which was purged with CO2. We know that A vs B will taste different after a few weeks, but what about A vs C. Once slightly aged, will A taste close to the un-oxidized C?

Great experiment and surprised such a visible difference was noticeable. It’s great when chemistry theory actually works in practice!

However, I would love to see if fully purged keg with/without SMB makes a difference.

It’s useful to have different comparisons, but at the end of the day I (along with everyone here) want to make the freshest brightest NEIPA possible.

Purging by pushing out sanitiser from a completely full keg with CO2, followed by transferring a beer by CO2 is the gold standard (you’ve shown this). If you have equipment to do this (and you care enough) there should be no shortcut to doing this on an IPA, period.

However, some DO is inevitable so if adding SMB in addition to completely purging a keg makes a difference then I’ll do both. But I’d rather not start adding something unnecessarily as, there always a risk of making things worse.

You talk about his like every one has a keg set up at home. What about the guys who are bottling?

If you read you will see I did say “for those who have the equipment to do this”, so no assumptions made.

Most experiments here use kegs so that’s why it isn’t a mute question. There’s a plethora of equipment out there that people use, my point is if you have it, or can get it, what’s the best combination you can use to get the best results?

This experiment shows SMB can help bottlers without kegs, so the next question is, can it help people with kegs?

Or more correctly, addition of SMB can help people when oxygen isn’t excluded using a closed loop transfer system, but does SMB help those that package their beer in a closed loop system like a pre-purged keg (or close enough to)?

On a side note, I also bottle >90% of my beers, but I use a keg and a beer gun. However some oxygen pickup is inevitable at every transfer stage (however small it is), so will SMB make a noticeable improvement here?

In fairness this was mostly covered by the Kölsch experiment, but it would be most interesting on a NEIPA (given the focus on low O2 for this style, short turnaround to drink and the very visible changes in colour)

Anyone use SMB at bottling? How to disolve it,with water,just put in bottling bucket before bottling? Those numbers are ok?- 0.3 grams for 5 gal.? I just order it and want to know before doing it…

Simply add it to your bottling bucket/barrel and rack on top. As a preservative is will be as close to sterile as any ingredient you could add. If it’s powder then use it as it is. You may want to crush first if in tablet form to speed up how quickly is dissolves, but shouldn’t be an issue if you don’t as it’s sold in tablet form for this very use in wines. Saying that, if it’s oxidation you want to limit (which happens quickly as opposed to long term preserving effects) a powder may be the way to go.

0.3g per gal is what the author used so go with that. You could probably double it without any negative effects as it’s under the taste threshold and will not harm your beer yeast, however……..

My experiences with adding a small amount of SMB post fermentation (only the once to a very low ABV kegged beer many years back, probably 2-4 times the concentration used in this experiment) was that it completely ruined the beer. Before adding it was decent, but straight after the grainy maltiness was gone and replaced by a very strange, very un-beer like bitter flavour. It was flat out nasty, Even after several days it stayed the same so it was dumped.

Curiously, in this beer experiment, the author preferred the non-SMB beer in the first week and then his preference switched over. I wonder if, like my experience adding SMB does make things worse like-for-like compared to a fresh beer, but as oxidation sets in, SMB dosed beer fares better until the non-SMB beer eventually tastes worse. If this is the case, then if you can severely limit oxygen exposure to begin with (I’ve never had a NEIPA darken like in this experiment, they’ve always remained bright and light even after bottling) NOT adding SMB may be better for the overall beer taste/aroma, but that remains to be tested.

Ok, but author says he put 0.3 g for 1 keg, that is 5 gal.?

I wil bottle it next week, around 13 gal., and will add cca 1 g of smb in powder. Hope there will be no sulfur smell as one says it happens to him…

U do this every time when bottling?

Sory for my eng.😉

I have made some experiments with SMB and my conclusion is as follows:

-If you add it the same moment as you bottle the SMB will not be solved in the beer and the effect will not be as desired.

-If you add it 24 h pre bottling in the fermentation chamber you will have good effect from the SMB.

The downside is that your beer will smell eggfart for 1 month (at least). But if you are patient the sulfur will disappear after some time.

I have a theory that lager yeast (like W-34) produce sulfur on their own and will have a better protection against oxygen, therefor I never add SMB to lagers.

How much you’ve added to beer?

I have added 0,15 g Potassium metabisulfite in 12 L

Can I suggest when you take photos to show differences in colour that you put a white board behind the beers. Otherwise the background detail affects the light transmission and visual perception.

@Mario: A keg is around 18.9 litres to the brim (which is 5 US gallons). Typically I fill a keg to 18L to avoid accidently pushing beer up the gas dip tube and to give a bit more headspace to hasten carbonation, so the author may do the same, but it shouldn’t matter if you use more or less SMB, it won’t be that sensitive

Would also have bern nice to know the overall ompact of the test beers. A taste rating, if you will, to see if oxidization made the beers less enjoyable

In my process, the two times that oxygen stresses me out are at dry hop and at packaging. Your article deals nicely with the second circumstance. What are your thoughts about dry hopping? Could it be useful to use SMB at dry hop as well? How much might be needed? Will a dry hop addition plus a package addition potentially have negative effects? Could a dry hop addition also cover oxygen ingress during packaging, thus necessitating only one addition for both circumstances?

I recently followed this process and I’m having major rotten egg smell(and minor taste) in my kegged beer. I’ve been blowing it off with c02 serving pressure(11psi) but it’s not clearing. Any tips on getting this to blow off quicker?

Sorry if this has been discussed before but I only have campden tablets not the SMB powder and in doing research for this, there seems to be a concentration difference of the sulfites in powder form vs tablet form. Does anyone know the correlation between the two? I’ve read that when you have tablets you have to use more than 0.3g because its not as concentrated as the powder.

I am very curious if there are additional benefits to be gained by adding metabisulfite when dry hopping. Of course, no need if you have a hop doser, but I imagine the majority of homebrewers are introducing significant oxygen with every dry hop addition. The S/KMB addition could be spit half at dry hop and half at kegging. Double and triple dry hopping pose even more potential for cold side oxidation in NEIPA or Hazy IPA styles.