Author: Jake Huolihan

Oxidation of beer occurring once fermentation is complete is known to hinder shelf stability and lead to undesirable off-flavors. When fermented beer comes into contact with oxygen, often during the packaging process, it reacts with various carbonyl compounds that get converted to other compounds tasters can perceive as stale, cardboard-like, and unpleasantly sweet. Good commercial brewers invest quite a bit of effort to prevent their beer from being exposed to oxygen, usually involving cumbersome and expensive equipment that significantly limits total oxygen in the packaged beer.

Most homebrewers don’t have access to equipment like this and have to rely on more rudimentary methods for reducing post-fermentation oxidation. While cold crashing with CO2 filled balloons in place of an airlock and purging kegs prior to filling have been shown to have some effect, these methods do little to remove whatever small amount of oxygen might end up in the actual beer. This is where a chemical called sodium metabisulfite (SMB) comes into play.

Often sold in the form of Campden tablets, SMB releases sulfur dioxide when added to beer, turning it into a strong reducing agent that initiates a redox reaction. To put it simply– adding SMB to beer will fairly rapidly lead to lower levels of dissolved oxygen. Sulfites have a long history of use in the wine and juice industries, but it’s essentially absent in commercial brewing, perhaps due to the fact government regulations require disclosing its use on packaging. Exempt from such regulations, homebrewers have begun experimenting with using sulfites at various points in the brewing process to improve flavor stability. Inspired by a recent chat with Dr. Charlie Bamforth, I was curious to see what impact adding SMB to beer at packaging has and put it to the test!

| PURPOSE |

To evaluate the differences between a beer dosed with sodium metabisulfite at packaging and the same beer packaged without the chemical.

| METHODS |

I decided to brew a Kölsch for this xBmt, as its simple enough to allow any subtle differences to shine.

Preservation

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.5 gal | 60 min | 40.3 IBUs | 4.0 SRM | 1.051 | 1.012 | 5.2 % |

| Actuals | 1.051 | 1.012 | 5.1 % | |||

Fermentables

| Name | Amount | % |

|---|---|---|

| Odyssey Pilsner | 11.25 lbs | 97.83 |

| Carahell | 4 oz | 2.17 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Perle | 23 g | 60 min | Boil | Pellet | 8 |

| Perle | 25 g | 25 min | Boil | Pellet | 8 |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| Dieter (G03) | Imperial Yeast | 75% | 60°F - 69°F |

Notes

| Water Profile: Ca 65 | Mg 0 | Na 8 | SO4 67 | Cl 68 |

Download

| Download this recipe's BeerXML file |

While collecting the brewing liquor the night before brewing, I weighed out and milled the grain.

After adjusting the water to my desired profile, I dropped my heat stick in and scheduled it to turn on early the next morning.

I woke up to hot liquor the next morning and immediately mashed in, checking to ensure I hit my target mash temperature.

The mash was left to rest for 60 minutes.

At this point, I weighed out the kettle hops.

When the mash was complete, I collected the sweet wort in my single boil kettle and brought it up to a boil.

Following a 60 minute boil, I quickly chilled the wort.

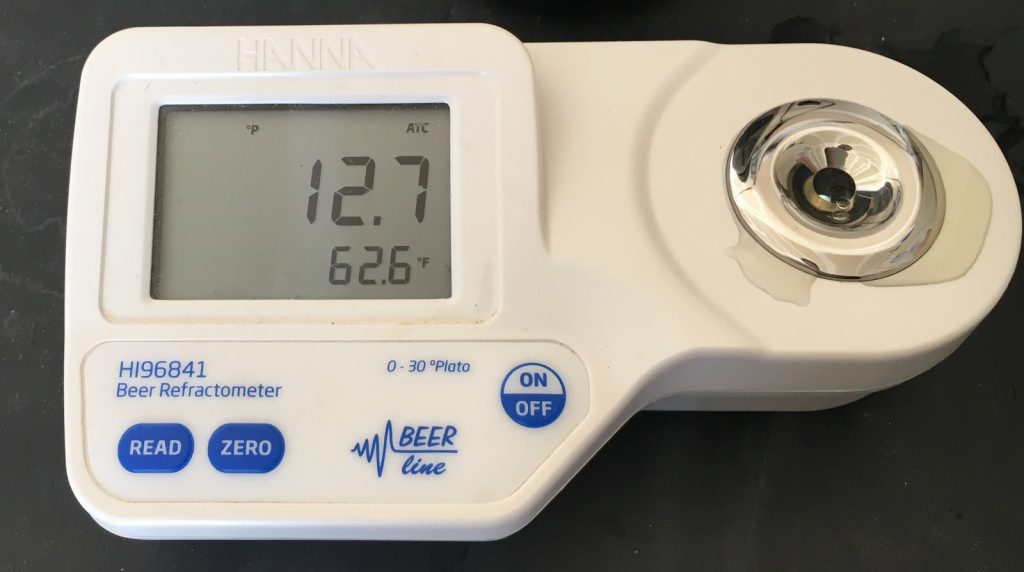

A refractometer reading showed the wort was right at my planned OG.

The wort was split evenly between two sanitized Brew Buckets, which I connected to my glycol system set to maintain a fermentation temperature of 62°F/17°C. I then direct pitched a pouch of Imperial Yeast G03 Dieter into each batch.

After 3 days of active fermentation, I began raising the temperature of each vessel to 66°F/19°C. With signs of fermentation absent after 13 days, it was time to introduce the variable and package the beers. To scrub the oxygen from 5 gallons/19 liters of beer, it’s recommended to add 10 ppm SMB, which amounted to only 0.3 grams (1 gram SMB = 175 ppm/gallon). Strong stuff.

After sanitizing and purging a keg with CO2, I gently added the small amount of SMB, sealed the keg, and purged it again. The keg of the batch without SMB was also purged with CO2 prior to kegging.

The filled kegs were placed in my keezer on gas and allowed to condition for 6 weeks prior to serving, as I wanted to allow enough time for any impact of oxygen exposure to occur.

| RESULTS |

A total of 22 people of varying levels of experience participated in this xBmt. Each participant was served 2 samples of the beer packaged without SMB and 1 sample of the beer packaged with SMB in different colored opaque cups then asked to identify the unique sample. A total of 12 tasters (p<0.05) would have had to accurately identify the unique sample in order to reach statistical significance, which is exactly how many did (p=0.033), indicating participants in this xBmt were able to reliably distinguish a Kölsch packaged with SMB from one packaged without the preservative.

The 12 participants who made the accurate selection on the triangle test were instructed to complete a brief preference survey comparing only the beers that were different. A total of 5 tasters reported preferring the beer packaged with SMB, another 5 liked the beer packaged without SMB more, and 2 people reported no preference despite perceiving a difference.

My Impressions: Out of the 5 blind triangle tests I attempted, I easily selected the odd-beer-out every time based on aroma alone, though I perceived differences in flavor as well. To me, the beer kegged without SMB had a distinct smell that was reminiscent of Golden Grahams cereal– biscuity and slightly sweet. This characteristic was completely absent in the beer kegged with SMB, which I perceived as having a cleaner Pilsner malt character. While both beers were good, my preference went to the one packaged with SMB.

| DISCUSSION |

It’s well known that oxygen is an enemy to beer, hastening the staling process and turning good beer bad. While most brewers rely on methods of oxygen reduction that involve cumbersome and expensive machines, a seemingly simpler though much less popular option is to add sodium metabisulfite (SMB), a compound that reacts with beer to remove oxygen. The fact tasters in this xBmt were capable of reliably telling apart a beer kegged with SMB from one kegged without the substance seems to suggest it does have an impact.

In addition to reducing the risk of oxidation, SMB also hinders the growth of spoilage microbes like wild yeast and bacteria, which may lead one to wonder why it’s so rarely used in the brewing industry. Claims that sulfites lead to headaches have been debunked, and while higher amounts have been shown to cause respiratory issues, the levels present in beverages treated at the proper rates are low enough to be a non-issue. Perhaps there’s a stigma associated with the use of “chemicals” in beer, similar to the way people fear GMO.

Given its apparent oxygen sensitivity, I’m curious to explore the impact this method has extending freshness of NEIPA, and I also plan to look into whether a small dose of SMB might be able to replace the process of purging kegs with oxygen. Regardless, I prefer fresh beer and have zero concerns about the minuscule amount of sulfite present when using SMB at packaging. With the results of this xBmt backing up my personal experience with the beers, which I was initially skeptical about, I absolutely plan to make packaging with SMB a normal part of my process.

If you have any thoughts about this xBmt, please do not hesitate to share in the comments section below!

Support Brülosophy In Style!

All designs are available in various colors and sizes on Amazon!

Follow Brülosophy on:

FACEBOOK | TWITTER | INSTAGRAM

If you enjoy this stuff and feel compelled to support Brulosophy.com, please check out the Support page for details on how you can very easily do so. Thanks!

95 thoughts on “exBEERiment | Cold-Side Oxidation: Impact Adding Sodium Metabisulfite (SMB) At Packaging Has On A Kölsch”

Would one be able to use this if one bottle conditioned ones beer ? Would it not kill off the remaining yeast ?

Maybe maybe not, depends on yeast health, I would not chance it.

The remaining yeast should scrub the oxygen.

I’ve done it in my NEIPAs. Just use the proper dosage and it should bean issue.

What dosage did you use?

The yeast should remove the oxygen during the conditioning process so it seems unnecessary, in fact bottle or keg conditioning is a great alternative.

Yes, I have myself used 5-10ppm and it works fine for bottle conditioning. “A molecular SO2 level of 0.4 ppm (equivalent to a free SO2 level of 20 ppm @ 3.50 pH) will

kill wild yeast without adversely affecting Saccharomyces.”

http://www.practicalwinery.com/janfeb09/page3.htm

Saccharomyces is usually very tolerant to sulfite concentrations.

Great post and really excited to see that this has a perceivable effect. When I saw that you were testing it with a kolsh I thought that it would come back as non-significant. I assumed that it would be very hard to pick up any degradation of flavour in a kolsh that went into a purged keg. The fact that tasters were able to pick up the difference and this also lines up with your own experience is pretty striking to me. I really look forward to seeing this repeated with hoppier styles where I would have thought that the effect might be even more significant. In the meantime, I’m going to start playing around with this for my next few brews.

It would be awesome if you could link to some of the debunked claims about sulfites as well as the threshold for respiratory issues. I think that would be my biggest concern as I’ve heard many people discuss sulfite sensitivity as a reason they don’t consume certain products. But this is really interesting.

This.

I can’t drink wine, particularly red wine, because of my allergy to sulfites. I go into anaphylactic shock and can’t breathe after a glass or two of red wine. That’s why I only drink beer.

Red wines typically contain less sulfites than white. You are more likely allergic to the compounds that get pulled out from aging the wine on the stems and skins

SMB makes my face itch unfortunately, pretty allergic to that stuff 🙁

Are you allergic to potassium metabisulfite as well? Has the same effect on O2.

You can’t be allergic to one without the other since metabisulfite is the same in both. And you can’t live without sodium OR potassium 🙂

Did you taste the SMB beer early in the aging process? Curious to see if you could detect any off flavors/aroma that needed time to dissipate. Would be the only downside I could see (having to wait the 6 weeks to enjoy).

yes, it tastes sulphury and smells awful.

Really interesting and I too would love to see if out to the test in a nice hoppy pale ale – Im actually thinking of giving up on brewing at home since it hoppy ales I love and I can never get anywhere near commercial levels with my little homebrew setup!

switch to keg fermenting and spunding and you might change your mind

Interesting post, I have a question though on your impression of the beer, you said by the aroma alone you were able to distinguish the beers because the treated one had a different aroma (less sweet). If this is the case an the aroma of the hops is what you are looking for in a NEIPA wouldn’t the SMB have an effect on that as well?

It would also be interesting to design an experiment to see how long it takes for a beer to develop an oxidized taste, find a style that is known for this and try it for several weeks until it develops the cardboard taste then use it as a baseline for these types of experiments. With all the methods we have these days it would be interesting to know the time period that beer stays tasting its best.

As always, please keep up the information and keep feeding us more knowledge.

The thing is I believe that Graham cracker aroma is a symptom of oxidiation. Since hops have aroma no matter what I would think the sulfites wouldn’t prevent aroma in the same way

Very interesting! It’d also be interesting to see if SMB use has an effect when bottling.

wow! i can’t believe there was a difference given how little free SO2 is probably in the beer due to the relatively higher pH of beer vs wine! Very interesting. I’d love to see this done on an NEIPA!

Real interesting xBmt. I have k-meta on-hand and I have 5gal of a hoppy pilsner and 5gal of a Vienna lager (both warm-fermented, btw) that I’m kegging mid-week and I’m going to add k-meta into each keg after i rack those. Obviously I have nothing to compare either to so I guess i may as well just lean into my bias and anticipate my belief that they’re my best lagers yet since perception is reality.

Would it be possible to share your source on the dosing rates using sodium metabisulfite for scrubbing oxygen? Just wanted to see if there’s a difference one needs to consider if using k-meta versus SMB. I’ll probably use the same 0.3g of k-meta since that’s not too different than what I typically add to 5gal of cider.

Cheers

If I’m not mistaken, with k-meta, 10 ppm for 5 gallons is closer to 0.38g (or 0.4g depending on scale accuracy) because of the difference in mw between Na and K.

I would guess the dosage is not the same with K meta as SMB. Really you need to figure out the ppm contribution per gram/gallon and convert it to what you have and what ppm sulfite you’re looking for.

I have Campden tablets right now. According to my research online:

” Campden tablets typically contain 0.44 g each of sodium metabisulfite (plus filler) and 10 of these are equivalent to one level teaspoon (5 mL) of sodium metabisulfite. Other related substances are sodium/potassium sulfite/bisulfite. “

This should be repeated but with an NEIPA to see what type of results you get. This was a great exbeeriment!

Was the perceived difference because of the lack of o2 or the taste of the sodium metabisulfite? I would love to see this test ran again and do a taste test when the beers are fresh and then again in the 6 weeks.

“While cold crashing with CO2 filled balloons in place of an airlock and purging kegs prior to filling have been shown to have some effect”

Could someone point me in the direction of the exbeeriments to justify this statement?

Interesting article, but downplaying the effect sulfites can have on those sensitive to it is a bit irresponsible. Sulfite reactions are fairly rare, but can be very dangerous to those who experience them. Which is why labeling in the US of foods containing sulfites is required. It’s not GMO fear-mongering, it is well documented in medical literature.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4017440/#!po=0.892857

It is extraordinarily rare though – people ‘think’ they are allergic, when it is in fact something else. There are a lot of common, unprocessed foods with more sulfites than what ends up in wine.

This is something I would do when long term conditioning.

Interesting. I’ve taken a page from the LODOers and added Camden to my mash and sparge liquors. Also, when I rack to a carboy for lagering, I’ve started adding one Camden tab. But I haven’t added a packaging time(I bottle) because I thought it might lead to an off-flavor. But at 10ppm, I guess it wouldn’t. Guess I’ll give it a try next bottling day.

Where did this recommendation come from or how was it arrived at?

“To scrub the oxygen from 5 gallons/19 liters of beer, it’s recommended to add 10 ppm SMB”

This is fascinating and might lead me to dropping a Campden tablet into my keg prior to carbonation. However, I used a closed system to transfer beer from my fermenter to my keg, and then to transfer to another keg if filtering, for the express reason of avoiding post-fermentation oxidation. As such, I am having difficulty figuring out when to drop in the Campden tablet, without opening my system and exposing it to air. Do you think dropping it into the carboy (or, in my case, the bunghole of my Catalyst fermenter) prior to transferring to a keg would be reasonable? How long would it need to sit in the fermenter then, prior to transfer to the keg? Any other suggestions?

Crush it up, add the right amount to the bottom of your serving keg. Purge, transfer, carb, done.

Can’t do that if you’re purging fully/properly, which means filling the keg with liquid (water or starsan) and then pushing it all out with CO2.

Broncosaurus, the taste threshold of sulfites is in the 100’s of ppm. It is generally not recommended to go over 300 ppm in wines. The 10 ppm dosing of SMB used here will result in ZERO free sulfites in the beer after oxygen is consumed and sulfites bind to organic compounds. For reference, 50 ppm SO2 is commonly used in racking of wines and ciders and to “sanitize” fresh juice or must by killing wild bacteria, but not yeasts. Here’s a good read: http://www.cider.org.uk/sulphite.html

I agree. I tried adding a Campden tablet to finished beer many years ago and it introduced an awful sulphurous smell, but I guess I was way over 10ppm. Also, before I started using RO water as my liquor base, I would add 0.5 tsb SMB to remove any chloramine/chlorine from the tap water and didn’t notice any effect on flavour. I wonder whether adding SMB at the start like this will prevent oxidation through the brewing process rather than addressing the problem at the end? I have also used 0.5 tsb ascorbic acid (vitamin C) added to the liquor to scrub O2 out and noticed no effect on flavour but the mash pH was low. I’m wondering if I should add some SMB to my liquor even when I use RO water? Interesting stuff!

Any thoughts on the difference in head on the final beers? Was this just a result of pouring vigor?

I think that it was simply pouring vigor. Head retention seemed identical for these two

I agree with Buddy about experiment design and establishing a solid baseline. On a different, but related note, what distribution of the experiments on this site have resulted in exactly the right number of participants to achieve statistical significance? It seems like it happens a lot. What distribution would we expect if someone had a “finger on a scale”?

Landing at exactly the needed participants doesn’t happen all that often. Believe that we’re sitting around 30% of xbmt which reject the null and not sure exactly how many land on the threshold. Given we have no desire to p-hack or chase significance I’m not quite sure what you mean by finger on the scale? Marshall doesn’t even share data with us until we’re done collecting data as a further way to combat p-hacking in the “ok I’m done” or “let me get a couple more” way

I too am interested to know where you got the 10 ppm number from? SInce this chemical seems to be used primarily for wine there are no instructions for using in beer.

So the wording there could be a little better sorry about that. Oxygen scavengers added at packaging really need to be tailored to your finished product and practices. I got some research sent by a friend in a wine/juice program and through some calculations of potential oxygen present we settled on 10 ppm for a first go as Malcolm had been using that to great success for many years now.

Technically to dial this in I would need to test for free sulfite (basically unconverted by oxygen) a few days post packaging. This would give indication of how much sulfite reacted with oxygen. If nothing was left next kegging should bump up to say 20 ppm and test again. To sum it up really there isn’t a hard and fast number as every system will be exposed to a different amount of TPO.

I’ve got a gose on the go in my Robobrew kettle @ 95F-ish with a kveik yeast (tastes amazing already FYI). Once the primary ferment is done, I’m transferring it to a secondary with plums. Would it be worthwhile adding SMB to the secondary, or wait until bottling time? Or both?

Really enjoyed the article but was curious about the choice of a Kolsch. The style indicates a small amount of sulfur is acceptable and it seems like one of the “knocks” on SMB is sulfur production. Did you notice any difference in sulfur levels in this exbeeriment or in your general use? Or is that more a matter of proper dosing? Interesting that tasters choice was evenly split. Again, great article and really appreciate all you guys do there.

Does this have any impact on the flavor of the finished beer? Does it impact hop or malt or hop aroma?

It destroyed the nice hop aroma in my NEIPA. It was replaced with a rotten egg aroma.

I have Campden tablets that are potassium metabisulfite. Is there any reason that would work differently than SMB?

Yes it does work differently than SMB in that it contributes potassium instead of sodium to the beer.

“. . .and I also plan to look into whether a small dose of SMB might be able to replace the process of purging kegs with oxygen.”

Think you meant purging kegs “of oxygen”?

Great xbeeriment, keep up the interesting work!

Purging with oxygen would certainly make for an interesting test in this case!

Here is a good paper about the sulfites in beer:

http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0103-90162016000200189

Also, have you considered using ascorbic acid? I have used it in combination with potassium metabisulphite and the difference is quite clear when preserving especially hoppy beers, compared to if the beer doesn’t have any added antioxidants. I have used potassium metabisulphite 5-10mg/L (ppm) and ascorbic acid 20-50mg/L.

“Ascorbic acid (vitamin C) has anti-oxidative properties that make it a good preservative, specifically in preserving color in white wines. However, it should strictly be used in conjunction with sulfite to increase the effectiveness of the sulfite solution. Effectiveness is increased since ascorbic acid decreases the pH of the sulfite solution. Ascorbic acid should never be used without sulfite or without the recommended minimum level of free SO2, otherwise, it will actually favor oxidation.”

https://winemakermag.com/article/634-solving-the-sulfite-puzzle

I’ve used ascorbic acid with and without SMBS but, given your post, I may have to check how much of each I have used. My results show no adverse effect of either on flavour when added to the hot liquor pre-mash, although the ascorbic acid drops the mash pH (which I believe is a lesser evil than raising mash pH). However, I’ve had a persistent problem with beers going “off” after about a month in the keg which I always assumed was due to an infection, but I am now wondering if I’m suffering from hot side aeration (I’ve not always been careful about avoiding splashing of the hot extract during sparging) and the ascorbic acid/SMBS is protecting me from that (when I use it). I haven’t run any stats on my data, but it looks like these additions may be helping me, whatever the reason may be-I have a much lower occurrence of dumping beer when I’ve used one and/or the other.

As I’ve gone through various iterations of my brewing set up and process I have probably changed the amount of HSA as well as additions and I think I may be able to see a pattern that makes sense. While some (too many) beers have gone off within a month, I’ve had other beers that have remained in very good condition after 2+ years in the keg, so my assumption that I had a persistent infection problem may not be correct.

For my most recent brew I used ascorbic acid and took steps to avoid hot side splashing so fingers crossed…

Les a do you have any updates to your two year old post above. Interesting stuff.

Can’t wait to see this performed on an NEIPA with tastings conducted after several weeks from kegging. Maybe even give it 4 months when a NEIPA would no longer be considered fresh.

Agreed…maybe even some vertical tastings on both batches over 4 weeks, 6, 8 etc. For my NEIPA…I can usually get them to last 6 weeks before any significant drop-off. Which actually isn’t too shabby. This definitely has me considering trying this though in the future.

Nice ‘Men in Blazers’ mug. Please tell me you are not a scouser!

Thanks! Believe you’re the first ever to notice, used to sneak in a patch or a mug into most articles. Not a scouser, but I do like Chelsea, which could be worse depending on your allegiances haha

I tried this after your post. Added very little SMBS (0.3g into a 19L keg) and it ruined the brew. The normal fresh hop aroma was replaced by sulfurous smell. Couldn’t drink it, will have to dump it. Won’t be doing that again 🤢😡

Sorry that was your experience man. I’ve never experienced that flavor from adding 10 ppm at kegging. Perhaps you had a fermentation issue?

Nah not fermenting problem. It was a 40L ferment. One 19L keg was perfect with no SMBS added. The other keg with 0.3g SMBS was rotten egg.

No clue man, only time I’ve ever heard of sulfite contributing rotten egg is if it’s in there during active ferment. Vitners and mazers regularly have ppm sulfite magnitudes higher than if you added 0.3 grams of sodium metabifsulfite to 5 gallons of beer at FG

Been brewing for 20 years and never dumped a brew before. Today 19L went down the drain while the other keg is just fine (delicious actually). You live and learn, won’t ever do that again.

20 years and you’ve never tried to use sulfite? Seems odd, been flirting in and outta popularity last 15 years

20 years and never dumped a batch? that’s impressive. i think i dump at least two batches per year. i brew a lot though and try a lot of things that don’t always work out. or, i just replace a mediocre batch with something better.

I would wonder if the measurement was accurate. I have used ~0.3 grams MANY times. For some beers, and some people’s processes, ie with a very tight transfer and low O2 levels, the sulfur smell can remain for a few days but dissipates after about a week or so.

Perhaps the 0.3g was not as accurate as it should be (though it would’ve been within +/- 0.05g given decimal place limitations on my scale).

Obviously everyone’s equipment/process is different. I’ve never had bad oxidation of my beer even after 6 months (probably the longest I’ve had a beer last before it was consumed).

I’ve only ever used sodium meta bisulfite years ago to sterilise bottles before I started kegging. Never touched it since and definitely never added it to the beer.

I kept this one keg for a week and there was no let up in the Sulfur smell and no presence of the (heavily hopped) hops. Just smelled like a fart with every glass pour.

I’m glad it works for you guys but I won’t go there again.

Another thought, I add gypsum to the HLT for Pales and IPAs. I did for this brew too, about 10g to 50L mash and anoth 10g to the sparge water. Could the the 0.3 g/ 19L keg of SMBS be adding too much Sulfur because of this gypsum add ?.

We use 50ppm in wine as a matter of course, with no ill-effects. My father (the winemaker) is asthmatic, so doesn’t react well to sulphur at all, but we use it because it’s the best at what it does. Rarely do we use more than 50ppm, however we don’t use much less either. 10ppm wouldn’t even register, even slightly. We do still have to include the note on the label (being a commercial product) that the wine contains sulphites/etc, just as you would if you use egg-whites for fining.

Something to keep in mind – some scales are NOT accurate at the lowest part of their range, they might be 0.01gr accurate – but if a scale is 0-200gr in range, it might only be that accurate in the 5-200gr range, not the 0-5gr range. It may only be be accurate to .1gr or even higher amounts, in the lower range. It’s worth testing.

This scares me. My only experience with campden is when using it to neutralize chlorine/chloromine in my brewing liquor. Even a day later there is a noticeable sulfur smell and even some particulate that never seems to fully dissolve- I would imagine that to be the binder. Per Greg’s comment above that campden tablets only have approx. 0.44 g of metabisulfate, my usual dosage of a half tablet should contribute less than the .3 recommended here. Am I wrong?

You can use SMB powder or K-meta powder vs the Campden tablets – no filler. A Campden tab provides ~ 67 ppm/ gal, so in 5 gal batch that is 13.7 ppm of sulfur dioxide.

Same here, 0.3g for 19L. Sulfur smell in the Beer.

Same exact thing happened to me. Wont do this again…. Terrible idea…

You wrote:

“To scrub the oxygen from 5 gallons/19 liters of beer, it’s recommended to add 10 ppm SMB, which amounted to only 0.3 grams (1 gram SMB = 175 ppm/gallon). Strong stuff.”

Not sure I understand the math here. If you need 10 ppm (10 mg/L) to scrub DO, one would need 190 mg (0.19 g) for a 19L batch. Also 1 g SMB into 5 gallons would be (1000 mg/19L)*3.785 gal/L = 199 ppm.

The math is correct, I wanted 10 ppm of sulfite. 1 gram of SMB contributes 175ppm/gal of sulfite thus 35 ppm per gram in 5 gal so approx 1/3 of that to get 10 ppm sulfite

yes, 0.28g of SMS should yield 0.19g of free SO2 assuming it all reacts to SO2. winemakers always calculate free SO2 as a function of pH. I suppose it all oxidizes in beer pretty quickly as long as the mass added is low enough?

Ok, it wasn’t clear to me that you were calculating just sulfite rather than the entire molecule.

Now that I’ve had some coffee. . .Jake your statement in the article could use some clearing up. 😉 You stated “10 ppm SMB” which isn’t what the math shows. You meant 10 ppm sulfite, and yes I see now that your math is correct for that.

Also Aaron, sulfite (SO3) is not the same as sulfur dioxide (SO2), even though SMB dissociates into both your math is also correct for sulfur dioxide.

This is really interesting! I don’t really know how the SMB works, but I thought when it solution it produces SO2 gas. Does this SO2 not need to off-gas? Being in a keg under pressure, seems like it has no way of getting out.

Are you not supposed to add the SMB pre-mash instead of post-boil? If thinking Low Oxygen Brewing.

Curious if the sulfur smell is a result of O2 scrubbing, or just SMB. Anyone know?

Wouldn’t it be neat if you measured if any O2 was present to be scavenged before declaring victory? As of now, the way this “experiment” is conducted the following statements are equally true: “SMB additions keep away bees” “SMB additions prevent baseballs from forming in the legged beer”. Slow. Clap.

Would using Potassium Metabisulfite have the same effect you think? I know the chemicals are very similar.

Yes. Potassium Metabisulfite is better because sodium obviously can add some salty flavor you may not want.

I also added 1/2 Camden tablet to a recent 5 gallon batch that I primed and bottled. Batch was totally destroyed. Strong rotten egg smell. Perhaps I measured wrong.

Tried this with two 5 gallon batches only added .25 grams at packaging in both and they are nothing but rotten eggs. One was a hoppy saison and the other a kveik ipa. I took them out of the keezer and hope that the smell will fade! Probably not going to try this again.

I think you mis-measured. If you put that much in 5 gallons of water you couldn’t taste anything. .25 grams is a little bigger than a pinch.

Same thing happened to me, terrible idea.

In my process, the two times that oxygen stresses me out are at dry hop and at packaging. Your article deals nicely with the second circumstance. What are your thoughts about dry hopping? Could it be useful to use SMB at dry hop as well? How much might be needed? Will a dry hop addition plus a package addition potentially have negative effects? Could a dry hop addition also cover oxygen ingress during packaging, thus necessitating only one addition for both circumstances?

Instructions for packaging wine with SMB say to use 1/16 tsp (1 tab) per US gallon. If my math is correct, that’s a whole lot more than what was used here: today I used 5/16 tsp for 22L, this experiment used less than 1/16 tsp for 21L.

I’m having a hard time figuring out how much to use for beer. Today I just followed the wine instructions and used 1/16 tsp (1 tab) per gallon of beer. I assume since they use this dosage for wine I won’t die from drinking this batch…

Where would I go to find the correct amount of SMB to use when bottling beer? Does anyone know?

Awesome job! I make mead and wine and there is no doubt adding potassium metabisulfite protects them from oxidation. I’ve bought a canned mead from NH that wasn’t sulfited and by the time it made it to Illinois it was severely oxidized.

And 10ppm is so low it’s exactly at the point legally beverages need to labeled with “contains sulfites”.

I hope the beer world embraces its use. Out will only make beer better.

I brewed many neipas with addition of dry hopping with kmeta,hops contain lots of metals those can cause very fast chain oxidation.if you smell rotten eggs,no worries,it takes week or two to dissipate.sulphites naturally decrease during time,so do they antioxidative effect.id never brew neipa without kmeta