Author: Jake Huolihan

Of the many esoteric brewing practices, one of the least approachable to homebrewers is top cropping, which involves skimming kräusen from the top of the fermenting beer. Primarily practiced by some traditional German and English breweries, the main reason for top cropping is to harvest fresh, viable, and vital yeast for reuse in subsequent batches. However, another benefit proposed by some has to do with the actual removal of the kräusen from the beer, as some claim it can impart harsh or astringent flavors to the finished beer.

In addition to healthy yeast cells, kräusen also contains some dead cells along with excess wort proteins, hop derived compounds, and other fermentation byproducts. As anyone who has ever been curious enough to taste kräusen knows, it’s rather unpleasant stuff, very bitter, nothing like the beer that rests beneath it. As such, it makes practical sense that removing it might reduce the chances of those flavors carrying over into the finished product.

Outside of a select few modern commercial breweries, top cropping appears to be a fairly unpopular practice, and it seems even less favorable among homebrewers. Not only does the method necessitate a fermentation vessel that allows ample access to the beer it contains, but the level of attention and involvement required by the brewer is pretty high, which may be unappealing to some. But for those committed to making the best beer possible, kräusen removal may very well play a contributing factor. Possessing both a love for German lager and just enough masochism, I decided to put it to the test!

| PURPOSE |

To evaluate the differences between a beer that had the kräusen regularly skimmed during fermentation and one that was fermented with the kräusen intact.

| METHODS |

I designed a simple Helles for this xBmt, as I thought it would make an excellent tableau to explore this potentially subtle flavor altering practice.

Dump

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 43.9 IBUs | 4.5 SRM | 1.051 | 1.015 | 4.8 % |

| Actuals | 1.051 | 1.011 | 5.3 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Odyssey Pilsner | 11.5 lbs | 96.84 |

| Carahell (Weyermann) | 4 oz | 2.11 |

| Melanoidin (Weyermann) | 2 oz | 1.05 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Loral | 23 g | 60 min | Boil | Pellet | 10.3 |

| Loral | 15 g | 30 min | Boil | Pellet | 10.3 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

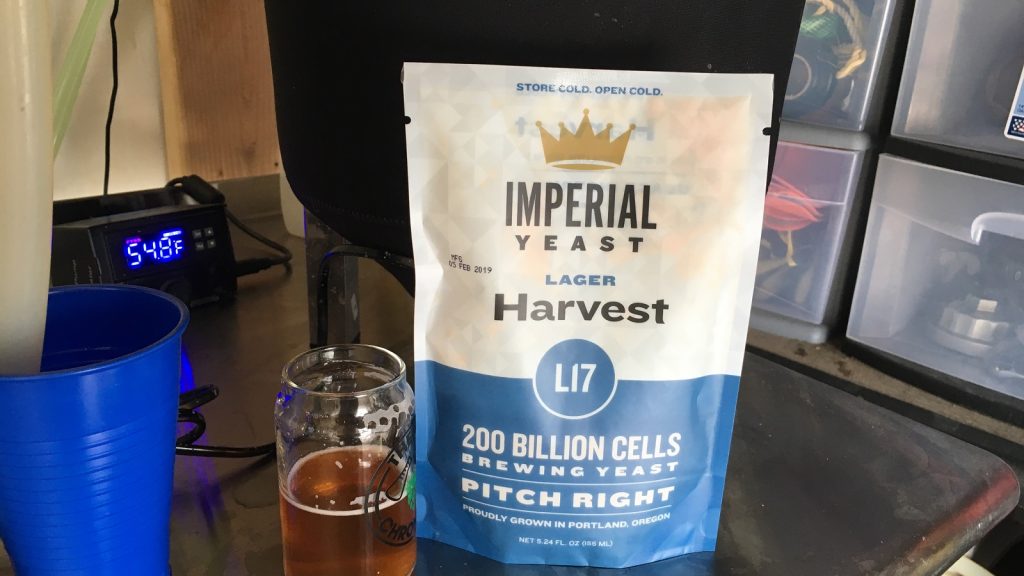

| Harvest (L17) | Imperial Yeast | 72% | 50°F - 60°F |

Notes

| Water Profile: Ca 49 | Mg 0 | Na 8 | SO4 38 | Cl 61 |

Download

| Download this recipe's BeerXML file |

After collecting my grains the night before brewing, I prepared the water by adjusting it to my desired profile then scheduled my heat stick to turn on a few hours before I planned to start the next day. I started off the following morning by milling the grain.

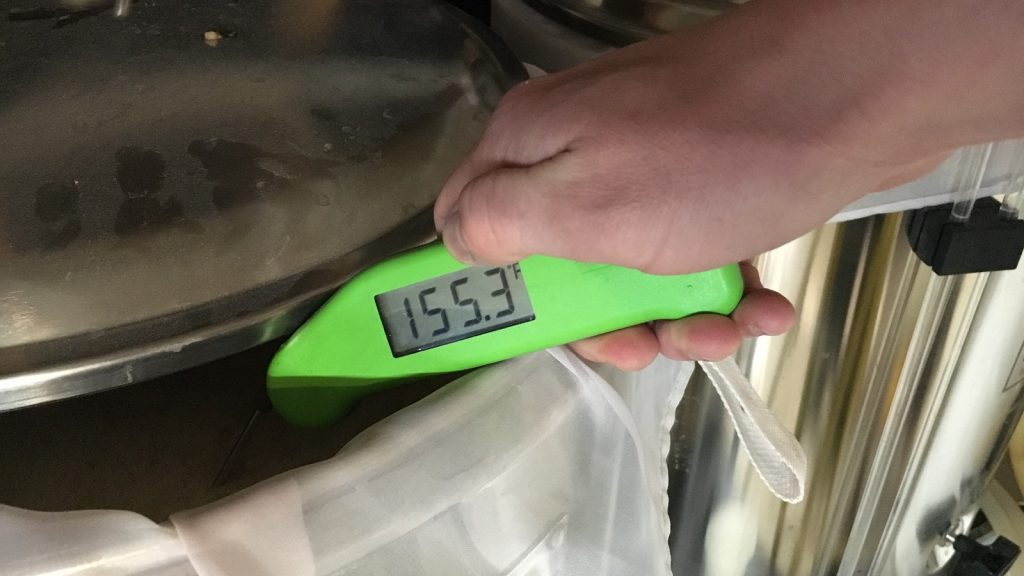

With the water properly heated, I incorporated the grist then checked to make sure it was at my target mash temperature.

The mash was left to rest for 60 minutes during which I stirred every 15 minutes with my large whisk .

With the mash rest complete, I transferred the sweet wort from the MLT to the kettle.

The wort was then boiled for 60 minutes, during which the hops were added at the times stated in the recipe.

Once the boil was complete, I quickly chilled the wort.

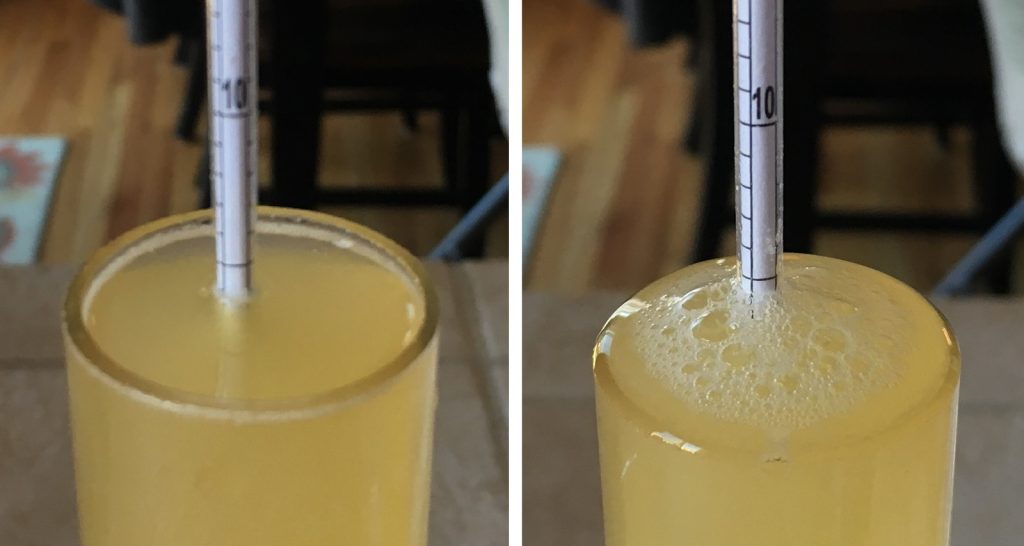

A refractometer reading showed the wort was sitting right at my planned OG.

Equal amounts of wort were then transferred to a pair of identical fermentation vessels that got connected to my glycol rig set to 52°F/11°C. The worts were chilled after just a few minutes, so I direct pitch a pouch of Imperial Yeast L17 Harvest into each batch.

With the beers bubbling away the next morning, I removed both lids to keep things as equal as possible then skimmed the kräusen of one of them, a process I repeated every 12 hours over 3 days.

By the final skimming, the differences in kräusen appearance were easily observed.

I stopped skimming the kräusen when I noticed fermentation dying down in order to reduce the risk of oxidation. After a week, I took hydrometer measurements confirming both beers had reached the same FG.

I let the beers sit a few more days before confirming no change in FG and proceeding with packaging.

The filled kegs were placed in my keezer where they were burst carbonated overnight before I reduced the gas to serving pressure and left them alone for a lagering period. The first samples taken after 3 weeks revealed a rather noticeable difference in appearance.

Following a couple more weeks of lagering, the beers were equally carbonated and had taken on a more similar appearance.

| RESULTS |

A total of 21 people of varying levels of experience participated in this xBmt. Each participant was served 1 sample of the skimmed kräusen beer and 2 samples of the beer with the kräusen left intact in different colored opaque cups then asked to identify the unique sample. While 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, only 10 (p=0.12) did, indicating participants in this xBmt were unable to reliably distinguish a pale lager that had the kräusen removed during fermentation from one where the kräusen remained throughout fermentation.

My Impressions: Out of the 5 triangle tests I attempted, I identified the odd-beer-out every time, which was surprising. To me, both beers had the same aroma and flavor, the only thing I perceived as being different was a slight bitterness on the back of my tongue in the non-skimmed batch. While this wasn’t particularly unpleasant, I did somewhat prefer the skimmed batch, though they were so similar, I’m not sure I would have been able to tell them apart if I was going in blind.

| DISCUSSION |

Whereas some brewers aim to produce the best beer with the least effort possible, others are willing to engage in more arduous methods on the hope it’ll have some positive effect. The current paucity of talk surrounding the process of skimming kräusen during fermentation, particularly as a means of improved beer quality, seems to indicate it may not have much of a perceptible impact, which is supported by the results from this xBmt showing tasters could not reliably tell apart beers made with and without the kräusen skimmed.

There’s no denying kräusen contains dead yeast cells, hop compounds, and other perceptible compounds, though considering the results of this xBmt, it would seem it mostly gets left behind in the trub. Seeing as I was somehow able to consistently tell these beers apart, I’m left wondering if perhaps the some people may be more sensitive to the flavor impact of kräusen than others. Regardless, I have no plans to integrate this method into my normal brewing process, as the differences I perceived were slight and definitely not worth the extra effort.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

22 thoughts on “exBEERiment | Impact Skimming Krausen During Fermentation Has On Munich Helles”

It seems to me also a question of scale.

This same weekend I was brewing a quad, and I decided to go for open fermentation, although with a cheesecloth on top to keep things out. So I researched about open fermentation, etc.

After this post, what I noticed, is that it might be possible for a homebrewer to skim all kraüsen, but it seems ver impractical in a commercial setting when you see the size of those open fermentation vessels, and the little guy next to it with his tiny stick.

It seems to me that the only reason top cropping is done there is to get fresh yeast, not to get rid of all kraüsen.

Isn’t it that in these cases the beer is racked off from underneath the kraüsen? That would be more practical to get rid of it.

Did you use gelatin fining? I am thinking about that back of the tongue bitterness you picked up on 5 out 5 times when tasting blind, wondering if it might be some compound that would get pulled out by finings.

I don’t fine beers anymore for fears of oxidation, so these were not fined.

Thanks for the reply. So maybe it is some compound that would be removed with fining. To be tested by someone sometime in the future. Different question: Are your concerns over fining based on exposure to oxygen at the time of adding the fining agent, or is it that the finings themselves might agents of oxidation?

100% oxygen exposure is my concern on our scale.

Would you consider fining with a mixture of gelatin and SMB to reduce the oxidation risk?

Does blow off have a similar affect? On my previous batches with blow of a lot of the same material is lost to blow off.

I would guess it has the exact same effect.

Interesting. If this were true you could leave little headspace and have a blow off into a big container to get the same benefits without having to break into the fermentation regularly. Hmmmm

I’ve read a lot about German heffeweizen and krausen skimming seems to be a usual practice that results in more yeast stress and is purportedly going to result in more esters. Do you think this experiment would have the same result with a weizen strain?

I was interested to see that Timothy Taylor’s brewery skim from their large open fermenters, which is feasible; they say to avoid too much yeasty flavour in finished beer (they’re also harvesting). See from 11.25 minutes in their You Tube video of brewing process. https://youtu.be/4Cak4stt9v4

You should repeat this experiment by Krausening the skimmed beer to condition it. Just do it in the keg. I bet you will get even more of a difference.

I did not skim beer simply krausen. Definitely think krausening would be a fun xbmt and is on the list.

Fun fact – if you follow Russian River’s IG you get to the their yeast harvester in action (kind of like top cropping). Mesmerizing to watch!

New Glarus does the same I saw the machine in operation during a visit once, so badass. Interesting that two of the best breweries America has to offer practice this method 🤔.

I agree that fining or cold storage might reduce the difference. The extra bitterness is presumably caused by non isomerised alpha acids, since skimming should affect anything in solution. So I’m guessing both beers would have the same IBU level, if that was tested in a lab.

I’ve done this on my last four Hefe’s. Open fermentation makes it pretty easy. However, not sure I’m tasting any difference. May give it a shot on my next Pilsner though.

Isn’t the Krausen a protective cap created by the yeast to keep out other yeast? I thought I read that somewhere but no idea where.

Nice xBmt.

44 IBUs seems a lot for a Helles, don’t you think? Most examples from Munich lie somewhere between 15 and the low 20s, maybe 25.

The idea of skimming always seemed strange to me. What makes the kräusen bitter are hop compounds which went out of solution once the pH dropped, at the start of fermentation. How would they go back into solution?

Of course, yeast has its own bitterness in taste, but shouldn’t the yeast drop out anyways? Moreover, in the pictures taken after 3 weeks, the non-skimmed batch is noticeably clearer, in line with some other xbmts where heavy, visible trub seemed to reduce the more subtle chill haze, possibly caused by these small particles attaching to the bigger ones (and sinking with them).

I wouldn’t really shy away from the extra effort, but I’d worry about oxidation – that is, worry about it even more than I do now – as yeast doesn’t seem to consume much oxygen once fermentation has started (afaik).

I brew at altitude so my hop utilization is actually around 60%, the recipes show in BS assuming 100%

In your introductory paragraph, you’re mixing two different procedures, the harvesting of top fermenting (ale) yeast and the removal of the bitter braunhefe. I do both. I open ferment my English style ales and use a yeast that produces a thick yeast pancake as the kraeusen, or barm, subsides, typically day three. Before that, I skim the foam, which contains braunhefe. I think it includes cold break as well as other stuff I don’t want in my beer, but not very much yeast early on. The heat pancake is fairly moist but not dry, and rather dense. I lift it out with a perforated flat ladle.

I’m my early days of brewing I was confused by the mention in English books of top fermenting yeast. None of the yeast available back then, all dry ale yeasts, did anything on top. It wasn’t until the availability of wet or fresh yeast from Wyeast and later others that I got it. Even now, most strains sold don’t form the typical thick pancake, probably because they’ve been selected to work in cylindro-conical fermenters, but a few do. My favorite is White Labs WLP 022 Essex yeast, which I collected from the now closed Ridley Brewery in England and provided to White Labs. Sadly, it is now a seasonal strain, but there are others that behave the same.

Around 1999, a number of us attended the second Master Conference of Amateur Brewers (MCAB II) in St. Louis and got a full, nothing held back, behind the scenes tour of the 15 bbl. Budweiser pilot brewery. We were told that AB precisely fills their fermenters so that as the kraeusen rises, it just hits the top of the closed container, to which the braunhefe sticks when the kraeusen falls. I think that blowoff does the same, which is how I ferment lagers.

This experiment would be interesting to try with a variety of yeasts and styles. Ale yeasts wouldn’t benefit from lagering like test beer this experiment might have. And different yeasts don’t ferment as cleanly indicating in my mind less reclimation of off flavors or at least generating more off flavors during fermentation.

This exBeeriment is a great example of my growing opinion that while these tests frequently yield statistically insignificant results, it doesn’t necessarily follow that the tested variable doesn’t matter. Jake successfully picked the odd beer out 100% of the time. I think what this shows us that there is a difference, but that it is small.

I fear that some observers might come to the conclusion that none of these things matter and are just old brewers’ tales. My guess is that while individually, the variables may not matter much, collectively, they may. I am familiar enough with Brülosophy’s many Short and Shoddy tests which have largely been successful, virtually always producing tasty and occasionally prizewinning beers, yet I am generally inclined to continue to follow conventional wisdom, except where results prove that the unconventional is actually superior. However, these statistically insignificant results have proven to me that many brewing practices don’t have a huge impact, which allows me to not sweat an error or oversight, making homebrewing far less stressful and much more fun. Thanks for all your hard work!